Professional Documents

Culture Documents

New CCH Data Sheet As at July 2019 Innovex

Uploaded by

Taoufik KhorchaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New CCH Data Sheet As at July 2019 Innovex

Uploaded by

Taoufik KhorchaniCopyright:

Available Formats

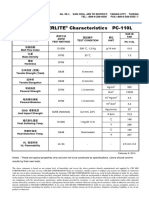

CC HydroTM Properties 1906.01.

EN

Typical Values

Pre-set Test Method Unit

CCH5TM CCH8TM

Physical Properties

Total Thickness BS EN 1849-2 mm 6 9

Bulk Roll Sizes m 1.0x150 1.0x100

Mass per Unit Area BS EN 1849-2 kg/m 2

8 13

Concrete Density BS EN 1849-2 kg/m3 1430-1540

Density Increase on Curing % Increase 30-35

Other Properties

Peel Strength (strength of internal linking fibres) BS EN ISO 13426-2 kN/m 4.0 4.5

Tensile Strength of Geomembrane Barrier MD/CMD (MARV) BS EN ISO 527-4 kN/m 14/13

Working Time from Hydration (refer to the CC HydroTM Hydration Guide) Hours 1 to 2

Post-set Typical Values

Test Method Unit

(Hydrated by full immersion in accordance with ASTM D8030. Water:GCCM ratio of 0.33) CCH5TM CCH8TM

Mechanical Performance

Compressive Strength of Cementitious Mix+ - 24 Hour BS EN 12390-3 MPa 50

Compressive Strength of Cementitious Mix - 28 Day +

BS EN 12390-3 MPa 80

Flexural Strength at 24 Hours from Hydration - Initial Break (MD) ASTM D8058 MPa >4.0

Flexural Strength at 24 Hours from Hydration- Final Break (MD) ASTM D8058 MPa >13 >13

Static Puncture Resistance (mean ultimate puncture force) BS EN ISO 12236 kN 3.5 4.5

Dynamic Puncture Resistance (depth of perforation) BS EN ISO 13433 mm 0*

Pyramid Puncture Resistance BS EN ISO 14574 kN 7.5 10

Differential Ground Movement (strain to PVC failure - min. 250mm per 1m width) % >25

Coefficient of Thermal Expansion α (mm/mk) 0.012-0.015

Impermeability (Geomembrane Barrier)

Water Permeability BS EN 14150 m/s 1 x 10-11

Gas Permeability ASTM D1434 5 x 10-12

Environmental Durability (minimum 50 year expected life)

Weathering Resistance (refer to CC HydroTM Age Certification) BS EN 12467 - Passed

Chemical Resistance - Retained Initial Flexural Strength (MD)

Method A - Acid (10% solution H2 SO4 ) BS EN 14414 % 79 85

Method B - Alkaline (saturated suspension Ca(OH)2 ) BS EN 14414 % 132 138

Method C - Solvation & Swelling (35% vol diesel, 35% vol paraffin, 30% vol lubricating oil HD30) BS EN 14414 % 128 110

Method D - Synthetic Leachate BS EN 14414 % 133 129

Root Resistance (refer to CC Root Resistance Testing) DD CEN/TS 14416 - Passed

Flammability (refer to CC HydroTM Fire Certification) CAN/ULC-S668-12 - Passed

Hydraulic Performance

Abrasion Resistance (cementitious barrier depth of wear) ASTM C1353 mm/1000 Cycles 0.2

Manning’s Roughness Coefficient ASTM D6460 n 0.011

Recommended Permissible Velocity (intermediate fixings may be required - contact CC Ltd) m/s Application

Dependent <8.6

+

Cube testing at Water:Powder ratio of 0.3 to correspond to GCCM hydration by immersion to ASTM D8030 * Probe did not make a full penetration through the product, therefore the depth of penetration is zero.

Occasionally there will be a Beam Fault (fabric imperfection under 100mm wide running across the width) in a Bulk Roll. This fault is unavoidable due to the manufacturing process and the fault will be clearly marked with

a white tag, there will be a maximum of (1) one Beam Fault in any Bulk Roll. A joint may need to be made on site where there is a Beam Fault as the material at a fault will not reach the performance specified in this Data

Sheet. The maximum un-useable material due to any Beam Fault will be 100mm. There are no beam faults in standard batched rolls.

CC HydroTM should not be used for the primary containment of liquids that would be detrimental to the environment. Information is provided based on current test data and may be subject to change as new information

becomes available. The versatile nature of CC HydroTM means that all application conditions cannot be anticipated. Concrete Canvas Ltd makes no warranties and assumes no liability in connection with this information.

Project specific testing may be required to determine the suitability for CC HydroTM material use in a particular application.

1.877.836.1333 ventes@innovex.ca www www.innovex.ca

The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express

© Concrete Canvas Ltd. 2019

You might also like

- Ship Stability FormuleDocument12 pagesShip Stability FormuleHaziq Ismail100% (1)

- Concrete Mix Design C40/20-400 KG MSRC: Combined GradingDocument1 pageConcrete Mix Design C40/20-400 KG MSRC: Combined GradingkamakshiNo ratings yet

- ASTM Flexural Test Methods PDFDocument9 pagesASTM Flexural Test Methods PDFDanNo ratings yet

- An Biaya Pembuatan JettyDocument7 pagesAn Biaya Pembuatan Jettyherry100% (1)

- Avm Imnr44 17aDocument2 pagesAvm Imnr44 17aRani HendrikusNo ratings yet

- Bill of Materials Northgate TownhouseDocument4 pagesBill of Materials Northgate TownhouseJohnNo ratings yet

- FRP Vessel CalculationDocument16 pagesFRP Vessel Calculationmukesh76% (17)

- NIST-2659 Earthworks and Drainage Rev 2Document33 pagesNIST-2659 Earthworks and Drainage Rev 2CK TangNo ratings yet

- MIMIXDocument751 pagesMIMIXKopalNo ratings yet

- STR DWGDocument23 pagesSTR DWGsamerNo ratings yet

- Pump Foundation Design PDFDocument18 pagesPump Foundation Design PDFArchana ArchuNo ratings yet

- Lab (GPDK)Document49 pagesLab (GPDK)Murali MurariNo ratings yet

- Precast FlooringDocument20 pagesPrecast FlooringantonamxNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Mac DrainDocument24 pagesMac Drainsundra0No ratings yet

- Concrete Canvas Data SheetDocument1 pageConcrete Canvas Data SheetSeasonNo ratings yet

- 06 LANT DATASHEET SORIC XXF WebDocument1 page06 LANT DATASHEET SORIC XXF WebAlejandro AlbanesiNo ratings yet

- Fatigue Analysis GuideDocument1 pageFatigue Analysis Guidebalamech91No ratings yet

- Rigid Inflatable Boat: Transom Strengthening of A (Rib) To Increase Propulsion PowerDocument7 pagesRigid Inflatable Boat: Transom Strengthening of A (Rib) To Increase Propulsion PowerAldy SyahriNo ratings yet

- Qdrain C20 65 10F EngDocument1 pageQdrain C20 65 10F EngThameem SharaafNo ratings yet

- Printing & Pouching Film Matte, Non Heat Sealable: PCT-2 (M)Document1 pagePrinting & Pouching Film Matte, Non Heat Sealable: PCT-2 (M)U KsNo ratings yet

- Qdrain C15 65 10F Eng 1Document1 pageQdrain C15 65 10F Eng 1Thameem SharaafNo ratings yet

- EF - 2013!02!26 - Radiation Resistance of Insulation Systems For IR Triplets - Summary For Giorgio AmbrosioDocument15 pagesEF - 2013!02!26 - Radiation Resistance of Insulation Systems For IR Triplets - Summary For Giorgio AmbrosiocrisNo ratings yet

- WP1 - A2-2 CapwapDocument5 pagesWP1 - A2-2 CapwapMegah Adhi KaryaNo ratings yet

- Bengalon Coal Project: 1 Preliminary WorksDocument2 pagesBengalon Coal Project: 1 Preliminary WorksPied PrintingNo ratings yet

- Qdrain C15 65 14F Eng 1Document1 pageQdrain C15 65 14F Eng 1Thameem SharaafNo ratings yet

- AC410Document1 pageAC410P Singh KarkiNo ratings yet

- LantorDocument1 pageLantorAdamMitchellNo ratings yet

- Ds - TECHDRAIN GTG 720 - enDocument1 pageDs - TECHDRAIN GTG 720 - enThameem SharaafNo ratings yet

- Ds - INTERDRAIN GMG 620 - enDocument1 pageDs - INTERDRAIN GMG 620 - enThameem SharaafNo ratings yet

- SEIP For 080-AC-001: GeneralDocument5 pagesSEIP For 080-AC-001: GeneralThinh NguyenNo ratings yet

- Concrete Canvas Material Data Post Set CC Properties: StrengthDocument1 pageConcrete Canvas Material Data Post Set CC Properties: StrengthAnriansyah DwitamaNo ratings yet

- TDS Nitoplate CP Strips Saudi ArabiaDocument4 pagesTDS Nitoplate CP Strips Saudi ArabiaKareem SaberNo ratings yet

- Nitoplate CP StripsDocument4 pagesNitoplate CP StripstalatzahoorNo ratings yet

- Specification For Conveyor and Elevator Textile Belting: IS: 1891 (Part 3) - 1988Document2 pagesSpecification For Conveyor and Elevator Textile Belting: IS: 1891 (Part 3) - 1988Toufik KarimNo ratings yet

- Beam 1Document16 pagesBeam 1Nurul SyafiqahNo ratings yet

- Peek Optima Reinforced 4Document7 pagesPeek Optima Reinforced 4Davis LarrubiaNo ratings yet

- TC PC WireDocument3 pagesTC PC WireSM AreaNo ratings yet

- Lap - QUALITY KARGO Bulan JAN.2021Document11 pagesLap - QUALITY KARGO Bulan JAN.2021Alif SyarifudinNo ratings yet

- 16MM Bare CopperDocument1 page16MM Bare CopperGKB tubeNo ratings yet

- Accc/Tw Helsinki (160) : Data SheetDocument1 pageAccc/Tw Helsinki (160) : Data SheetkmiqdNo ratings yet

- Accc/Tw Helsinki (160) : Data SheetDocument1 pageAccc/Tw Helsinki (160) : Data SheetkmiqdNo ratings yet

- Technical Specifications: ©envirobuild 2017Document4 pagesTechnical Specifications: ©envirobuild 2017Gonzalo Agulló FernándezNo ratings yet

- Scaffolding Safety Training Scaffold Components & Load Class ChartDocument5 pagesScaffolding Safety Training Scaffold Components & Load Class ChartNizar MohamedNo ratings yet

- B-TVS-M: Metallized BOPP FilmDocument2 pagesB-TVS-M: Metallized BOPP FilmSayed FathyNo ratings yet

- UmaPET EC104 - 140Document2 pagesUmaPET EC104 - 140Luz Angela GuerreroNo ratings yet

- Lap - QUALITY KARGO Bulan DES.2020Document13 pagesLap - QUALITY KARGO Bulan DES.2020Alif SyarifudinNo ratings yet

- Products Portfolio Update MostarDocument46 pagesProducts Portfolio Update MostarNicolas Arturo MartinezNo ratings yet

- EE002Document1 pageEE002johnkarl.bentingNo ratings yet

- Sae PC Wonderlite Characteristics PC-110L: February 6, 2014Document1 pageSae PC Wonderlite Characteristics PC-110L: February 6, 2014Ilton EduardoNo ratings yet

- UV Stabilized PC WONDERLITE Characteristics PC-115U: January 23, 2014Document1 pageUV Stabilized PC WONDERLITE Characteristics PC-115U: January 23, 2014DiegoTierradentroNo ratings yet

- B-THL: Standard Transparent Heat Sealable BOPP FilmDocument2 pagesB-THL: Standard Transparent Heat Sealable BOPP FilmSayed FathyNo ratings yet

- FILMON® BX TDS JNF Apr 2021Document1 pageFILMON® BX TDS JNF Apr 2021Donny SinagaNo ratings yet

- Material: Polyethylenterephtalate Abbreviation: PET-H: Mechanical Values Dry HumidDocument1 pageMaterial: Polyethylenterephtalate Abbreviation: PET-H: Mechanical Values Dry Humidricva_rjNo ratings yet

- 23882Document1 page23882skiu paket 31No ratings yet

- Numerical Simulation of A Stage Constructed Rockfill Dam On Plastic Clay Foundation - Ashwani Kumar Verma - CWCDocument13 pagesNumerical Simulation of A Stage Constructed Rockfill Dam On Plastic Clay Foundation - Ashwani Kumar Verma - CWCdeepakverma33546No ratings yet

- MS-1H Epoxy PDSDocument2 pagesMS-1H Epoxy PDSAndre CalmonNo ratings yet

- ERG Scheda Stirrer WEBDocument4 pagesERG Scheda Stirrer WEBt_pradipNo ratings yet

- 96aluminaprops PDFDocument1 page96aluminaprops PDFHerdi ArdianaNo ratings yet

- EPOXYDocument3 pagesEPOXYJamila BerrúNo ratings yet

- Avm Imnr62 17aDocument2 pagesAvm Imnr62 17aRani HendrikusNo ratings yet

- Wash Pad LV and Oil TrapDocument2 pagesWash Pad LV and Oil TrapPied PrintingNo ratings yet

- TDS UBE NYLON 1024B, CastDocument1 pageTDS UBE NYLON 1024B, CastAlexander ShvetsNo ratings yet

- Flexmetprotect C-CNM-M: Technical Data SheetDocument1 pageFlexmetprotect C-CNM-M: Technical Data Sheetminni choubeyNo ratings yet

- Annexure-1-Price Schedue-PKG106CDocument1 pageAnnexure-1-Price Schedue-PKG106CMuhammed FaheemNo ratings yet

- Aprisa - Alarm PDFDocument333 pagesAprisa - Alarm PDFNhân Tâm100% (1)

- 3.4 Diaphragm WallDocument16 pages3.4 Diaphragm Wallcy stNo ratings yet

- Huawei V1R8 V3R5 Software Upgrade Guide v1 2Document58 pagesHuawei V1R8 V3R5 Software Upgrade Guide v1 2ivanjcm85No ratings yet

- Vacuum CastingDocument7 pagesVacuum Castingmeet vermaNo ratings yet

- Comandos Basicos OltDocument5 pagesComandos Basicos OltCordobes CordobaNo ratings yet

- Conservado SP: Water-Repellent For Facades With A High Protective PowerDocument2 pagesConservado SP: Water-Repellent For Facades With A High Protective PoweracarisimovicNo ratings yet

- TH THDocument4 pagesTH THmike millNo ratings yet

- 7T SubTurbine B2176BKDocument2 pages7T SubTurbine B2176BKLuis AguirreNo ratings yet

- Red Hat HPC Solution OverviewDocument34 pagesRed Hat HPC Solution OverviewAdolfo Soto GonzalezNo ratings yet

- Aesthetics of Building MaterialsDocument2 pagesAesthetics of Building MaterialsShubham Dua0% (1)

- Lecture 9 Reading Assignment 2Document9 pagesLecture 9 Reading Assignment 2Dennis KorirNo ratings yet

- Thermal Processing: Applications ManualDocument18 pagesThermal Processing: Applications ManualMike RocciNo ratings yet

- DIP3E Chapter02 ArtDocument44 pagesDIP3E Chapter02 Artclaude feuneNo ratings yet

- Earth & Rockfill DamsDocument21 pagesEarth & Rockfill DamsshrikantharleNo ratings yet

- Idiake and Bala-Improving Labour Productivity in Masonry Work in NigeriaDocument10 pagesIdiake and Bala-Improving Labour Productivity in Masonry Work in Nigeriadox4print100% (1)

- The Mechanical Properties of Poly (Ether-Ether-Ketone) (PEEK) With Emphasis On The Large Compressive Strain ResponseDocument18 pagesThe Mechanical Properties of Poly (Ether-Ether-Ketone) (PEEK) With Emphasis On The Large Compressive Strain ResponseUriel PeñaNo ratings yet

- Standard Practice: 1995 EditionDocument8 pagesStandard Practice: 1995 EditionKaan TekinturhanNo ratings yet

- Building The Kra Canal andDocument9 pagesBuilding The Kra Canal andPete Maverick MitchellNo ratings yet

- Panduan Share ITSDocument335 pagesPanduan Share ITSReynaldi BagaskaraNo ratings yet

- Application Form To Register As A Structural Engineer and To Get Listed in The Directory of Structural EngineersDocument5 pagesApplication Form To Register As A Structural Engineer and To Get Listed in The Directory of Structural EngineersDilina HettiarachchiNo ratings yet

- Cartan Structure EquationsDocument6 pagesCartan Structure EquationsSumanto Chanda100% (4)

- Seaeye Sabertooth: The Deep Water Hybrid Auv/RovDocument2 pagesSeaeye Sabertooth: The Deep Water Hybrid Auv/Rovwxzcldw163.comNo ratings yet

- Claas Kgaa MBHDocument3 pagesClaas Kgaa MBHRasoolKhadibiNo ratings yet

- 06 SKKK1113 201415 - 2 Chap 4.4 4.6Document13 pages06 SKKK1113 201415 - 2 Chap 4.4 4.6Eunice AnneNo ratings yet