Professional Documents

Culture Documents

3D Printing Plastics Technical Specifications

Uploaded by

kponnu31Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3D Printing Plastics Technical Specifications

Uploaded by

kponnu31Copyright:

Available Formats

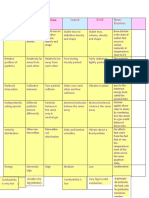

MATERIALS COMPARISON -

TECHNICAL DATASHEET

Polymers

TENSILE TENSILE ELONGATION AT HARDNESS CHARPY IMPACT CHARPY IMPACT HDT B REBOUND

MELTING POINT CERTIFICATIONS

MODULUS STRENGTH BREAK SHORE NOTCHED UNNOTCHED (0,45 MPa, DRY) RESILIENCE

Is the temperature

Is the ratio between the

Is the mechanical Is the ability of a Is a scale of values Is the energy required Is the energy required from which specimens

Certificate issued energy returned by the

stress that would Is the stress from material to elongate for characterizing the to break a test to break a test subjected to a

Is the temperature by an independent material and the energy

generate a theoretical which a material plastically before hardness of a material. specimen (sample of specimen (sample of load of 0.45MPa in

at which a crystalline body attesting to the supplied to generate a

elongation of 100% of deforms irreversibly. breaking during a The Shore A scale is for material) previously material) not previously their center and at

material changes from material’s compliance deformation of the latter.

the initial length of a This value tensile test. The higher flexible «soft» materials notched. This value notched. This value a temperature in

a solid state to a liquid with the standards It represents the ability

material. The higher characterizes the this value, the more and the D scale is for measures the impact measures the impact constant rise undergo

state and regulations in of a material to absorb

this value, the more resistance of a material ductile the material is rigid materials resistance of a material resistance of a material a conventional bending

force shock

rigid the material is of 0.2%

Type A Type B

35° 30°

MATERIAL

SLS Technology

Biocompatibility

min. 172°C,

PA12 1700 ± 150 MPa 45 ± 3 MPa 20 ± 5 % 75±2 D 4,8±0,3 kJ/m² - 154 °C Food assessment -

max. 180°C REACH

Nylon 3200

3200 MPa 51 MPa 9% 176°C 80 D 5,4 kJ/m² - 157 °C REACH -

Glass Filled

min. 172°C,

Alumide 3600 ± 150 MPa 45 ± 3 MPa 3 ± 0.5 % 76 D 4.6 kJ/m² - 177 °C REACH -

max. 180°C

Ultrasint® TPU

75 MPa 8 MPa 270 % - 88-90 A No break - - - 63 %

88A

Ultrasint® PA6

3300 MPa 62 MPa 7% 219 °C - 3.1 kJ/m² 27.8 kJ/m² 209 °C - -

MF

XY: >28%

Ultrasint® XY: 1750 MPa XY: 52 MPa XY: 5.1 MPa XY: 184 MPa

(Tensile) 203 °C - 176 °C - -

PA11 Z: 1800 MPa Z: 54 MPa Z: 3.9 MPa Z: 85 MPa

Z: 24% (Tensile)

Ultrasint® XY: 3150 MPa XY: 65 MPa XY: 37% (Tensile) XY: 6.6 MPa XY: 80 MPa

204 °C - 186 °C - -

PA11 ESD Z: 2150 MPa Z: 55 MPa Z: 49% (Tensile) Z: 4.7 MPa Z: 90 MPa

Ultrasint® XY: 5900 MPa XY: 82 MPa XY: 7% (Tensile) XY: 6.4 MPa XY: 54MPa

202 °C - 189 °C - -

PA11 CF Z: 2500 MPa Z: 55 MPa Z: 11% (Tensile) Z: 4.7 MPa Z: 33 MPa

Biocompatibility

MJF Technology

PAHs certificate

PA12 1700 MPa 48 MPa 20% 187°C - - - 175°C RoHS/REACH -

UL94 and

UL746A

X/Y: 20%

PP 1600 MPa 30 MPa 187°C - - - 100°C - -

Z: 18%

Ultrasint®

75 MPa 9 MPa 220% 120-150°C 88 A No break - - - 63%

TPU01

Multi Jet XY 1700 MPa XY: 54 MPa XY: 40% XY: 7.0 kJ/m²

- - - - - -

Fusion PA11 Z: 1800 MPa Z: 54 MPa Z: 25% Z: 4.5 kJ/m² (Izod)

FDM Technology

PLA Big-Rep - 60 MPa - - 60 D 7.5 kJ/m² - 40 °C - -

This information and values are presented as guidance only and based on Sculpteo's knowledge and experience. It is believed to be accurate, however all guarantees are explicitly denied. This document was updated Nov 2021.

You might also like

- 3D Printing Resins Technical SpecificationsDocument1 page3D Printing Resins Technical Specificationskponnu31No ratings yet

- Mechanical Materials Testing Methods Basic Knowledge - EnglishDocument2 pagesMechanical Materials Testing Methods Basic Knowledge - EnglishFATHI HAKIMI BIN ANWAR STUDENTNo ratings yet

- Void Collapse Simulation Hs UdaykumarDocument12 pagesVoid Collapse Simulation Hs UdaykumarSrijan NeogiNo ratings yet

- Launch Performance Degradation of TheDocument11 pagesLaunch Performance Degradation of TheHO LinNo ratings yet

- Edx Ial 词汇手册物理汇总Document27 pagesEdx Ial 词汇手册物理汇总Cai MingleiNo ratings yet

- ASTM D4848-98 (Reapproved 2012)Document6 pagesASTM D4848-98 (Reapproved 2012)Sandra LopesNo ratings yet

- ST FFEMS 2007 RailWheelDocument14 pagesST FFEMS 2007 RailWheelPawan KishoreNo ratings yet

- Homework Selection of MaterialsDocument2 pagesHomework Selection of MaterialsJ7C2No ratings yet

- Basic Knowledge Mechanical Materials Testing Methods EnglishDocument5 pagesBasic Knowledge Mechanical Materials Testing Methods EnglishankamraojNo ratings yet

- ANTEOLA Module4Document10 pagesANTEOLA Module4Zoe Angel Mhae AnteolaNo ratings yet

- Strema Prelim Reviewer PDFDocument3 pagesStrema Prelim Reviewer PDFCharmie Cabeltera CuelloNo ratings yet

- Shear Strength of Reinforced ConcreteDocument19 pagesShear Strength of Reinforced ConcreteJoão Paulo MendesNo ratings yet

- Journal of Nuclear MaterialsDocument12 pagesJournal of Nuclear MaterialsAlexanderNo ratings yet

- Liu Et Al 2024 Experimental Study On Dynamic Bond Behavior Between Reinforcement and Concrete Under FireDocument15 pagesLiu Et Al 2024 Experimental Study On Dynamic Bond Behavior Between Reinforcement and Concrete Under FireN.prem kumarNo ratings yet

- Material Properties: Basic ScienceDocument6 pagesMaterial Properties: Basic SciencebaoNo ratings yet

- Thermal ResistanceDocument1 pageThermal ResistanceLOPEZ BARAJAS GABRIELNo ratings yet

- Miskat Raw 2Document35 pagesMiskat Raw 2salmanalamj5No ratings yet

- Mech CurvesDocument12 pagesMech CurveskasreedharNo ratings yet

- Module #20Document32 pagesModule #20kamel touilebNo ratings yet

- 3Document8 pages3Azriel John SierraNo ratings yet

- Lect 14, 15 Energy, Numerical MethodsDocument20 pagesLect 14, 15 Energy, Numerical MethodsFaysal AsadNo ratings yet

- 1111fracture ToughnessDocument4 pages1111fracture ToughnessPei-YuChenNo ratings yet

- Mechanical Properties of Stainless SteelDocument8 pagesMechanical Properties of Stainless SteelFahrul Nur ArifinNo ratings yet

- Moniz Notes XDDocument2 pagesMoniz Notes XDSasaleleNo ratings yet

- 1) Astm-D257-99Document18 pages1) Astm-D257-99Nazanin AkramNo ratings yet

- Evaluation of Packaging MaterialDocument26 pagesEvaluation of Packaging MaterialSadhana GhimireNo ratings yet

- Astm A956-06 PDFDocument12 pagesAstm A956-06 PDFfccphongcongnghiep100% (2)

- 10 3390@s20071952Document9 pages10 3390@s20071952Muhammad Omer AsimNo ratings yet

- Closing The Word Gap - ScienceDocument24 pagesClosing The Word Gap - ScienceabuazfaNo ratings yet

- Glossary of TermsDocument10 pagesGlossary of TermsKanupriya JainNo ratings yet

- Actividad de Sienciea Cuadro 7X7Document1 pageActividad de Sienciea Cuadro 7X7luz gilNo ratings yet

- Frequency Dependence of Junction Capacitance: IETE Journal of ResearchDocument5 pagesFrequency Dependence of Junction Capacitance: IETE Journal of ResearchhesoyamyecgaaaNo ratings yet

- NDT GlossaryDocument61 pagesNDT Glossaryoulfa2013No ratings yet

- ASTM D4541-09 Pull OffDocument17 pagesASTM D4541-09 Pull OffrobertabarreiroNo ratings yet

- Bangcola, Yusoph Salahaddin Pat A. Materials Testing 1. Tensile TestDocument2 pagesBangcola, Yusoph Salahaddin Pat A. Materials Testing 1. Tensile TestIvandelist XNo ratings yet

- MSEnewDocument11 pagesMSEnewMIGUEL ANTONIO MACARAEGNo ratings yet

- MypptDocument60 pagesMypptMD GamingNo ratings yet

- Fundamentals of Material ScienceDocument15 pagesFundamentals of Material ScienceRoadNo ratings yet

- Module 2 Mechanics of Deformable BodiesDocument3 pagesModule 2 Mechanics of Deformable BodiesWency LagumbayNo ratings yet

- 15-TRB.90.ResRec1278.PWM-FHK - Det Insitu Ko Clay - OcrDocument9 pages15-TRB.90.ResRec1278.PWM-FHK - Det Insitu Ko Clay - OcrAndres PuertaNo ratings yet

- States of Matter: 3 Liquids and SolidsDocument6 pagesStates of Matter: 3 Liquids and SolidsyasinzalentiNo ratings yet

- Eproxy Graphite FibersDocument5 pagesEproxy Graphite FibersJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Glossary Online OVDocument62 pagesGlossary Online OVadnanbutt1984No ratings yet

- Overview of Mechanical TestingDocument39 pagesOverview of Mechanical TestingRobinson PrabuNo ratings yet

- Structures Journal of Intelligent Material Systems andDocument5 pagesStructures Journal of Intelligent Material Systems andprashant tadalagiNo ratings yet

- Astm d470 Crosslinked Insulations and Jackets ForDocument25 pagesAstm d470 Crosslinked Insulations and Jackets ForYimmy VelasquezNo ratings yet

- ASTM F118 Gaskets Terms DefinitionsDocument2 pagesASTM F118 Gaskets Terms DefinitionsDieguitoOmarMoralesNo ratings yet

- Physical Properties & Mechanical Properties of Dental MaterialDocument6 pagesPhysical Properties & Mechanical Properties of Dental Materialramly9833% (3)

- Astm D4439-02Document5 pagesAstm D4439-02anon_128393458No ratings yet

- 11th August Crash Program SOS-2023Document4 pages11th August Crash Program SOS-2023tecnosir959No ratings yet

- Norma Astm g76 18 PDFDocument4 pagesNorma Astm g76 18 PDFCesar Guerra100% (1)

- TA380 Thermal Analysis Techniques Applied To Solar Energy and PV MaterialsDocument10 pagesTA380 Thermal Analysis Techniques Applied To Solar Energy and PV MaterialsHaider AddewanyNo ratings yet

- Unit - IV: Mechanical Testing of MaterialsDocument13 pagesUnit - IV: Mechanical Testing of Materialsjoel jNo ratings yet

- Sumsem1-2018-19 Mee1005 Eth Vl2018198000361 Reference Material I 20-May-2019 l28-29 - Mechanical Properties of MaterialsDocument32 pagesSumsem1-2018-19 Mee1005 Eth Vl2018198000361 Reference Material I 20-May-2019 l28-29 - Mechanical Properties of MaterialsADAM ISMAILNo ratings yet

- How It Works: How It Works: How It Works:: Vickers Hardness TestDocument1 pageHow It Works: How It Works: How It Works:: Vickers Hardness TestGrim WorkNo ratings yet

- DMA PowerPoint Presentation Prepared by Yared FikreDocument24 pagesDMA PowerPoint Presentation Prepared by Yared FikreYAREDNo ratings yet

- Deformation Geometry for Materials Scientists: International Series on Materials Science and TechnologyFrom EverandDeformation Geometry for Materials Scientists: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- TDS Enus 0PDocument111 pagesTDS Enus 0Pkponnu31No ratings yet

- Resin MSDS 2Document82 pagesResin MSDS 2kponnu31No ratings yet

- General - Resin - TDS - 2023824-EN (Standard Pro Resin White Jagme - HE)Document5 pagesGeneral - Resin - TDS - 2023824-EN (Standard Pro Resin White Jagme - HE)kponnu31No ratings yet

- BingAnswers 20231221 131234Document2 pagesBingAnswers 20231221 131234kponnu31No ratings yet

- Morality in Criminal Law and Criminal Procedure:Principles, Doctrines, and Court CasesDocument4 pagesMorality in Criminal Law and Criminal Procedure:Principles, Doctrines, and Court CasestareghNo ratings yet

- Bpharm Winter 2014Document1 pageBpharm Winter 2014babaf79912No ratings yet

- Final Economics Project Report 1Document56 pagesFinal Economics Project Report 1vikrant4us77% (13)

- The Weber Grill Magazine: So Much More Than Just A GrillDocument40 pagesThe Weber Grill Magazine: So Much More Than Just A GrillZheng JiangNo ratings yet

- Method Statement For Installation of Underground Checmical Waste TanksDocument8 pagesMethod Statement For Installation of Underground Checmical Waste TanksDiana Abu Hassan HatoumNo ratings yet

- Book - Mouse Models of Innate Immunity 2013Document230 pagesBook - Mouse Models of Innate Immunity 2013Nathália LuísaNo ratings yet

- Midterm Exam Vib 3 Industrial 2015Document3 pagesMidterm Exam Vib 3 Industrial 2015Judex OnyekabaNo ratings yet

- Preface: Mr. Manish Jain, Head of DepartmentDocument45 pagesPreface: Mr. Manish Jain, Head of DepartmentNitinAgnihotriNo ratings yet

- Rahim2017 Article ImprovingSocialResponsibilityI PDFDocument20 pagesRahim2017 Article ImprovingSocialResponsibilityI PDFMd DidarNo ratings yet

- Topic 2 Cultural Diversity PrelimDocument9 pagesTopic 2 Cultural Diversity PrelimRhaven GutierrezNo ratings yet

- Bricks Reading 240 Nonfiction - L1 - WB - Answer KeyDocument18 pagesBricks Reading 240 Nonfiction - L1 - WB - Answer KeyNathan HNo ratings yet

- KJR 2010 02Document144 pagesKJR 2010 02Sree MahalakshmiNo ratings yet

- Bongard Vs Stellar Recovery Inc FDCPA Complaint MinnesotaDocument6 pagesBongard Vs Stellar Recovery Inc FDCPA Complaint MinnesotaghostgripNo ratings yet

- Present Perfect and Past SimpleDocument21 pagesPresent Perfect and Past SimpleYoukan AcademyNo ratings yet

- Muliple Choice Questions (Compiled) 2Document25 pagesMuliple Choice Questions (Compiled) 2A.BensonNo ratings yet

- Mid QuestionsDocument4 pagesMid QuestionsMAMA LALANo ratings yet

- Cbs Esp 001 Notes PDFDocument8 pagesCbs Esp 001 Notes PDFمحمد عبد الحليم شعراويNo ratings yet

- H. B. Green (auth.), J. T. Fraser, N. Lawrence (eds.) - The Study of Time II_ Proceedings of the Second Conference of the International Society for the Study of Time Lake Yamanaka-Japan (1975, Springer-Verlag Berli.pdfDocument491 pagesH. B. Green (auth.), J. T. Fraser, N. Lawrence (eds.) - The Study of Time II_ Proceedings of the Second Conference of the International Society for the Study of Time Lake Yamanaka-Japan (1975, Springer-Verlag Berli.pdfEduardo GuedesNo ratings yet

- Rules For Significant FiguresDocument7 pagesRules For Significant FiguresJoeleo Aldrin SupnetNo ratings yet

- Social Science MS - 2017Document56 pagesSocial Science MS - 2017dashrathrai17No ratings yet

- H14YS-5B-2309-Reminder - 011424Document4 pagesH14YS-5B-2309-Reminder - 011424BẢO Nhi LêNo ratings yet

- Binani Cement Research ReportDocument11 pagesBinani Cement Research ReportRinkesh25No ratings yet

- Famine, Affluence, and Morality by Peter Singer - A Summary - Clueless Political Scientist PDFDocument4 pagesFamine, Affluence, and Morality by Peter Singer - A Summary - Clueless Political Scientist PDFNeil ShroffNo ratings yet

- Career PathDocument2 pagesCareer PathLove GonzalesNo ratings yet

- Cheb Yshev PolynomialsDocument13 pagesCheb Yshev PolynomialsBolitten VianeyNo ratings yet

- NEH Education Summer Programs 2014Document33 pagesNEH Education Summer Programs 2014Richard G. FimbresNo ratings yet

- Level Iii Assertion Reasoning Type TaxonomyDocument8 pagesLevel Iii Assertion Reasoning Type TaxonomyPraveen JainNo ratings yet

- Tongue Twister PracticeDocument5 pagesTongue Twister PracticeFlavio Leal JovchelevitchNo ratings yet

- Bowen Bowen University: OyepaDocument2 pagesBowen Bowen University: OyepaLO NI MINo ratings yet

- R5176b PDFDocument53 pagesR5176b PDFAnum ZahraNo ratings yet