Professional Documents

Culture Documents

Clm-Smaw Ncii Uc1 - Core

Uploaded by

Alcantara Castillo0 ratings0% found this document useful (0 votes)

21 views2 pages1. The document provides a contextual learning matrix for the unit of competency "Weld Carbon Steel Plates and Pipes Using SMAW" which includes learning outcomes, assessment criteria, estimated learning hours and knowledge and skills required.

2. The learning outcomes cover performing a root pass, cleaning the root pass, welding subsequent filling passes, and performing capping in accordance with specifications, work procedures and industry standards.

3. The associated knowledge and skills include understanding materials and welding processes, measurement, communication, problem solving, and consideration of occupational health and safety issues.

Original Description:

Original Title

2. Clm-smaw Ncii Uc1 - Core

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document provides a contextual learning matrix for the unit of competency "Weld Carbon Steel Plates and Pipes Using SMAW" which includes learning outcomes, assessment criteria, estimated learning hours and knowledge and skills required.

2. The learning outcomes cover performing a root pass, cleaning the root pass, welding subsequent filling passes, and performing capping in accordance with specifications, work procedures and industry standards.

3. The associated knowledge and skills include understanding materials and welding processes, measurement, communication, problem solving, and consideration of occupational health and safety issues.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views2 pagesClm-Smaw Ncii Uc1 - Core

Uploaded by

Alcantara Castillo1. The document provides a contextual learning matrix for the unit of competency "Weld Carbon Steel Plates and Pipes Using SMAW" which includes learning outcomes, assessment criteria, estimated learning hours and knowledge and skills required.

2. The learning outcomes cover performing a root pass, cleaning the root pass, welding subsequent filling passes, and performing capping in accordance with specifications, work procedures and industry standards.

3. The associated knowledge and skills include understanding materials and welding processes, measurement, communication, problem solving, and consideration of occupational health and safety issues.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

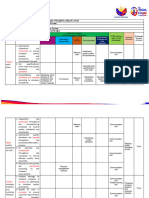

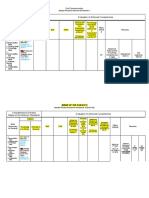

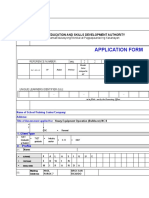

Contextual Learning Matrix (CLM)

Qualification Title: SHIELDED METAL ARC WELDING (SMAW) NCII

Unit Of Competencies: Weld Carbon Steel Plates and Pipes Using SMAW

Code: MEE721306

Module Title: Welding Carbon Steel Plates and Pipes Using SMAW

Prepared By: FLORDELIZA C. ALCANTARA

Learning Concepts

STEM knowledge (Disciplinal)

STEM thinking Estimate

Learning Environment Learning

Assessment Criteria skills (Trans d Number

Outcome: Technology/ al issues and Activities

SCIENCE MATH Communication disciplinary) of Hours

Engineering other

concerns

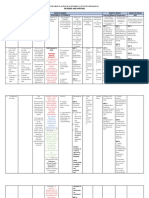

1. Root pass is performed

in accordance with WPS understanding Interpreting

Measure Communication

materials and Arc welding/ client OHS

and/or client their properties

ment

specification

skill

specifications.

2. Task is performed in

accordance with

Communication

company or industry skill

requirement and safety Performin

Perform

procedure g root 60hours

root pass pass

3. Weld is visually checked understanding Arc welding/

Problem solving

for defects and materials and process of OHS

skill

repaired, as required their properties checking

4. Weld is visually

acceptable in Interpreting

Measure Communication

accordance with ment

codes and

skill

applicable codes and standards

standards

1. Root pass is cleaned and

Clean Measure Cleaning

free from defects and Equipment

ment

OHS

root pass

24 hours

root pass

discontinuities

2. Task is performed in

accordance with Communication

skill

approved WPS

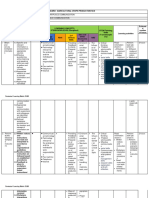

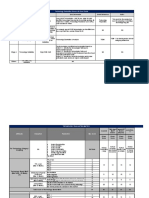

1. Subsequent/ filling

passes is performed in understanding Interpreting

Measure Communication

materials and Arc welding/ client OHS

accordance with ment skill

their properties specification

approved WPS

Weld

2. Weld is visually checked understanding Arc welding/ Welding

subseque Problem solving subseque

for defects and materials and process of OHS

skill

nt/ their properties checking nt/ 50hours

repaired, as required filling

filling

3. Weld is visually passes

passes

acceptable in Interpreting

Measure Communication

accordance with ment

codes and

skill

applicable codes and standards

standards

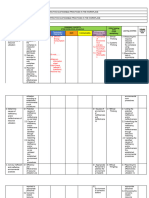

1. Capping is performed in

accordance with WPS understanding Interpreting

Measure Communication

materials and Arc welding/ client OHS

and/or client their properties

ment

specification

skill

Perform

specifications

capping

2. Weld is visually checked understanding Arc welding/

Problem solving

for defects and materials and process of OHS

skill Performin

their properties checking 60hours

repaired, as required g capping

3. Weld is visually

acceptable in Interpreting

Measure Communication

accordance with ment

codes and

skill

applicable codes and standards

standards

You might also like

- New Holland D180 Service ManualDocument417 pagesNew Holland D180 Service ManualDiego100% (4)

- 135 Service Manual PDFDocument540 pages135 Service Manual PDFФорум Рязань100% (2)

- REYNOLD LAURON Day 2 - FCAAM TemplateDocument6 pagesREYNOLD LAURON Day 2 - FCAAM TemplateREYN100% (1)

- TRAINING PLAN For SMAW 1Document16 pagesTRAINING PLAN For SMAW 1Mark Marasigan100% (10)

- TSPP8Document76 pagesTSPP8Ian Naylor100% (1)

- DDDocument34 pagesDDDraciv VicardNo ratings yet

- Curriculum Map ICT 10Document2 pagesCurriculum Map ICT 10Jessa Edulan100% (5)

- CBC - Hydraulic Excavator Ncii NewDocument56 pagesCBC - Hydraulic Excavator Ncii NewAlcantara CastilloNo ratings yet

- Clm-Smaw Ncii Uc4 - CommonDocument2 pagesClm-Smaw Ncii Uc4 - CommonAlcantara CastilloNo ratings yet

- Integrated-CLM CORE SMAWDocument3 pagesIntegrated-CLM CORE SMAWMICHELLE BITALASNo ratings yet

- Engineering Mechanics PDFDocument6 pagesEngineering Mechanics PDFDia CamilleNo ratings yet

- Cocu 7 - Military EquipmentDocument8 pagesCocu 7 - Military EquipmentMuhammad nazrien NizamNo ratings yet

- Grade 9 & 10 Curriculum MapDocument11 pagesGrade 9 & 10 Curriculum MapRussell SanicoNo ratings yet

- CoCU 6Document8 pagesCoCU 6ksina 1052No ratings yet

- FEM - Shiela Mae UcangDocument4 pagesFEM - Shiela Mae UcangShiela Mae Sotto UcangNo ratings yet

- I. Objectives: Daily Lesson LogDocument4 pagesI. Objectives: Daily Lesson LogSara Jane CorpuzNo ratings yet

- Centrespread 8Document1 pageCentrespread 8757rustamNo ratings yet

- Classroom Instruction Delivery Alignment Plan: The Learners Shall Be Able ToDocument1 pageClassroom Instruction Delivery Alignment Plan: The Learners Shall Be Able ToRaymond Alvarez ArabejoNo ratings yet

- Part 3. FcaamDocument5 pagesPart 3. Fcaammike abanNo ratings yet

- EIM NC II - Core CompetenciesDocument3 pagesEIM NC II - Core CompetenciesFe Marie Jison100% (1)

- Unit of Competency Learning Outcomes Learning Activities Methodologies Assessment Methods Nominal DurationDocument8 pagesUnit of Competency Learning Outcomes Learning Activities Methodologies Assessment Methods Nominal Durationvanjoseph01No ratings yet

- Flexible Classroom Assessment Activities Mechanism: Oral Communication in ContextDocument2 pagesFlexible Classroom Assessment Activities Mechanism: Oral Communication in ContextJunjoy CalimzonNo ratings yet

- Curriculum of Competency Unit (Cocu)Document13 pagesCurriculum of Competency Unit (Cocu)Muhammad FathilNo ratings yet

- Css Le Iacss9 Sucn Iva J 33 FluorineDocument4 pagesCss Le Iacss9 Sucn Iva J 33 FluorineMarvz LeoNo ratings yet

- Basic CLM Smaw nc2 For ManualsDocument46 pagesBasic CLM Smaw nc2 For ManualslildensixxNo ratings yet

- Contextual Learning Matrix (CLM) : Social SkillsDocument31 pagesContextual Learning Matrix (CLM) : Social SkillsRoh MerNo ratings yet

- Feb. 17-21, 2020Document2 pagesFeb. 17-21, 2020Rialyn Burlas Fuerzas-BordiosNo ratings yet

- CSWIP Plant Inspection - Levels 1,2 and 3: An Internationally Recognised Certification of CompetenceDocument1 pageCSWIP Plant Inspection - Levels 1,2 and 3: An Internationally Recognised Certification of Competenceafiq ahmadNo ratings yet

- Tesda Op Co 01 f11 Heo Moi Basic 400311321Document5 pagesTesda Op Co 01 f11 Heo Moi Basic 400311321Stelito JumaranNo ratings yet

- 8 - Uc 8 CLMDocument3 pages8 - Uc 8 CLMmariaestercampos22No ratings yet

- B.Tech AWC New Lesson Plan - 2018-19Document9 pagesB.Tech AWC New Lesson Plan - 2018-19Rvh PrasadNo ratings yet

- Cocu 1Document9 pagesCocu 1Atie ZakariaNo ratings yet

- Grade 11 SMAW - q2 w7Document6 pagesGrade 11 SMAW - q2 w7Jhon Vernie Reponte GambitoNo ratings yet

- TRB For Print 2022Document13 pagesTRB For Print 2022Ralfh De GuzmanNo ratings yet

- NASSCOM Assessment of Competence-Technology (NAC-Tech)Document7 pagesNASSCOM Assessment of Competence-Technology (NAC-Tech)செல்வம் முத்துராமன்No ratings yet

- Alignment Classroom Instruction Delivery (Acid) Plan: First QuarterDocument22 pagesAlignment Classroom Instruction Delivery (Acid) Plan: First Quarterclaire cruzNo ratings yet

- FIDP 1 Quarter CSS1Document8 pagesFIDP 1 Quarter CSS1jonathan labajoNo ratings yet

- 2018 ECE Annex VI - USAID PBEd Workshop OutcomesDocument2 pages2018 ECE Annex VI - USAID PBEd Workshop OutcomesJanice PusposNo ratings yet

- Competency Matrix For Scope 27 Shivam SinghDocument4 pagesCompetency Matrix For Scope 27 Shivam Singhhammad.phistreamNo ratings yet

- Lampiran Tabel A-II/2 Kompetensi STCW Amandemen 2010Document15 pagesLampiran Tabel A-II/2 Kompetensi STCW Amandemen 2010Dhamar Tri AnggoroNo ratings yet

- Tle 10 Curriculumn MapDocument16 pagesTle 10 Curriculumn MapIvo LunaNo ratings yet

- Vector EMOB 2017 Michael ScholzDocument13 pagesVector EMOB 2017 Michael ScholzUdayakumar LNo ratings yet

- Curriculum Map: Immaculate Heart of Mary SeminaryDocument4 pagesCurriculum Map: Immaculate Heart of Mary SeminaryMary Sharlyn Jumawid RubinNo ratings yet

- CSS LE - IACSS9-SUCN-IVa-j-33 - FluorineDocument4 pagesCSS LE - IACSS9-SUCN-IVa-j-33 - FluorineDianne Brucal - MatibagNo ratings yet

- Unit of Learning Outcomes: ActivityDocument1 pageUnit of Learning Outcomes: Activitypaulomarques22No ratings yet

- COCU 5 Electronic 171214Document6 pagesCOCU 5 Electronic 171214Atie ZakariaNo ratings yet

- Concepts of Design: Massachusetts Institute of Technology, Subject 2.017Document14 pagesConcepts of Design: Massachusetts Institute of Technology, Subject 2.017Dr. Ir. R. Didin Kusdian, MT.No ratings yet

- RCC-E 2012 Qualification and Manufacturing of Electrical EquipmentDocument1 pageRCC-E 2012 Qualification and Manufacturing of Electrical Equipmentmuhammad mustafa iqbalNo ratings yet

- TRAINEE - PROGRESS SheetDocument12 pagesTRAINEE - PROGRESS SheetEmmanuel GallidoNo ratings yet

- FORM 1.1 Self-Assessment Check INSTRUCTIONS: This Self-Check Instrument Will Give The Trainer NecessaryDocument11 pagesFORM 1.1 Self-Assessment Check INSTRUCTIONS: This Self-Check Instrument Will Give The Trainer NecessaryALEXIS SUELTONo ratings yet

- Introduction To Design in Mechanical EngineeringDocument2 pagesIntroduction To Design in Mechanical Engineeringlazaro floresNo ratings yet

- Toaz - Info Research 2 Cidam PRDocument7 pagesToaz - Info Research 2 Cidam PRRonelle San buenaventuraNo ratings yet

- MC4 CoCU 5 - Welding Inspection Activities CoordinationDocument14 pagesMC4 CoCU 5 - Welding Inspection Activities Coordinationnizam1372No ratings yet

- Competencies To Develop Based On The Minimum Standards Evaluation of Achieved CompetenciesDocument3 pagesCompetencies To Develop Based On The Minimum Standards Evaluation of Achieved CompetenciesJunjoy CalimzonNo ratings yet

- Curriculum MapDocument2 pagesCurriculum MapChed Augustus AranNo ratings yet

- Curriculum Map Ict 10 PDF FreeDocument2 pagesCurriculum Map Ict 10 PDF FreeAndrew C. BrazaNo ratings yet

- Relevance of The Course 2. Basic Concepts and Core Competencies in Computer Hardware Servicing 3. Career OpportunitiesDocument1 pageRelevance of The Course 2. Basic Concepts and Core Competencies in Computer Hardware Servicing 3. Career OpportunitiesDanny TagpisNo ratings yet

- Integration Plan Eim NC Ii RoseDocument34 pagesIntegration Plan Eim NC Ii RosejaysonNo ratings yet

- Modified Home-Based Work Immersion Program in The New Normal in Line With Accountancy, Business, Management (Abm)Document6 pagesModified Home-Based Work Immersion Program in The New Normal in Line With Accountancy, Business, Management (Abm)Jobbie Mae TomasNo ratings yet

- Concepts of Design: Massachusetts Institute of Technology, Subject 2.017Document15 pagesConcepts of Design: Massachusetts Institute of Technology, Subject 2.017pen2trinity3200No ratings yet

- Syllabus - SKK-11: Allocation Time: 62 X 45 MinutesDocument3 pagesSyllabus - SKK-11: Allocation Time: 62 X 45 MinuteswahyudinNo ratings yet

- Power BI AssignmentDocument147 pagesPower BI AssignmentAditya SharmaNo ratings yet

- This Study Resource Was: Arsalan HassanDocument1 pageThis Study Resource Was: Arsalan HassanSome oneNo ratings yet

- Presentation CLM DevelopmentDocument31 pagesPresentation CLM DevelopmentAlcantara CastilloNo ratings yet

- Request Vehicle-LetterDocument1 pageRequest Vehicle-LetterAlcantara CastilloNo ratings yet

- Wheel Loader ManualDocument112 pagesWheel Loader ManualAlcantara CastilloNo ratings yet

- Pre Assessment ToolsDocument12 pagesPre Assessment ToolsAlcantara CastilloNo ratings yet

- SESSION PLAN Common 1Document13 pagesSESSION PLAN Common 1Alcantara CastilloNo ratings yet

- Consent FormDocument1 pageConsent FormAlcantara CastilloNo ratings yet

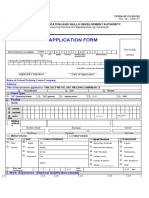

- Application Form Smaw NC IiDocument3 pagesApplication Form Smaw NC IiAlcantara CastilloNo ratings yet

- Application Form: Technical Education and Skills Development AuthorityDocument4 pagesApplication Form: Technical Education and Skills Development AuthorityAlcantara CastilloNo ratings yet

- Contract FatimaDocument2 pagesContract FatimaAlcantara CastilloNo ratings yet

- MA. FATIMA A. CATLI, Filipino of Legal Age, Single With Residence and Postal Second PartyDocument2 pagesMA. FATIMA A. CATLI, Filipino of Legal Age, Single With Residence and Postal Second PartyAlcantara CastilloNo ratings yet

- Application Form: Technical Education and Skills Development AuthorityDocument3 pagesApplication Form: Technical Education and Skills Development AuthorityAlcantara CastilloNo ratings yet

- Appendix B: Consent FormDocument1 pageAppendix B: Consent FormAlcantara Castillo100% (2)

- Handbook - Weld Defects 08Document1 pageHandbook - Weld Defects 08Danilova SonjaNo ratings yet

- Train 7 Fire Incident at The Petronas LNG ComplexDocument8 pagesTrain 7 Fire Incident at The Petronas LNG ComplexAmroKashtNo ratings yet

- CBT Welding QuestionDocument57 pagesCBT Welding QuestionRishiNo ratings yet

- Ferite CheckDocument16 pagesFerite CheckAli VarmazyarNo ratings yet

- Specs - Steel CasingDocument4 pagesSpecs - Steel CasingAlhad PanwalkarNo ratings yet

- Miller Pipepro 450 RFCDocument92 pagesMiller Pipepro 450 RFCmart_aloNo ratings yet

- Soudokay Strip Cladding - PrincipesDocument31 pagesSoudokay Strip Cladding - PrincipesRenny DevassyNo ratings yet

- Habtamu B-Design of Leaf JigDocument50 pagesHabtamu B-Design of Leaf JigNardos Bialfew DamtieNo ratings yet

- Stilling Well PDFDocument13 pagesStilling Well PDFRitesh VishambhariNo ratings yet

- PAES 525 - Overhead Rail System - SpecificationsDocument14 pagesPAES 525 - Overhead Rail System - SpecificationsMark Jay SilverioNo ratings yet

- Effect of Multi-Pass SMAW Welding On The Surface HDocument7 pagesEffect of Multi-Pass SMAW Welding On The Surface HYousab CreatorNo ratings yet

- GraphitizationDocument9 pagesGraphitizationpouya_ms100% (2)

- Csa w471 Vs Aws d11 Similarities and DifferencesDocument2 pagesCsa w471 Vs Aws d11 Similarities and Differences99demonNo ratings yet

- Mars Quotation of Chicken Cage Welding Machine DP-AW-1200HDocument10 pagesMars Quotation of Chicken Cage Welding Machine DP-AW-1200HRobert AdrianNo ratings yet

- Visual Inspection WeldsDocument35 pagesVisual Inspection Weldsaravindan100% (8)

- Field Inspection ReportDocument14 pagesField Inspection ReportRanjit SinghNo ratings yet

- Fabric Expansion Joints-2 PDFDocument15 pagesFabric Expansion Joints-2 PDFhbookNo ratings yet

- IndexDocument49 pagesIndexdsgs456tergdrfgdfg45qddgNo ratings yet

- Design and Fabrication of Rack and PinionDocument5 pagesDesign and Fabrication of Rack and PinionAlex Jordan50% (2)

- Standards Approvals & Certificates: Rmrs Ce DNV-GL LR Classnk Tuv BV Abs Rina TL DBDocument2 pagesStandards Approvals & Certificates: Rmrs Ce DNV-GL LR Classnk Tuv BV Abs Rina TL DBKhaled GamalNo ratings yet

- Piping Works Daily ReportDocument19 pagesPiping Works Daily ReportGomathyselviNo ratings yet

- Manual de Montacarga CatDocument20 pagesManual de Montacarga CatJulio Elias Mayta Ramos67% (6)

- GH MELTEMI - SMS Manual 2 of 3 - Fleet Instructions Manual PDFDocument226 pagesGH MELTEMI - SMS Manual 2 of 3 - Fleet Instructions Manual PDFKLM100% (1)

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- Metal Workers BizHouse - UkDocument3 pagesMetal Workers BizHouse - UkAlex BekeNo ratings yet

- Asme Sec 9Document12 pagesAsme Sec 9ckkashyap0007No ratings yet

- Spezifikation HazemagDocument3 pagesSpezifikation HazemagaansewuNo ratings yet