Professional Documents

Culture Documents

Si WX 0209

Uploaded by

Rabea EzzatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Si WX 0209

Uploaded by

Rabea EzzatCopyright:

Available Formats

SI-WX-0209

New Release

File In/With: N/A

Issue Date 2-Apr-11

Equipment Affected: All YK Chillers with VGD

Service Information Subject: Cause Analysis & Adjustment Means of

Leaving Chilled Water Temperature Fluctuation and

Hunting

Background:

Recently, it is reported from field that such a phenomenon of temperature, current or condenser

liquid level fluctuating and hunting as follows often occurs to some YK chillers which are equipped

with VGD. It is embodied as:

1. When the chiller is running at partial load, its leaving chilled water temperature is unable to

get stable. Even though enter chilled water temperature fluctuates very little, the fluctuation of

℃

the leaving water temperature is still over 0.4 .

2. Meanwhile, current, PRV position and condenser liquid level, etc. also show large amplitude

of fluctuation.

3. It lasts a long time. The fluctuation still cannot be stabilized after several hours even several

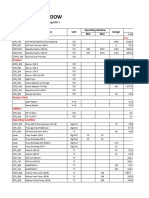

days. A status of fluctuation is shown as figure 1.

Fig. 1

YORK (Wuxi) Air Conditioning & Refrigeration co., Ltd. 1

Equipments Affected:

All YK chillers with VGD

Causes of Failure:

As per our analysis based on the control curves that were captured at job sites, we think that this

is because PRV first react and on many occasions VGD also begins to act soon when the external

load of the chiller changes. As PRV and VGD generally act in reverse directions when controlling

water temperature, the PRV turns out to have large amplitude of position change insensibly. If we

want to avoid the PRV from acting in a too large scale, we must reduce the amplitude in which the

VGD moves each time.

Solutions:

On the VGD setpoints screen in control panel, decreasing the difference between “HIGH LIMIT”

and “LOW LIMIT” can reduce the amplitude of each time’s VGD action. So, we can make the setting

in the following ways:

■ Under default conditions, “HIGH LIMIT” is 0.8 and “LOW LIMIT” is 0.6. Their difference is:

0.8-0.6=0.2. If to decrease the difference, we can set the “HIGH LIMIT” as 0.8 and “LOW LIMIT” as

0.7. Thus, the amplitude of each time’s VGD action will be reduced.

■ If we hope to further reduce the times of VGD action, we can try to set “HIGH LIMIT” as 1.0

and “LOW LIMIT” as 0.8.

■ At the same time, we can change “PRV OFFSET” into “0” to decrease the amount of PRV

position changes during STALL Waiting State.

Please refer to figures 2 and 3.

YORK (Wuxi) Air Conditioning & Refrigeration co., Ltd. 2

Fig. 2

Fig. 3

YORK (Wuxi) Air Conditioning & Refrigeration co., Ltd. 3

Figure 4 shows that the fluctuation was improved or controlled by changing the VGD settings.

Fig. 4

Therefore, we can see that the default VGD setpoints are not necessarily suitable for all working

conditions. They need to be adjusted somewhat appropriately. Besides, sometimes, a chiller with

VGD may have an obviously insufficient capacity during starting process. Even when its current has

reached 100%FLA, its capacity remains obviously insufficient. This is also because the VGD

setpoints fail to be set well. It is most possible that the VGD has already acted during the starting

process. We can set “PRV-VGD Inhibit” downward from the default value 95%. The minimum may be

40%. This is especially recommended for those chillers whose PRV position is relatively low at full

load.

YORK (Wuxi) Air Conditioning & Refrigeration co., Ltd. 4

You might also like

- Daiken Chiller Service ManualDocument266 pagesDaiken Chiller Service ManualMuhammad Ahmad50% (2)

- UniConn SWD Troubleshooting CompanionDocument16 pagesUniConn SWD Troubleshooting CompanionJose Luis Cristancho100% (2)

- MFL62432403 (Saudi) Single Package (60Hz, R22) 0310 FinalDocument92 pagesMFL62432403 (Saudi) Single Package (60Hz, R22) 0310 FinalsasyedaNo ratings yet

- Battery ChargerDocument16 pagesBattery ChargerJose Basualdo100% (1)

- Why BMS Not PLCDocument11 pagesWhy BMS Not PLCBashar HashamNo ratings yet

- Basic Concepts and Definitions: CE6011 Smart Buildings and Automation 2013-2014Document29 pagesBasic Concepts and Definitions: CE6011 Smart Buildings and Automation 2013-2014RK MEHTANo ratings yet

- SI0283Document4 pagesSI0283Mosleh AbdelkaderNo ratings yet

- VGOHVGO ROuting To Crude Tank - Nov2022Document6 pagesVGOHVGO ROuting To Crude Tank - Nov202200083583rfNo ratings yet

- Webinar Follow Up Why All Oil Free Chillers Are Not Created Equal QADocument4 pagesWebinar Follow Up Why All Oil Free Chillers Are Not Created Equal QAwta12No ratings yet

- Ducted Split: LG Air ConditionersDocument100 pagesDucted Split: LG Air Conditionersjose antonioNo ratings yet

- ACPI Regulator/Controller For Dual Channel DDR Memory Systems FeaturesDocument15 pagesACPI Regulator/Controller For Dual Channel DDR Memory Systems FeaturesnakameiyoNo ratings yet

- U02 Manual: RevisionDocument8 pagesU02 Manual: RevisionparthivNo ratings yet

- Provision System ZDocument36 pagesProvision System ZDaud Antony BonteNo ratings yet

- Skill Developement On Vgo HDT TripDocument2 pagesSkill Developement On Vgo HDT Trip00083583rfNo ratings yet

- VR2272 Operating Manual Iss 05Document16 pagesVR2272 Operating Manual Iss 05ArjunroyEdwardNo ratings yet

- SI0428Document3 pagesSI0428Hector FalconNo ratings yet

- FOC I Utara Juli-September 2012Document77 pagesFOC I Utara Juli-September 2012mahaNo ratings yet

- Ceiling & Floor (60Hz, R22)Document92 pagesCeiling & Floor (60Hz, R22)jose antonioNo ratings yet

- Chiller Erl 1000Document27 pagesChiller Erl 1000goldic andiNo ratings yet

- SI WX 0611TroubleshootingofVSDSinglePhaseonYKChillersDocument5 pagesSI WX 0611TroubleshootingofVSDSinglePhaseonYKChillersRabea EzzatNo ratings yet

- ICE3A2065ZDocument33 pagesICE3A2065ZMateus CorrêaNo ratings yet

- Final - CG - Paper Cold Start and Storage Test On 5 5MVA WTG TransformerDocument10 pagesFinal - CG - Paper Cold Start and Storage Test On 5 5MVA WTG TransformeruseronlysvNo ratings yet

- Huf75344G3, Huf75344P3: N-Channel Ultrafet Power Mosfet FeaturesDocument10 pagesHuf75344G3, Huf75344P3: N-Channel Ultrafet Power Mosfet FeaturesChristina MullinsNo ratings yet

- Solenoid Valves 90barDocument31 pagesSolenoid Valves 90baralessandro silvaNo ratings yet

- Ir4570 033Document7 pagesIr4570 033Anonymous NfRzgLoGVsNo ratings yet

- SI0240Document12 pagesSI0240Kavi SaikrishnaNo ratings yet

- SK480-8LC ElectricDocument12 pagesSK480-8LC ElectricAgus RahmanNo ratings yet

- LG Single Package Leaflet 2022Document6 pagesLG Single Package Leaflet 2022numaantanwarNo ratings yet

- PCU0610A - Chiller (Small)Document16 pagesPCU0610A - Chiller (Small)jeromeduytscheNo ratings yet

- KV enDocument4 pagesKV enMostafaNo ratings yet

- Acson Lexus ChillersDocument59 pagesAcson Lexus ChillersKardos Zoltan100% (1)

- SI WX 0109ASolutiontoAbnormalSurgeCountDocument2 pagesSI WX 0109ASolutiontoAbnormalSurgeCountRabea EzzatNo ratings yet

- Haier AU422XIEAA User ManualDocument89 pagesHaier AU422XIEAA User Manualmavaka aiameNo ratings yet

- BRC Geral SD 0100-2E02Document3 pagesBRC Geral SD 0100-2E02eduardogss100% (1)

- SI0373 V04 MarkedDocument4 pagesSI0373 V04 MarkedMohammad yasinNo ratings yet

- PRDF OB5269CPDocument11 pagesPRDF OB5269CPtomopiNo ratings yet

- Start-Up & Commissioning Manual 2 To 3Document6 pagesStart-Up & Commissioning Manual 2 To 3S.KNo ratings yet

- Infineon ICE5ARxxxxBZS DS v02 - 10 EN PDFDocument36 pagesInfineon ICE5ARxxxxBZS DS v02 - 10 EN PDFanand shekhawatNo ratings yet

- Distributed Power: Cooling Systems Application of VGF Engines at Elevated Jacket Water TemperaturesDocument5 pagesDistributed Power: Cooling Systems Application of VGF Engines at Elevated Jacket Water TemperaturesGustavo BerbergiNo ratings yet

- Coolset™-F3 (Jitter Version) : Ice3B0365J Ice3B0565J Ice3B1565JDocument26 pagesCoolset™-F3 (Jitter Version) : Ice3B0365J Ice3B0565J Ice3B1565JrenzoNo ratings yet

- Description: Quick Start Guide For Demonstration Circuit 295B LTC1705Document7 pagesDescription: Quick Start Guide For Demonstration Circuit 295B LTC1705Luis AlarconNo ratings yet

- Service Manual X-Multi AU182XFERADocument79 pagesService Manual X-Multi AU182XFERAeliel100% (1)

- ATTACHMENT 3 Start-Up and Operational Manual For Steam TurbineDocument116 pagesATTACHMENT 3 Start-Up and Operational Manual For Steam TurbineMuhammad Junaid KhanNo ratings yet

- Infineon ICE3BXX65J DS v02 - 09 en PDFDocument28 pagesInfineon ICE3BXX65J DS v02 - 09 en PDFcadizmabNo ratings yet

- GOR Vs GVFDocument8 pagesGOR Vs GVFlutfi awnNo ratings yet

- Water ChillerDocument74 pagesWater ChillerDimitri LyssiNo ratings yet

- Daikin Techno Commercial Offer For Govt Project, New Delhi (R1)Document12 pagesDaikin Techno Commercial Offer For Govt Project, New Delhi (R1)sachin231979No ratings yet

- 13 - Ice and Rain ProtectionDocument5 pages13 - Ice and Rain ProtectionJoão BernardisNo ratings yet

- Ice3b0365j Ice3b0565j Ice3b1565j Ice3b2065jDocument28 pagesIce3b0365j Ice3b0565j Ice3b1565j Ice3b2065jAntonio AscanioNo ratings yet

- Optimizing Chilled Water SystemsDocument35 pagesOptimizing Chilled Water Systemsmadan karkiNo ratings yet

- Product Information: X-Ray Tube DG-073B-DC DG-073B-AC Stationary Anode X-Ray TubeDocument6 pagesProduct Information: X-Ray Tube DG-073B-DC DG-073B-AC Stationary Anode X-Ray TubeMohamedKecibaNo ratings yet

- WK Measurement PointDocument8 pagesWK Measurement PointSanda NeumanNo ratings yet

- Refrigeration Laboratory Unit R715: P.A.Hilton LTDDocument5 pagesRefrigeration Laboratory Unit R715: P.A.Hilton LTDvineet SinghNo ratings yet

- Buck/Boost Switch-Mode Regulator: FeaturesDocument30 pagesBuck/Boost Switch-Mode Regulator: FeaturesErasmo Franco SNo ratings yet

- Casetinas SchneiderDocument8 pagesCasetinas SchneiderFrancisco Agustín FernandezNo ratings yet

- D Manual 521 K12Document127 pagesD Manual 521 K12nghiagpvnNo ratings yet

- Samsung Nevera Serie RB PDFDocument62 pagesSamsung Nevera Serie RB PDFAlexander NarvaezNo ratings yet

- 09 Testing Procedures CP - ENDocument95 pages09 Testing Procedures CP - ENandersson benito herreraNo ratings yet

- VRD3-RE Retrofit Documentation: Variable Air Volume - RetrofitDocument7 pagesVRD3-RE Retrofit Documentation: Variable Air Volume - RetrofitCTHNo ratings yet

- Necs-W: Climaveneta Technical BulletinDocument32 pagesNecs-W: Climaveneta Technical BulletinVictor AANo ratings yet

- Aermec Hidronics Kit WST - enDocument4 pagesAermec Hidronics Kit WST - ensloba68No ratings yet

- 160.75-m1Document70 pages160.75-m1Rabea EzzatNo ratings yet

- 50.40-M1Document8 pages50.40-M1Rabea EzzatNo ratings yet

- AP Battle Cards - YVAA vs. Trane RTAC - ENDocument2 pagesAP Battle Cards - YVAA vs. Trane RTAC - ENRabea EzzatNo ratings yet

- PC Semi Hermetic Compressors Maintenance.1218104663 PDFDocument28 pagesPC Semi Hermetic Compressors Maintenance.1218104663 PDFВячеслав Анатольевич Азаркевич100% (1)

- SS DCC7Document48 pagesSS DCC7Rabea EzzatNo ratings yet

- CAT 257 3-20Tn Light CommercialDocument122 pagesCAT 257 3-20Tn Light CommercialRabea EzzatNo ratings yet

- Si 0051Document2 pagesSi 0051Rabea EzzatNo ratings yet

- SI-WX-0213 Software Enhancements LYS-HP 10V15Document1 pageSI-WX-0213 Software Enhancements LYS-HP 10V15Rabea EzzatNo ratings yet

- SI WX 0112VSDPre StartupChecklistDocument5 pagesSI WX 0112VSDPre StartupChecklistRabea EzzatNo ratings yet

- Fivc PN16 Vodrv DN65 600Document9 pagesFivc PN16 Vodrv DN65 600Rabea EzzatNo ratings yet

- MVAC DesignDocument566 pagesMVAC Designman chit suenNo ratings yet

- Check Valve DetailDocument1 pageCheck Valve DetailAhmed AliNo ratings yet

- Automation BuildingDocument32 pagesAutomation BuildingmohyousifNo ratings yet

- Johnson Controls, Inc., 60 Loveton Circle, Sparks, Maryland - (Eric Badders At: Telephone 410-527-2607)Document15 pagesJohnson Controls, Inc., 60 Loveton Circle, Sparks, Maryland - (Eric Badders At: Telephone 410-527-2607)SalimYousufNo ratings yet

- lbwd06 SpecDocument4 pageslbwd06 SpecKarla Yanina RuizNo ratings yet

- EET455 - M1 Ktunotes - inDocument44 pagesEET455 - M1 Ktunotes - inrajkumarNo ratings yet

- YORK VRF GEN II JTOH CondenDocument36 pagesYORK VRF GEN II JTOH CondenSebastian Molina - TRS MEDELLIN REFRIGERACIONNo ratings yet

- HUMITECHDocument1 pageHUMITECHtimNo ratings yet

- Technology Company Creates Showcase Intelligent BuildingDocument6 pagesTechnology Company Creates Showcase Intelligent BuildingXiao QiNo ratings yet

- Bedroom Fan Coil Unit DS A4 - Layout 1Document3 pagesBedroom Fan Coil Unit DS A4 - Layout 1Dejan DosljakNo ratings yet

- Chofu Commissioning Guide 1Document20 pagesChofu Commissioning Guide 1EmiljanoNo ratings yet

- Products DogoDocument2 pagesProducts DogoBassamNo ratings yet

- Heat Load Calculation 2Document44 pagesHeat Load Calculation 2Na'aim Bin RommaliNo ratings yet

- 2021 Control Solution - DataDocument100 pages2021 Control Solution - DataU Kyaw San OoNo ratings yet

- Bmej 1 11 2009Document28 pagesBmej 1 11 2009Thai Nguyen QuocNo ratings yet

- HVAC System QuizDocument1 pageHVAC System QuizVince SorianoNo ratings yet

- CGCL CatalogDocument24 pagesCGCL CatalogMNo ratings yet

- Ebla Data Book PDFDocument82 pagesEbla Data Book PDFJoão VazNo ratings yet

- Sustainable Building Design: Leed and HVACDocument20 pagesSustainable Building Design: Leed and HVACNajam24No ratings yet

- ABB E Clipse Bypass Users ManualDocument100 pagesABB E Clipse Bypass Users Manualkvramanan_1No ratings yet

- RXC31.5 DatasheetDocument16 pagesRXC31.5 DatasheetDylan AertgeertsNo ratings yet

- Energy Audit of 107Document17 pagesEnergy Audit of 107Mark Angelo UyNo ratings yet

- On Off Data Sheet For 9,12,18 &24KDocument2 pagesOn Off Data Sheet For 9,12,18 &24KcharbelNo ratings yet

- Special Installation Building Automation System (BAS) Intelligent Building SecurityDocument71 pagesSpecial Installation Building Automation System (BAS) Intelligent Building SecurityHafizah AyobNo ratings yet

- Lab 8Document3 pagesLab 8AhmedNo ratings yet

- SBC PCD PG5 SoftwareDocument34 pagesSBC PCD PG5 SoftwareAlwyn GeorgeNo ratings yet

- Ebook Edge Computing 101Document20 pagesEbook Edge Computing 101nelson_esplugaNo ratings yet

- Heat Exchanger Design Using HTRI PDFDocument30 pagesHeat Exchanger Design Using HTRI PDF966571016208No ratings yet