Professional Documents

Culture Documents

API Tubing 2010

Uploaded by

Jose Marval RodriguezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API Tubing 2010

Uploaded by

Jose Marval RodriguezCopyright:

Available Formats

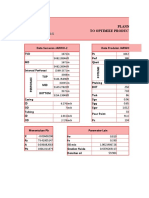

API TUBING

Lables Nominal linear Masses a,b Type of end-finish

2 Wall

O.D

Non-upset Ext upset Integ Joint Thickness N80

1 (in) H40 J55 L80 C90d T95d P110

T&c T&c (lb/ft) (lb/ft) (in) type1,Q

NU EU

IJ

T&C T&C

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

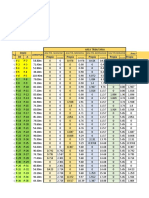

4.00 - - 2.375 4.00 - - 0.167 PN PN PN PN PN PN -

4.60 4.70 - 2.375 4.60 4.70 - 0.190 PNU PNU PNU PNU PNU PNU PNU

2 3/8 5.80 5.95 - 2.375 5.80 5.95 - 0.254 - - PNU PNU PNU PNU PNU

6.60 - - 2.375 6.60 - - 0.295 - - P - P P -

7.35 7.45 - 2.375 7.35 7.45 - 0.336 - - PU - PU PU -

6.40 6.50 - 2.875 6.40 6.50 - 0.217 PNU PNU PNU PNU PNU PNU PNU

7.80 7.90 - 2.875 7.80 7.90 - 0.276 - - PNU PNU PNU PNU PNU

8.60 8.70 - 2.875 8.60 8.70 - 0.308 - - PNU PNU PNU PNU PNU

2 7/8

9.35 9.45 - 2.875 9.35 9.45 - 0.340 - - PU - PU PU -

10.50 - - 2.875 10.50 - - 0.392 - - P - P P -

11.50 - - 2.875 11.50 - - 0.440 - - P - P P -

7.70 - - 3.500 7.70 - - 0.216 PN PN PN PN PN PN -

9.20 9.30 - 3.500 9.20 9.30 - 0.254 PNU PNU PNU PNU PNU PNU PNU

10.20 - - 3.500 10.20 - - 0.289 PN PN PN PN PN PN -

3 1/2 12.70 12.95 - 3.500 12.70 12.95 - 0.375 - - PNU PNU PNU PNU PNU

14.30 - - 3.500 14.30 - - 0.430 - - P - P P -

15.50 - - 3.500 15.50 - - 0.476 - - P - P P -

17.00 - - 3.500 17.00 - - 0.530 - - P - P P -

9.50 - - 4.000 9.50 - - 0.226 PN PN PN PN PN PN -

10.70 11.00 - 4.000 - - - 0.262 PU PU PU PU PU PU -

13.20 - - 4.000 13.20 - - 0.330 - - P - P P -

4

16.10 - - 4.000 16.10 - - 0.415 - - P - P P -

18.90 - - 4.000 18.90 - - 0.500 - - P - P P -

22.20 - - 4.000 22.20 - - 0.610 - - P - P P -

12.60 12.75 - 4.500 12.60 12.75 - 0.271 PNU PNU PNU PNU PNU PNU -

15.20 - - 4.500 15.20 - - 0.337 - - P - P P -

17.00 - - 4.500 17.00 - - 0.380 - - P - P P -

4 1/2 18.90 - - 4.500 18.90 - - 0.430 - - P - P P -

21.50 - - 4.500 21.50 - - 0.500 - - P - P P -

23.70 - - 4.500 23.70 - - 0.560 - - P - P P -

26.10 - - 4.500 26.10 - - 0.630 - - P - P P -

*P: Plain End; N= Non-upset threaded and coupled, U= External upset threaded and coupled, I =Integral joint.

a. Nominal linear masses, threads and coupling (col 2,3,4) are shown for information only.

b. The densities of martensitic chromium Steels (L80 types 9Cr and 13Cr) are different from carton steels. The masses shown are therefore not accurate for martensitic chromium

steels. Amass correction factor of 0,989 may used.

c.Non-upset tubing is available with regular couplings or special bevel couplings. External- upset tubing is available with regular, special-level, or special-clearance couplings.

d. Grade C90 and T95 tubing shall be furnished in sizes, masses and wall thickness as listed above, or as shown on the purchase agreement.

You might also like

- AISI 1018 Mild/Low Carbon Steel Properties & UsesDocument4 pagesAISI 1018 Mild/Low Carbon Steel Properties & UsesFikri Rahim100% (1)

- Shear Wave PDFDocument6 pagesShear Wave PDFcutefrenzyNo ratings yet

- Benefits of induction heating for metal forging applicationsDocument4 pagesBenefits of induction heating for metal forging applicationsdhruvNo ratings yet

- Tabela de Caracteristicas de Transistores BC e BD PDFDocument3 pagesTabela de Caracteristicas de Transistores BC e BD PDFCarlos Karl100% (1)

- Vessel FormulaDocument13 pagesVessel Formulaismansaleh27No ratings yet

- Hardness Experiment ReportDocument15 pagesHardness Experiment ReportsinabirecikNo ratings yet

- CrossReference PDFDocument21 pagesCrossReference PDFninzau100% (1)

- Compress Sample: Item Qty Description MaterialDocument1 pageCompress Sample: Item Qty Description MaterialSivi NallamothuNo ratings yet

- Secondary Steelmaking Refractories: A Practical Training SeminarDocument4 pagesSecondary Steelmaking Refractories: A Practical Training SeminarJose Marval RodriguezNo ratings yet

- Shandong Dongbao Steel Pipe Co., Ltd OCTG Products CatalogDocument31 pagesShandong Dongbao Steel Pipe Co., Ltd OCTG Products CatalogAF Dowell MirinNo ratings yet

- Harga Bahan Konstruksi dan PeralatanDocument666 pagesHarga Bahan Konstruksi dan PeralatanSyahrul KadriNo ratings yet

- BILL OF MATERIALS FOR SERVICE WATER TANK PIPINGDocument1 pageBILL OF MATERIALS FOR SERVICE WATER TANK PIPINGABAID ULLAHNo ratings yet

- Inquiry - Japan Marine (S) Pte. LTDDocument2 pagesInquiry - Japan Marine (S) Pte. LTDteamgNo ratings yet

- Impedancias de Transformadores de Dos DevanadosDocument7 pagesImpedancias de Transformadores de Dos DevanadosEDUARDO SALINAS LOPEZNo ratings yet

- Equinor ProductionDocument42 pagesEquinor ProductionGHIFFARI PARAMANTA ELBEESNo ratings yet

- Steel beam materials and profilesDocument2 pagesSteel beam materials and profilesRafael Ramírez GómezNo ratings yet

- Item 2 SENSOR 2270 159300116 SUIZADocument1 pageItem 2 SENSOR 2270 159300116 SUIZALuis Breña DiazNo ratings yet

- PT Padma Panji Pratama PVC Piping Price List 2022Document4 pagesPT Padma Panji Pratama PVC Piping Price List 2022onshopNo ratings yet

- family residence floor planDocument1 pagefamily residence floor planHarini hariniNo ratings yet

- 222 PDFDocument1 page222 PDFHanderson MqzNo ratings yet

- CuSn6 Phosphor Bronze SpecificationDocument1 pageCuSn6 Phosphor Bronze SpecificationRemo StortiniNo ratings yet

- Hola de CalculoDocument14 pagesHola de CalculoMaria alejandra Herrera ReyesNo ratings yet

- Drilling Log: STA 11+475 Hole NoDocument2 pagesDrilling Log: STA 11+475 Hole NoKris SiregarNo ratings yet

- 18.05.10 Metrado Estructuras PLACAS JPLDocument26 pages18.05.10 Metrado Estructuras PLACAS JPLMabel BarreraNo ratings yet

- Harga Beton 300 & 350 - KomparasiDocument9 pagesHarga Beton 300 & 350 - KomparasiRini AdelinaNo ratings yet

- P055azor 03WD00 0001 51Document1 pageP055azor 03WD00 0001 51alhad.maNo ratings yet

- Lap SPV Npk-1 - DayDocument1 pageLap SPV Npk-1 - Dayricho rosmansyahNo ratings yet

- Hub ControllersDocument5 pagesHub ControllerszhuNo ratings yet

- Tarea 1 ProgramaDocument7 pagesTarea 1 Programaleonel fernandezNo ratings yet

- P-WAY PLANDocument10 pagesP-WAY PLANAditya arya singhNo ratings yet

- RSF 11 5 SeriesDocument1 pageRSF 11 5 SeriesKavin SengodanNo ratings yet

- Gangguan Bulan April 2019Document1 pageGangguan Bulan April 2019Ahmad ZainuriNo ratings yet

- Ryobi FlyerDocument4 pagesRyobi FlyerSM CreationNo ratings yet

- Mitsubishi HeavyDocument17 pagesMitsubishi HeavyNguyễn Văn CảnhNo ratings yet

- Elevation Pipe Total Weld Fitting - X Fitting - Y Pipe Name (P) Length GAP Size Size LengthDocument6 pagesElevation Pipe Total Weld Fitting - X Fitting - Y Pipe Name (P) Length GAP Size Size LengthbabuNo ratings yet

- Angular Pins DimensionDocument1 pageAngular Pins Dimension007-18-DEEPAK SHARMANo ratings yet

- SummaryDocument1 pageSummarysagar baralNo ratings yet

- Mine SeQ FormDocument213 pagesMine SeQ FormOK TechNo ratings yet

- Variance DMDLDocument28 pagesVariance DMDLRey Joyce AbuelNo ratings yet

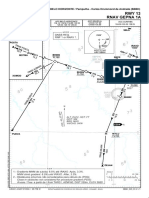

- VVNB Airport InformationDocument12 pagesVVNB Airport InformationSon NguyenNo ratings yet

- Properties of Du 5q47rp971 PDF FileDocument3 pagesProperties of Du 5q47rp971 PDF FileNeylan Ogutveren AularNo ratings yet

- Estimated weights and dimensions of air handling unitsDocument8 pagesEstimated weights and dimensions of air handling unitsKamal AliyevNo ratings yet

- SAOLIDocument289 pagesSAOLIGajendra UkeyNo ratings yet

- Resumen Controles de ConcretoDocument9 pagesResumen Controles de ConcretoGeraldi Sinche BustillosNo ratings yet

- Analitico TabacuyuccDocument13 pagesAnalitico TabacuyuccWagner A. Carrera AndiaNo ratings yet

- Bloco SanitarioDocument1 pageBloco SanitarioZefanias TaualeNo ratings yet

- Ilovepdf MergedDocument3 pagesIlovepdf MergedRahesh MNo ratings yet

- SBBH - Rnav Gepna 1a Rwy 13 - Sid - 20210225Document1 pageSBBH - Rnav Gepna 1a Rwy 13 - Sid - 20210225Yago MojaesNo ratings yet

- 01 Corrida Sistema San JorgeDocument2 pages01 Corrida Sistema San Jorgericardo apazaNo ratings yet

- 8 - Detail KusenDocument1 page8 - Detail KusenIvan JordanNo ratings yet

- Bor Profile 2Document1 pageBor Profile 2Saldy AnwarNo ratings yet

- Uta 22002173Document6 pagesUta 22002173إبراهيم محمد بريدانNo ratings yet

- Pier P0-34-35 - BH P0-20Document2 pagesPier P0-34-35 - BH P0-20Ravindra JagadaleNo ratings yet

- P055azr 05P00 3059 01Document1 pageP055azr 05P00 3059 01Deshwa SaravananNo ratings yet

- Malaysia Prices of Crude Palm OilDocument1 pageMalaysia Prices of Crude Palm OilFazrul FadilNo ratings yet

- Drilling Log: STA 11+125 Hole NoDocument2 pagesDrilling Log: STA 11+125 Hole NoKris SiregarNo ratings yet

- CW Pump Calculation Ss Pipe 20221204Document1 pageCW Pump Calculation Ss Pipe 20221204mohd faisal jamilNo ratings yet

- Ibf Imec International - 2022 Indian Valid From: 1 Jan 2022 N-101Document9 pagesIbf Imec International - 2022 Indian Valid From: 1 Jan 2022 N-101avishkar guptaNo ratings yet

- Drilling Log: STA 11+075 Hole NoDocument2 pagesDrilling Log: STA 11+075 Hole NoKris SiregarNo ratings yet

- Cps Tds Pe Stub Flanges and RingsDocument5 pagesCps Tds Pe Stub Flanges and Ringsaissa kittouNo ratings yet

- Ge CBDocument1 pageGe CBIvan BliminseNo ratings yet

- Meeting chair OPCDocument1 pageMeeting chair OPCFajar Muhammad SidiqNo ratings yet

- Drilling Log: STA 11+455 Hole NoDocument2 pagesDrilling Log: STA 11+455 Hole NoKris SiregarNo ratings yet

- B2_Timbangan Sd Jam 18 Tgl 21.04.2024Document2 pagesB2_Timbangan Sd Jam 18 Tgl 21.04.2024Muhammad Zainal HafizNo ratings yet

- PROGRAMA SIDERURGIADocument18 pagesPROGRAMA SIDERURGIAJose Marval RodriguezNo ratings yet

- Alcotac FE14 TI EVH 0020-1Document2 pagesAlcotac FE14 TI EVH 0020-1Jose Marval RodriguezNo ratings yet

- Electromagnetic Stirring in Continuous Casting ProcessDocument4 pagesElectromagnetic Stirring in Continuous Casting ProcessJose Marval RodriguezNo ratings yet

- Alcotac FE14 TI EVH 0020-1Document2 pagesAlcotac FE14 TI EVH 0020-1Jose Marval RodriguezNo ratings yet

- SVPWM Using Sic Gan Power Driven MotorsDocument12 pagesSVPWM Using Sic Gan Power Driven MotorsJose Marval RodriguezNo ratings yet

- CCM INTRODUCCION POLACADocument9 pagesCCM INTRODUCCION POLACAJose Marval RodriguezNo ratings yet

- 1-s2.0-S2452321623003487-mainDocument6 pages1-s2.0-S2452321623003487-mainJose Marval RodriguezNo ratings yet

- ALTO HORNO LITERATURADocument11 pagesALTO HORNO LITERATURAJose Marval RodriguezNo ratings yet

- Organic Binders Used To Agglomerate A Wide Variety of Mineral SubstratesDocument1 pageOrganic Binders Used To Agglomerate A Wide Variety of Mineral SubstratesJose Marval RodriguezNo ratings yet

- 08 Rietow AISTech08 Nailboard Paper PostDocument11 pages08 Rietow AISTech08 Nailboard Paper PostJose Marval RodriguezNo ratings yet

- Optimization of Strand and Final Electromagnetic Stirrers of Round Bloom Casters With Multiple SectionsDocument2 pagesOptimization of Strand and Final Electromagnetic Stirrers of Round Bloom Casters With Multiple SectionsJose Marval RodriguezNo ratings yet

- Viscosity Reduction of Extra Heavy Crude Oil by MaDocument23 pagesViscosity Reduction of Extra Heavy Crude Oil by MaJose Marval RodriguezNo ratings yet

- The Useof Deep Learningfor Sticker Detection During Continuous CastingDocument7 pagesThe Useof Deep Learningfor Sticker Detection During Continuous CastingJose Marval RodriguezNo ratings yet

- Study of The Deskulling Problem of Tundishes in Continuous CastingDocument14 pagesStudy of The Deskulling Problem of Tundishes in Continuous CastingJose Marval RodriguezNo ratings yet

- Induction Furnace A EviewDocument9 pagesInduction Furnace A EviewsandipanNo ratings yet

- LT1 DRI MarketDocument12 pagesLT1 DRI MarketJose Marval RodriguezNo ratings yet

- Powder Waste Capitulo 8Document4 pagesPowder Waste Capitulo 8Jose Marval RodriguezNo ratings yet

- WGC Akin 22080Document7 pagesWGC Akin 22080Jose Marval RodriguezNo ratings yet

- Api Performing A Storage Tank Risk Assessment v2Document3 pagesApi Performing A Storage Tank Risk Assessment v2Jose Marval RodriguezNo ratings yet

- Applications Steel: Plexicoke in The VmezuelanDocument8 pagesApplications Steel: Plexicoke in The VmezuelanJose Marval RodriguezNo ratings yet

- FCC Anlisis 2Document13 pagesFCC Anlisis 2Jose Marval RodriguezNo ratings yet

- Mold Powders Continuous CastingDocument6 pagesMold Powders Continuous CastingJose Marval RodriguezNo ratings yet

- Quik BoreDocument2 pagesQuik BoreJose Marval RodriguezNo ratings yet

- By Michael Moles, Ph. DDocument8 pagesBy Michael Moles, Ph. DJose Marval RodriguezNo ratings yet

- Polvo Escpria GapDocument15 pagesPolvo Escpria GapJose Marval RodriguezNo ratings yet

- Shell Like Fractures in Continuously Cast SlabsDocument7 pagesShell Like Fractures in Continuously Cast SlabsJose Marval RodriguezNo ratings yet

- API Equipment Inventory List For QUTE Phased Array Examinations - 01-2011.ashxDocument1 pageAPI Equipment Inventory List For QUTE Phased Array Examinations - 01-2011.ashxJose Marval RodriguezNo ratings yet

- Lightherm - Mix Design TableDocument3 pagesLightherm - Mix Design TableRafael Obusan IINo ratings yet

- Micro MachiningDocument26 pagesMicro MachiningJishnu UnniNo ratings yet

- Concentric TubeDocument34 pagesConcentric TubeNajwa NaqibahNo ratings yet

- Technical FinalDocument16 pagesTechnical FinalHardik P PatelNo ratings yet

- FAILUREDocument20 pagesFAILUREMarcharlie PadillaNo ratings yet

- Taylor Southon NI&M-B 2007 PDFDocument6 pagesTaylor Southon NI&M-B 2007 PDFSean Pitman, MDNo ratings yet

- International Journal of Fatigue: Urbi Pal, Goutam Mukhopadhyay, Ankush Sharma, Sandip BhattacharyaDocument7 pagesInternational Journal of Fatigue: Urbi Pal, Goutam Mukhopadhyay, Ankush Sharma, Sandip BhattacharyaRodrigo Alejandro Flores ZuñigaNo ratings yet

- Handouts Gas Laws and Chemical ReactionsDocument5 pagesHandouts Gas Laws and Chemical ReactionsMary Rose AliquioNo ratings yet

- 8th Floor Plumbing BOQDocument6 pages8th Floor Plumbing BOQsathish virupaksheNo ratings yet

- Initial Release 12-04-2017 Kippel, Brad A Revised 3.2 Manufacturer Standard Paint System 07-23-2019 Kippel, BradDocument7 pagesInitial Release 12-04-2017 Kippel, Brad A Revised 3.2 Manufacturer Standard Paint System 07-23-2019 Kippel, BradSaravoot MetahNo ratings yet

- Microbiology A Laboratory Manual 10th Edition Cappuccino Solutions ManualDocument3 pagesMicrobiology A Laboratory Manual 10th Edition Cappuccino Solutions Manualzeldaguinevereiur100% (28)

- Determination of Conductivity Exp3 - PDFDocument12 pagesDetermination of Conductivity Exp3 - PDFSusheel TalrejaNo ratings yet

- Synthesis and Characterization of in Situ Formed Titanium Diboride Particulate Reinforced AA7075 Aluminum Alloy..Document9 pagesSynthesis and Characterization of in Situ Formed Titanium Diboride Particulate Reinforced AA7075 Aluminum Alloy..Selvaraj GuruNo ratings yet

- Vicat Opc 43 48 2019Document1 pageVicat Opc 43 48 2019bhushan deoreNo ratings yet

- Butt 2000Document100 pagesButt 2000kasra7No ratings yet

- 제12주차 Chapter07 박막증착공정Document8 pages제12주차 Chapter07 박막증착공정K SiriusNo ratings yet

- B-Protech John CraneDocument6 pagesB-Protech John CranePatricia J ÁngelesNo ratings yet

- SAFETY DATA SHEET-FucdicDocument5 pagesSAFETY DATA SHEET-FucdicYousifNo ratings yet

- Quiz 5: Machine Design Part 1: Fig. 1: Isometric View of Rod OABDocument6 pagesQuiz 5: Machine Design Part 1: Fig. 1: Isometric View of Rod OABGururaj0% (1)

- Controlling Aluminum Pouring ProcessesDocument5 pagesControlling Aluminum Pouring Processesnagola10No ratings yet

- 9.estimation of Residual ChlorineDocument19 pages9.estimation of Residual ChlorineAbinavNo ratings yet

- Glyphosate MSDS SummaryDocument5 pagesGlyphosate MSDS SummaryAhfi Rizqi FajrinNo ratings yet

- Toyama Battery ManualDocument5 pagesToyama Battery ManualmarckalhiNo ratings yet

- IGCSE Chemistry: Organic Chemistry Lesson 2Document64 pagesIGCSE Chemistry: Organic Chemistry Lesson 2Brandeice BarrettNo ratings yet

- Relation Between Elastic ConstantsDocument5 pagesRelation Between Elastic Constantsnitin_johri100% (1)

- Operational Implementation of Ammonium Perchlorate BiodegradationDocument60 pagesOperational Implementation of Ammonium Perchlorate BiodegradationكشكووولNo ratings yet

- Benzocaine Gel FormDocument4 pagesBenzocaine Gel Formgaiselramos240No ratings yet

- Neo-Dyn Series 130PDocument2 pagesNeo-Dyn Series 130PDaniel ReyNo ratings yet