Professional Documents

Culture Documents

Rti Thermalrock S

Uploaded by

Michael WaltersOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rti Thermalrock S

Uploaded by

Michael WaltersCopyright:

Available Formats

ThermalRock S ROCKWOOL India & Middle East

ISSUED: 2013-07-29

ThermalRock S

TM

INDIA & MIDDLE EAST

General Product Information

ROCKWOOL stone wool products are made of basalt, a volcanic stone.

TM

ROCKWOOL stone wool products are non-combustible with melting point of

TM

approximately 1000 O C. They are particularly suitable for thermal insulation, fire

protection and sound reduction/absorption.

ROCKWOOL stone wool is inorganic and contains no nutritious substance. Therefore

TM

it will not be attacked by micro organisms. Stone wool will not rot and does not attract

vermin. No CFCs, HFCs, HCFCs, or asbestos are used in the manufacture of

ROCKWOOL stone wool products.

TM

TM

INDIA & MIDDLE EAST

Fully owned subsidiary of ROCKWOOL International A/S, Denmark

ThermalRock S ROCKWOOL India & Middle East

ISSUED: 2013-07-29

Reaction to Fire Classification

ROCKWOOLTM Thermal Rock S range achieves an A1 Non-Combustible reaction to fire classification; including faced and unfaced

variations.

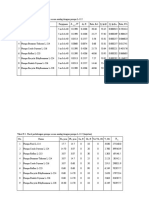

ThermalRock S Range – Technical Parameters

Product Types S40 S50 S60 S80 S90 S100 Standards

Nominal Density (kg/m3) 40 50 60 80 90 100

Thermal Conductivity at 20oC (W/mK)* 0.034 0.034 0.035 0.035 0.036 0.035 ASTM C518

Sound Absorption Class B A A A A A ISO 354/ ASTM C 423

Fire Performance Non-Combustible/A1 Fire Clas sification EN 13501-1 / UL 723

Water Vapor absorption* 0.04 % by Vol ASTM C1104/C1104M

Water absorption (partial immersion) < 1 Kg/m2 EN 1609:97

* Typical Values

Acoustic Performance

Due to the naturally random orientation of ROCKWOOL fibres, all ROCKWOOL products make excellent acoustic absorbers; the

ROCKWOOL Thermal Rock S range has been extensively tested & has a proven track record for it being used to substantially improve

the acoustic performance of any application.

Below is a sample graph of the acoustic absorption coefficients that can be achieved; it must also be noted that the majority of

thicknesses and densities have achieved a Class A absorber rating.

For further acoustic information please contact our technical representatives.

Figure 2 : Plot for Random incidence sound absorption coefficient (RISAC) of Rockwool slabs (S60) for

50 mm, 75 mm and 100 mm at one third octave frequencies

1.10

1.00

0.90

Random Incidence Sound Absorption Coefficient

0.80

0.70

0.60

0.50

0.40

0.30

0.20

Rockwool slab (S60) and 50 mm thickness - NRC = 0.93 , αw = 0.95 and Class A

Rockwool slab (S60) and 75 mm thickness - NRC = 1.00 , αw = 1.00 and Class A

0.10

Rockwool slab (S60) and 100 mm thickness - NRC = 1.03 , αw = 1.05 and Class A

0.00

125 160 200 250 315 400 500 630 800 1000 1250 1600 2000 2500 3150 4000 5000 6300 8000

One third octave frequency band , Hz

*Acoustic information for the other densities is also available on request.

Typical Applications

Internal Partitions – S40/S60

As well as excellent thermal performance the Thermal

Rock S range also provides a high level of acoustic

benefit; as such, it has also undergone rigorous acoustic

testing and has attained a Class A absorption rating.

This excellent acoustic performance makes ROCKWOOL

Thermal Rock Slab the ideal product for use as an

acoustic material in internal partitions; its use can

greatly increase the sound deadening properties of any

light weight construction.

2

TM

INDIA & MIDDLE EAST

Fully owned subsidiary of ROCKWOOL International A/S, Denmark

ThermalRock S ROCKWOOL India & Middle East

ISSUED: 2013-07-29

Façade – S80 Soffit Slab – S100

Robust ROCKWOOL designed for installation behind TM

High density soffit liner designed to act as a high grade

façade constructions. This material gives a high level thermal & fire upgrade to concrete soffits. Designed as a

of acoustic & thermal protection to the envelope of the single solution to the issue of thermally protecting the

building; whilst maintaining its non combustible concrete soffit and providing an upgrade to the existing

certification. When installed correctly the slabs will fire protection properties. Available un-faced or with

knit together, thereby reducing any extraneous heat black/white tissue facing. All boards should be

loss through the board joints. Due to the materials mechanically fixed directly to the concrete soffit as per

open cell nature, this product allows the structure to the recommended fixing detail below; fixings can

include SFS Intec MDD-S 8.0D (for non Fire Rated

breath reducing the risk of condensation.

applications) & ITW Roof Grip or SPIT Isomet Hammer

fixings with 50mm steel washers (for Fire Rated

applications).

Light Fittings & Services

Thermal Rock Façade

Thermal Rock Soffit Slab should not be used to support

any fixtures or fittings. All services must be fixed back

through the insulation, directly to the concrete soffit.

Metal Rainscreen Bracket and Angle

System including Thermal Break Pad

Façade Cladding

1000mm

To obtain the optimum performance from the system

the slabs should be applied vertically with all joints

tightly butted together. Fix using a combination of

metal & polypropylene as per the detail below;

600mm

possible fixing manufacturers include: SFS Intec, Hilti, 500mm

Ejot.

300mm

100mm

100mm

100-150mm

Key

Metal fixing

Polypropylene fixing

3

TM

INDIA & MIDDLE EAST

Fully owned subsidiary of ROCKWOOL International A/S, Denmark

ThermalRock S ROCKWOOL India & Middle East

ISSUED: 2013-07-29

Dimensions Packing and Storage

Length Width Thickness Density ThermalRock S is shrink-wrapped in polyethylene

(MM) (MM) (MM) (KG/M3) sheets for ease of handling, transportation, storage

and identification. Products should be stored indoors

1200 600 30,50,75,100 40

or under a waterproof covering.

1200 600 30,50,75,100 50

1200 600 30,50,75,100 60

1200 600 30,50,75,100 80

1200 600 30,50,75,100 90

1200 600 30,50,75,100 100

* Please contact yout local representatives for sizes and densities not stated in the data sheet

Various Certificate Earned by ROCKWOOL TM

FILE : R27712

ROXUL ROCKWOOL Technical ROXUL ROCKWOOL Technical

Insulation India Pvt. Ltd. Insulation Middle East FZE

705, Center point, J.B. Nagar, Dubai Airport Freezone

Andheri-Kurla Road, 6WB 139,

Andheri-East, Mumbai-400 059 P.O. Box 293585, Dubai, Unites Arab Emirates

T:+91 22 6715 7740 T:+971 42146284

F:+91 22 6715 7710 F:+971 42146285

info.rti.india@rockwool.com info.rti.dubai@rockwool.com

http://www.rockwool.in

TM

INDIA & MIDDLE EAST

Fully owned subsidiary of ROCKWOOL International A/S, Denmark

You might also like

- Thermalrock S Product Data Sheet inDocument4 pagesThermalrock S Product Data Sheet inIvyrod Umalsa- EnterprisesNo ratings yet

- Rockboard 40Document2 pagesRockboard 40zaidg9876553No ratings yet

- Fabrock 30: Board Insulation For OEM ApplicationsDocument2 pagesFabrock 30: Board Insulation For OEM ApplicationsCristhian RangelNo ratings yet

- Safe _n_ Silent Pro Product Data Sheet IndiaDocument2 pagesSafe _n_ Silent Pro Product Data Sheet IndiaMd Farid AhmedNo ratings yet

- Rockwool Rocktech WM en DsDocument4 pagesRockwool Rocktech WM en DsZain Al AbidinNo ratings yet

- Precision Thin Film Chip ResistorsDocument3 pagesPrecision Thin Film Chip ResistorsJaPan LifeNo ratings yet

- Fea en Tile Datasheet Rockfon Artic D 02 20203Document4 pagesFea en Tile Datasheet Rockfon Artic D 02 20203sirikhwan wonganuntNo ratings yet

- Rti Searox SL 740 PDFDocument1 pageRti Searox SL 740 PDFAlexandre GomesNo ratings yet

- Rockwool 740Document1 pageRockwool 740Alexandre GomesNo ratings yet

- Rockwool 159: 2.2 Insulation ProductsDocument1 pageRockwool 159: 2.2 Insulation ProductsZouhair AIT-OMARNo ratings yet

- ROCKWOOL SLAB CompressedDocument2 pagesROCKWOOL SLAB CompressedGhulam HussainNo ratings yet

- Rockfon Medicare Standard: DatasheetDocument4 pagesRockfon Medicare Standard: Datasheetאורלי בן יוסףNo ratings yet

- Rockwool SeriesDocument12 pagesRockwool SeriesUsamah AhmadNo ratings yet

- Searox SL 480: Marine Slab 200Document1 pageSearox SL 480: Marine Slab 200sivlag01No ratings yet

- Searox SL 640 PDFDocument1 pageSearox SL 640 PDFSuryana MamanNo ratings yet

- 1206 Thick Film Chip Resistor: Standard Grade, WraparoundDocument1 page1206 Thick Film Chip Resistor: Standard Grade, WraparoundSlavko KeserNo ratings yet

- Roxul Comfortboard 80: Insulated SheathingDocument1 pageRoxul Comfortboard 80: Insulated SheathingMark RauNo ratings yet

- Description: Standard Density and ThicknessDocument2 pagesDescription: Standard Density and Thicknessarash khajeimNo ratings yet

- High Temperature Corrosion Resistance of Steels and AlloysDocument35 pagesHigh Temperature Corrosion Resistance of Steels and AlloysdennykvgNo ratings yet

- Rockwool SlabsDocument4 pagesRockwool SlabsBinu AyaniyattuNo ratings yet

- PDS Rockwool Marine Firebatts 100Document1 pagePDS Rockwool Marine Firebatts 100Alexandre GomesNo ratings yet

- Conrock Data SheetDocument2 pagesConrock Data Sheetcahyo hutomoNo ratings yet

- Thermalrock S Data Sheet - inDocument2 pagesThermalrock S Data Sheet - inlac ngoNo ratings yet

- Rockwool-Rocktech-Spi en Ds 202007Document4 pagesRockwool-Rocktech-Spi en Ds 202007pisun chumsriNo ratings yet

- Aluminium foil history and production processDocument19 pagesAluminium foil history and production processKalyan HalderNo ratings yet

- Aluminium AlloyDocument14 pagesAluminium AlloyPenka VasilevaNo ratings yet

- Safe N Silent Data Sheet inDocument2 pagesSafe N Silent Data Sheet inApoorv MahajanNo ratings yet

- Datasheet Rockfon PacificDocument4 pagesDatasheet Rockfon Pacificsirikhwan wonganuntNo ratings yet

- FT Hardrock-391 Bigpanel inDocument1 pageFT Hardrock-391 Bigpanel injcunha4740No ratings yet

- Rockwool (India) Limited: Your Thermal & Acoustic Insulation PartnerDocument22 pagesRockwool (India) Limited: Your Thermal & Acoustic Insulation PartnerOmkar sinhaNo ratings yet

- Astm SL540 HRDocument1 pageAstm SL540 HRMd Farid AhmedNo ratings yet

- Preparation and Characterization of Supported Nickel Catalysts.Document12 pagesPreparation and Characterization of Supported Nickel Catalysts.Hugo SolìsNo ratings yet

- Searox SL 320: Marine Slab 60Document1 pageSearox SL 320: Marine Slab 60Novan AndriantoNo ratings yet

- Zincalume G300 Steel: Metallic Coated - MC Structural - SDocument2 pagesZincalume G300 Steel: Metallic Coated - MC Structural - SPranatia Wisnu HeryudaNo ratings yet

- Thermal and acoustic insulation for lofts and ceilingsDocument2 pagesThermal and acoustic insulation for lofts and ceilingspaulina7shiNo ratings yet

- Datasheet Zincalume G550Document2 pagesDatasheet Zincalume G550adihindNo ratings yet

- Prorox WM 960 Sa LRDocument1 pageProrox WM 960 Sa LRr afriantoNo ratings yet

- Rigid, Semi-Rigid and Flexible Slabs: Versatile Thermal Acoustic Insulation SlabsDocument7 pagesRigid, Semi-Rigid and Flexible Slabs: Versatile Thermal Acoustic Insulation SlabsPhan LongNo ratings yet

- 03 - SeAH Metal - Company - EngDocument4 pages03 - SeAH Metal - Company - EngHOSSIENNo ratings yet

- Rockwool Slab SL930Document1 pageRockwool Slab SL930Lee Kok RoyNo ratings yet

- Zincalume G550 G550S PDFDocument2 pagesZincalume G550 G550S PDFkartikkeyyanNo ratings yet

- 27 - Searox - SL - 620 PDFDocument1 page27 - Searox - SL - 620 PDFAntonio MartinNo ratings yet

- A 463 - A 463M - 02 - Qtq2my9bndyzts1sruqDocument8 pagesA 463 - A 463M - 02 - Qtq2my9bndyzts1sruqJOSE DE LA TORRENo ratings yet

- SA/AS 1548 - PT460NR (L0, L20) XLERPLATE Steel: Plate - PL Pressure Vessel - PVDocument3 pagesSA/AS 1548 - PT460NR (L0, L20) XLERPLATE Steel: Plate - PL Pressure Vessel - PVJang CoiNo ratings yet

- SUPRA50®: Chemical Composition (Weight %)Document3 pagesSUPRA50®: Chemical Composition (Weight %)malaya tripathyNo ratings yet

- Foamular SpecsDocument1 pageFoamular SpecsalokNo ratings yet

- SeaRox - SL - 740 - Thermal OnlyDocument1 pageSeaRox - SL - 740 - Thermal OnlyPaul MathewNo ratings yet

- Prorox SL 580 PDFDocument1 pageProrox SL 580 PDFgowtham_venkat_4No ratings yet

- Proro PDFDocument1 pageProro PDFgowtham_venkat_4No ratings yet

- INDUSTRIAL AND TECHNICAL ROCKWOOL PRODUCT SHEET FOR PROROX SL 580 STONE WOOL SLABDocument1 pageINDUSTRIAL AND TECHNICAL ROCKWOOL PRODUCT SHEET FOR PROROX SL 580 STONE WOOL SLABgowtham_venkat_4No ratings yet

- Ficha Tecnica Sv200neoDocument1 pageFicha Tecnica Sv200neoMauricio Ramirez PerezNo ratings yet

- ASTM_SL580_HRDocument1 pageASTM_SL580_HRMd Farid AhmedNo ratings yet

- LT95 AppgDocument7 pagesLT95 AppgAlexVelasquezQNo ratings yet

- Focus Dg CatalogueDocument6 pagesFocus Dg CatalogueEddy NgNo ratings yet

- Metal-Coated - Galvsteel: Data SheetDocument2 pagesMetal-Coated - Galvsteel: Data SheetjcvalenciaNo ratings yet

- Rockwool Thermalrock S (Slab) : General Product InformationDocument2 pagesRockwool Thermalrock S (Slab) : General Product InformationMohsin RazaNo ratings yet

- ANTI-SEIZE Stainless - GBDocument3 pagesANTI-SEIZE Stainless - GBHasan RazaNo ratings yet

- Universal Twu1.5-Technical SheetDocument1 pageUniversal Twu1.5-Technical SheetCruz ArangoNo ratings yet

- Rockwool Technical Insulation Product DatasheetDocument1 pageRockwool Technical Insulation Product DatasheetPaul Mathew100% (1)

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Calculo de BridasDocument39 pagesCalculo de Bridasguillermo garciaNo ratings yet

- Qwrfs Bhil KolDocument16 pagesQwrfs Bhil KolridminjNo ratings yet

- FRP Ashland - Different FRP Resin Chemistries For Different Chemical EnvironmentsDocument6 pagesFRP Ashland - Different FRP Resin Chemistries For Different Chemical EnvironmentsHafiz Kamal100% (1)

- Steam Tracing CalculationDocument44 pagesSteam Tracing CalculationsafaldNo ratings yet

- Ips6e Ex ST PDFDocument216 pagesIps6e Ex ST PDFDaniesha ByfieldNo ratings yet

- Applying EI Vibration & SBC GuidelinesDocument22 pagesApplying EI Vibration & SBC GuidelinesvicopipNo ratings yet

- All-In Labour Rate Build-Up - EstimatingDocument3 pagesAll-In Labour Rate Build-Up - EstimatingMichael WaltersNo ratings yet

- ASTM A105 Flange Heat TreatmentDocument16 pagesASTM A105 Flange Heat TreatmentpuffdNo ratings yet

- Guide to uPVC pipe sizes and specificationsDocument5 pagesGuide to uPVC pipe sizes and specificationsAldi ErzanuariNo ratings yet

- Estimation of Pipe Paint Quantity The Piping Engineering WorldDocument5 pagesEstimation of Pipe Paint Quantity The Piping Engineering WorldMichael Walters100% (1)

- Estimating Time Management - EstimatingDocument3 pagesEstimating Time Management - EstimatingMichael WaltersNo ratings yet

- LBNL 51042 PDFDocument9 pagesLBNL 51042 PDFraguNo ratings yet

- HVAC Duct Sizing GuideDocument91 pagesHVAC Duct Sizing GuidePrabir Bhowmik100% (1)

- Design Guidelines For Safety in Piping NetworkDocument15 pagesDesign Guidelines For Safety in Piping NetworkrvnesariNo ratings yet

- HVACManl PDFDocument166 pagesHVACManl PDFErvinaNo ratings yet

- Bolt Stress RevBDocument50 pagesBolt Stress RevBMichael Walters100% (1)

- Klinger Gasket FactorsDocument3 pagesKlinger Gasket FactorsGeorge TanasescuNo ratings yet

- Pipe Support CalculationDocument2 pagesPipe Support Calculationthanh100% (1)

- Bolt Stress RevBDocument50 pagesBolt Stress RevBMichael Walters100% (1)

- Bolt Sizing EngineerdogDocument43 pagesBolt Sizing EngineerdogHans GoetheNo ratings yet

- Calculate Pressure Thrust and Weld Stress for Bracket DesignDocument19 pagesCalculate Pressure Thrust and Weld Stress for Bracket DesignMichael WaltersNo ratings yet

- Ducting Handbook 4th Ed Final Rev 11-16Document56 pagesDucting Handbook 4th Ed Final Rev 11-16Cristian SNo ratings yet

- Using Bellville Springs To Maintain Bolt PreloadDocument30 pagesUsing Bellville Springs To Maintain Bolt PreloadsulemankhalidNo ratings yet

- Buckling of Free Pipe Under External PressureDocument38 pagesBuckling of Free Pipe Under External Pressurevictortownshend100% (1)

- Valve Sizing Worksheet Instructions Rev 5Document24 pagesValve Sizing Worksheet Instructions Rev 5Michael WaltersNo ratings yet

- Gasket Thickness SelectionDocument3 pagesGasket Thickness SelectionKarthick DuraiNo ratings yet

- Ase Documents EN1591 BasisDocument8 pagesAse Documents EN1591 BasisSharat ChandraNo ratings yet

- A & S Couplings: Home Products Industrial CouplingsDocument1 pageA & S Couplings: Home Products Industrial CouplingsMichael WaltersNo ratings yet

- EN 12874-2001 Flame Arresters - Performance Requirements, Test Methods and Limits For Use PDFDocument46 pagesEN 12874-2001 Flame Arresters - Performance Requirements, Test Methods and Limits For Use PDFMichael WaltersNo ratings yet

- 10019Document12 pages10019Emir MujićNo ratings yet

- Mechanical Design (Compile Draft 1)Document87 pagesMechanical Design (Compile Draft 1)IRIZREENNo ratings yet

- Federal Praktis Orientasi Topikal STPM Chemistry Sem 2 InorganicDocument86 pagesFederal Praktis Orientasi Topikal STPM Chemistry Sem 2 InorganicSharon RamaiahNo ratings yet

- Introduction to Electronic Materials and DevicesDocument8 pagesIntroduction to Electronic Materials and DevicesSahana MecheriNo ratings yet

- Introduction General Organic, and Biochemistry: Twelfth EditionDocument22 pagesIntroduction General Organic, and Biochemistry: Twelfth EditionFrankenstein MelancholyNo ratings yet

- Chapter One: Complex StressesDocument42 pagesChapter One: Complex StressesAbel YohannesNo ratings yet

- Principle of FloatationDocument9 pagesPrinciple of FloatationAngela NuñezNo ratings yet

- JEE Main 2023 Jan 24th Morning Shift - Physics: QuestionsDocument14 pagesJEE Main 2023 Jan 24th Morning Shift - Physics: Questionsychiru540No ratings yet

- Corbel For Bottom Slab of Water Tank Design of Corbel at El+18.266Document2 pagesCorbel For Bottom Slab of Water Tank Design of Corbel at El+18.266mathuNo ratings yet

- Gkournelos Triantafillou 2023 Out of Plane Behavior of in Plane Damaged Masonry Infills Retrofitted With TRM andDocument14 pagesGkournelos Triantafillou 2023 Out of Plane Behavior of in Plane Damaged Masonry Infills Retrofitted With TRM andN.prem kumarNo ratings yet

- Calendario Vacunas para EstudiarDocument8 pagesCalendario Vacunas para EstudiarKlisman A. Flores DurandNo ratings yet

- 3D Analysis of Failure Modes in The Charpy Impact TestDocument21 pages3D Analysis of Failure Modes in The Charpy Impact TestEdna Odette Melo UscangaNo ratings yet

- Plane Failure Analysis Wedge Failure Analysis Toppling Failure AnalysisDocument30 pagesPlane Failure Analysis Wedge Failure Analysis Toppling Failure AnalysisSEDIMNo ratings yet

- Module 7: Lesson 2 AssignmentDocument2 pagesModule 7: Lesson 2 AssignmentCharity GoertzenNo ratings yet

- Comparision - RC - Building ETABS and Midas GenDocument16 pagesComparision - RC - Building ETABS and Midas Genmarkespino100% (2)

- Jurnal Rekayasa Proses: Dew Point Control UnitDocument22 pagesJurnal Rekayasa Proses: Dew Point Control UnitMelvin FelixanderNo ratings yet

- ML11229A688Document91 pagesML11229A688leonard dalaliNo ratings yet

- Galilean and Aristotelian MotionDocument2 pagesGalilean and Aristotelian MotionAliah Colleen V. AgnesNo ratings yet

- MOLECULAR DIFFUSION THEORYDocument6 pagesMOLECULAR DIFFUSION THEORYHey YoNo ratings yet

- Support 3Document15 pagesSupport 3Shreyas AlagundiNo ratings yet

- Machine Component Design QuestionsDocument6 pagesMachine Component Design Questionssuneel kumar rathoreNo ratings yet

- All India Integrated Test Series For JEE Advanced 2023Document2 pagesAll India Integrated Test Series For JEE Advanced 2023Ayaan SidddiquiNo ratings yet

- Elder 1967Document22 pagesElder 1967ALEJANDRO GANCEDO TORALNo ratings yet

- A Review On Failure Modes of Wind Turbine BearingsDocument44 pagesA Review On Failure Modes of Wind Turbine Bearingsmans199No ratings yet

- Physics Investigatory ProjectDocument19 pagesPhysics Investigatory ProjectKrish KaushikNo ratings yet

- Quaternary Science ReviewsDocument19 pagesQuaternary Science ReviewsFernando Nicolas Ureta GodoyNo ratings yet

- Belajar KaznaeDocument277 pagesBelajar KaznaewahyuNo ratings yet

- Chemical EquilibriumDocument67 pagesChemical Equilibriummukesh kumar_0709No ratings yet

- Ch03 Harmonically Excited Vibrations Part1 PDFDocument19 pagesCh03 Harmonically Excited Vibrations Part1 PDFIsfan Satriyo PramudaniNo ratings yet

- Structural Steel Trusses Analysis and DesignDocument39 pagesStructural Steel Trusses Analysis and DesignSai Sasank CHNo ratings yet

- Lecture 6a Pavement DesignDocument20 pagesLecture 6a Pavement DesignEngr Asad Ahmad ShahNo ratings yet