Professional Documents

Culture Documents

Seagull Answer Sheet

Uploaded by

lalchahanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seagull Answer Sheet

Uploaded by

lalchahanCopyright:

Available Formats

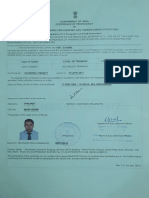

DIRECTORATE GENERAL OF SHIPPING

TRAINING RECORD BOOK (TRB) FOR RATINGS FORMING PART OF AN ENGINEERING WATCH

Prepared in compliance with the 2010 Manila amendments to the STCW Convention and Code and is approved by the Directorate General of Shipping (DGS), Government of India.

INDoS No. :19GM1768

Trainee Rating’s Particulars:

19GM1768

Name of the : BP Marine Academy - Panvel MTI No. : 201002

Name : MOHAMMAD BELAL Date of Birth : 25-MAY-1994

INDoS Number : 19GM1768 Indian CDC Number : MUM 426417

Signature of Rating :

Certification of the Company

Representative/Authorized person of RPSL Company

This is to certify that the information provided in the Record of Sea Service is true and accurate and record of Structured Shipboard Training in accordance with STCW 2010, Table A-III/4, has been received by the Trainee

Rating.

Date : Signature of Authorized Person

Place : Authorized Person’s Name : INDoS No. :

Official Stamp

Name of RPSL Company :

RPSL Number :

Report printed on : 22/02/2024 10.52 AM INDoS No. : 19GM1768 Page 1 of 8

Guideline for Completion of this Book

For the attention of Chief Engineer Officer, Designated Training Officers and Ratings

The purpose of this onboard Training Record book is to ensure that Ratings follow a structured programme of practical training during their sea service.

This training book will be required to be submitted to the facilitation centres appointed by Director General of Shipping after completing all the tasks mentioned in the record book.

Proper use and completion of the Record Book is very essential. It should be scrutinized by Chief Engineer Officer of the ships on which the rating serves and by the Designated Training Officer on board the vessel and the

shipping Company.

On receipt of this Record Book

The rating should complete the information required, including details of basic training received in accordance with the STCW Convention. The Trainee will be personally responsible for:

a)Maintaining this record book in clean and tidy condition.

b)Filling in details as and when required.

c)Drawing attention of Senior Engineer Officers on board towards training for different tasks as tasks as mentioned in the book.

d)Providing reasons from Designated Training Officers for inability to complete part of the Training.

On joining each ship

On joining ship Rating should report to the Designated Training Officer appointed by Chief Engineer Officer and present the TAR Book. Designated Training Officer should check progress of training of the rating regularly. The

rating should be provided with the following during training period:

1.Appropriate guidelines and training material.

2.Ensure that the rating understands responsibilities towards training.

3.Monitor the progress of the training on board.

During seagoing service.

Training tasks and record of achievements which are listed in this Book should be progressively completed. Chief Engineer Officer should inspect the book regularly and should record his comments.

19GM1768

The shipboard training officer must inspect this record book once the rating joins the vessel and subsequently every 2 weeks.

After Leaving the Ship

Rating should present the TAR Book to the Company Training Officer/Authorized Person of RPSL Company for his signature and further action as per DGS Circular.

Record of Sea Service

IMO Date Total Sea Service Ship’s

Ship Number GRT Master’s Signature Stamp

Signed on Signed off Months Days

Total Services:

Report printed on : 22/02/2024 10.52 AM INDoS No. : 19GM1768 Page 2 of 8

Designated Training Office & CEO’s review of Rating’s Training Progress

Ship Comments of STO Signature with Date of STO Comments of CEO Signature with Date Stamp

19GM1768

Signature of Authorized Person

Report printed on : 22/02/2024 10.52 AM INDoS No. : 19GM1768 Page 3 of 8

Rating forming a Part of Engine Room Watch

To be completed by a Ship Training Officer (STO) and Certified by the Chief Engineer

FUNCTION: Marine engineering at the support level

COMPETENCE: Carry out a watch routine appropriate to the duties of a rating forming part of an engine room watch.

1 Understand orders and be understood in matters relevant to watch keeping duties

Task/Duty Signature Date

1.1 Demonstrate correct use of terms used in the machinery spaces and the names of various machinery and equipment.

1.2 Identify different machinery units in the engine room with their names.

1.3 Observe and note normal parameters of various machineries in the engine room.

1.4 Know and identify various parts of machineries like, Cylinder head, Jacket, piston, inlet exhaust valves, Fuel injectors, crank case,

Know and identify different portable hand tools such as spanners, hack saws, screw drivers, Hole Punches, Hammers, Chisels, Centre Punch, scissors, files etc.

1.5

1.6 Read and ascertain different parameters of machinery and equipment like pressure, temperature, level etc.

1.7 Open up different type of simple filters such as bilge filters, Lubrication oil filters, air filters etc, clean and box back.

1.8 Understand different grades of fuel oil used and locate their storage tanks.

1.9 Understand that various grades of lubricating oil used and locate their storage tanks.

19GM1768

1.10 Locate and identify different types of valves in the engine room and operate them.

1.11 Ascertain Lub. Oil level in the auxiliary engines and replenish if required.

1.12 Assist in transferring F.O. from D.B. Tank to settling tanks.

1.13 Ascertain all lubricating point in running auxiliary engines and lubricate them when needed.

1.14 Locate the lubricating oil tank for stern tube seals and report to Engineer if anything abnormal found.

1.15 Feel the temperature of different running machinery by hand and report if any abnormality found.

1.16 Identify the normal sound produced by different running machineries and report for any abnormal sound.

1.17 Ascertain vibrations produced by different running machineries and report if any abnormal vibration found.

1.18 Drain water from main air cylinders regularly.

1.19 Ascertain air quantity in Sea Water and Fresh Water Hydrophor Tanks. Charge air if necessary.

1.20 Ascertain the quality of exhaust gas coming out of the funnel and report if any abnormality found.

Signature of Authorized Person

Report printed on : 22/02/2024 10.52 AM INDoS No. : 19GM1768 Page 4 of 8

1.21 Ascertain the bilge level in the engine room, report if high.

1.22 Check for any Fuel oil leakages from running engines.

1.23 Check for any Lub. Oil leakages from running engines.

1.24 Check for any Cooling water leakages from running engines.

1.25 Clean all running machinery at suitable intervals.

1.26 Identify different types of Gland Packing and their uses.

1.27 Check for any leakages from various valve glands.

1.28 Rectify if any valve gland found leaking.

1.29 Identify different types of joints used for sealing.

1.30 Demonstrate ability to cut different type of joints according to the required sizes.

1.31 Assist Duty Engineer with preparations for manoeuvring.

1.32 Assist duty Engineer for sea watches.

1.33 Assist Duty Engineer for port or anchor watches.

19GM1768

1.34 Assist duty engineer during arrival port.

1.35 Assist duty engineer during departure port.

1.36 Assist Duty Engineer for shutting down Main Engine plant after receiving FWE.

1.37 During sea passage ascertain all cylinder lubricators are working, report if any abnormality found.

1.38 Ascertain Lub Oil level in each Main Engine Lubricators, replenish if required.

1.39 Assist engineers while opening units, cleaning parts and boxing back.

1.40 Identify various electrical equipment like alternators, Main Switch board, Motors, starters etc.

1.41 Understands the meaning of various safety symbols pasted at various places in the ship including Engine room.

1.42 Lists out the gear needed to be worn for protection of Head, eyes, Feet, hands, ear etc.

Signature of Authorized Person

1.43 Explains the need of permit to work.

1.44 Demonstrate safe procedures for entry into confined spaces.

Report printed on : 22/02/2024 10.52 AM INDoS No. : 19GM1768 Page 5 of 8

1.45 Demonstrate safe procedure for working below floor plates.

1.46 Demonstrate ways to handle heavy load safely.

1.47 Demonstrate knowledge of pollution by various substances.

1.48 Demonstrate knowledge of basic MARPOL rules for prevention of pollution of sea by oil.

1.49 Demonstrate ability to use ship’s internal communication system correctly.

1.50 Demonstrate ability to use ship’s alternate emergency communication effectively.

1.51 Demonstrate knowledge of location of communication equipment placed at various spaces.

1.52 Demonstrate knowledge about Engine room alarm system.

1.53 Demonstrate knowledge about grouping of alarms in the engine control room.

1.54 Demonstrate ability to identify the source or cause of alarm.

1.55 Demonstrate ability to acknowledge alarm in engine control room and informing duty engineer.

1.56 Demonstrate knowledge to distinguish engine room fire extinguishing gas release alarm.

1.57 Demonstrate knowledge actions to be taken after hearing engine room fire extinguishing gas release alarm.

FUNCTION: Marine engineering at the support level

2.1

2.2

19GM1768

COMPETENCE:For keeping a boiler watch:Maintain the correct water levels and steam pressure.

Task/Duty

Demonstrate knowledge about following before firing a boiler:Oil Temp, Pre purge, Water level in boiler

Assist in bring up water level in boiler manually.

STO Signature Date

2.3 Assist in starting a boiler.

2.4 Assist in change over of fuel from diesel to heavy oil.

2.5 Assist in opening up the main steam stop valve.

2.6 Demonstrate ability to detect leakages of steam/water from steam pipes/ manhole or hand hole doors.

2.7 Demonstrate knowledge of flame failure alarm and it’s importance.

2.8 Check water level locally and remotely.

2.9 Assist in soot blowing operation.

2.10 Check for contamination of condensate return water with oil

Report printed on : 22/02/2024 10.52 AM INDoS No. : 19GM1768 Page 6 of 8

2.11 Assist stopping/ closing down a boiler.

3 Competence: Operate emergency equipment and apply emergency procedure.

Task/Duty STO Signature Date

3.1 Demonstrate ability to take correct actions on hearing fire alarm

3.2 Demonstrate ability to take correct actions on Generator black outs.

3.3 Demonstrate ability to take correct actions on stoppage of Main Engine at sea.

3.4 Assist I changing over to emergency steering system.

3.5 Demonstrate ability to take correct actions on oil spill drill.

3.6 Demonstrate ability to start emergency fire pump and maintain pressure in fire main.

3.7 Demonstrate ability to start emergency air compressor to fill up emergency air bottle.

3.8 Assist in starting emergency generator alternate manual mode.

19GM1768

3.9 Assist with a drill of closing all ventilation flaps prior release of fire extinguishing gas.

3.10 Locate the place where personal safety equipment i.e. Life jacket, emergency escape breathing apparatus are stored in the engine room.

3.11 Demonstrate escape through engine room escape root.

3.12 Check of any hindrance in the emergency escape route.

3.13 Check that emergency escape root is well illuminated.

3.14 Familiarity with the location and use of fire fighting equipment in the machinery spaces.

3.15 Demonstrate correct actions on seeing a fire in engine room.

3.16 Perform duties successfully in fire in Engine Drill.

3.17 Take part in drill of fire extinguishing gas release in to the engine room.

Signature of Authorized Person

3.18 Assist in shutting down quick closing valves remotely.

3.19 Assist in shutting down E.R. blowers, Pumps etc remotely.

3.20 Demonstrate ability to use effectively portable Foam type Fire Extinguisher.

Report printed on : 22/02/2024 10.52 AM INDoS No. : 19GM1768 Page 7 of 8

3.21 Demonstrate ability to use effectively portable Dry Powder type Fire Extinguisher.

3.22 Demonstrate ability to use effectively portable CO2 Fire Extinguisher.

3.23 Demonstrate donning of Fireman’s outfit correctly.

3.24 Demonstrate donning of breathing apparatuses correctly.

3.25 Take part in fire patrol.

Signature of Authorized Person

19GM1768

Report printed on : 22/02/2024 10.52 AM INDoS No. : 19GM1768 Page 8 of 8

You might also like

- Load WKReportDocument8 pagesLoad WKReportgulla srinivasaraoNo ratings yet

- Tar BookDocument8 pagesTar BookRaj RiderNo ratings yet

- Pavan Shere Taar BookDocument11 pagesPavan Shere Taar Bookpavanshere1998No ratings yet

- 201806060508043021916DGS - Cir - 18 - 2018 - TRG Authorized Signatory MTIDocument2 pages201806060508043021916DGS - Cir - 18 - 2018 - TRG Authorized Signatory MTIshwetabh sharmaNo ratings yet

- Adobe Scan 03 Dec 2021Document1 pageAdobe Scan 03 Dec 2021Amit SharmaNo ratings yet

- Certificate of Class: Lloyd's Register EMEADocument3 pagesCertificate of Class: Lloyd's Register EMEANevzat AlkoçNo ratings yet

- Reporting Checklist For Officers/Petty Officers/Trainees: Section: Form: 02page: 4 4of 4Document4 pagesReporting Checklist For Officers/Petty Officers/Trainees: Section: Form: 02page: 4 4of 4Sarin Ramakrishna Kartha HariNo ratings yet

- COPDGSOAC2022898: (Regulation V/1-1 Paragraph 2 of STCW Convention, As Amended)Document1 pageCOPDGSOAC2022898: (Regulation V/1-1 Paragraph 2 of STCW Convention, As Amended)Danish AnsariNo ratings yet

- Ab-Utpal Kumar - STCWDocument4 pagesAb-Utpal Kumar - STCWUtpal KantNo ratings yet

- On Board Training Record Book: Officers in Charge of An Engineering Watch Engineer Officer Class Iii (Eoc-Iii)Document104 pagesOn Board Training Record Book: Officers in Charge of An Engineering Watch Engineer Officer Class Iii (Eoc-Iii)Dwiki Ardiansyah SaputraNo ratings yet

- Officer's Particulars: Musat Radu-StefanDocument7 pagesOfficer's Particulars: Musat Radu-StefanRadu M.No ratings yet

- Officer's Particulars: Musat Radu-StefanDocument7 pagesOfficer's Particulars: Musat Radu-StefanRadu M.No ratings yet

- Chartership Application Guidelines Booklet V 5Document21 pagesChartership Application Guidelines Booklet V 5RICROD71No ratings yet

- Oil Pollution Prevention Certificate DetailsDocument7 pagesOil Pollution Prevention Certificate DetailsVirtual ExtrovertNo ratings yet

- Apl Sec 17-C - AsmDocument8 pagesApl Sec 17-C - AsmMik SerranoNo ratings yet

- Assesment Checklist Nautical RevisedDocument1 pageAssesment Checklist Nautical RevisedPhase One Cheif MateNo ratings yet

- DC BASIC GAS at Ravi Ranjan KumarDocument1 pageDC BASIC GAS at Ravi Ranjan KumarRAVI RANJAN KUMARNo ratings yet

- TRB Att IiiDocument99 pagesTRB Att IiiIkram MadridistaNo ratings yet

- DGS India Ship Assessment ChecklistDocument2 pagesDGS India Ship Assessment ChecklistChetanNo ratings yet

- DGS Circular 22 dt.02.06.2020Document57 pagesDGS Circular 22 dt.02.06.2020Rakesh VaikomNo ratings yet

- GREF personnel management guideDocument331 pagesGREF personnel management guideatanuchandrima100% (1)

- Application Form 29Document5 pagesApplication Form 29ashish ranjanNo ratings yet

- AcrysilDocument205 pagesAcrysilTotmolNo ratings yet

- FSI Form A PDFDocument1 pageFSI Form A PDFOnkars SinghNo ratings yet

- Standard Operating Procedures For Igf Cop-25-01-21Document7 pagesStandard Operating Procedures For Igf Cop-25-01-21Ashok KumarNo ratings yet

- BQADOC1633Document707 pagesBQADOC1633Tran ChrisNo ratings yet

- WCT - TP02 - MS - Ar - 0003 R5Document21 pagesWCT - TP02 - MS - Ar - 0003 R5yasinsparktimerNo ratings yet

- Ojt Booklet B2Document20 pagesOjt Booklet B2raviNo ratings yet

- TRB 1-10Document10 pagesTRB 1-10khara teanoNo ratings yet

- Reportservlet PDFDocument11 pagesReportservlet PDFclintonNo ratings yet

- Document of Compliance For ISMDocument2 pagesDocument of Compliance For ISMcaptainajaykumaryadavNo ratings yet

- CHECK LIST FOR ABLE SEAFARER CERTIFICATIONDocument1 pageCHECK LIST FOR ABLE SEAFARER CERTIFICATIONAnindya DeyNo ratings yet

- Oisd-Std-129 - INSPECTION OF STORAGE TANKSDocument56 pagesOisd-Std-129 - INSPECTION OF STORAGE TANKSAnoopNo ratings yet

- Form AOC-4-11122019 - SignedDocument16 pagesForm AOC-4-11122019 - SignedNi007ckNo ratings yet

- Director General of Shipping: Subject: Certification of Ratings Forming Part of A Navigational / Engineering WatchDocument3 pagesDirector General of Shipping: Subject: Certification of Ratings Forming Part of A Navigational / Engineering Watchaolaya14No ratings yet

- Sps NewDocument5 pagesSps NewDelta MaritimeNo ratings yet

- 1 ClassDocument3 pages1 ClassLuu Quang HoaNo ratings yet

- Cargo Ship Safety Equipment Certificate (HarmoDocument3 pagesCargo Ship Safety Equipment Certificate (HarmoRay ShippingNo ratings yet

- Condition Evaluation ELBEDocument8 pagesCondition Evaluation ELBElmNo ratings yet

- Certificate of ClassificationDocument2 pagesCertificate of ClassificationVirtual ExtrovertNo ratings yet

- SOM 6.1 D3 Chief Officer Handover Report Rev 0.0Document3 pagesSOM 6.1 D3 Chief Officer Handover Report Rev 0.0Amit BhadauriaNo ratings yet

- Agm Egm Imh 20220419Document204 pagesAgm Egm Imh 20220419Contra Value BetsNo ratings yet

- 582 Form Basic Practical Part LogbookDocument23 pages582 Form Basic Practical Part LogbookTrần Triệu PhongNo ratings yet

- PROPOSED STCW CIRCULAR AB DeckDocument12 pagesPROPOSED STCW CIRCULAR AB DeckFEMFI ENGINENo ratings yet

- Material Approval Submission: Jazz City KulimDocument13 pagesMaterial Approval Submission: Jazz City KulimMuhamad Yazid Bin Md YatinNo ratings yet

- S HRN SDL 137 Resolution 202136312113Document128 pagesS HRN SDL 137 Resolution 202136312113helloNo ratings yet

- 船上訓練記錄簿Document137 pages船上訓練記錄簿YUAN TSAINo ratings yet

- Form No. Aoc-4: Form For Filing Financial Statement and Other Documents With The RegistrarDocument14 pagesForm No. Aoc-4: Form For Filing Financial Statement and Other Documents With The RegistrarA KumarNo ratings yet

- Tar BookDocument2 pagesTar BookRaj RiderNo ratings yet

- Job Desc Crewing CoordinatorDocument3 pagesJob Desc Crewing Coordinatorsudarmadi100% (4)

- GARBAGE MANAGEMENT MANUALDocument21 pagesGARBAGE MANAGEMENT MANUALAnant Ajithkumar100% (1)

- DG Article of AgreementDocument12 pagesDG Article of AgreementkevinmNo ratings yet

- Aircraft Maintenance Engineer S Log BookDocument39 pagesAircraft Maintenance Engineer S Log BookPhellipe CovetousNo ratings yet

- MX MDR Technologies LTD Finincial For Year 2018-19-220812 - 202646Document111 pagesMX MDR Technologies LTD Finincial For Year 2018-19-220812 - 202646Grimisha BandagaleNo ratings yet

- 3 - Copy of The SMCDocument3 pages3 - Copy of The SMCMURAT GÖNENNo ratings yet

- Design Appraisal Document: ATS/19-673/P/001 0Document21 pagesDesign Appraisal Document: ATS/19-673/P/001 0william sykesNo ratings yet

- Post Qua Report CSIS OfficeDocument4 pagesPost Qua Report CSIS OfficeKim Patrick VictoriaNo ratings yet

- MV Trans Thalia - ClassDocument3 pagesMV Trans Thalia - Class911swf911No ratings yet

- Prestige Annual Report 2019-20Document164 pagesPrestige Annual Report 2019-20KhalidNo ratings yet

- BoardingCard 335545026 OTP LPLDocument1 pageBoardingCard 335545026 OTP LPLcri29sorinNo ratings yet

- Task 2 English Maritime Anggoro Yudho PrabowoDocument3 pagesTask 2 English Maritime Anggoro Yudho Prabowoanggoro yudho prabowoNo ratings yet

- Spare Parts Catalog: 2 HL 70 Material Number: 4143.070.030 Current Date: 02.11.2020Document51 pagesSpare Parts Catalog: 2 HL 70 Material Number: 4143.070.030 Current Date: 02.11.2020ludewludew100% (1)

- Tổng Hợp Câu Hỏi Ielts Speaking Chủ Đề Travel & HolidayDocument5 pagesTổng Hợp Câu Hỏi Ielts Speaking Chủ Đề Travel & HolidaykatieNo ratings yet

- Manual de Partes MTC Husqvarna 545Document45 pagesManual de Partes MTC Husqvarna 545Brandon AlvarezNo ratings yet

- Transport and Accommodation Guide for World ChampionshipsDocument11 pagesTransport and Accommodation Guide for World ChampionshipsMeri LomidzeNo ratings yet

- 13 Things Mentally Strong People Dont Do (Telugu) by Amy MorinDocument256 pages13 Things Mentally Strong People Dont Do (Telugu) by Amy MorinPala Pala Mohankishore100% (2)

- Ad 2. Aerodromes Vanp Ad 2.1 Aerodrome Location Indicator and NameDocument21 pagesAd 2. Aerodromes Vanp Ad 2.1 Aerodrome Location Indicator and NameAyaan KhanNo ratings yet

- Ud Assign 1Document9 pagesUd Assign 1Divyanshu GuptaNo ratings yet

- CITILINK HLP-SUB-HLP 28 FEB, WYNMHV Pak Daniel PolintiusDocument1 pageCITILINK HLP-SUB-HLP 28 FEB, WYNMHV Pak Daniel PolintiusCharlesNo ratings yet

- Me Performance ReportDocument1 pageMe Performance ReportgioNo ratings yet

- Guidance On ECM Certification Process - Rotated Annexes - SonDocument168 pagesGuidance On ECM Certification Process - Rotated Annexes - SonBaşak AYSALNo ratings yet

- Fco Rail Scrap 08 - 04Document11 pagesFco Rail Scrap 08 - 04Raghavendra100% (1)

- Cell Trasport Worksheet ANSWER KEYDocument3 pagesCell Trasport Worksheet ANSWER KEYFatima Al sharifNo ratings yet

- BRAKES Park Brake Chevy SonicDocument55 pagesBRAKES Park Brake Chevy SonicSebastian RReyesNo ratings yet

- 114AL01Document1 page114AL01Mohamed AbdisalanNo ratings yet

- 15 03 2020bajajDocument48 pages15 03 2020bajajFamous AutoNo ratings yet

- Genio 13K0JL01 0Document107 pagesGenio 13K0JL01 0Aljade Luke ReaNo ratings yet

- Machine Design 2 Quiz SolutionsDocument2 pagesMachine Design 2 Quiz SolutionsMarc Graham NacuaNo ratings yet

- Customer Vehicle Mileage Telephone No Reg No Colour Job Number VIN Technician Dealer Check CompletedDocument3 pagesCustomer Vehicle Mileage Telephone No Reg No Colour Job Number VIN Technician Dealer Check CompletedSteven HamiltonNo ratings yet

- Dink (Yager GT) 50 - SM10AA (RO) - 2012.02.28Document133 pagesDink (Yager GT) 50 - SM10AA (RO) - 2012.02.28petreNo ratings yet

- 1 Ga Drawing For HT GensetDocument1 page1 Ga Drawing For HT GensetprabhumanocNo ratings yet

- MAN Engines - Portrait - ENDocument34 pagesMAN Engines - Portrait - ENOveis DarvishiNo ratings yet

- Forsan Foods Factories: Purchase OrderDocument4 pagesForsan Foods Factories: Purchase OrderMoorthy SomasundaramNo ratings yet

- Power Control System: SectionDocument80 pagesPower Control System: SectionAliNo ratings yet

- Filmora RegisterDocument1 pageFilmora RegisterHarsh Desai54% (13)

- Bendix Bxfgs70-In-C 30627Document24 pagesBendix Bxfgs70-In-C 30627Casey King100% (1)

- Highway Link DesignDocument28 pagesHighway Link DesignAhmad Fauzan Ahmad MalikiNo ratings yet

- A Perfect Storm: Australian Inter-State Freight SurgesDocument44 pagesA Perfect Storm: Australian Inter-State Freight SurgesPedro Henriques100% (1)

- RTD Regional BRT Feasibility StudyDocument93 pagesRTD Regional BRT Feasibility StudyShohel Rana TituNo ratings yet