Professional Documents

Culture Documents

Geeta Engineering Liquid Penetrant Examination Report 07.02.2022

Geeta Engineering Liquid Penetrant Examination Report 07.02.2022

Uploaded by

Pranali NDT Services0 ratings0% found this document useful (0 votes)

7 views1 pageThis document provides a liquid penetrant examination report for weld joints of a rudder on a ship. It summarizes the test details, materials tested, procedures followed, and results. No recordable indications were observed on the full penetration joints tested, consisting of plates of various thicknesses welded together. The test was carried out according to applicable ASME and ASTM standards and the welds were found acceptable.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a liquid penetrant examination report for weld joints of a rudder on a ship. It summarizes the test details, materials tested, procedures followed, and results. No recordable indications were observed on the full penetration joints tested, consisting of plates of various thicknesses welded together. The test was carried out according to applicable ASME and ASTM standards and the welds were found acceptable.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageGeeta Engineering Liquid Penetrant Examination Report 07.02.2022

Geeta Engineering Liquid Penetrant Examination Report 07.02.2022

Uploaded by

Pranali NDT ServicesThis document provides a liquid penetrant examination report for weld joints of a rudder on a ship. It summarizes the test details, materials tested, procedures followed, and results. No recordable indications were observed on the full penetration joints tested, consisting of plates of various thicknesses welded together. The test was carried out according to applicable ASME and ASTM standards and the welds were found acceptable.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

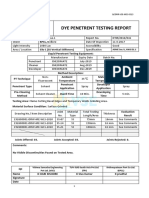

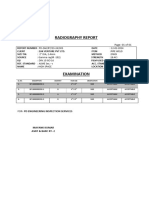

LIQUID PENETRANT EXAMINATION REPORT

CLIENT: M/S. GEETA ENGINEERING WORKS PVT. LTD.

Test Report No. : PNDT/MD/DP/215/2022 Description of Item Tested: Weld Joints of Rudder (STBD)

Test Date : 07/02/2022 (THANE) Stage of Examination: After Welding

MATERIAL: IRS Gr. B Surface condition : Satisfactory

LPT DETAILS :

Surface Temperature Ambient Penetrant Make & ID Pradeep Batch no-7615

Penetrant Test Technique Solvent Removable Visible Dye Developer Make & ID Pradeep Batch no-7628

Stage of Examination After Welding Cleaner Make & ID Pradeep Batch no-7627

Extent of Examination 100 % Sensitivity Block No. None

Method of application Spraying Illumination 1076 lux

Penetrant Dwell time 10 minutes Surface cleaning Wiping with Solvent

Drying method Natural Evaporation/Air Viewing conditions 100 Watt Bulb 1076 lux

Post cleaning method Wiping with Solvent Method of recording flaws Marking

Reference Documents :

PT Specification ASME Sec. V Article ,6 & ASTM SE-165

Acceptance Standard ASME Sec. VIII , Appendix - 8

TEST RESULTS

SIR. NO. ITEM IDENTIFICATION OBSERVATION RESULTS

1. YARD NO: 3027

FULL PENETRATION JOINTS:

1) RUDDER STOCK WITH TOP PLATE (Circular joints) :

25 MM THICK

NO RECORDABLE ACCEPTABLE TO

2) I) TOP PLATE: 25MM THICK II) NOSE PLATE: 16 MM INDICATION SPECIFICATION

THICK III) COVER PLATE: 12 MM THICK OBSERVED

3) I)BOTTOM PLATE: 25MM THICK II)COVER PLATE:

12 MM THICK III) NOSE PLATE: 16 MM THICK

4) I) NOSE PLATE: 16 MM THICK II) COVER PLATE

(Vertical joint) : 12 MM THICK

TEST CARRIED BY MR. SUNIL YADAV- NDT LEVEL-II

FOR PRANALI NDT SERVICES CLIENT WITNESSED BY

MR. HARSHAD ARONDKAR

(IRS)

You might also like

- Test Reports - NBRDocument105 pagesTest Reports - NBRImtiyaz KhanNo ratings yet

- Acid Cleaning ReportDocument1 pageAcid Cleaning Reportg_sanchetiNo ratings yet

- FORTA-FERRO - Guide SpecificationDocument1 pageFORTA-FERRO - Guide SpecificationSamiNo ratings yet

- Water Tank-Sail WB 6KLDocument1 pageWater Tank-Sail WB 6KLRiyu RathodNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document1 pageDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Test PackDocument17 pagesTest PackMuhammad Bilal Arif100% (4)

- Arudra Engineers LPT ProcedureDocument3 pagesArudra Engineers LPT ProcedureSundar KpNo ratings yet

- STIR (Surface Treatment Inspection) Qaqc-003Document1 pageSTIR (Surface Treatment Inspection) Qaqc-003AliDadKhanNo ratings yet

- LPT Report.Document6 pagesLPT Report.Narendra VermaNo ratings yet

- Report TemplateDocument3 pagesReport TemplatePretech AnandNo ratings yet

- Corr-Con Inspection Services: Coating Procedure Test (CPT) ReportDocument4 pagesCorr-Con Inspection Services: Coating Procedure Test (CPT) ReportArun Prasad100% (1)

- Drillen UT Report-SodetailDocument1 pageDrillen UT Report-SodetailGaurang PandyaNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Client:: Sritech Electronics Systems PVT LTDDocument2 pagesClient:: Sritech Electronics Systems PVT LTDESHWAR CHARYNo ratings yet

- PT InternalDocument1 pagePT Internalwidnu wirasetiaNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Arandela Plana Galv Cal 58Document1 pageArandela Plana Galv Cal 58knery684No ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MP100% (1)

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- WPS - 025Document4 pagesWPS - 025MAT-LIONNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- VRM 2 UT and MPT ReportsDocument3 pagesVRM 2 UT and MPT ReportsSunny G CNo ratings yet

- SATRDocument1 pageSATRAhmed BoraeyNo ratings yet

- Method Statement Format SuranderDocument13 pagesMethod Statement Format SuranderSurya PrakashNo ratings yet

- Inspection Report: Setcore Arabia Petroleum ServiceDocument1 pageInspection Report: Setcore Arabia Petroleum ServiceMahmoud SalahNo ratings yet

- Dye Penetrant Inspection ProcedureDocument6 pagesDye Penetrant Inspection ProcedureRidoNo ratings yet

- Ultrasonic Examination Report: The Royal Utilisation Services Pvt. LTDDocument9 pagesUltrasonic Examination Report: The Royal Utilisation Services Pvt. LTDNazmul HasanNo ratings yet

- Hydro Test ProceduresDocument6 pagesHydro Test ProcedureswillNo ratings yet

- Hil Renukoot Ut 2022-2023Document249 pagesHil Renukoot Ut 2022-2023duttcon engineeringNo ratings yet

- Field Density TestDocument14 pagesField Density Testsridevi73No ratings yet

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Document2 pagesQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTONo ratings yet

- Test Certificate (Declaration of Conformity) : Material TestedDocument6 pagesTest Certificate (Declaration of Conformity) : Material TestedSarath PillaiNo ratings yet

- Hydro Test Procedure For y Type StrainerDocument8 pagesHydro Test Procedure For y Type StrainernarendraNo ratings yet

- Ut 2829Document1 pageUt 2829quality cncNo ratings yet

- 9952T 1311 F0001 PD2 A CDocument169 pages9952T 1311 F0001 PD2 A CBarbara HowellNo ratings yet

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- NDT Procedure - PCN - Test1Document32 pagesNDT Procedure - PCN - Test1Pedro Oliveira100% (2)

- Coupler Plate DP TestDocument1 pageCoupler Plate DP Testshindemitesh17No ratings yet

- L.P.T Reports.Document12 pagesL.P.T Reports.Shaikh AdilNo ratings yet

- 2009 BV SocketWelded DatasheetDocument2 pages2009 BV SocketWelded DatasheetAqib Khan VCSPNo ratings yet

- 09,10.02.2023 PT ReportsDocument3 pages09,10.02.2023 PT ReportsSIS CERTIFICATIONSNo ratings yet

- Doosan Power Systems India PVT Limited: Magnetic Particle Examination ReportDocument1 pageDoosan Power Systems India PVT Limited: Magnetic Particle Examination ReportBalkishan DyavanapellyNo ratings yet

- 06.04.2023 PT ReportsDocument2 pages06.04.2023 PT ReportsSIS CERTIFICATIONSNo ratings yet

- Satr H 1003Document1 pageSatr H 1003Moghal AliNo ratings yet

- Inspection DishendDocument5 pagesInspection DishendVarun MalhotraNo ratings yet

- Ut PWPS 001Document1 pageUt PWPS 001Goutam Kumar Deb100% (1)

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Test Certificate Kawalbir SinghDocument1 pageTest Certificate Kawalbir SinghSusrutAdapakaNo ratings yet

- Air Comp 5 Thickness Report Mall of EgyptDocument1 pageAir Comp 5 Thickness Report Mall of EgyptKadry Nabil HegazyNo ratings yet

- M.T Confident-1 (Docking 2023) MPI Test ReportDocument1 pageM.T Confident-1 (Docking 2023) MPI Test Reportsushanto.mtbdNo ratings yet

- Coldbond MergedDocument63 pagesColdbond Mergedomkarborde2313No ratings yet

- Ect 11-12-2018Document1 pageEct 11-12-2018SIS CERTIFICATIONSNo ratings yet

- Procedure For Ultrasonic Examination of Clad PlatesDocument8 pagesProcedure For Ultrasonic Examination of Clad PlatesJYOTI RANJAN BISWALNo ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- Physical Inspection Report On Hardware - Fittings Components.Document20 pagesPhysical Inspection Report On Hardware - Fittings Components.რაქსშ საჰაNo ratings yet

- Radiography Report: Page-01 of 01Document1 pageRadiography Report: Page-01 of 01PD ENGINEERING INSPECTION SERVICESNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- AdsorptionDocument3 pagesAdsorptionali105No ratings yet

- 220kV Cable Accessory Technical SpecificationDocument9 pages220kV Cable Accessory Technical Specificationanurag_pugaliaaNo ratings yet

- Ex9m Su20s Eu en 20210623 PDFDocument29 pagesEx9m Su20s Eu en 20210623 PDFOgnjen DevicNo ratings yet

- Hydrostop 2 Py MDocument2 pagesHydrostop 2 Py MPrashantBaruaNo ratings yet

- Technical Information To Install and Establish Earthing System Connected To Existing Grid Refer To Itb Drawing NoDocument2 pagesTechnical Information To Install and Establish Earthing System Connected To Existing Grid Refer To Itb Drawing NoYo Wee LiamNo ratings yet

- Web Tapered Girder Design Based On AISC-ASD 9th Appendix F And/or AISC Design Guide 25Document4 pagesWeb Tapered Girder Design Based On AISC-ASD 9th Appendix F And/or AISC Design Guide 25Amey GudigarNo ratings yet

- Bolted-Connection Design: Forest ServiceDocument25 pagesBolted-Connection Design: Forest ServiceamarggNo ratings yet

- Vessel Design GuideDocument17 pagesVessel Design GuideCecy HaroNo ratings yet

- Thrust Block Design (Horizontal Elbow)Document18 pagesThrust Block Design (Horizontal Elbow)Ali Akl0% (1)

- Design of Beams 1: Act BCXDocument27 pagesDesign of Beams 1: Act BCXleimrabottNo ratings yet

- Tank Foundation Design Using CSI SafeDocument18 pagesTank Foundation Design Using CSI Safefebri Noval100% (1)

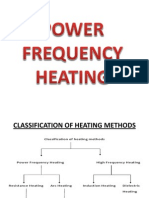

- Power HeatingDocument24 pagesPower HeatingRadhika GandhiNo ratings yet

- In-Service Condition Monitoring of Piping Systems in Power Plants Requirements and Advanced TechniquesDocument13 pagesIn-Service Condition Monitoring of Piping Systems in Power Plants Requirements and Advanced Techniquesamirreza_eng3411No ratings yet

- BMC Ebook by Je Civil Adda PDFDocument9 pagesBMC Ebook by Je Civil Adda PDFKailash ChaudharyNo ratings yet

- Electricity: UNIT 2: Chapter No. 4. Protective DevicesDocument63 pagesElectricity: UNIT 2: Chapter No. 4. Protective DevicesPooja MantriNo ratings yet

- BASF Acronal S 400Document1 pageBASF Acronal S 400Victor LopezNo ratings yet

- Mil DTL 27426CDocument17 pagesMil DTL 27426CbhorstmannbNo ratings yet

- Universal Assembly Instructions For Versatube Frontier Garage BuildingsDocument35 pagesUniversal Assembly Instructions For Versatube Frontier Garage BuildingsMatthew BurkhalterNo ratings yet

- EHV CableDocument19 pagesEHV Cablevikrant jainNo ratings yet

- FullDocument68 pagesFulltachetNo ratings yet

- Ras18 22skveDocument114 pagesRas18 22skveRodrigo VictorNo ratings yet

- Rapt 11Document16 pagesRapt 11tailieuxaydung2019No ratings yet

- CVG 4184 - 6305 - Ch5 - Strength and Deformation PDFDocument47 pagesCVG 4184 - 6305 - Ch5 - Strength and Deformation PDFStar998No ratings yet

- Div 03544 Cement Based ScreedDocument8 pagesDiv 03544 Cement Based ScreedrayNo ratings yet

- NBC 105 Revision - 2019 (C)Document59 pagesNBC 105 Revision - 2019 (C)Abinash Mandal100% (7)

- Flexure Behavior of Reinforced Masonry Assemblages Under Monotonic and Cyclic LoadingDocument12 pagesFlexure Behavior of Reinforced Masonry Assemblages Under Monotonic and Cyclic LoadingNanjund Rao KsNo ratings yet

- Engineering Materials ReviewerDocument23 pagesEngineering Materials ReviewerMuhammad Abundi Malik100% (6)

- Final BeamDocument18 pagesFinal BeamNikhilNo ratings yet