Professional Documents

Culture Documents

General Notes Equipment Schedule: Romeo M. Bathan

Uploaded by

Mark Anthony ValbuenaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes Equipment Schedule: Romeo M. Bathan

Uploaded by

Mark Anthony ValbuenaCopyright:

Available Formats

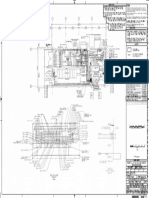

GENERAL NOTES EQUIPMENT SCHEDULE

1. ALL EQUIPMENT SHALL BE INSTALLED IN APPROXIMATE LOCATION AS SHOWN ON THE

AIR CURTAIN, SUPPLY AND EXHAUST FAN

DRAWINGS. WHEEL ELECTRICAL DATA

2. ALL EQUIPMENT SHALL BE MOUNTED ON OR SUPPORTED WITH VIBRATION ISOLATOR EQUIP. CAPACITY T.S.P.

OR ASSEMBLIES AS SPECIFIED ON THE DRAWINGS. NO. QTY. TYPE (CFM) (PA) INCH RPM HP KW VOLTS PH. Hz.

REMARKS

3. INSTALLATION OF ALL WORKS SHALL BE DONE IN A NEAT AND WORKMANLIKE MANNER,

IMPROPERLY SETWORK OR FINISH AS DETERMINED BY THE ARCHITECT SHALL BE 1 SISW-BACKWARD 7,968 500 26 1850

EAB-1 5.0 3.7 230 3 60

REMOVED AND REPLACED AT NO EXTRA COST. CURVE CENTRIFUGAL

4. ALL MATERIALS TO BE USED SHALL BE BRAND NEW & CLEAN. SISW-FORWARD SIMILAR TO NIAGARA KRUGER

5. DEVIATIONS AND REVISIONS FROM PLANS SHALL BE REFERED TO THE ARCHITECT FOR FAB-1 1 7170 500 14 1850 5.0 3.7 230 3 60

CURVE CENTRIFUGAL OR APPROVED EQUAL (MUST

REVIEW AND APPROVAL. HAVE NONSPARKING BLADES)

6. ALL NECCESSARY GOVERNMENT PERMIT SHALL BE SECURED AND PAID FOR BY THE TEF-1 2 CEILING CASSETTE 100 65 - - - 0.1 230 3 60 OR EXPLOSION PROOF

CONTRACTOR.

7. ALL DIMENSION ARE IN MILLIMETER UNLESS OTHERWISE SPECIFIED. 3 CEILING CASSETTE 300 65 - - - 0.15 230 3 60

EF-1

8. ALL MECHANICAL WORKS SHALL BE . IN ACCORDANCE WITH THE LATEST MECHANICAL

ENGINEER'S CODE ASME, SMACNA AND ASHRAE STANDARD AND ALL ON SITE

ACTIVITIES SHALL BE SUPERVISED BY THE REGISTERED MECHANICAL RNGINEER. FUME SCRUBBER

9. MECHANICAL CONTRACTOR SHALL OBSERVED ALWAYS SAFETY AND ORDERLINESS.

10. MECHANICAL CONTRACTOR SHALL VERIFY SITE PRIOR TO ACTUAL INSTALLATION. CAPACITY WATER TANK INLET AND OUTLET SIZE PUMP WIND RESISTANCE

EQUIP. SIZE DRAIN OUTLET

11. ALL FRESH AIR DUCT EXPOSED TO WEATHER SHALL BE PAINTED WITH ANTI-CORROSIVE

NO. QTY. (CFM) (mm) (mm) (mm) (mm) (kw) (Pa.)

PAINT. USE EPOXY PRIMER FOR ALL APPLICATION.

12. THE MECHANICAL CONTRACTOR SHALL SUBMIT TESTING, BALANCING AND

COMMISSIONING PROCEDURE FOR APPROVAL BY JFC PRIOR TO IMPLEMENTATION AT FS-1 1 7,968 1,800 DN 50 700(w) X 1200(l) X 700(h) 650 3.75 500

SITE AND SHALL BE WITNESSED BY EITHER INHOUSE OR OUTSOURCED TESTING

BALANCING AND COMMISSIONING PROVIDER.

13. ALL METAL SUPPORTS SHALL BE FULLY WELDED. DUCT SCHEDULE

14. ALL CONTROL WIRING SHALL BE BY THIS CONTRACTOR.

15. ALL POWER WIRING SHALL BE BY ELECTRICAL CONTRACTOR. LOW PRESSURE GALVANIZED STEEL DUCTWORK SPECIFICATION TABLE FLEXIBLE DUCT

16. ALL PLANS WITH COMMENTS MUST ALWAYS BE PRESENT ON SITE PRIOR TO

CONSTRUCTION MONITORING AND AS BASIS OF CONSTRUCTION. CONNECTOR (TYP.)

METAL GAGE TRANSVERSE JOINTS HANGERS

17. THE CONTRACTOR SHALL ENSURE THAT EVERYTHING HAS BEEN VERIFIED AND DUCT LONGEST SIDE TRANSVERSE JOINTS

FRESH AIR DUCT

COORDINATED WITH ALL OTHER DICIPLINES AS TO CONSTRUCTIBILITY, FUNCTIONALITY

GALVANIZED STEEL DIMENSION (MM) SPACING BRACING ROD DIA. SHELF ANGLE SPACING

AND MAINTAINABILITY OF THE EQUIPMENT AND UTILITIES. IF FOR ANY REASON, CONSTRUCTION (MM) (MM) (MM) (MM)

CONFLICT ARISE DUE TO CONTRACTORS FAILURE TO FOLLOW STANDARD

SPECIFICATIONS AND GOOD ENGINEERING PRACTICES OR ITS LACK OF DUE 26 UP THRU 300 25 POCKET LOCK HEMMED "S"SLIP

2400 NONE

DELIGENCE, ALL WORKS AS NECESSITATED SHALL BE PERFORMED BY THE 325 THRU 450 DRIVE SLIP (VERTICAL ONLY) 40x25x2

CONTRACTOR WITHOUT ADDITIONAL COST VARIATION ORDER TO THE OWNER. 10 U-CHANNEL 2400

18. IN THE ABSENCE OF ANY OTHER REQUIREMENT NOT FOUND IN PSME CODE. THE 1200 NONE

24 25 POCKET LOCK HEMMED "S"SLIP G.I. SHEET

MATERIALS, CONSTRUCTION AND INSTALLATION OF DUCTWORKS SHALL COMPLY WITH 475 THRU 750 25x25x2 ANGLE CENTERED

THE REQUIREMENT OF SMACNA OR ASHRAE. DRIVE SLIP (VERTICAL ONLY) 2400

BETWEEN JOINTS

19. ALL DUCTWORKS SHALL CONFORM WITH THE PHILIIPPINE MECHANICAL CODE,

25 POCKET LOCK STANDING "S" SLIP 1200 NONE 40x25x2

AMERICAN STANDARDS FOR TESTING MATERIALS, AMERICAN SOCIETY OF HEATING,

775 THRU 1050 25x25x2 ANGLE CENTERED 10 U-CHANNEL 1800

REFRIGERATION AND AIR CONDITIONING ENGINEERS, AIR CONDITIONING AND 25 REINFORCED BAR SLIP FRESH AIR DUCT INTAKE

REFRIGERATION INSTITURE, NATIONAL FIRE PROTECTION ASSOCIATION, SHEET

2400 BETWEEN JOINTS G.I. SHEET STEEL SUPPORT

22 W/ INSECT SCREEN (TYP.)

METAL AND AIR CONDITIONING CONTRACTORS NATIONAL ASSOCIATION, BUILDING 1200 NONE OR CROSS BREAK 50x25x2

OFFICIALS AND CODE ADMINISTRATORS, INTERNATIONAL, MANUFACTURERS 40 POCKET LOCK STANDING "S" SLIP

1075 THRU 1350 40x40x2 ANGLE CENTERED 15 U-CHANNEL 1800

STANDARDIZATION SOCIETY OF THE VALVE AND FITTINGS INDUSTRY, INC., AND OTHER 40 REINFORCED BAR SLIP 2400

BETWEEN JOINTS G.I. SHEET

LOCAL AND INTERNATIONAL CODES PERTINENT TO THIS SECTION. VIBRATION ISOLATOR

20. ALL FRESH AIR AND EXHAUST VENTILATION DUCTS SHALL BE OF ASTM 653 HOT DIPPED, 1375 THRU 1500 1200 40x40x2 ANGLE CENTERED

40 REINFORCED BAR SLIP BETWEEN JOINTS 50x25x2 STRUCTURAL STEEL PLATFORM

BY MECH'L CONT'R

ZINC COATED STEEL SHEET CONFORMING TO SMACNA STANDARDS AND LOCK FORMED 20 15 U-CHANNEL 1200

AND SEALED WITH DUCT SEALANT CONFORMING TO ASTM E 84. 1525 THRU 2100 40 STANDING "S" SLIP 40x40x2 ANGLE ON 600 BY MECH'L CONT'R

2400 BETWEEN JOINTS G.I. SHEET

21. PROVIDE CONTINUOUS CORNER BENDS ON ALL DUCTS MADE OF 0.6mm ASTM 653 HOT

DIPPED, ZINC COATED STEEL SHEET, PROPERLY FASTENED WITH PLASTIC STRAPS 1200 40x40x5 ANGLE ON 600

EVERY 300mm. 2115 THRU 2400 CENTERED BETWEEN JOINTS

40x40x5 ANGLE FLANGES

22. ALL HVAC WORKS SHALL BE SUPERVISED BY A REGISTERED MECHANICAL ENGINEER 40x40x5 ANGLE ON 600

OF GOOD STANDING.

18

2400 CENTERED BETWEEN JOINTS

15

75x75x6

1200

D FRESH AIR BLOWER INSTALLATION DETAIL

1500 50x50x6 ANGLE CENTERED ANGLE BAR NTS

2415 THRU 3050 50x50x6 ANGLE FLANGES BETWEEN JOINTS M-01

50x50x6 ANGLE ON 600

2400

CENTERED BETWEEN JOINTS

LEGEND & SYMBOLS: EXHAUST CLEAN GAS

SYMBOL/

ABBREV. DESCRIPTION

CONCRETE SLAB

-

- EQUIPMENT TAG

FRESH AIR BLOWER EXPANSION HANGER ROD

FAB

BOLT

EAB EXHAUST AIR BLOWER 32 MM 12 MM DIA. MIN.

NON-ASBESTOS

EAG EXHAUST AIR GRILLE FABRIC W/ INSULATION SHEETMETAL SELF-

TAPPING SCREW

FAG FRESH AIR GRILLE U-STRAP (TYP.)

CHIMNEY

EAD EXHAUST AIR DUCT MACHINE BOLT AIR DUCT NUT

8.50

STEEL ANGLE

FAD

32 MM

32 MM

FRESH AIR DUCT STEEL ANGLE

COLLAR (TYP.) VARIES

SISW SINGLE INLET, SINGLE WIDTH

CONCRETE SLAB

6.05

HP HORSEPOWER STEEL

BEAM

EQUIPMENT WASHER

TYP TYPICAL

4.95

CASING OR BOTTOM CHORD

BEAM

DUCT LINER OR STEEL JOIST

TSP TOTAL STATIC PRESSURE MIXING BOX CLAMP FLAT

HANGER ROD

HANGER ROD BAR

Pa PASCAL

DUCT NOTE : INLET FROM DUCTING

VD VOLUME DAMPER

5" MIN.

1. FOR A/C & VENTILATION, MAX HANGER SPACING SHALL BE 1500 MM. PROVIDE INLET FROM DUCTING

A AMPERE 32X32X4MM STL ANGLE DUCT SUPPORT. FOR KITCHEN EXHAUST, MAX SPACING MOTOR

SHALL BE 1000 MM. PROVIDE 50X50X6 MM STL ANGLE DUCT SUPPORT.

KG KILOGRAM 2. ANGLE BAR SUPPORT SHALL CONFORM WITH SMACNA 5TH EDITION, TABLE 5-3.

3. HANGER ROD SHALL CONFORM WITH SMACNA 5TH EDITION, TABLE 5-1.

PH PHASE

HZ HERTZ

CFM CUBIC FEET PER MINUTE A FLEXIBLE DUCT CONNECTION B DUCT HANGER DETAIL C AMMONIA SCRUBBER DETAIL

NTS NTS

M-01 M-01 M-01

REPUBLIC ACT 9266 PROJECT TITLE: OWNER: SHEET CONTENT: SHEET NO.

Sec. 33. Ownership of Plans, Specifications, and

Other Contract Documents. -

GENERAL NOTES

ROMEO M. BATHAN LEGEND AND SYMBOLS

PROPOSED AMMONIA PRODUCTION PLANT MR. APOLLO PEREZ JR.

A R C H I T E C T - EQUIPMENT SCHEDULE

MISCELLANEOUS DETAIL M-01

Address: Area F, Block 41, Lot 1, Earth st., Brgy. A. Olaes, GMA Cavite REG.NO. - PTR: - Location: Brgy. Ambulong, Tanuan Batangas Address: DATE: NOVEMBER 30, 2022

Mobile no. : 09212903352 / 09158918961

DATE ISSUED: -

Email. : bathanromeo01@gmail.com TIN NO. - ISSUED AT: -

You might also like

- 5 Variable K-MapDocument15 pages5 Variable K-MapBen SewellNo ratings yet

- Mesa Sorsogon Mech'l Layout 08.03.22Document6 pagesMesa Sorsogon Mech'l Layout 08.03.22Mark Anthony ValbuenaNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- Da 950065 001Document1 pageDa 950065 001BIPIN BALANNo ratings yet

- MECHANICAL PLAN RAWIS 2 STOREY Model2Document1 pageMECHANICAL PLAN RAWIS 2 STOREY Model2Catherine ZamudioNo ratings yet

- 100095.12kV Electrical Drawings - Bid SetDocument1 page100095.12kV Electrical Drawings - Bid SetAwlia Khan KakarNo ratings yet

- HVAC Abbreviations and Legend GuideDocument1 pageHVAC Abbreviations and Legend GuideShrikant SomvanshiNo ratings yet

- FF To Roof: Storey MarkingDocument1 pageFF To Roof: Storey MarkingHong Jin YaoNo ratings yet

- CK Lucena - CD Drawing Me 01 PDFDocument1 pageCK Lucena - CD Drawing Me 01 PDFVen Mar SalinasNo ratings yet

- Schedule of Loads: To Service Entrance 2WIRE, 1 PHASE, 230V, 60 HZ FrequencyDocument1 pageSchedule of Loads: To Service Entrance 2WIRE, 1 PHASE, 230V, 60 HZ FrequencyVincent FilomenaNo ratings yet

- DVD-VCR: Service ManualDocument135 pagesDVD-VCR: Service ManualJordi Mes Electro ElectriNo ratings yet

- PLUMBINGDocument5 pagesPLUMBINGKhalil AlluhaybiNo ratings yet

- Bhsarp 21 MTB ZZ Me DWG 320701 - D02Document1 pageBhsarp 21 MTB ZZ Me DWG 320701 - D02Jss Aircond & ElectricalNo ratings yet

- SD10102-002 - Pile Cap Bar Bending Schedule and Details PDFDocument1 pageSD10102-002 - Pile Cap Bar Bending Schedule and Details PDFMohammed AdilNo ratings yet

- CN-230F (1) Dtq-21u4ss PDFDocument64 pagesCN-230F (1) Dtq-21u4ss PDFPedroNo ratings yet

- Description REV Date Construction Drawing 0 JUNE'22Document1 pageDescription REV Date Construction Drawing 0 JUNE'22rajavelNo ratings yet

- General Notes: Contract Drawing Notes:: Commonwealth of PennsylvaniaDocument8 pagesGeneral Notes: Contract Drawing Notes:: Commonwealth of PennsylvaniawalidNo ratings yet

- LG DVD DS9313CPM (3829RHP038B)Document48 pagesLG DVD DS9313CPM (3829RHP038B)videosonNo ratings yet

- J1273-S001-General NotesDocument1 pageJ1273-S001-General Notesroy jackNo ratings yet

- 7 Septic VaultDocument1 page7 Septic VaultB R PAUL FORTINNo ratings yet

- Install Cruise Control On Toyota Corolla AltisDocument7 pagesInstall Cruise Control On Toyota Corolla AltisFrank JosephNo ratings yet

- Service Manual: Color TelevisionDocument42 pagesService Manual: Color TelevisionGerardo Aguirre MNo ratings yet

- J0673-S001 - General NotesDocument1 pageJ0673-S001 - General NotesEmon RayNo ratings yet

- Saudi Arabian Oil Company: DA-727899 005 P 0A3 K07 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-727899 005 P 0A3 K07 RestrictedWaqarNo ratings yet

- Daewoo DTQ 29u1scDocument65 pagesDaewoo DTQ 29u1scIrving CarvajalNo ratings yet

- VRV 4A AC INSTALLATION NOTESDocument7 pagesVRV 4A AC INSTALLATION NOTESJerry MaratasNo ratings yet

- Jn1252-S001-General NotesDocument1 pageJn1252-S001-General Notesroy jackNo ratings yet

- Key Plan Reinforcement Details for Unit Substation FoundationDocument1 pageKey Plan Reinforcement Details for Unit Substation FoundationAyman SaberNo ratings yet

- Quiruben M. Mera Engr. Landrito R. Pilao: S-1 Highline Builders CompanyDocument1 pageQuiruben M. Mera Engr. Landrito R. Pilao: S-1 Highline Builders CompanyHighline BuildersNo ratings yet

- D Eugp1 TPT G 000 Gen FWG 001 R01Document1 pageD Eugp1 TPT G 000 Gen FWG 001 R01debapriyoNo ratings yet

- Foundation reinforcement detailsDocument12 pagesFoundation reinforcement detailsIsrael AdegboyegaNo ratings yet

- 2 Structural DrawingsDocument7 pages2 Structural DrawingsRA LapitanNo ratings yet

- De02 Struc 2024-03-13 - Wip 1Document59 pagesDe02 Struc 2024-03-13 - Wip 1AnandPrabuNo ratings yet

- General Notes, Legends and Vicinity MapDocument1 pageGeneral Notes, Legends and Vicinity MapDenisse Dean OcampoNo ratings yet

- J0647-S001 - General NotesDocument1 pageJ0647-S001 - General NotesEmon Ray100% (1)

- E6 Electrical SamplesDocument1 pageE6 Electrical Samplesgeneveve colasitoNo ratings yet

- Service ManualDocument130 pagesService ManualOliver GaisburgerNo ratings yet

- WH10-FSYS-GN-XX0001-002002 REV-00-layoutDocument1 pageWH10-FSYS-GN-XX0001-002002 REV-00-layoutengrabbas75No ratings yet

- Cyclonic FurnaceDocument2 pagesCyclonic FurnaceOff Roedz Jeenchuriky'zNo ratings yet

- Boundary Wall: Ground Floor PlanDocument1 pageBoundary Wall: Ground Floor PlanSundar RadnusNo ratings yet

- M-0.1 - Mechanical SpecificationsDocument1 pageM-0.1 - Mechanical SpecificationsAbdellatif AlhNo ratings yet

- Khajuripada Phulbani: Longitudinal Section at A-ADocument1 pageKhajuripada Phulbani: Longitudinal Section at A-ACRAPTS BhubanesawarNo ratings yet

- J1078-S001-General NotesDocument1 pageJ1078-S001-General Notesroy jackNo ratings yet

- I R75 WPCDocument128 pagesI R75 WPCAmer RafiqueNo ratings yet

- 1967-68 Mustang Without Factory AirDocument23 pages1967-68 Mustang Without Factory AirnilusomegaNo ratings yet

- Cn001a Dtq20q1fs TV DaewooDocument42 pagesCn001a Dtq20q1fs TV DaewooNicolasBastidasNo ratings yet

- Compressor ManualDocument28 pagesCompressor ManualbrianellsinNo ratings yet

- STR 05Document1 pageSTR 05Karrena ArabiaNo ratings yet

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliNo ratings yet

- Nad M 55 Service Manual PDFDocument74 pagesNad M 55 Service Manual PDFSergey VissarionovNo ratings yet

- Manual Service MT1389seDocument28 pagesManual Service MT1389seR OneNo ratings yet

- Section 1: Product Safety Servicing Guidelines For Video Products Servicing PrecautionsDocument47 pagesSection 1: Product Safety Servicing Guidelines For Video Products Servicing PrecautionswittmaewNo ratings yet

- Saudi Arabian Oil Company: DA-728550 005 P 0A3 K11 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-728550 005 P 0A3 K11 RestrictedWaqarNo ratings yet

- SPA CombinedDocument24 pagesSPA CombinedMarielle Anne SantiagoNo ratings yet

- Notes:: Plan End ViewDocument1 pageNotes:: Plan End Viewsowman tungNo ratings yet

- 383-2016 Drawing E1.1-R0 PDFDocument1 page383-2016 Drawing E1.1-R0 PDFKothapeta Shekhar100% (1)

- Electrical Sheets ColusaCoAdminOff - Elec - BidAdd3Document4 pagesElectrical Sheets ColusaCoAdminOff - Elec - BidAdd3Pinky CutNo ratings yet

- Turbo Submittal At200-0.8s g5p Cargill (1) (2) - 1Document2 pagesTurbo Submittal At200-0.8s g5p Cargill (1) (2) - 1ivantellez-famNo ratings yet

- Dry clean air compressor installation notesDocument4 pagesDry clean air compressor installation notesRio WijayantoNo ratings yet

- TV Daewoo Chasis Cn-115i Modelo Dtq-14n2fc - dtq20j2fsDocument43 pagesTV Daewoo Chasis Cn-115i Modelo Dtq-14n2fc - dtq20j2fsJorge UrbaezNo ratings yet

- 7 Langka Jsinegwelas JlansonesDocument3 pages7 Langka Jsinegwelas JlansonesMark Anthony ValbuenaNo ratings yet

- A Equipment & Tank: Others Pls SpecifyDocument2 pagesA Equipment & Tank: Others Pls SpecifyMark Anthony ValbuenaNo ratings yet

- 4 - Hot Water Recir PumpDocument1 page4 - Hot Water Recir PumpMark Anthony ValbuenaNo ratings yet

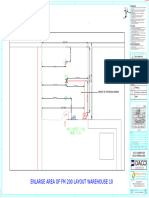

- Romeo M. Bathan: Proposed Ventilation Layout ADocument1 pageRomeo M. Bathan: Proposed Ventilation Layout AMark Anthony ValbuenaNo ratings yet

- Series 4030: SubmittalDocument2 pagesSeries 4030: SubmittalDaniel RiveraNo ratings yet

- Affidavit Change PIC ElectricalDocument1 pageAffidavit Change PIC ElectricalMark Anthony ValbuenaNo ratings yet

- Rajagiri Public School Unit Test PhysicsDocument3 pagesRajagiri Public School Unit Test PhysicsNITHINKJOSEPHNo ratings yet

- Encapsulation and Inheritance in Object-Orlented Programming LanguagesDocument8 pagesEncapsulation and Inheritance in Object-Orlented Programming Languageszsolt kormanyNo ratings yet

- Bread and Pastry Production NCII June 10, 2019 - July 03, 2019 ReviewerDocument14 pagesBread and Pastry Production NCII June 10, 2019 - July 03, 2019 ReviewerJames BaculaNo ratings yet

- Parapsychology QP - WikiDocument371 pagesParapsychology QP - WikiAdamNo ratings yet

- Validation of Correlations Between A NSPT PDFDocument12 pagesValidation of Correlations Between A NSPT PDFAgus WahyudiNo ratings yet

- State of The Art in Roller Compacted Concrete (RCC) PDFDocument226 pagesState of The Art in Roller Compacted Concrete (RCC) PDFEduardoDavilaOrtegaNo ratings yet

- Fault Codes: STO U AndriivDocument3 pagesFault Codes: STO U AndriivAtochkavNo ratings yet

- vCloudPoint Sharing Computing Solution Data Sheet PDFDocument8 pagesvCloudPoint Sharing Computing Solution Data Sheet PDFkus satria dNo ratings yet

- Kapla ResumeDocument35 pagesKapla ResumeAbinashNo ratings yet

- A Grammar of Anong Language Death Under Intense ContactDocument409 pagesA Grammar of Anong Language Death Under Intense ContacthaoyichuanNo ratings yet

- Gem EscortingDocument7 pagesGem Escortingsuman sutharNo ratings yet

- IGCSE Biology 4325 2H Mark SchemeDocument14 pagesIGCSE Biology 4325 2H Mark SchememuhajireenNo ratings yet

- Mohair FiberDocument33 pagesMohair FiberMuhammad Ahsan AftabNo ratings yet

- Owner S Manual Subaru LegacyDocument20 pagesOwner S Manual Subaru LegacyLexBgNo ratings yet

- 6 Health Benefits of Bitter MelonDocument7 pages6 Health Benefits of Bitter Melonlove sardualNo ratings yet

- Fire and Blast in The Future OffshoreDocument45 pagesFire and Blast in The Future OffshoredrgNo ratings yet

- SR. NO. Capacity/Descirption of Machine Client: A.C. Generator StatorsDocument5 pagesSR. NO. Capacity/Descirption of Machine Client: A.C. Generator Statorsmtj4uNo ratings yet

- Design & Operation of Clean Room-1Document39 pagesDesign & Operation of Clean Room-1Hafizur Rahman0% (1)

- Life Time Prediction of GRP Piping SystemsDocument15 pagesLife Time Prediction of GRP Piping SystemsRamon FrenchNo ratings yet

- Understanding The Nature of ReligionDocument41 pagesUnderstanding The Nature of Religioneden l. abadNo ratings yet

- 09 Exp 11 Buffer SolutionsDocument8 pages09 Exp 11 Buffer SolutionsShainmaugne AdvientoNo ratings yet

- S2 Papers FinalizedDocument149 pagesS2 Papers FinalizedRaffles HolmesNo ratings yet

- Amco Veba Marine - Brochure - LRDocument24 pagesAmco Veba Marine - Brochure - LRHươngTpuNo ratings yet

- API 510 BasicsDocument40 pagesAPI 510 BasicsBalakumarNo ratings yet

- Wda 201Document72 pagesWda 201MoussaNo ratings yet

- OrlDocument186 pagesOrlMuli MaroshiNo ratings yet

- Preferred Drug ListDocument2 pagesPreferred Drug ListRamNo ratings yet

- SteelsDocument72 pagesSteelsLLNo ratings yet

- Violet Flame Clearing of The Heart ServiceDocument16 pagesViolet Flame Clearing of The Heart ServiceMySecret Gardenmdp82% (11)