Professional Documents

Culture Documents

Ku-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 Capacity

Ku-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 Capacity

Uploaded by

Abdur RehmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ku-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 Capacity

Ku-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 Capacity

Uploaded by

Abdur RehmanCopyright:

Available Formats

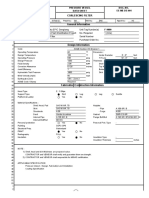

DATA SHEET FOR DIESEL TANK (5 m3 CAPACITY)

KU-TWK-20-ME-DTS-0006

License TWK

DATA SHEET FOR DIESEL DAY TANK (5 m3 CAPACITY)

Project Title Refinery Heater Replacement

Contractor Project No. - Contractor Doc. No. -

COMPANY Project No. KU-TWK-095 COMPANY Doc. No. KU-TWK-20-ME-DTS-0006

CONTRACT NO - DNO Rev. 0 Page 1 of 5

Refinery Heater Replacement

DATA SHEET FOR DIESEL DAY TANK (5 m3 CAPACITY)

REVISION RECORD

DNO Rev. Originated Approved

Date Description Checked by

No. by by

0 13-12-2023 Issued for Tender KR RK MP

Proprietary Information

This document is the property of DNO. It must NOT be reproduced or transmitted to others without authorization

from the COMPANY.

KU-TWK-20-ME-DTS-0006 Rev. 0 Page 2 of 5

DATA SHEET FOR DIESEL DAY TANK (5 m3 CAPACITY) Rev.0

1 Owner/Operator DNO Iraq Service Diesel

2 For TWK P&ID No: KU-TWK-20-PR-PID-0202-46

3 Site Topping Plant Location Outdoor

4 No. Reqd. 01 Model N/A Tag No. 47-TK-03

5 Manufacturer VTA Orientation Horizontal

6 Measurement of Units SI

7 DESIGN DATA

8 Design Code UL-142 Latest Edition

3

9 Capacity m # 5 m^3 #10 m^3 #20 m^3

10 Dimensions (ID x L) mm ID 1500 x 3062 L

11 Fluid Diesel

3

12 Density kg/m 850-880

13 Operating Pressure (Internal / External) - ATM

14 Design Pressure (Internal / External) barg Full of Water + 5 mbarg / -2.5 mbarg

15 Test Pressure barg As per UL-142

16 Operating Temperature (Internal / External) °C -10 / 55

17 Design Temperature (Internal / External) °C 85

18 Minimum Design Metal Temperature °C -10

19 Joint Efficiency Shell / Heads 0.7

20 Insulation N/A

21 Fire Proofing N/A

22 Tank Bundwall Capacity 110% of Tank Capacity

23 MATERIALS & THICKNESS

SA-36 / SA-285 8 / 8(Min) mm SA-193 Gr. B7 /

24 Shell / Heads / Bund Wall Bots/Nuts

Gr.C Thk SA-194 Gr. 2H

SA-106 Gr.B / SS316 Spiral Wound with Graphite Filler, SS

25 Nozzle Neck (Pipe / Plate) Gaskets

CS Inner Ring and CS Outer Ring

26 Nozzle Falnge / Blind Flange SA-105 / CS Lifting Lugs / Earthing Lugs Carbon Steel

27 Name Plate SS 316 Platform / Ladder Carbon Steel

28 INSPECTION AND TESTING SURFACE PREPARATION AND PAINTING

29 Radiographic/Ultrasonic As per UL 142

Surface Preparation : Sa 2 1/2

30 Dye Penetrant / Magnetic Particle As per UL 142 External Painting: System P-01 in accordance with KURD-PRO-INSP-014

Internal Coating: System P-103 in accordance with KURD-PRO-INSP-014

31 Hydrostatic Test As per UL 142

32 WEIGHT ACCESSORIES

33 Empty Weight kg 3773.187 Flame Arrestor Required

34 Operating Weight kg 9457 Level Gauge Required

35 Hydrostatic Test Weight kg 9457 Level Transmitter By Others

36 DOCUMENTATION Name Plate Required

37 GA Drawing Required Earthing Lugs, Lifting Lugs Required

38 Manufacturer Data Book Required Platform / Ladder Required

39 Inspection and Test Plan Required Bundwall Required

40 Others As per Manufacturer Std. Others As per Manufacturer Std.

KU-TWK-20-ME-DTS-0006 Rev. 0 Page 3 of 5

DATA SHEET FOR DIESEL TANK (5 m3 CAPACITY) Rev.0

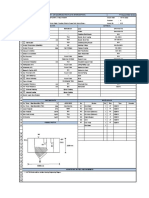

1 NOZZLE SCHEDULE

Nozzle Location (mm for length)-

2 RF Pad (mm)

Size Fl.Class/Ra Nozzle (*)

Mark Qty. Service Remarks

NPS ting/Face Sch. Stand From Orient Pad Pad

2

Out Ref. TL (A) OD Thk

Diesel Truck Filling

3 N1 2 1 150# WNRF 80 150 400 0 - - Note 1

Connection

3 N2 2 1 Diesel Outlet 150# WNRF 80 200 See Sketch 180 - - Note 2

4 N3 2 1 Drain 150# WNRF 80 150 150 180 - - Note 3

4 N4 2 1 Vent 150# WNRF 80 150 1300 0 - - Note 4

5 N5A 2 1 LG 150# WNRF 80 200 See Sketch 0 - - Notes 5, 9

5 N5B 2 1 LG 150# WNRF 80 200 See Sketch 180 - - Notes 5, 9

6 N6 2 1 Spare 150# WNRF 80 200 See Sketch - - - Note 6

6 N7 4 1 Level Transmitter Connection 150# WNRF 80 150 1700 0 - -

7 N8 2 1 Diesel Return Filling Point 150# WNRF 80 150 800 0 - - with Dip Pipe, Note 6

7 N9 A/B 2 2 Containment Drain 150# WNRF 80 150 VTA VTA - - Note 8

8 N10 2 1 Diesel Inlet Filling Connection 150# WNRF 80 150 2910 0 - - With Dip Pipe & Float Valve

8 N11 2 1 N2 Purge Connection 150# WNRF 80 200 See Sketch - - - Note 7

9 M1 24 1 Manway 150# WNRF 8 Thk 150 2310 VTA - - Note 10

9 NOTES:

10 1. Complete with Dip Pipe, Ball Valve, Check Valve and and Quick coupling routed to skid edge (See typical Model below)

10 2. Complete with vortex breaker, flange, ball valve and pipe spool connected to bund wall.

11 3. Complete with valve, gasket & bolts/nuts

11 4. Complete with Falme Arresotr and Bird Screen

12 5. Complete with Valve, Level Gauge, Gaskets and Bolt/Nuts

12 6.Complete with Blind Flange, Bolt/Nuts and Gaskets

13 7. Complete with ball valve, check valve and quick coupling

13 8. Complete with Flange, Valve, Blind Flange, Bolts/Nuts and Gaskets

14 9. Magentic type level gauge to be provided.

14 10. Complete with cover, gasket, Bolts / Nuts, Davit etc.

15 11. Standout is from Shell OD / Flat Cover outside to Nozzle Flange Face.

15 12. Pipework materials shall be in accordance with Company General Spec KU-TWK-00-PI-SPC-0004 for line class 01C03N

16 13. Earthing bosses to be provided on opposite corners (2no.)

16 14. Brackets and mounting provisions for installation of Lightning Protection air terminals and down conductors (if required).

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24 Typical Diesel Tank Model (For Reference Only)

NOTES:

VTA*= Vendor to Advice

KU-TWK-20-ME-DTS-0006 Rev. 0 Page 4 of 5

DATA SHEET FOR DIESEL DAY TANK (5 m3 CAPACITY) Rev.0

SKETCH OF DIESEL TANK

1

2 3062 L

3 N1 N4 N7 N8 M1

4 400 400 500 400 750

5 N10

N5A

6

ID 1500 mm

N6

600

7

8

N2 N5B

600

9 150

10

11

N3

N9B

12 N9A

13 531 2000

14

15

N8

N11 N7 N10

16 N1 M1 N4

17

18

19

20

21 N5A N6

910

22

606

23

24

25 N1

518

26

27

1155

N11

28 N2

N5B

29

30 N3

31

32

33

34

35

36

37

NOTES:

VTA*= Vendor to Advice

KU-TWK-20-ME-DTS-0006 Rev. 0 Page 5 of 5

You might also like

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- ManualDocument27 pagesManualAbdur Rehman0% (1)

- Parts Catalogue: Bsvi DATE: 02 10 20Document59 pagesParts Catalogue: Bsvi DATE: 02 10 20sudhir67% (3)

- KU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFDocument7 pagesKU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFRexx Mexx100% (1)

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Data Sheet Basket Filter-ATF R2Document4 pagesData Sheet Basket Filter-ATF R2Suaib VCSNo ratings yet

- Data Sheet: Cpi (Corrugated Plate Interceptor)Document1 pageData Sheet: Cpi (Corrugated Plate Interceptor)wahyu hidayatNo ratings yet

- Hav HKN 219001 Gas Me DS 0017Document5 pagesHav HKN 219001 Gas Me DS 0017bkm dizaynNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- 0A Didin M Gadhafi / Khairul Bahri Aswin Widjaja Issued For CommentsDocument5 pages0A Didin M Gadhafi / Khairul Bahri Aswin Widjaja Issued For CommentsYusri Fakhrizal100% (1)

- Data Sheet For Temperature Gauges and ThermowellsDocument29 pagesData Sheet For Temperature Gauges and ThermowellsSardar PerdawoodNo ratings yet

- Data Sheet Basket Filter-ATF R1Document3 pagesData Sheet Basket Filter-ATF R1Suaib VCSNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-DIT - 288Document2 pagesQ1Co 3000 Q1Co 3620 3620-DIT - 288JHONATAN RODRIGUEZ VENTONo ratings yet

- DS Cartride F DWA R1Document1 pageDS Cartride F DWA R1wahyu hidayatNo ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- Contractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)Document4 pagesContractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)BABILIN VNo ratings yet

- 1280a4-8430-Ds-0001 Rev F1Document6 pages1280a4-8430-Ds-0001 Rev F1Stephen LowNo ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument2 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- YS2-03-C10017-TL-DTS-M-003 Rev 0 (6 Inch Mobile Pig Launcher)Document4 pagesYS2-03-C10017-TL-DTS-M-003 Rev 0 (6 Inch Mobile Pig Launcher)Gajendra PatilNo ratings yet

- SAP FILTER-May-2020-1200Dia-Rev - PDocument4 pagesSAP FILTER-May-2020-1200Dia-Rev - PHasmukh DaveNo ratings yet

- YS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Document4 pagesYS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Gajendra PatilNo ratings yet

- PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaDocument13 pagesPT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaJan Richardo GultomNo ratings yet

- XXXX-DS-PI-001-Rev.00-GATE VALVE DATASHEETDocument8 pagesXXXX-DS-PI-001-Rev.00-GATE VALVE DATASHEETDương HoàngNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Data Sheet For Absorber Reflux Drum (GTPT-V-250-003)Document4 pagesData Sheet For Absorber Reflux Drum (GTPT-V-250-003)Mohamed hamza souissiNo ratings yet

- Manual Calc. Welded Storage Tank API-650Document1 pageManual Calc. Welded Storage Tank API-650safar bahariNo ratings yet

- U2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1ADocument14 pagesU2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1ATommy ArjanggiNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-DIT - 188Document2 pagesQ1Co 3000 Q1Co 3620 3620-DIT - 188JHONATAN RODRIGUEZ VENTONo ratings yet

- Folhas de Dados - CondensadorDocument6 pagesFolhas de Dados - Condensadorvazzoleralex6884No ratings yet

- 305026-PVE-DD-ME-DAS-006 Internal Floating Roof Rev0Document3 pages305026-PVE-DD-ME-DAS-006 Internal Floating Roof Rev0Vo trung quanNo ratings yet

- Precision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetDocument1 pagePrecision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetAnonymous AyDvqgNo ratings yet

- MDS Diesel TankDocument2 pagesMDS Diesel TankrifkynetNo ratings yet

- BCI11N03-070!04!0004-DS - Datasheet Compressed Air Line Accessories - 0Document7 pagesBCI11N03-070!04!0004-DS - Datasheet Compressed Air Line Accessories - 0Arifian NugrohoNo ratings yet

- R1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1Document15 pagesR1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1ajwalNo ratings yet

- 10J01762 Ict DS 000 012 D0Document14 pages10J01762 Ict DS 000 012 D0Sardar PerdawoodNo ratings yet

- Precision Equipments (Chennai) Pvt. LTD.: Design Data Tema TypeDocument2 pagesPrecision Equipments (Chennai) Pvt. LTD.: Design Data Tema TypeAnonymous AyDvqgNo ratings yet

- Treated Water PumpDocument8 pagesTreated Water PumpKELVIN TECHNOLOGIESNo ratings yet

- Job No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedDocument3 pagesJob No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedgauravNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- KTA - TB-PAC03-M07-005.Rev0 - GLYCOL REBOILER & STILL COLUMN PIDDocument2 pagesKTA - TB-PAC03-M07-005.Rev0 - GLYCOL REBOILER & STILL COLUMN PIDlamNo ratings yet

- Pressure VesselDocument6 pagesPressure VesselKiranNo ratings yet

- Surge DiverterDocument2 pagesSurge DiverterKa TranNo ratings yet

- 0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2Document6 pages0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2fathan fathullahNo ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- T4638 DatasheetDocument12 pagesT4638 DatasheetMUHAMMAD ABHAR AMZAR BIN ZAMZURINo ratings yet

- s5113 Mm41 Plate CoolerDocument79 pagess5113 Mm41 Plate CoolerJorge AguilarNo ratings yet

- Strainer PDFDocument7 pagesStrainer PDFvinoj chandranNo ratings yet

- Metscco Heavy Steel Industries Co. LTD.: Internal TransmittalDocument3 pagesMetscco Heavy Steel Industries Co. LTD.: Internal TransmittalErin JohnsonNo ratings yet

- 72400726-DS-002 Rev 0Document8 pages72400726-DS-002 Rev 0prabakaran365No ratings yet

- EPN-KSO-LBJ-TBBM-In-DTS-005 Data Sheet For Temperature Relief Valve (TRV) R2 Re-AFC Rev 1 ApprovedDocument15 pagesEPN-KSO-LBJ-TBBM-In-DTS-005 Data Sheet For Temperature Relief Valve (TRV) R2 Re-AFC Rev 1 Approvedboy telerNo ratings yet

- Data Sheet For Special Piping Parts: (Strainer)Document2 pagesData Sheet For Special Piping Parts: (Strainer)dimas prasetyoNo ratings yet

- Piping Class Specification - CNE-001-2006-E-08-M-L-10126Document20 pagesPiping Class Specification - CNE-001-2006-E-08-M-L-10126Mubashir fareedNo ratings yet

- 19FW-M28-10-M21-0008 R1 Data Sheet of Expansion JointDocument2 pages19FW-M28-10-M21-0008 R1 Data Sheet of Expansion JointCaspian DattaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- KU-TWK-00-PI-SPC-0004 - 0 - General Specification - Piping Line Classes and ValvesDocument75 pagesKU-TWK-00-PI-SPC-0004 - 0 - General Specification - Piping Line Classes and ValvesAbdur RehmanNo ratings yet

- Technical QuestionnaireDocument1 pageTechnical QuestionnaireAbdur RehmanNo ratings yet

- Tank Heat Losses Cal. For Insulated TankDocument24 pagesTank Heat Losses Cal. For Insulated TankAbdur RehmanNo ratings yet

- Client: Contract: Job / Project TitleDocument5 pagesClient: Contract: Job / Project TitleAbdur RehmanNo ratings yet

- REV Description Date Originated BY Checked BY Approved BY: 01B IFR - Issued For ReviewDocument10 pagesREV Description Date Originated BY Checked BY Approved BY: 01B IFR - Issued For ReviewAbdur RehmanNo ratings yet

- Client: Contract: Job / Project TitleDocument4 pagesClient: Contract: Job / Project TitleAbdur RehmanNo ratings yet

- DN Dat001 001Document4 pagesDN Dat001 001Abdur RehmanNo ratings yet

- MD 502 3DMB Eg PR RPT 0001 - C01Document195 pagesMD 502 3DMB Eg PR RPT 0001 - C01Abdur RehmanNo ratings yet

- PhysicsDocument2 pagesPhysicsAbdur RehmanNo ratings yet

- Client: Contract: Job / Project TitleDocument10 pagesClient: Contract: Job / Project TitleAbdur RehmanNo ratings yet

- Engr. Etizaz Ahsan Noor: Qualification Bsc. Chemical Engineering (Uet Lahore) Subject Specialist: (Matric, FSC Chemistry)Document1 pageEngr. Etizaz Ahsan Noor: Qualification Bsc. Chemical Engineering (Uet Lahore) Subject Specialist: (Matric, FSC Chemistry)Abdur RehmanNo ratings yet

- Measurement and Instrumentation Lab: Experiment # 1Document4 pagesMeasurement and Instrumentation Lab: Experiment # 1Abdur RehmanNo ratings yet

- Amir Ali Shah: Contact InformationDocument3 pagesAmir Ali Shah: Contact InformationAbdur RehmanNo ratings yet

- Stability of A Floating BodyDocument11 pagesStability of A Floating BodyAbdur RehmanNo ratings yet

- Heat Exchanger Lab Report Shell and TubeDocument26 pagesHeat Exchanger Lab Report Shell and TubeAbdur Rehman67% (3)

- Lap Joint Stub End PDFDocument2 pagesLap Joint Stub End PDFBowo Edhi WibowoNo ratings yet

- Visual Vessel DesignDocument22 pagesVisual Vessel DesignRebecca CameronNo ratings yet

- Utility Write UpDocument15 pagesUtility Write UpmishtinilNo ratings yet

- API 610 PumpsDocument2 pagesAPI 610 Pumpsanon_684099349No ratings yet

- Catalogue 2018 PDFDocument84 pagesCatalogue 2018 PDFmartinNo ratings yet

- Material Take-Off List: Wbs-4 Expense (Demolition/Sec)Document135 pagesMaterial Take-Off List: Wbs-4 Expense (Demolition/Sec)Jonald DagsaNo ratings yet

- Standardy Techniczne Biura Techniki - Urządzenia Ciśnieniowe ENG - Rev5Document58 pagesStandardy Techniczne Biura Techniki - Urządzenia Ciśnieniowe ENG - Rev5arek74krakowNo ratings yet

- Component Definitions: N2 - CL150 RFFE, CS, Trim 8Document27 pagesComponent Definitions: N2 - CL150 RFFE, CS, Trim 8Chirag ShahNo ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

- 40C1 (1H40C450E1) AL115C Mio SportyDocument56 pages40C1 (1H40C450E1) AL115C Mio SportyRen0% (2)

- CCV Product OverviewDocument7 pagesCCV Product OverviewRizal NasutionNo ratings yet

- Manifolds Overview BrochureDocument2 pagesManifolds Overview Brochurecorsini999No ratings yet

- Frames and Bed PlateDocument12 pagesFrames and Bed PlateVyasaraj Kumar0% (1)

- Tentec Tensioning ToolsDocument5 pagesTentec Tensioning ToolspankilNo ratings yet

- Style Alpha FC: Installation InstructionsDocument2 pagesStyle Alpha FC: Installation InstructionsAjiCiangsanaNo ratings yet

- JIS Flange STDDocument10 pagesJIS Flange STD何宗仁No ratings yet

- AVK Hydrants BrochureDocument11 pagesAVK Hydrants Brochuremubarak aliNo ratings yet

- Estimasi SI Boiler Central Final Fix AllDocument94 pagesEstimasi SI Boiler Central Final Fix AllTri LionNo ratings yet

- HPTDocument48 pagesHPTyg89No ratings yet

- Red Ex: Expansion Joints & Rubber Fabricated ProdDocument24 pagesRed Ex: Expansion Joints & Rubber Fabricated ProdPiero Graffigna PruzzoNo ratings yet

- SVH NMB DatasheetDocument2 pagesSVH NMB DatasheetBanupriya BalasubramanianNo ratings yet

- Passion Pro 100 TR 2014Document94 pagesPassion Pro 100 TR 2014Faker FockerNo ratings yet

- Plug Valve Spec VP-011 ReportDocument91 pagesPlug Valve Spec VP-011 ReportjechurchNo ratings yet

- Manual 1008-1010Document12 pagesManual 1008-1010Edgar Eduardo Tellez RuizNo ratings yet

- Butterffly Valves, BFV TypeDocument16 pagesButterffly Valves, BFV TypeJader Alonso Acosta GuarinNo ratings yet

- 04 Samss 041Document6 pages04 Samss 041Moustafa BayoumiNo ratings yet

- GSW-NG01017640-GEN-LA7303-00002 - Material Requisition For Pig Launcher and Receiver - D01Document22 pagesGSW-NG01017640-GEN-LA7303-00002 - Material Requisition For Pig Launcher and Receiver - D01Nnamdi Umezuruike100% (1)

- Design Calculation: Donaldson Equipmentt ModelDocument49 pagesDesign Calculation: Donaldson Equipmentt ModelmuratcanNo ratings yet

- Pressure-Reducing Valves For Steam ServiceDocument8 pagesPressure-Reducing Valves For Steam ServiceDarwin DarmawanNo ratings yet