Professional Documents

Culture Documents

Chapt 6 Rotation

Uploaded by

ManuelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapt 6 Rotation

Uploaded by

ManuelCopyright:

Available Formats

Service Training Manual ECM 580

Rotation Circuits

For normal drilling the rotation of the drifter is supplied from hydraulic

pump #1. This pump supplies 60 LPM (15.8 GPM) to the rotation

circuit. The rotation is adjustable to 5 different speed settings. This

is done by changing the position of the rotary rotation control valve

found on the drifter. A 5/8” hex wrench is required. The system also

provides a “Super Rotation” circuit. If “Super Rotation” is selected,

the rotation system valves direct rotation fluid as well as percussion

fluid through the rotation motor prior to supplying the percussion.

“Super Rotation” should not be used in normal drilling conditions

however, because high rotation speeds will drastically shorten the life

of the bit and can be detrimental to the rotation mechanism in the

drifter.

As discussed in a previous chapter, the ∆P across the rotation motor

(pressure difference between rotation and percussion) is the main

factor that regulates the Strata-Sense drilling system.

Drilling is controlled by the levers on the drill console. The position of

the percussion and rotation levers selects the drilling mode. That is;

automatic or manual drilling or super rotation. The cab control levers

are pilot operators. Pilot pressure is supplied by the # 4 hydraulic

pump.

During the rod changing cycle, the rotation is limited by relief valve #6

(PG3 in the relief valve manifold). There is a pilot to open check

valve connected to the forward rotation circuit. This valve is piloted to

open ARC pressure when the selector in the cab is placed in the ARC

(rod changer) position. At that time relief valve #6, which is set at 870

PSI (60 Bar) is connected to the rotation circuit and limits the forward

rotation pressure. This is done to prevent spinning the rod in the

ARC clamps while tightening the top coupling during rod removal.

When rattling to loosen the couplings, a small amount of fluid is

allowed to pass through the drifter rotation motor in the reverse

direction. This means that the shank or striking bar will rotate very

slowly in reverse while rattling is taking place.

Chapter 6 Page 1 Rotation Circuits

Service Training Manual ECM 580

Adjustments:

Relief valve #6 (PG3), found in the relief valve manifold, limits the

rotation pressure while in the rod changing mode. To check the

setting of this valve perform the following steps.

1. Install a 200 Kg/cm2 (3000 PSI) (200 Bar) test gauge on the #6

(PG3) relief valve test port. The test port is found on the back side of

the relief valve manifold.

2. Start the unit and place and place the engine speed switch in the

drilling position. Place the ARC/dust collector switch in the ARC

position.

3. Operate the forward rotation control with the rotation in a stalled

condition (close the centralizers on the bit).

4. Observe the test gauge at relief #3. The test gauge should

indicate 60 Kg/cm2 (670 PSI).

5. If the pressure is not correct, adjust the valve accordingly. Turn

the adjustment screw in (CW) to raise the pressure and out (CCW) to

lower the pressure.

Main Rotation Relief Valve:

The main rotation relief valve is factory preset at 140 Kg/cm2 (1990

PSI) and is not adjustable.

Rotation Speed:

Rotation speed is adjustable at the drifter. Locate the hose inlet block

at the side of the drifter. There is a round valve with a 5/8” hex key

slot. The adjustment allows 5 different rotation speed settings. The

drilling rotation speed will only be applicable while the unit is drilling.

In the rod changing cycle, rotation is always at maximum speed.

Chapter 6 Page 2 Rotation Circuits

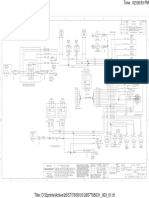

To R1 Port of Drifter To R2 Port of Drifter

Forward Rotation Reverse Rotation

"R1" "R2"

Chapter 6

Pressure signal

from inlet of

drifter valve

Rotation Percussion

Service Training Manual

Logic

Valves

"P1"

Page 3

"P2"

V3 Cut valve

Pilot to open Check Valve

Pilot pressure to

V3 valve in

Stratasense

Relief Valve #6 (PG3)

Drill Hour Manifold

60 Kg/cm 2 (670 PSI)

meter

Drill Rotate Feed

Pressure signal from

ARC circuit only when

in ARC mode

Rotation Circuits

ECM 580

Drill controls in the cab

Service Training Manual ECM 580

Chapter 6 Page 4 Rotation Circuits

Service Training Manual ECM 580

The diagrams on the following pages show the operation of the logic

valves in different operational modes.

R1 R2 Automatic Drilling

R1=Rotation

R2=Percussion

T

V2

P2

P1

Manual Drilling R1 R2

R1=Rotation

R2=Percussion

T

V2

P2

P1

Chapter 6 Page 5 Rotation Circuits

Service Training Manual ECM 580

Rattling R1 R2

R1=Rotation

R2=Percussion

T

V2

P2

P1

R1 R2 Unthreading

R1=Rotation

R2=Percussion

T

V2

P2

P1

Chapter 6 Page 6 Rotation Circuits

Service Training Manual ECM 580

R1 R2 Threading

R1=Rotation

R2=Percussion

T

V2

P2

P1

100 %

40 % X

60 % X

Logic valve operation

Chapter 6 Page 7 Rotation Circuits

Service Training Manual ECM 580

Notes:

Chapter 6 Page 8 Rotation Circuits

You might also like

- Critical Wear Areas & Vacuum Test Locations: Lower Control Body - 4R100 Non-PTO ShownDocument5 pagesCritical Wear Areas & Vacuum Test Locations: Lower Control Body - 4R100 Non-PTO Shownbelchior100% (1)

- Grinding Errors and Possible SolutionsDocument6 pagesGrinding Errors and Possible SolutionsPinak ThankiNo ratings yet

- Fdocuments - in Manual Installation Cummins 67l Paccar PX 6 Fitting 4 Jic 18 NPTDocument17 pagesFdocuments - in Manual Installation Cummins 67l Paccar PX 6 Fitting 4 Jic 18 NPTManuelNo ratings yet

- Simple Home Made PengunDocument1 pageSimple Home Made Pengundennis86% (28)

- TDS-3S Operating GuideDocument20 pagesTDS-3S Operating GuideSaidNo ratings yet

- OMS Manual PDFDocument84 pagesOMS Manual PDFRaghuNo ratings yet

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- 26brake ValveDocument26 pages26brake ValveAlexander Mugabe100% (1)

- MECHATRO HANDBOOK SELF DIAGNOSIS AND TROUBLESHOOTING GUIDEDocument40 pagesMECHATRO HANDBOOK SELF DIAGNOSIS AND TROUBLESHOOTING GUIDEPaul Galvez100% (6)

- Hydraulic System.Document95 pagesHydraulic System.zae nurdinNo ratings yet

- CCI Primer Usage Chart 10262013Document1 pageCCI Primer Usage Chart 10262013IM_JohnnyVNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Catalogo Tração CarraroDocument9 pagesCatalogo Tração Carrarotrader troladorNo ratings yet

- Overview of 140T CraneDocument163 pagesOverview of 140T Cranekr_abhijeet72356587100% (2)

- ECM 660 Hydraulic Pump and Pilot Circuit TrainingDocument48 pagesECM 660 Hydraulic Pump and Pilot Circuit TrainingJannie van Staden100% (1)

- Rotary Compressor Guide: Types and How They WorkDocument37 pagesRotary Compressor Guide: Types and How They WorkhichamNo ratings yet

- Rexroth Flush ValveDocument2 pagesRexroth Flush ValveanandsubbiahNo ratings yet

- Hydraulic Pumps: Service Training Manual ECM 720Document10 pagesHydraulic Pumps: Service Training Manual ECM 720victor laraNo ratings yet

- R55-9 1Document57 pagesR55-9 1hungNo ratings yet

- Electro-Hydraulic I/H Converter and WSR Way ValveDocument12 pagesElectro-Hydraulic I/H Converter and WSR Way ValveNAYEEM100% (1)

- Technical Manual Sections for Ingersoll-Rand Drilling MachineDocument450 pagesTechnical Manual Sections for Ingersoll-Rand Drilling MachineGUILLERMO SEGURA92% (12)

- Ra 92003 PDFDocument35 pagesRa 92003 PDFAgus Yulfizar100% (1)

- Sparte Parts - Boomer L1CDocument1,091 pagesSparte Parts - Boomer L1CManuelNo ratings yet

- Microsoft PowerPoint - ECM660 III Hyd Info Read-OnlyDocument32 pagesMicrosoft PowerPoint - ECM660 III Hyd Info Read-OnlyJannie van Staden100% (2)

- Chapter 1 Pneumatic SystemDocument19 pagesChapter 1 Pneumatic Systemdivien rajNo ratings yet

- Microsoft PowerPoint - ECM660 III BDocument51 pagesMicrosoft PowerPoint - ECM660 III BJannie van Staden100% (2)

- Hl710 Specification Sheet EnglishDocument2 pagesHl710 Specification Sheet EnglishRene Ramos MenesesNo ratings yet

- Chapter 7 Rev 2 Rotation CircuitsDocument19 pagesChapter 7 Rev 2 Rotation CircuitsAnonymous 340A7vnwV1No ratings yet

- Chapter 10 Rev 3 Rod ChangingDocument13 pagesChapter 10 Rev 3 Rod ChangingAnonymous 340A7vnwV1No ratings yet

- Pump Device Structure and FunctionDocument9 pagesPump Device Structure and FunctionJose SanchezNo ratings yet

- Section 2 Structure and FunctionDocument9 pagesSection 2 Structure and FunctionالمهندسوليدالطويلNo ratings yet

- Section 2 Structure and Function: Group 1 Hydraulic PumpDocument8 pagesSection 2 Structure and Function: Group 1 Hydraulic PumpالمهندسوليدالطويلNo ratings yet

- Section 2 Structure and FunctionDocument6 pagesSection 2 Structure and FunctionالمهندسوليدالطويلNo ratings yet

- GROUP 8 TRANSMISSION (Up To #0978) : 1. StructureDocument14 pagesGROUP 8 TRANSMISSION (Up To #0978) : 1. StructureVladimir ParamonovNo ratings yet

- CM 760/780 Hydraulic Pump Specifications and Adjustment ProceduresDocument7 pagesCM 760/780 Hydraulic Pump Specifications and Adjustment Proceduresvictor laraNo ratings yet

- CHPT 3 RotateDocument6 pagesCHPT 3 RotateManuelNo ratings yet

- Variable Pump T2VK, Bent Axis Design: For Open & Closed CircutDocument6 pagesVariable Pump T2VK, Bent Axis Design: For Open & Closed CircutPrime HydraulicsNo ratings yet

- Ch9Rotation CircuitDocument8 pagesCh9Rotation CircuitManuelNo ratings yet

- CHPT 5 DrifterDocument4 pagesCHPT 5 DrifterManuelNo ratings yet

- CHPT 4 FeedDocument6 pagesCHPT 4 FeedManuelNo ratings yet

- Cerato 1.6 2010 - Transmissão A4CF1 - EspecificaçõesDocument3 pagesCerato 1.6 2010 - Transmissão A4CF1 - EspecificaçõesWiterMarcosNo ratings yet

- 2-1. Structure and Function hx85x HyundaiDocument83 pages2-1. Structure and Function hx85x HyundaiAlfonso BerRamNo ratings yet

- 660III HYD CircuitDocument32 pages660III HYD CircuitaugustoNo ratings yet

- Manual 820-Pp AsDocument12 pagesManual 820-Pp AsjabalpuramitNo ratings yet

- Technical Training ManualDocument8 pagesTechnical Training ManualGabo Luna MorenoNo ratings yet

- Group 8 Transmission: 1. StructureDocument7 pagesGroup 8 Transmission: 1. StructureĐạt VươngNo ratings yet

- Catalogue Models F10 and F50 Flow SwitchesDocument12 pagesCatalogue Models F10 and F50 Flow SwitchesNUR AFIFAHNo ratings yet

- PH-85 Set Up - TDS 6SDocument3 pagesPH-85 Set Up - TDS 6SJim SharpNo ratings yet

- Steam Turbine Governing System 210mwDocument74 pagesSteam Turbine Governing System 210mwRajani Kanta MundaNo ratings yet

- Group 3 Pilot Circuit Solenoid Valves & ComponentsDocument9 pagesGroup 3 Pilot Circuit Solenoid Valves & ComponentsNv Thái100% (1)

- Part 4 Hydraulic Control Principle and ParametersDocument22 pagesPart 4 Hydraulic Control Principle and ParametersrohanNo ratings yet

- 3.hydraulic and Electrical SystemDocument35 pages3.hydraulic and Electrical Systempangel29No ratings yet

- GCV & SRV ServovalveDocument11 pagesGCV & SRV ServovalvechdiNo ratings yet

- Hyundai R450LC-7 Pilot CircuitDocument20 pagesHyundai R450LC-7 Pilot CircuitHai VanNo ratings yet

- Chapter 2 Rev 3 Hydraulic PumpsDocument9 pagesChapter 2 Rev 3 Hydraulic PumpsAnonymous 340A7vnwV1No ratings yet

- 2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPDocument17 pages2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPPaco Caballero SaorinNo ratings yet

- Case Study - Unexpected Vibraion On A Centrifugal Compressor Caused by Vibration Probe SupportDocument23 pagesCase Study - Unexpected Vibraion On A Centrifugal Compressor Caused by Vibration Probe SupportLong Nguyen100% (1)

- Z2FS 6 New Series... 40BDocument6 pagesZ2FS 6 New Series... 40Bnemi90No ratings yet

- 2015 G 1.2 MPI KAPPA Automatic Transaxle SpecsDocument49 pages2015 G 1.2 MPI KAPPA Automatic Transaxle SpecsHikmah Jevie YusriNo ratings yet

- Automatic Transaxle ., ") 7 A 0 "P ,:, , ..R: "+Document83 pagesAutomatic Transaxle ., ") 7 A 0 "P ,:, , ..R: "+captne76100% (1)

- Optimize Hydraulic System Circuit DiagramDocument11 pagesOptimize Hydraulic System Circuit DiagramManuals CE & AgNo ratings yet

- Control ValveDocument35 pagesControl Valveshivani DubeyNo ratings yet

- Oil Pump Type T GEAR SIZES 2-3-4-5Document2 pagesOil Pump Type T GEAR SIZES 2-3-4-5Eden Ben100% (1)

- General Service. Bulletin RTAA-SB - 4. Lit TRANE - SL Ide Valve Operat Ion and Troubleshoot I Ng. SuDocument6 pagesGeneral Service. Bulletin RTAA-SB - 4. Lit TRANE - SL Ide Valve Operat Ion and Troubleshoot I Ng. Suahmed gamalNo ratings yet

- Montacargas DP 100 - LL2SPEEDDocument57 pagesMontacargas DP 100 - LL2SPEEDJonny Zambrano MeraNo ratings yet

- Pantera1100 T 7Document43 pagesPantera1100 T 7Danet SutrisnoNo ratings yet

- 10 Major Minor Block Hydraulics Detail Nov 2006Document32 pages10 Major Minor Block Hydraulics Detail Nov 2006marceloNo ratings yet

- Prince Hydraulics Sectional Body Model SV Offered by PRC Industrial SupplyDocument18 pagesPrince Hydraulics Sectional Body Model SV Offered by PRC Industrial SupplyPRC Industrial SupplyNo ratings yet

- ECM720 coverDocument2 pagesECM720 coverManuelNo ratings yet

- Chapter 9 Feed CircuitDocument10 pagesChapter 9 Feed CircuitManuelNo ratings yet

- Chapter 9 Feed CircuitDocument10 pagesChapter 9 Feed CircuitManuelNo ratings yet

- im6088Document48 pagesim6088ManuelNo ratings yet

- Orbitol Motor TMTHWDocument20 pagesOrbitol Motor TMTHWRodolfo ErenoNo ratings yet

- Chapter 2 Hyd PumpDocument8 pagesChapter 2 Hyd PumpManuelNo ratings yet

- Electrical Schematic 2657795031 003Document4 pagesElectrical Schematic 2657795031 003ManuelNo ratings yet

- Chapt 2 PumpsDocument6 pagesChapt 2 PumpsManuelNo ratings yet

- Orbitol Motor TMTHWDocument20 pagesOrbitol Motor TMTHWRodolfo ErenoNo ratings yet

- Hyd Schematic 2657787657 003 01Document3 pagesHyd Schematic 2657787657 003 01ManuelNo ratings yet

- ROC D7 D9 and D7LF - 9851 2418 01g HighresDocument4 pagesROC D7 D9 and D7LF - 9851 2418 01g HighresManuelNo ratings yet

- Parker (P70CF, P70CP) Directional Control Valves, Open CenterDocument32 pagesParker (P70CF, P70CP) Directional Control Valves, Open CenterManuelNo ratings yet

- GX Dynapac InternationalDocument55 pagesGX Dynapac InternationalManuelNo ratings yet

- Roc 442PCDocument5 pagesRoc 442PCluizpmrNo ratings yet

- ENG Scooptram RRC Operator Material - Uppdated - OscarDocument69 pagesENG Scooptram RRC Operator Material - Uppdated - OscarManuelNo ratings yet

- Air Filters For Europiclon Air Cleaners PDFDocument4 pagesAir Filters For Europiclon Air Cleaners PDFManuelNo ratings yet

- Terminales de Tubo de CobreDocument3 pagesTerminales de Tubo de CobreManuelNo ratings yet

- Cummins Engine EGR Fault CodesDocument4 pagesCummins Engine EGR Fault CodesManuelNo ratings yet

- 3319 Roc 203Document1 page3319 Roc 203ManuelNo ratings yet

- Roc 442PCDocument5 pagesRoc 442PCluizpmrNo ratings yet

- Spec Ranger Dx700 t4 4 en 16228 WebDocument3 pagesSpec Ranger Dx700 t4 4 en 16228 WebManuelNo ratings yet

- Engine Air Replacement Filters: The New StandardDocument4 pagesEngine Air Replacement Filters: The New StandardManuelNo ratings yet

- Rotary compressor data sheetDocument1 pageRotary compressor data sheetEnd SoonNo ratings yet

- Spec Ranger Dx700 t4 4 en 16228 WebDocument3 pagesSpec Ranger Dx700 t4 4 en 16228 WebManuelNo ratings yet

- Stainless Steel Swing Check Valve: Threaded Connection - 200 WOGDocument1 pageStainless Steel Swing Check Valve: Threaded Connection - 200 WOGJuan Gutierrez CastilloNo ratings yet

- Data Item PlastikanDocument196 pagesData Item PlastikanAdy YudaNo ratings yet

- Übersicht SOTS BeanstandteileDocument1 pageÜbersicht SOTS Beanstandteilelwin84.lwNo ratings yet

- Din 13-23Document21 pagesDin 13-23rajeskumarNo ratings yet

- Kitchen Selector Pricelist 2015 MRP PDFDocument26 pagesKitchen Selector Pricelist 2015 MRP PDFSachin SachdevNo ratings yet

- Marposs T18 For HAAS LatheDocument1 pageMarposs T18 For HAAS Lathealejandro777_eNo ratings yet

- Annexure IVa - GCH FPS FAPA LOMDocument5 pagesAnnexure IVa - GCH FPS FAPA LOMwaz ahmedNo ratings yet

- Land and Weapon SystemsDocument1 pageLand and Weapon SystemsJuan FacundoNo ratings yet

- Pipeline Pigging Handbook 10Document1 pagePipeline Pigging Handbook 10Bruno GonçalvesNo ratings yet

- SF Flow Switch RielsDocument2 pagesSF Flow Switch RielsEdwin Angel Solis VitorNo ratings yet

- 32 322 Dc2 Groheminta™ Single-Lever Sink Mixer 1/2": Product DescriptionDocument2 pages32 322 Dc2 Groheminta™ Single-Lever Sink Mixer 1/2": Product DescriptionCesar Alfredo TrejoNo ratings yet

- Manual Corta Pescuezos Jarvis CPEDocument8 pagesManual Corta Pescuezos Jarvis CPEJorge Jimenez100% (1)

- Design of Machine Element-1Document23 pagesDesign of Machine Element-1rutvikvavale0375No ratings yet

- STS-Axle Kit Parts - Lock Down (Tubos, Soportes y Seguros)Document1 pageSTS-Axle Kit Parts - Lock Down (Tubos, Soportes y Seguros)Jose Luis DominguezNo ratings yet

- DIN 11850 Sanitary Tubes Specification SheetDocument2 pagesDIN 11850 Sanitary Tubes Specification SheetPrithpal RawatNo ratings yet

- Conventional Vs Glass CockpitDocument15 pagesConventional Vs Glass Cockpitparas100% (1)

- GALIL LESSON 8 (Pamphlet)Document4 pagesGALIL LESSON 8 (Pamphlet)Curtis DavidsonNo ratings yet

- Hydrostatic Testing Procedure 02250-1Document2 pagesHydrostatic Testing Procedure 02250-1RanielNo ratings yet

- CU400 CU500: Machine SpecificationDocument4 pagesCU400 CU500: Machine SpecificationГеорги НеновNo ratings yet

- Bahir Dar Institute of Technology (BIT) Introduction To Robotics and AutomationDocument24 pagesBahir Dar Institute of Technology (BIT) Introduction To Robotics and AutomationBelayneh BirhanNo ratings yet

- Ariel Corporation sales order parts listDocument46 pagesAriel Corporation sales order parts listpapashoNo ratings yet

- Manual de Partes 027CL (2015 - 03 - 28 03 - 12 - 03 UTC)Document75 pagesManual de Partes 027CL (2015 - 03 - 28 03 - 12 - 03 UTC)Julio Chapilliquen SandovalNo ratings yet

- Parts List: Industrial Sewing MachinesDocument37 pagesParts List: Industrial Sewing MachinesTharindu50% (2)

- Power Steering: PreparationDocument1 pagePower Steering: PreparationClodoaldo BiassioNo ratings yet

- Maintain Farm Facilities SafelyDocument4 pagesMaintain Farm Facilities Safelyrolando baletaNo ratings yet