0 ratings0% found this document useful (0 votes) 1K views20 pagesWire Drawing

Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content,

claim it here.

Available Formats

Download as PDF or read online on Scribd

- General: Discusses the basic process and principles of wire drawing including the forces involved.

- Drawing Ratio (DR): Explains the significance of drawing ratio in wire drawing operations and its calculations.

- Steps Involved In Wire Drawing: Describes the sequential steps in the wire drawing process.

- Work Done in Homogeneous Deformation: Covers the calculation of work done during deformation affecting wire dimensions.

- Work Formula for Wire Drawing: Provides formulas used to determine work in wire drawing processes.

- Maximum Possible Reduction of Area: Discusses the maximum reduction achievable in a single pass of drawing.

- Expression for True Strain and Fraction Reduction: Details the mathematical expressions for strain and area reduction in wire drawing.

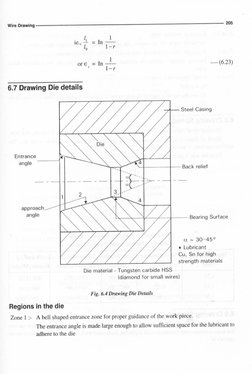

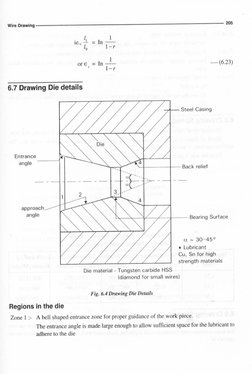

- Drawing Die Details: Illustrates the design and components of a wire drawing die.

- Drawing Stress: Calculates the stress encountered during wire drawing based on material and process parameters.

- Drawing Speed: Explains the effect of speed on wire drawing including temperature impacts.

- Expression for Drawing Force in Wire Drawing: Mathematically derives the force required during wire drawing processes.

- Frictionless Drawing of Cylindrical Rod: Considers drawing processes without friction and their effects on material processing.

- Tube Drawing Processes: Explores various methods for tube drawing including fixed plug, floating plug, and mandrel drawing.

- Worked Problems: Presents solved problems about wire drawing to illustrate practical applications.

- Questions: Lists review questions to test understanding of wire drawing concepts covered in the chapter.

WIRE DRAWING

Contents

————

6.0 General ; 6.1 Drawing Ratio ; 6.2 Steps in Wire drawing ; 6.3 Work done in

Homogeneous deformation ; 6.4 Work formula for wire drawing ; 6.5 Maximum

possible reduction of area in drawing ; 6.6 Expression for true strain and fraction

reduction ; 6.7 Drawing die details ; 6.8 Drawing speed ; 6.9 Drawing stress ;

6.10 Expression for Drawing force in wire drawing ; 6.11 Frictionless drawing of

cylindrical rod ; 6.12 Tube drawing process ; Worked Problems ; Questions�Wire Drawing 199

6.0 General

Wire drawing is an operation wherein the workpiece in the form of a rod/thick wire is pulled

through a die opening to get a reduced diameter. It is carried out in cold state The mechanical

work required is greater than in rolling operation. Compressive forces acting at the contact surface

causes plastic flow of metal.

‘The central portion of the work does not undergo any deformation, Only the outer forces are

severely deformed, This is due to frictional forces acting at the contact surface. Fig, 6.1 shows the

process.

work Die

— J—» pulling

Ve force

yf /

MY)

Fig. 6.1 wire drawing process

Difference between wire and rod is somewhat arbitrary. In general wire refers to small diameter

products under 5 mm.

es

6.1 Drawing Ratio (DR)

‘The ratio of final diameter to the initial diameter in drawing operation is referred to as limiting

ratio or drawing ratio

d

Drawing Ratio (DR) = 7 (6.1)

i

final dia of wire

where d,

d, = initial dia of work

DR = 0.95 for steel

= 0.925 for copper

0.9 for Iron

¢ To draw arod into a wire of given diameter, the rod must be passed through a series of dies of

gradually decreasing diameter.

+ when repeated drawing is done, the tensile strength is greatly increased and ductility is

reduced in the same ratio.

¢ Hence, after each drawing operation, the wire is annealed to restore ductility before

commencing the next drawing operation.

Annealing is normally carried out in a closed atmosphere.

# Scale formed on the surface is removed by pickling using very dilute 1,50,�200. Manufacturing Process - I

6.2 Steps Involved In Wire Drawing

Rod ——» cleaned by___» Toremove___» Coated with» Drawn

Hat rolled] pickling scale/oxide Lime or Cuor Sn through

in dilute, H,SO, Layer Lime neutralises the die

(which causes the residue of

seeassalde ei |

wear and surface

defects) Annealed

before

Steps repeated till the given drawing

size of the wire is obtained again

Reduction] Coarse - 20-50% Foneech paserthe valet

por pass [Fine wires - 10-25% and length of the wire will

increase proportionately

6.3 Work Done in Homogenous deformation

Let A - Area of specimen and L = Length of specimen

& - Instantaneous yi

€ - Strain

stress

Fig. 6.2 Deformation Process

Increment of W.D in increasing the length of the specimen by ‘8’ beyond the strain € is

bW = (oA). 8 = (6.2)

4 Increment of work per unit volume is

bw bw (o.A)8E

235 o.- 63)

Vv AL Al l i)

# Assume no volume change and integrating we get

Rh xy i

w 3 f 5 8

vo Jey y8 Se asde= 7 (64)

- Original length

1, - final length

- initial strain

€, - final strain�201

Wire Drawing

jomogenous deformation is equal to the area of o-€ curve between

¢ ie., W.D/unit volume in Hi

d directly from the dimensional change

the appropriate strain values, This may be evaluate

assuming an average yield stress 6,,.

ty

w él

— : iF ---- (6.5)

LA

+ Fig. 6.3 Stress Vs Strain

w

© = Fue I 4) gives reasonable approximation for a metal which has been work hardened

f

before tensile stretching.

since Ajl, = Ajl, ~~ (volume is constant)

|

Ls 8 ---- (6.6)

hy A,

= 9,,,I0 A --- (6.7)

se

6.4 Work formula for wire drawing

F = drawing force in moving from 1-2

J, = Length of the drawn wire

¢ WD by drawing force

--- (6.8)�202 Manufacturing Process - I

but we know that for homogeneous deformation per unit volume

the W.D in forming the wire in the die

w h

¢ — =o,, In 1 from sec 6.3

v ae 0

4

W = Vo, In |

aie |

In the absence of friction

wew,

Fl, = Vo, inh

is

hy

v v

F= So. Ina ~~ (6411

yoy

Since V = 4,4,=1,A, in plastic deformation we get

oe rettg nh

4 4

L

A, 6,,.In 2 (6.12)

vind

replacing 4. by a from constant volume relation.

pA

F = A,o,,.In 4 (6.13)

a

AA:

but r= =1-

A

F/

JA,

~. Drawing stress 0,

1

o,=9,,In without friction = (6.14)

yg or�Wire Drawing 203

6.5 Maximum Possible reduction of area (one pass) in drawing

Drawing of wire is limited by the tensile failure of the drawn wire.

For such a heavy pass the maximum tensile stress will be nearly equal to the Y.S (because of

severe strain hardening of wire).

At the limiting reduction

6, = 5,=0, ---- (6.15)

The rate of strain hardening will be small so that the mean y.s, 6,,, Will also be equal to 0,

(o,,, =6,). The maximum reduction r,, is thus given by the condition.

‘we

St 2130, = --- Put r=, in equation 6.14

Sy

6, =

°

Si ty ----(6.16)

Oy 1-

ie,

ioe

Fg SB 27

ie,r, = 0.63 (6.17)

«. The maximum possible reduction with perfect lubrication

strain hardening is appreciable).

But internal distortion and friction, limits this. Under favourable circumstances, wire may be

drawn with reductions of area well over 50%.

~ 63% or slightly more (if the�Manufacturing Process - I

204.

6.6 Expression for true strain and fraction reduction

‘The most basic relationship for plastic deformation is the constant volume relationship.

Since large deformations are involved in mechanical working, it is important to express strain

in terms of True or Natural strain

For constant volume relationship, the sum of total strains in any three mutually perpendicular

direction is zero.

€,+€,+6,=0 ---- (6.18)

Compressive stresses and strains predominate in metal working process

Ifa block of height ‘h’, is compressed to height ', then the axial compressive True strain

fi

€,= fe aie hy> h, ---- (6.19)

pa ty hy

Conventional Strai e = Moe A (620)

nventional Stra 2 Z a

‘onventi in om Th

calculated strains will be negative, indicating compressive strains

In metal working, the convention is reversed so that compressive stresses and strains are

defined as positive.

e In & fg—hy

* (comp) =" (comp) ~ hy

Fraction reduction in area =

but volume is constant Aj, = Ag

Ay

A, = final area of C.S

1, = Initial length

J, = final length

from (6.21)

és

ee ae ce�Wire Drawing

---- (6.23)

6.7 Drawing Die details

Steel Casing

Entrance

angle

Back relief

approach ——~

angle

2 Bearing Surface

o = 30-45°

* Lubricant

Cu, Sn for high

strength materials

Die material - Tungsten carbide HSS

(diamond for small wires)

Fig. 6.4 Drawing Die Details

Regions in the die

Zone 1 :- A bell shaped entrance zone for proper guidance of the work piece.

‘The entrance angle is made large enough to allow sufficient space for the lubricant to

adhere to the die�206: Manufacturing Process - Ill

Zone 2:- A conical working zone

Approach angle - In this region, the actual reduction in diameter takes place.

Zone.3 :- A straight short cylindrical zone to add stability to the operation.

Bearing surface - guides the product as it comes out of the die. No reduction takes

place.

Zone 4:- A bell shaped exit zone

Back relief

Allows the metal to expand slightly us the wire leaves the die. prevents abrasion of the

die.

6.8 Drawing Speed

Drawing speed varies from 10m/min for larger diameter to 1800 m/min for a very thin wire,

Speed of drawing is limited mainly by the heat generated due to friction in the die. The

temperature rises to hundreds of degrees.

Finer the wire higher the speed of drawing.

Drawing

speed

—=—=—=—=

Dia of wire

Fig. 6.6 Variation of drawing speed wart wire dia

Table 6.1. Drawing speed ft/min (M/min)

Wire diameter | Wire diameter | Steel, cel Tron and Brass

(mm) (in) (M/min) Ftmin (M/min)

6.25 0.250 300 (90) 350 (105) 400 (120)

3.12 0.125 500 (150) 600 (180) 500 (150)

1.56 0.0625 800 (240) 1000 (300) 1200 (360)

6.9 Drawing Stress

‘The actual force required for drawing is much more than the theoretical force because friction

has to be overcome and redundant work is present. Redundant work does not participate in drawing

operation.�Wire Drawing 207

A, = area before reduction

A, = area after reduction

6, = average yield stress

@&Q = Drawing stress

with

friction

and

redundant

work

metal i

y.s of

without friction

and redundant

Drawing Stress

tog,| 2.

Strain “Nol

Fig. 6.6 Drawing Stress Vs. strain

Theoretical work per unit volume

= ©,. log, Ar

(6.24)

Refer Fig. 6.6

Y.S of the material increases with strain hardening.

Drawing stress also increases with increase in strain.

‘The intersection of these two curves determine the maximum possible reaction.

Friction and redundant work reduces the maximum possible reduction limit.

2

Drawing stress = So (0 +H). tog, (*A,} 39] === (6.25)

1 = Coefficient of friction between work and die

a= V, die angle�208:

Manufacturing Process - Ill

6.10 Expression for drawing force in wire drawing

Cylindrical rod drawing with a conical die (0, },

D,

D.

oe

Point O

Wire Drawing of ..Rod

ety

GIR

Fig. 6.7 Wire Drawing

G, are constant) plane strain YS

Initial diameter of the work

Outlet diameter of the wire

half die cone angle

virtual apex of the die cone

= distance of the virtual apex of the conical die to the point

"

"

of contact at exit plane w.r.t work

distance of the virtual apex of the conical die to the point |

of contact at entry plane w.r.t work

distance from the apex to the point of contact at just outlet

where dia = D

thickness of the element considered

Coefficient of friction on the element surface (slant surface)

Normal pressure on the slant surface

Drawing force

Radial Stress

g, and 6, + do, are the stresses on either side of the clement�Wire Drawing 209

For equilibrium condition of the small element in the working zone.

Considering force components acting in the axial direction.

T ™

Due to change in longitudinal stress ........... (0, + do,) ri (D+dDY-o, rt Dp

dx \..

Due to die pressure on the circumference ............. P| ™D. sina

cosa,

ge z y dx

@ Due to frictional force at the circumference. P| nD. cosa

cosa,

Under steady condition these must be in equilibrium

dx

Jeose =0

} sin & + UP (ro

cosa

au Tog dx

(6, +o.) = (D+db?-0," D'+ of ao.

A 4 cosa.

Neglecting product of dD.do, & dD we get

4.0,.2D.dD+ *D*.do, + P.nD.de.tanc.+uP.mD.de =0

+ by D, 20,,dD+ D.do, +4P.dxtana+ 4pP.dx = 0

*. 20,.dD+D.do, +2P.dD+2pP.cotc.dD =0

Rearranging

D.do, +2[o, + P(l+pcota)}dD =0 -~- (6.26)

or D.do, +2[5, + P+ UP.cota]}. dD =0

a%

ta - 2

fan 0 os

dD =2dx, tana

aD

dx =—. cota

ss 2 °°

Considering Radial forces for equilibrium

o,1D.dx + P. (20. ik ) cosa —uP (xo. ae } sina=0

cosa cosa

+ 1Ddx, Pr+P—P.tana= 0�210 Manufacturing Process - I!

o, = -P (I-ptana) (6.2)

Since pis small and ot is small, 1 tan ois still smaller

+. can be neglected (ex: w= 0.1,00=6 tan o.= 0.01)

‘The state of stress is cylindrical and the principal stresses are

6,=6, 6. o,=-P --~- (6.28)

H

‘Two principal stresses are equal

+. The stress system is equivalent (o uniaxial stress combined with a hydrostatic stress 50

that yield occurs at the value 5,

From V.M Criteria

E(0,-02) = > = 262

from (6.28) we get for uniaxial tension

2(0,-93) = 205

6,-9, = 6, == (6.29)

6,-(-P) = 6, (6.30)

6, +P = 0, = (6.31)

From (6.31) and (6.26)

Dido, +2[o,+P+PB\.dD=0 Letpcoto=B

Do, +2 [o,+(6,-9) 1 +B))dD=0

Do, +2 [o, +, + 5,8 -5,— 0B) dD=0

Do, - {Bo, -6, (1 + B)}. 26D =0

dD

do, _ 9 (632)

Tao, —o(1+ B)]

by rearrangings

If B and o, are constants, equation (6.32) can be integrated

1

2 n[Bo,—9,(1+B)] = 2In D + Constant

Solution of this expression is given by

Bo, -6, (1 +B) = C.D” ---- (6.33)

Assuming that there is no longitudinal stress at the entry

6,=9,,=0, D =D,

0-6, (1 +B) = CD;"

sae wg PE

---- (6.34)�Wire Drawing

an

From (6.33) and (6.34)

Bo, -9, (1+ B) =

oy

©. Drawing stress at D=Da_o,=0

1-8]

or,

In terms of the reduction of area

R

(ai)

Da)?

Db

2. Equation (6.36) becomes

Gia

Do

Drawing force F

Power required for drawing P

where V

Dd,

= < | always

D,

_ (1+ 8)

SE [diel]

= 6,,Aa

= FV

= Velocity at exit

--~ (6.35)

---- (6.36)

---- (6.37)

~~ (6,38)

---- (6.39)

---- (6.40)

(6.41)

(6.42)�212 Manutacturing Process - Ill

¢ For strip drawing the equation (6.40) can be used but o, is used in place of 6,

where 6, =

leet) iam (643)

B

. v3 (1+B 2

Drawing stress, 5, = Bol Ap -0-a) ]

D,

For Extrusion, ER = 7” =R> Lalways above analysis can be used,

G,, = O,...» ++ as compressive stress applied at the entrance.

20

1 1

:. Equation (6.36) = = hee [-(ze) |

0

1+B){)_ Je

- (4) (%)

Pressure in the die at entry P,

---- (6.44)

6.11 Frictionless Drawing of cylindrical rod (0, is constant)

When t= 0 then Bis also equal to 0 since B= pt cot &

from equation (6.26) D.do, + 2 (6, + P (1 +H cot | dD =0

reduces to D.do, + 2 [(a, + P)] dD =0

from yield criteria o, + P = 0,

substituting we get D.d 0, +20,dD =0 --- (648)

since ©, is constant we can integrate after rearranging

do, __2dD

So D

do, _ _,(dD

ja = 22�Wire Drawing 213

is —2 In D + constant ---- (6.49)

So

atentry 0, = 6,,=0, D=D,

Sri nih -2InD,+C

o,

$C 22nd,

©. equation (6.49) becomes

oy

= -2InD+2InD, ---- (6.50)

Dy .

ei = (6.51)

©. Drawing stress ¢, 6, is given by

Sey Bay 52

a Se mene

Ay ~ Ay

bebe

independent of the die angle

A. _( Pa )

stl, sila dts an elo

er) 4 7D,

reduction in strip drawing

Plane strain 6, is used in place of 6, 6, = 9, (%a)

: + " Do

since wide strip is constrained drawing during 6, = Ls

drawing by the undrawn elastic material entering the die

28

Sq 14+B |_| Bu

from (6.36) “Go = 2 2 D, ---- (6.36)�214. Manufacturing Process - Il

6.12 Tube Drawing Processes

Hollow tubes and pipes produced by hot forming methods such as extrusion and rolling are

cold finished by drawing process.

Cold drawing is a process of obtaining very close dimensional tolerances, of obtaining good

surface finish and to produce higher mechanical properties in the tube as a result of strain hardening,

And to produce tubes of thinner wall thickness or smaller diameters

Three basic types of tube drawing process are used in practice

1. Sinking

2. Plug drawing

3. Mandre! drawing

Inall these processes larger size (rough) tubes are drawn through the die and close control of

dimensions are obtained.

« Tube Sinking

‘The tube is simply passed through the die and pulled out as shown in figure 6.8.

Since the inside of the tube is not supported, the wall thickness and the inner surface become

uneven. The shearing at the entry and exit of the die is large.

small tube

Pull force

Fig. 6.8 Tube Sinking

Fixed Plug Drawing

A fixed plug is located near the die, leaving an annular clearance.

Here both inside and outside diameters are controlled. The plug may be conical or cylindrica

Greater dimensional accuracy is obtained. Since the plug offers more friction, the reduction in

area is limited to 30%. Fig. 6.9 shows this.

Die

Small to be

Pull force

Fixed

Fig. 6.9 Fixed plug drawing�215

Wire Drawing

« Floating Plug Drawing

A plug is located at the die and as the pulling takes place the plug seems to be floating,

By having a plug floating in the die, higher reduction in area is achieved. The plug has to be

carefully and properly designed. Drawing load is lesser than in fixed plug type. Tool design and

lubrication are very critical. Fig. 6.10 shows the arrangement.

Small

Tube

Pull force

Fig. 6.10 Floating plug drawing

¢ Moving Mandrel Drawing

Here friction is reduced appreciably. A long hard rod (mandrel) that extends over the entire

length of the tube is drawn through the die with the tube. Both the tube and the mandrel will be

moving with the same velocity. Fig. 6.11 shows this.

—Tube

mandrel

Fig. 6.11 Moving Mandrel Drawing

Worked Problems

Proglem : 6.1

What is the maximum reduction possible per pass in drawing Aluminimum rod through a die

of semi die angle 24°, 1» = 0.01.

Maximum or Limiting reduction is obtained by the equation

o 1+B

% 8 (1-(—-R)')

where 6, = drawing stress

can be written as 6, = ¥S

1-(-RY = — B = cota�216

Manufacturing Process - I!

canes f-2.]

1+B

d-) = Wy

(1+ By"

1+B = 1+peoto

We

(1+ By

ie,r = 1-

1

~ 2,692

1 +0.01 2.246)

= 1-03715

Maximum Reduction or ~ 63% = 0.6285

vs (14 BY = (1.0225)45 = 2.692

ow

"

W

fl

~ 0.0225~

semi die angle

Coefficient of friction

Dy

Dd,

dia at outlet

outlet dia

dia at inlet

1+0.01 . cot 24

0.0028

a�Wire Drawing: 217

6.1

6.2

6.3

64

65

6.6

67

68

6.9

6.1

6.2

6.3

64

6.5

6.6

6.7

61

6.6

QUESTIONS

Wire Drawing

Explain briefly wire drawing process

Explain drawing ratio.

With a flow chart briefly explain wire drawing process

What is the maximum reduction in area that is possible in drawing for one pass.

Draw a neat sketch of a drawing die and show al the zones and other details on it ?

Derive an expression in drawing die and show a cylindrical rod using a conical die.

1 26

[Den ont0,8 mM . oe) using regular resin

B

What will be the drawing stress assuming there is no friction involved.

Derive o,, =o, H24l = 1q-\) using regular notions

Db 1

Explain clearly how tubes are produced in drawing process.

What are the different methods available for tube drawing ? Explain.

Objective type of Questions

Answer according to each question

Wire drawing utilizes push force whereas direct extrusion utilizes pull force. True / False

Drawing ratio is the ratio of work piece diameter to final dia of the wire. True / False

Wire drawing is a hot working process. ‘True / False

Diameter of wire is greater than Smm True / False

Higher drawing speeds are required for higher dia wires. ‘True / False

Drawing stress increases with strain True / False

Tubes can be obtained by drawing process. Yes / No

Answers

False 6.2 False 6.3 False 6.4 False 6.5 True

True 6.7 Yes