Professional Documents

Culture Documents

PM Tamson TC 16 - Bath Circulator

Uploaded by

Sergey KichenkoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PM Tamson TC 16 - Bath Circulator

Uploaded by

Sergey KichenkoCopyright:

Available Formats

USER-

MANUAL

TC16-40-58

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 1/20

1 SAFETY AND WARNINGS ...................................................................................................................... 3

2 WARRANTY ............................................................................................................................................. 3

3 PRECAUTIONS AND HAZARDS ............................................................................................................ 4

4 INSTALLATION ........................................................................................................................................ 4

4.1 IMPORTANT ..........................................................................................................................................................4

4.2 UNPACKING..........................................................................................................................................................4

4.3 INITIAL USE...........................................................................................................................................................5

4.4 FILLING THE BATH .................................................................................................................................................5

5 CONNECTING .......................................................................................................................................... 7

6 INTRODUCTION TO THE TC SERIES .................................................................................................... 8

6.1 GENERAL .............................................................................................................................................................8

6.2 PUMP ..................................................................................................................................................................8

6.3 COOLING .............................................................................................................................................................8

6.4 OVER-TEMPERATURE SAFETY ................................................................................................................................9

6.5 ADJUSTING THE MECHANICAL OVER-TEMPERATURE PROTECTION THERMOSTAT ........................................................9

6.6 FLUID LEVEL ...................................................................................................................................................... 10

6.7 FLUID LEVEL DETECT .......................................................................................................................................... 10

7 OPERATION ........................................................................................................................................... 11

7.1 SWITCHING ON ................................................................................................................................................... 11

7.2 CONTROL PANEL ................................................................................................................................................ 11

7.3 BACKSIDE OF THE THERMOSTATIC BATH ................................................................................................................ 12

7.4 SELECTING PARAMETERS .................................................................................................................................... 12

8 QUICK START ........................................................................................................................................ 14

8.1 TUNING THE BATH ............................................................................................................................................... 14

8.2 TUNE PID VALUES .............................................................................................................................................. 15

8.3 DESELECT TUNING .............................................................................................................................................. 15

8.4 MANUAL TUNING ................................................................................................................................................. 15

8.5 DRAINING BATH FLUID.......................................................................................................................................... 16

8.6 USING THE DRAIN TAP (OPTIONAL) ........................................................................................................................ 16

8.7 MAINTENANCE .................................................................................................................................................... 16

9 TROUBLE SHOOTING ........................................................................................................................... 17

9.1 GENERAL ........................................................................................................................................................... 17

9.2 MESSAGE ON DISPLAY ......................................................................................................................................... 18

10 SPECIFICATION ................................................................................................................................. 18

10.1 TECHNICAL SPECIFICATIONS OVERVIEW ................................................................................................................. 18

11 SPARE PARTS ................................................................................................................................... 19

12 DISCLAIMER ...................................................................................................................................... 19

13 CE DECLARATION OF CONFORMITY ............................................................................................. 20

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 2/20

1 SAFETY AND WARNINGS

Make sure before installing or operating the equipment to read and understand all instructions and safety

precautions listed in this manual. If there are any questions concerning the operation of the equipment or

about the information given in this manual please contact your local dealer or our sales department first.

Performance of installation, operation, or maintenance other than those described in this manual may result

in a hazardous situation and may void the manufacturer's warranty.

Never operate equipment that is not correctly installed. Unqualified personnel must not operate the

equipment. Avoid damage to the equipment, or its accessories, caused by incorrect operation.

Important:

- When performing service, maintenance or moving the apparatus, always disconnect the apparatus

at the main's socket,

- Proper skilled and trained personnel are only allowed to operate this equipment,

- Take notice of warning labels and never remove them,

- Refer service and repairs to qualified technician,

- If a problem persists, call your supplier or Tamson Instruments bv.

2 WARRANTY

Tamson Instruments bv. warrants that all their manufactured equipment is free from defects in material and

workmanship, preventing the machine from normal operation. Tamson Instruments bv does not warranty that

the equipment is fit for any other use than stated in this manual. The manufacturer can only be held

responsible for the security, reliability and performance of the equipment, when operated in accordance with

the operating instructions, extensions, adjustments, changes and/or if repair is performed by Tamson

Instruments bv. or authorized persons only. This warranty is limited to one year from the date of invoicing. All

equipment and materials are subject to standard production tolerances and variations.

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 3/20

3 PRECAUTIONS AND HAZARDS

Before attempting to operate the bath read all parts

of this manual carefully to insure smooth operation

and avoid damage to the equipment or its

accessories.

If a malfunction occurs, consult section "Fout!

Verwijzingsbron niet gevonden.”, pageFout!

Bladwijzer niet gedefinieerd. at the end of this manual. READ

If problem persists, call your supplier or Tamson CAREFULLY

Instruments bv. Never operate the equipment if not

correctly installed. The equipment must be operated only

by qualified personnel. Avoid damage to the equipment

or its accessories through incorrect operation.

Environment

Panel sealing Confirms EN60529:

IP65

Environment Temperature 0 tot 35°C. Supply

enough ventilation

Humidity 5 tot 95 %, non

condensating

Atmosphere Not suited for altitudes

above 2000m

or

explosive/corrosive

environment

Pollution cat. 2 Conducting pollution

must be prevented

4 INSTALLATION

4.1 Important

Tamson Instruments bv is not responsible for any

consequential damage or harm caused by using this

bath. Repairs on the electrical system of the bath may

only be carried out by well trained and authorized

persons.

4.2 Unpacking

Before leaving the factory Tamson baths are adequately

packed to prevent damage during normal transportation.

Check the packing for external damage and make a note

on the shipping documents if any damage is found.

Always retain the cartons and packing material until the

bath has been tested and found in good condition. REMOVE ALL

(Transport companies generally will not honor a claim for PACKAGE MATERIAL

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 4/20

damage if the respective packing material is not available

for examination).

The shipment contains at least the bath as mentioned in

the delivery checklist. Further the consignment might

contain one or more viscometers, individually packed in

small boxes with the calibration certificate included in the

box, as well as ASTM thermometers, thermometer

holders etc. Please see the packing list for details

concerning total contents of consignment.

Before filling the bath remove any remaining packing

material from its interior. The interior of the bath can

be accessed by taking off the lid on the top of the

bath.

4.3 Initial use

Before filling the bath make sure that the bath is clean.

Place the bath spirit level, and connect it to the mains

after the mains switch is placed in “off” position. Use a

mains supply with proper grounding.

Important: Never use the bath without fluid

4.4 Filling the bath

The bath-fluid level must be 10- to 20 mm below the edge

of the top-plate.

10 - 20 mm

In no case the fluid level may be lower than 60 mm under

the edge. This can cause severe damage to the heating Max. 60 mm

element.

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 5/20

For working temperatures above +80°C a fluid with a high

boiling point must be used. The bath fluid also has to be

chemically stable and must have low viscosity preventing

damage to the pump. Tamson oil type 150 has these

characteristics and is recommended to use for

temperature ranges which lie between +80°C and

+150°C.

Silicon oil can be used for temperatures between +20°C

and +150°C.

It is very important to select a liquid with a viscosity of less

than 20 mm²/s at the operating temperature and a flash

point which is well above the operating temperature.

VISCOSITY

< 20 mm²/s

FLASH POINT

When viscosity of the bath fluid is too high at room > OPERATING

temperature, the motor-fuse will be activated. In such a TEMPERATURE

case the bath fluid can first be heated to set point PRESS

temperature. When the bath has reached it’s set point the BUTTON TO

motor fuse can be reset by pressing it. This way of RESET MOTOR

operating will reduce the life of the motor and is thus not FUSE

recommended.

Type Remarks Life Viscosity [mm²/s] X Temp. Package Ordering

150°C 200°C 250°C 80°C 100°C 150°C 200° Range code

C

Mineral T150 1/2 yr X X 20 7 3 80..150° 20 ltrs 00T0220

Yellow

Mineral oil

C

Silicon 200 -10 No limit 200hrs <10hrs 4 3.5 2.5 20..150° 20 ltrs 08T0001

Transparent

Dimethyl siloxane

C

polymer

Silicon 200 -50 No limit 200hrs <10hrs 20 15 9 80..150° 20 ltrs 00T0226

Transparent

Dimethyl siloxane

C

polymer

Silicon Silicon 210 No limit <2yrs <1yr (35) 30 22 12 80..250° 20 ltrs 00T0231

Dark

Dimethyl poly

C

siloxane

Silicon Silicon 550 No limit <1yr <1200 (50) 20 12 5 80..250° 20 ltrs 00T0238

Colorless

Polyphenyl methyl

hrs C

dimethyl siloxane

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 6/20

Do not use demineralized or distilled water. This

water can lead to corrosion of the bath and moving

parts. The corrosion can wear out the pump bearings

5 CONNECTING

Before plugging TC 16, TC40 or TC58 into the mains

socket, make sure the voltage of the bath corresponds to

the local voltage and frequency.

Use a mains supply that is well earthed, clean of

interference and suitable for the acquired electrical

load of the bath.

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 7/20

6 INTRODUCTION TO THE TC SERIES

The TAMSON model TC baths are used for precise

temperature control. This series offers a choice in

relatively large bath volumes.

6.1 General

The TAMSON baths are constructed throughout from

corrosion-resistant – stainless steel and brassTeflon –

materials. Outher casing is zinc plated powder coated

steel. The bath is effectively insulated against heat loss

by a layer of Armaflex® rubber between the inner tank

and outer casing. PRESS

BUTTON TO

6.2 Pump RESET MOTOR

A circulation pump is built-in to guarantee an uniform FUSE

temperature distribution within the bath and providing the

possibility to circulate through a closed external system.

The standard pump offers a motor protection (small

thermal fuse) which is placed on the back panel of the

motor compartment. This protects the motor from

excessive loads.

When pumping viscous liquids the thermal fuse can REMOVE DISK

be activated. The motor fuse can be reset by pressing WHEN

the button. CIRCULATING

The inlet and outlet of the pump are fitted with 8 mm hose

connections and 1/4” threaded fittings for metal tubing.

The outlet is provided with a small disc, stopping the

circulation action.

Before the fluid can begin circulating through

external systems this disc must be removed by

unscrewing the fitting and hose connection

removing the disc.

6.3 Cooling

The TC-bath is equiped with a cooling coil. Circulation of

fluid, with a lower temperature than the bath fluid, through

this coil will cool down the bath temperature. To get stable

control of the bath when using the cooling coil, the

temperature of the cooling fluid has to be approximately

5°C lower than the set point temperature of the bath.

Cooling is need for set point temperatures of

approximately 42°C and lower.

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 8/20

The cause for this relatively high temperature is the self

heating of the bath due to friction-heat of the pump. The

insulation of the bath prevents this energy to be

transferred into the environment. This causes a raise of

temperature in the bath up to 25 .. 30°C depending on the

environmental temperature and used bath fluid.

For cooling the bath down to lower temperatures, tap-

water is mostly used. Also a small circulator can be

connected to the cooling coil like the Tamson TLC10-3,

or TLC15.

6.4 Over-temperature safety

In case of electronic failure the possibility exists that the

heater element is continuously switched on. This will

cause extreme temperature raise. To prevent high

temperatures the bath is fitted with a mechanical

temperature switch (thermostat). This thermostat will

switch-off the bath at a preset temperature in the range

from 50 tot 270°C.

We advise to adjust the mechanical over temperature to

approximately + 25 C above the bath set point.

This safety construction prevents for example oil to be

heated above flash point which definetly will cause fire or

prevent evaporation of bath fluid due to high

temperatures.

The thermostat will automatically reset when the bath

temperature drops approximately 10°C below the pre-set

temperature. To continue normal operation the bath has

to be switched-off and on again.

6.5 Adjusting The Mechanical Over-

Temperature Protection Thermostat

• Turn the over-temperature protection (8, drawing

2) to its maximum (turn clockwise towards 50°C),

• Heat the bath to its set point,

• Gently turn the over-temperature protection anti-

clockwise, until the over-temperature protection is

activated, and system switches-off,

• Turn the over-temperature protection

approximately 25°C higher (turn clockwise),

Switch the bath off and on again. The bath is ready to

operate safely.

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 9/20

6.6 Fluid Level

Do not operate the bath with low fluid level.

When the fluid level is too low, bath fluid will vaporize

leading to toxic and flammable fumes.

Flammable fumes can lead to fire

Flammable fumes can be ignited by the not submersed

part of the heating element.

The level indicator(optional) will start to blink (white light)

when the fluid level is too low.

When the bath has been installed it must be filled

with an appropriate liquid. When working with water

the bath should be filled to 1 cm below the lid. For oil

the bath should be filled to not more than 5 cm below

the lid. Depending on the operating temperature the

liquid level in the bath should be observed and

excessive fluid should be removed.

The liquid level should be maintained between 1 and 3

cm below the lid during normal operation.

The heating element will be damaged when not fully

submerged in the bath fluid. A lower level than 5 cm

below the lid may damage the heaters. A high bath level

can cause overflow and might also damage the bath

insulation.

Low fluid level

- Can cause fire when heater gets partially

exposed

- Will damage the heater

6.7 Fluid Level Detect

Level detection is available as an option. When the fluid

level becomes too low an audible alarm is triggered.

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 10/20

7 OPERATION

7.1 Switching on

If the bath has been properly filled with fluid it can be SWITCH ON

switched with the mains switch located on the front panel.

Choose a working temperature (set point).

1

7.2 Control Panel

2

1. LED Display

2. LED Over-temperature* 3

3. LED Heater

4. Up - key 4

5. Down – key

6. Page – key

5

7. Scroll - key 6

8. Safety thermostat

9. Mains On/Off 7

10. Top lid

8 9

* When the overtemperature safety is activated

wait until the bath temperature is lowered several

degrees. The safety thermostat will reset itself. Turn the

bath off and on again. The bath will continue operation. 8 10

9

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 11/20

1

7.3 Backside of the thermostatic bath

1 Cooling fan 2

2 RS 232 Communication 7

3 In and outlet pump

side view connection: 3

4

4 Mains cable 6

5 Motor fuse 5

6 Cooling coil, 1/4" outher thread

7 Switch for fan (only for TC16 with p/n 31T0671/

31T0861)

8 Fan (only for TC16 with p/n 31T0671/31T0861) 8

7.4 Selecting parameters

The front panel layout shows the following four operating

keys:

Press shortly and following is displayed PAGE

SP.1 - Temperature set point in °C,

tU.n - Tuning the bath (“Atune”), LIST

Pb - Changing the tuning (PID) parameters "P"value

ti - Changing the tuning (PID) parameters "I"value

td - Changing the tuning (PID) parameters "D"value DOWN

OFSt - Change temperature readout offset (± 5°C)

UP

Each time is pressed another option is displayed.

Up and Down keys allow changing the listed value. All

changed values, like set point and PID parameters, will

be kept in memory when pressing the page key to leave

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 12/20

the menu. After switching off the power supply, changed

values are kept in memory.

SP.1 Set point adjust.

Press page key to confirm setting when altered.

tU.n Auto tuning PID parameters, set on or off.

Off is default value here.

On, when selecting parameter 2nd time.

On.A is played. This indicates adaptive tune. Bath is adapting

PID setting in background operation. When in On.A mode.

PID values can not be set manually anymore.

pb Changing the tuning (PID) parameters. 'Proportional band

value. Default value is 1, range 1 .. 100. (Proportional band

equals 1/proportional value).

Press page key to confirm setting when altered.

ti Changing the tuning (PID) parameters 'Integrator' value.

Default value is 200. Range 1 .. 1200.

Press page key to confirm setting when altered.

td Changing the tuning (PID) parameters 'Differentiator' value.

Default value is 0. Range 1 .. 600.

Press page key to confirm setting when altered.

OFST Set offset. The offset value is added to the displayed bath

temperature. I.e. when the displayed bath temperature is

20.0°C, an offset of 0.2 displays a value of 20.2°C. An offset

of -0.2°C will display 19.8°C. Range is -5°C .. +5°C.

Press page key to confirm setting when altered.

Note When tune is set to on, PID values can not be set. Change

tune to off en alter PID values.

Press page key to confirm setting when altered.

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 13/20

8 QUICK START

To quickly start operating the bath:

• Fill the bath with sufficient and appropriate fluid.

see filling the bath.

• Place the power plug,

• Switch on the bath using the mains switch, IN-TUNE

• Choose a working temperature (set point):

Press once. Display will indicate "SP.1". Alter set point

temperature by using up and down key to select

the desired bath temperature.

Confirm by pressing .

8.1 Tuning the bath

The temperature control of the bath is based on a digital

PID system. When using different fluids in the bath each

with their own heat capacity, the use of external cooling

and external connected processes (circulation), or

working at different set point temperatures requires new

settings of the PID parameters. These parameters have

to be optimized after changes to the system when optimal

and accurate temperature control of the bath liquid is

required.

Tuning of the bath results in:

• Stable temperature control of the bath,

• No over- or undershoot of the temperature set

point,

• Quick response to deviations from the set point

caused by external disturbances.

Tuning can be done automatically or manually. The

parameters mentioned in table 1 will influence the control

of the bath.

Parameter Description Display

Proportional band The bandwidth in display-units over which the output power is Pb

proportional between minimum and maximum

Integration time Determines the time taken by the controller to remove steady state error Ti

signals

Derivative time Determines the time taken by the controller to react on error signals. Td

Table 1 Parameters influencing the temperature control

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 14/20

8.2 Tune PID values

Choose desired set point,

Wait until the bath has reached the set point temperature,

Highest temperature accuracy can be achieved when

tuning the bath. Select tU.n by pressing twice.

Press to choose “ON”,

Press 5 times to return to displayed PV

(PID values can no longer be adjusted unless the "tU.n"

value is set to off)

8.3 Deselect tuning

• Pressing twice,

• Display shows ”tU.n”,

• Press to choose “Off”,

• Press 5 times to return to displayed PV.

8.4 Manual tuning

The parameters for the PID control can also be changed

manually. The method described below provides fast

finding of the PID settings and is refereed to as the

method of "Ziegler Nichols"

This procedure is only to be followed when automatic

tuning is not functioning.

This method provides fast manual findings of the PID

values. Start the bath at its required running temperature:

1. Set the integral time “Ti” and the derivative Time

“Td” to off

2. Check if the Lcb and Hcb are set to auto

3. Ignore the fact that the temperature may not

settle precisely at the set point

4. If the temperature is stable, reduce the

proportional band Pb so that the temperature just

starts to oscillate. If the temperature is already

oscillating, increase the proportional band until it

begins oscillating. Allow enough time between

each adjustment for the loop to stabilize. Make a

note of the proportional band value “B” and the

period of oscillation “T” Set the Pb, Ti and Td

parameter values according to the calculations

given in the table below

Type of control Proportional band Integral time "ti" Derivative Time "td"

Proportional only 2xB Off Off

P + I control 2,2xB 0,8xT Off

P + I + D control 1,7xB 0,5xT 0,12xT

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 15/20

8.5 Draining bath fluid

Before removing flammable bath liquids take the

appropriate fire hazard precautions against these liquids.

When draining the bath fluid, be sure that the bath fluid

has cooled down to ambient temperature. If viscosity is

too high at ambient temperature to remove the fluid,

make sure that the hose to drain and waste container

can withstand the temperature of the bath fluid.

When removing bath fluid do not inhale toxic vapor.

Always use appropriate ventilation.

8.6 Using the drain tap (optional)

The TC baths can be drained via the drain tap located at

the backside of the apparatus.

The drain has an inner diameter of 3/8” gas fitting. The

drain can be connected onto a pipe, tube or drainage

system.

For safety reasons the tap can only be opened by using

a screwdriver. The thread inside the tap is 3/8".

8.7 Maintenance

Keep the apparatus free from dust. Regularly check the

cooling openings and remove dust with vacuum cleaner.

If necessary remove cover and clean internally. Use

appropriate protection when cleaning, dust can be very

unhealthy.

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 16/20

9 TROUBLE SHOOTING

All Tamson products are well designed and carefully

tested before shipping. This will not fully prevent small

problems in the field. Following will help you to locate

commonly known problems and how to fix them. In case

of doubt please check your local dealer or Tamson

Instruments bv.

9.1 General

Bath malfunction

The motor is not running and electronics is dead Check mains fuse

Motor is not running: Probably the motor fuse is activated. Restart the

motor by pressing the motor fuse .

Check viscosity of the bath fluid. High viscosity will

activate the motor fuse.

Electrical defect. Motor capacitor defective.

Replace capacitor or contact local dealer or

Tamson Instruments bv.

Problems with set point

Heater LED is not burning, motor is turning and Setpoint too near to room temperature. Cooling of

temperature raises above set point: the bath is needed.

Temperature doesn’t reach set point, motor turns Bath fluid evaporates too quick. Use other fluid.

fast:

Heater malfunctions: Measure electric mains current. Current below 2

amps indicate a problem with the heating element.

Temperature not stable Tune the bath at the set point temperature.

Difference between ambient and bath temperature

is too small (Applied power indication is below

8%). Use cooling coil

PID values

Unable to set PID values: Check if ATUN has been set to on. PID values can

no longer be adjusted unless the ATUN value is

set to off. See 8.4 selecting parameters.

Readout / indicator

The temperature readout on the display does not Check the PT100 sensor

correspond to the temperature measured.

Level indicator on frontpanel blinks. Fluid level probably too low, check fluid level

Be aware that the fluid level always needs to be

higher than the heating element(s).

An heating element which partially operates above

the fluid (so partially exposed to air above the fluid

level) can get hot en may possibly ignite the fbath

fluid.

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 17/20

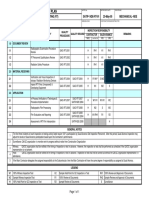

9.2 Message on display

Code What does it mean What action to take

E61 Defect / calibration PT100 Check wiring and element. Ohmic value

at 0C=100R and at 100C=138R.

Replace PT100

E70 Error on operational parameters

E50 EEprom error Auto - reset after 2 s

E82 Error on input during calibration

E4 EEprom error Auto - reset after 2 s

E5 EEprom error Auto - reset after 2 s

E6 Watchdog error Auto - reset after 2 s

10 SPECIFICATION

10.1 Technical specifications overview

Item Unit TC16 TC40 TC58

Ordering 50 or 00T0671 00T0681 00T0691

60Hz

code

230V

115V 50 or 00T0861 00T0851 00T0881

60Hz

Power [Watt] 1500 2900 2900

Materials Used inside bath: stainless steel 304, brass

Range Ambient .. 250C/..482F

Reading Standard C, F on request

Setting ± [°] 0.1

Stability ± [°K] 0.02 0.02 0.02

Heating [W] 1400** 2800 2800

Bath [L] 16 40 58

volume

Pump [mBar] Max pressure 300*

Pump [L/min] Max flow 7.5*

Opening [mm] 180 *210 420 *275 420 *275

Depth [mm] 220 200 300

bath

Length [mm] 455 705 705

Width [mm] 295 375 375

Height [mm] 440 440 590

Weight [Kg] 21 30 35

CE Conforms to CE regulation

* Optional pump with pressure max 1bar, flow max

16ltrs/min, reference: 24T0392. See specification sheet

"pumpgraph

** Additional heater 1400W optional to heat larger loads

when circualting

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 18/20

11 SPARE PARTS

Ordering number Description

230V 50/60Hz 115V 50/60Hz

25T1242 25T1242 Fan 60x60 12V

04T0035 04T0045 Pump complete

25T1290 25T1308 Pump motor

24T8080 24T8083 Motor fuse

24T3300 24T3312 Motor Capacitor

06T0496 06T0497 PCB TE series

25T0194 25T0195 Heater 1400 Watts

25T194 25T0195 Boost Heater 1400 Watts

24T8541 Mains switch

28T4106 Keypad foil

28T4107 Front sticker TC16

28T4108 Front sticker TC40

28T4109 Front sticker TC58

24T8581 Safety thermostat

28T3022 Controller PCB 115V & 230V (Not programmed, when

ordering always specify bath (i.e. TC16, TC40, TC58)

12 DISCLAIMER

Information given herein is offered in good faith as

accurate, but without guarantee. Conditions of use and

suitability of the product for particular uses are beyond

our control; all risks of use of the product

are therefore assumed by the user.

We expressly disclaim all warranties of every kind

and nature, including warranties of merchantability

and fitness for a particular purpose in respect to the

use or suitability of the product.

Nothing is intended as a recommendation for uses which

infringe valid patents or as extending license under valid

patents. Appropriate warnings and safe handling

procedures should be provided to handlers and users.

Alteration of this document is strictly prohibited. Except to

the extent required by law, republication or

retransmission of this document, in whole or in part, is not

permitted. Tamson Instruments bv assume no

responsibility for accuracy of information unless the

document is the most current available. Tamson

Instruments neither represent nor warrant that the format,

content or product formulas contained in this document

comply with the laws of any other country except the

Netherlands.

Tamson Instruments bv, All rights reserved

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 19/20

13 CE DECLARATION OF CONFORMITY

Following equipment is in complience with EMC Directive 2014/30/EU:

Product: Thermostatic bath and circulator

Model: TC16 / TC40 / TC58

Serial code: Effective from 07Txxx

Manufacturer: Tamson Instruments bv

van 't Hoffstraat 12

2665 JL Bleiswijk

The Netherlands

The products are in conformity with the following specifications:

Item Reference Description Test result

a RoHS Directive 2011/65EU p

b EN 61010-2-010 Safety requirements for electrical

equipment for measurement, control,

and laboratory use. Particular require-

ments for laboratory equipment for the

heating of material

c Machine Directive Machinery Directive, of the European p

2006/42/EC Parliament and of the Council of 17 May

2006/42/EC 2nd Edition June 2010

d EN 60204 Machinery Directive and Safety p, pi

requirements

e EN60950-1 Low Voltage Directive p

f EN61000-3-2 Harmonics p

g EN61000-3-3 Flicker p3

h EN61000-4-2 +A1+A2 ESD p

i EN61000-4-3 +A1+A2 Radiated immunity p (anechoic room)

j EN61000-4-4 Electrical Fast Transients Minimum requirements pass

k EN61000-4-5+A1 Surges Minimum requirements pass

l EN61000-4-6+A1 Conducted immunity p

m EN61000-4-11 +A1 Voltage dips and Voltage variations p

n EN55016-2-1 Conducted emission p

o EN55016-2-3 Radiated emission p (anechoic room)

p = Pass

pi = Individually tested

p3 = Pass, condition of operating during Pst measurement: Operational with heating element 1400W.

Pst and Plt are not evaluated in accordance with A.5 of Annex A of EN 61000-3-3(1995) + A1(2001).

not applicable were:

Conducted discontinuous emissions (Clicks)

Radiated emission (OATS)

Magnetic field immunity

Entity responsible for marking this declaration :

Manufacturer, Tamson Instruments bv, van 't Hoffstraat 12, Bleiswijk The Netherlands,

Name : R.C. van Hall

Function : Director

Date : Sept 18, 2017

Version : 1.03

ISO 9001 : 2015

NL/PRO 238239125 Tamson Instruments bv VAT: NL 80 66 34 984 B01

Bank account no.:

NL28 INGB 0007 350 370

Van ’t Hoffstraat 12

E-mail: sales@tamson.com NL95 RABO 0160100046

2665 JL Bleiswijk, The Netherlands

Website: www.tamson.com Chamber of commerce 27 16 95 41

T. 31 (0) 10 522 43 73

tc16-40-58-man.docx Rev. 2.4 UK 9-21 Page 20/20

You might also like

- User-Manual: TV12LTDocument30 pagesUser-Manual: TV12LTMOHD NOR IqbalNo ratings yet

- User-Manual: Tamson Instruments B.VDocument18 pagesUser-Manual: Tamson Instruments B.VFraz AhmadNo ratings yet

- User-Manual: TV2000MKII, TV4000MKII, TV4000MKIIDC TV17000Document33 pagesUser-Manual: TV2000MKII, TV4000MKII, TV4000MKIIDC TV17000Aatir AhmedNo ratings yet

- Scanner 3100 Efm Hardware User ManualDocument100 pagesScanner 3100 Efm Hardware User Manualeduardo goveaNo ratings yet

- TD1215-05sw Service Manual Maintemance YT-TT-RTDocument62 pagesTD1215-05sw Service Manual Maintemance YT-TT-RTСергей ЕлоховNo ratings yet

- Manual TuttnauerDocument102 pagesManual TuttnauerErick RamirezNo ratings yet

- Instruction Manual V-Line Water Cooled Compressor: V105, V150, V200, V250, V375Document69 pagesInstruction Manual V-Line Water Cooled Compressor: V105, V150, V200, V250, V375Dhairya SindhiNo ratings yet

- K-Tron Operating and Maintenance ManualDocument126 pagesK-Tron Operating and Maintenance ManualMiguel Angel Torres FuentesNo ratings yet

- Operational Manual - LITE 3Document52 pagesOperational Manual - LITE 3Navish Kumar Singh100% (1)

- Spreader manualDocument176 pagesSpreader manualhangdung19921991No ratings yet

- Saxon SH 2000Document69 pagesSaxon SH 2000JavedNo ratings yet

- Pcme Man DT780 DT280 Ing Issue 1.01Document86 pagesPcme Man DT780 DT280 Ing Issue 1.01Claudio NobregaNo ratings yet

- Tibc-10 Battery Charger Installation and Maintenance ManualDocument19 pagesTibc-10 Battery Charger Installation and Maintenance Manualagsan.algabh2718No ratings yet

- Operation: ManualDocument43 pagesOperation: Manualsolmolina20100% (1)

- Installation Manual t5350 enDocument36 pagesInstallation Manual t5350 enmayNo ratings yet

- Engine Instruction Manual (2012)Document464 pagesEngine Instruction Manual (2012)rafael.eloidasilvaNo ratings yet

- MB ManualDocument47 pagesMB ManualdangthanhlinhNo ratings yet

- Eletta Flow Meter Manual: Installation and OperationDocument39 pagesEletta Flow Meter Manual: Installation and OperationSANJAY DEOPURANo ratings yet

- Starcool CI5Document223 pagesStarcool CI5Jonas Matheus Sardena PeresNo ratings yet

- Operating Manual: Incubators With Mechanical AdjustmentDocument41 pagesOperating Manual: Incubators With Mechanical AdjustmentLamar Asociados Ltda.No ratings yet

- Pt-D-Ma-Pro0352010-101 - 03 Manual TW Slim Plus DuoDocument34 pagesPt-D-Ma-Pro0352010-101 - 03 Manual TW Slim Plus DuoEklou EfuiNo ratings yet

- Installation, Commissioning and Operations Manual for Flatpack2 Optus SystemDocument70 pagesInstallation, Commissioning and Operations Manual for Flatpack2 Optus SystemcleetusNo ratings yet

- MGDIZ Product ManualDocument31 pagesMGDIZ Product ManualMarinko BulićNo ratings yet

- PTM-185043659, Rev L, HC550Document55 pagesPTM-185043659, Rev L, HC550bender.saschaNo ratings yet

- Air Compressor V150Document385 pagesAir Compressor V150Palm Lukasz100% (5)

- Solid State Color TV: Important Safeguards - 1Document31 pagesSolid State Color TV: Important Safeguards - 1Anuta CosminNo ratings yet

- SBOX-2600 ManualDocument72 pagesSBOX-2600 ManualВикторNo ratings yet

- Operating Instructions: Controller B130/B150/B180/C280/P300/P310/P330Document56 pagesOperating Instructions: Controller B130/B150/B180/C280/P300/P310/P330ARYAN_FATHONI_AMRINo ratings yet

- Ricoh Aficio 2075 Users Manual 274493Document195 pagesRicoh Aficio 2075 Users Manual 274493Trần CôngNo ratings yet

- Manual JetCAT P80Document39 pagesManual JetCAT P80GicusorErnuNo ratings yet

- BB01 Programming-Manual EN Rev06Document34 pagesBB01 Programming-Manual EN Rev06Miguel Angel GómezNo ratings yet

- Merlin Chiller M33 Service ManualDocument78 pagesMerlin Chiller M33 Service ManualSoro FoxNo ratings yet

- Sootblower Operation and Maintenance ManualDocument78 pagesSootblower Operation and Maintenance Manualanbesivam87_49857255No ratings yet

- Pcme Man Dt200i Ing Issue 2.02Document35 pagesPcme Man Dt200i Ing Issue 2.02Claudio NobregaNo ratings yet

- SEVCON - Gen4 Size 8 Product Manual V1 - 2Document129 pagesSEVCON - Gen4 Size 8 Product Manual V1 - 2Jesse DavisNo ratings yet

- Machine Washing and Disinfection Service ManualDocument54 pagesMachine Washing and Disinfection Service ManualМаксим ПетровNo ratings yet

- Maintenance Manual: TH 59428 H01 TH 59429 H01Document16 pagesMaintenance Manual: TH 59428 H01 TH 59429 H01Вадім РусинчукNo ratings yet

- Calibration Unit 01.03.2011Document428 pagesCalibration Unit 01.03.2011krunopNo ratings yet

- 2611-2704-9900Document287 pages2611-2704-9900hangdung19921991No ratings yet

- E2T QUASAR Flare Monitors 8100 ManualDocument78 pagesE2T QUASAR Flare Monitors 8100 ManualChepe MatusalenNo ratings yet

- MT9602 US Service Manual V1.0 2020-3-27-1Document57 pagesMT9602 US Service Manual V1.0 2020-3-27-1Tena y EstebanNo ratings yet

- VIC - DocLib - 6114 - CUTMASTER 102 Operating Manual (0-5012) - April2012Document80 pagesVIC - DocLib - 6114 - CUTMASTER 102 Operating Manual (0-5012) - April2012Ruben David Ibañez RetamalNo ratings yet

- Manual SC30TDocument60 pagesManual SC30Tdetrusitol73% (15)

- TSCI Mistral-Air Plus MA-1100 - Service ManualDocument46 pagesTSCI Mistral-Air Plus MA-1100 - Service ManualLucila Figueroa GalloNo ratings yet

- MTK5659 (FHD Models) AM Service Manual Ver1.0 2018-5-31Document57 pagesMTK5659 (FHD Models) AM Service Manual Ver1.0 2018-5-31MarcosRomano100% (2)

- Titan Series CNC AC Servo Beam RobotDocument92 pagesTitan Series CNC AC Servo Beam RobotmohammadNo ratings yet

- Q320 maintenance manual 08-05-22Document60 pagesQ320 maintenance manual 08-05-22hungvu1001No ratings yet

- Neumoinsuflador Lut Service ManualDocument65 pagesNeumoinsuflador Lut Service Manualandres2013bio0% (1)

- COMPACTOR Tony Team User Manual TT240 v2Document19 pagesCOMPACTOR Tony Team User Manual TT240 v2catolinNo ratings yet

- Service Manual Alpha Units PDFDocument57 pagesService Manual Alpha Units PDFGraftec57% (7)

- Auxitrol Mannual 759197-FDocument255 pagesAuxitrol Mannual 759197-FGumaMohamed25% (4)

- Installation and Maintenance ManualDocument53 pagesInstallation and Maintenance ManualAndrey SamoylovNo ratings yet

- Installation Manual: General Information Open SystemDocument83 pagesInstallation Manual: General Information Open SystemhamzehNo ratings yet

- Master Controller Manual - 3.2Document32 pagesMaster Controller Manual - 3.2BernieNo ratings yet

- Ce-1100-Op-Eng-Fanuc-A01 1100-7713-100Document152 pagesCe-1100-Op-Eng-Fanuc-A01 1100-7713-100bogus asdfNo ratings yet

- User Manual: VT5230 VentilatorDocument183 pagesUser Manual: VT5230 VentilatorArtur FloriánNo ratings yet

- Consort ManualDocument9 pagesConsort Manualsowel ilhamiiNo ratings yet

- RCW - EngDocument77 pagesRCW - Engmeharatif3832No ratings yet

- Ce-1500-Op-Eng-Fanuc-D11 1500-7713-100Document155 pagesCe-1500-Op-Eng-Fanuc-D11 1500-7713-100pkandreiutzNo ratings yet

- InnerVue Diagnostics ServicesDocument1 pageInnerVue Diagnostics ServicesSergey KichenkoNo ratings yet

- Protecting plant piping from CUI with water repellencyDocument2 pagesProtecting plant piping from CUI with water repellencySergey KichenkoNo ratings yet

- Vapor Pressure Testing at Its Best: EravapDocument6 pagesVapor Pressure Testing at Its Best: EravapAdikoDenzeyAnonhNo ratings yet

- Brady Catalogue enDocument92 pagesBrady Catalogue enAde SetiawanNo ratings yet

- 2018-02-Halliburton-slidesDocument14 pages2018-02-Halliburton-slidesSergey KichenkoNo ratings yet

- SP-2275, Rev1Document48 pagesSP-2275, Rev1Moetaz Mohamed0% (1)

- QA/QC ManualDocument42 pagesQA/QC ManualGuilherme Dos Santos Moreira100% (1)

- Corrosion Monitoring Methods (Chevron)Document65 pagesCorrosion Monitoring Methods (Chevron)Sergey KichenkoNo ratings yet

- Operator Manual Dakota UT MVXDocument120 pagesOperator Manual Dakota UT MVXRoyce BergNo ratings yet

- Training Manual (GET Process) 1Document34 pagesTraining Manual (GET Process) 1Steve Wan100% (2)

- Corrosion Detection and ControlDocument47 pagesCorrosion Detection and ControlMassimo FumarolaNo ratings yet

- Comparison Corrosion Mapping Solutions Using PDFDocument10 pagesComparison Corrosion Mapping Solutions Using PDFfabian barraganNo ratings yet

- Salt in Crude Analyser ApparatusDocument2 pagesSalt in Crude Analyser ApparatusDAVID JUMANo ratings yet

- Analytical Systems Keco - 205L Laboratory H2S Analyzer in Crude OilDocument2 pagesAnalytical Systems Keco - 205L Laboratory H2S Analyzer in Crude OilSergey KichenkoNo ratings yet

- SAIC-RT-2005 Mat Insp-Fils Nad DevelopingDocument3 pagesSAIC-RT-2005 Mat Insp-Fils Nad DevelopingKirubhakarPooranamNo ratings yet

- The Three P's of High Temperature Plastic PipeDocument70 pagesThe Three P's of High Temperature Plastic PipeSergey KichenkoNo ratings yet

- ASTM D4929-19 Determination of Organic Chloride Content in Crude OilDocument10 pagesASTM D4929-19 Determination of Organic Chloride Content in Crude OilSergey KichenkoNo ratings yet

- SAIC-RT-2007 In-Process For RT ImplementationDocument7 pagesSAIC-RT-2007 In-Process For RT ImplementationSergey KichenkoNo ratings yet

- SAIC-RT-2003 Radiation Safety Procedure ReviewDocument1 pageSAIC-RT-2003 Radiation Safety Procedure ReviewKirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection Checklist: Radiographic Film Evaluation and Reporting SAIC-RT-2009 25-May-05 NdeDocument6 pagesSaudi Aramco Inspection Checklist: Radiographic Film Evaluation and Reporting SAIC-RT-2009 25-May-05 NdeSergey KichenkoNo ratings yet

- SAIC-RT-2004 Verify RT EquipmtDocument3 pagesSAIC-RT-2004 Verify RT EquipmtKirubhakarPooranamNo ratings yet

- Saic K 4039Document1 pageSaic K 4039dilshadmit1280No ratings yet

- SAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTION PLANDocument1 pageSAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTION PLANKirubhakarPooranamNo ratings yet

- XXX RadiographsDocument48 pagesXXX RadiographsJoseph MidouNo ratings yet

- Radiographic Inspection of Corrosion and Deposits in Pipes by X - and Gamma Rays Tangential Radiographic Inspection Technique (ISO 20769)Document16 pagesRadiographic Inspection of Corrosion and Deposits in Pipes by X - and Gamma Rays Tangential Radiographic Inspection Technique (ISO 20769)Sergey KichenkoNo ratings yet

- Iaea Tecdoc 1445Document114 pagesIaea Tecdoc 1445avazcNo ratings yet

- SAIC-RT-2002 Revw RT Person QualificationDocument1 pageSAIC-RT-2002 Revw RT Person QualificationKirubhakarPooranamNo ratings yet

- EN 16407 HOIS PresentationDocument26 pagesEN 16407 HOIS PresentationEsin DenizNo ratings yet

- Pipe Wall Thickness and Corrosion AssessmentDocument13 pagesPipe Wall Thickness and Corrosion AssessmentSantosh mishraNo ratings yet

- Measure Pipe Wall Thickness Using Tangential RadiographyDocument7 pagesMeasure Pipe Wall Thickness Using Tangential Radiographykirubha_karan2000No ratings yet

- Design & Operation of Clean Room-1Document39 pagesDesign & Operation of Clean Room-1Hafizur Rahman0% (1)

- Let Us Be HappyDocument2 pagesLet Us Be HappyMarjule DechavezNo ratings yet

- CD 0400 CH 4 X 100 ML: For in Vitro Diagnostic Use Only. LinearityDocument1 pageCD 0400 CH 4 X 100 ML: For in Vitro Diagnostic Use Only. LinearityNguyễn ThơiNo ratings yet

- HydrotherapyDocument7 pagesHydrotherapyGialys MoretaNo ratings yet

- General ALT Model For Step Stress TestDocument12 pagesGeneral ALT Model For Step Stress TestAnshul NautiyalNo ratings yet

- Image Forgery DetectionDocument17 pagesImage Forgery DetectionanlemacoNo ratings yet

- Legend of Nueva VizcayaDocument10 pagesLegend of Nueva VizcayaAndreanna Maria100% (1)

- Tejas: Practice Sheet JEE PhysicsDocument3 pagesTejas: Practice Sheet JEE PhysicsAshree KesarwaniNo ratings yet

- Pharmaceutical Ingredients and Excipient - LastpptDocument72 pagesPharmaceutical Ingredients and Excipient - LastpptFANTANo ratings yet

- Circuits Review P2Document44 pagesCircuits Review P2José CastilloNo ratings yet

- The Future - G&VDocument6 pagesThe Future - G&VManuelHerreraMontoyaNo ratings yet

- Chapter-1: Introduction of The StudyDocument21 pagesChapter-1: Introduction of The StudyViswanathanNo ratings yet

- Ras Abu Aboud Stadium Daily Report 040 (20190613)Document4 pagesRas Abu Aboud Stadium Daily Report 040 (20190613)tuan50% (2)

- API 510 BasicsDocument40 pagesAPI 510 BasicsBalakumarNo ratings yet

- Metal Enameling: Arts & CommunicationDocument15 pagesMetal Enameling: Arts & CommunicationAnjali DavidNo ratings yet

- Demonstration POSTNATAL EXAMINATION Easy WayDocument9 pagesDemonstration POSTNATAL EXAMINATION Easy Wayjyoti singhNo ratings yet

- Construction Site PremisesDocument78 pagesConstruction Site PremisesDrew B Mrtnz67% (6)

- Acute Severe Asthma Hospital ManagementDocument1 pageAcute Severe Asthma Hospital ManagementItharshan IndreswaranNo ratings yet

- Chapter 14 Chemical EquilibriumDocument29 pagesChapter 14 Chemical EquilibriumlynloeNo ratings yet

- Gen Ed Answer Key (A)Document7 pagesGen Ed Answer Key (A)Antonette Escarpe TorcinoNo ratings yet

- Auomotivr Fuel TanksDocument9 pagesAuomotivr Fuel Tankscolumba_mcNo ratings yet

- vCloudPoint Sharing Computing Solution Data Sheet PDFDocument8 pagesvCloudPoint Sharing Computing Solution Data Sheet PDFkus satria dNo ratings yet

- HydrotherapyDocument52 pagesHydrotherapyMpt Sports100% (1)

- Introduction To The Philosophy of The Human PersonDocument14 pagesIntroduction To The Philosophy of The Human PersonDan Niel50% (2)

- CaseStudy AmtrakDocument14 pagesCaseStudy Amtraksnob_kNo ratings yet

- Barney's Great Adventure - Barney Wiki - WikiaDocument2 pagesBarney's Great Adventure - Barney Wiki - WikiachefchadsmithNo ratings yet

- Mohair FiberDocument33 pagesMohair FiberMuhammad Ahsan AftabNo ratings yet

- Giddings & Lewis Sect08 HydDocument24 pagesGiddings & Lewis Sect08 HydAngel AdautaNo ratings yet

- NPT Pipe Thread Sizes and TapersDocument1 pageNPT Pipe Thread Sizes and TapersRajesh J BharadwajNo ratings yet

- Girbau STI-54 STI-77 Parts ManualDocument74 pagesGirbau STI-54 STI-77 Parts Manualrpm14sheratonbsasNo ratings yet