0% found this document useful (0 votes)

639 views5 pagesJob Hazard and Risk Assessment

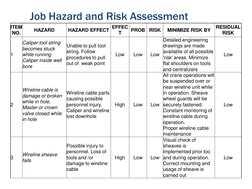

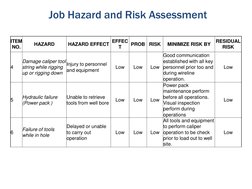

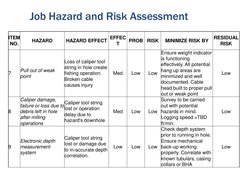

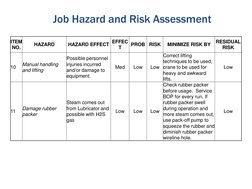

This document summarizes potential job hazards and risks associated with running a caliper tool string in a wellbore. Key hazards include the tool string becoming stuck, the wireline cable breaking, failure of the wireline sheave, failure of downhole tools, debris left in the hole impacting operations, inaccurate depth correlation causing tool loss, and manual handling injuries. Risks are minimized through procedures, maintenance, inspections, communications, and following correct lifting techniques. Residual risks are mostly low after risk mitigation actions are taken.

Uploaded by

asponce2003Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

639 views5 pagesJob Hazard and Risk Assessment

This document summarizes potential job hazards and risks associated with running a caliper tool string in a wellbore. Key hazards include the tool string becoming stuck, the wireline cable breaking, failure of the wireline sheave, failure of downhole tools, debris left in the hole impacting operations, inaccurate depth correlation causing tool loss, and manual handling injuries. Risks are minimized through procedures, maintenance, inspections, communications, and following correct lifting techniques. Residual risks are mostly low after risk mitigation actions are taken.

Uploaded by

asponce2003Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Job Hazard and Risk Assessment: Provides a detailed analysis of job-related hazards and their associated risks, controls, and potential impacts.