Professional Documents

Culture Documents

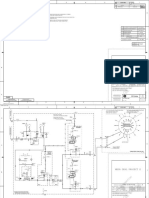

Water Injection System - MOD

Uploaded by

mustafa1989ocCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Injection System - MOD

Uploaded by

mustafa1989ocCopyright:

Available Formats

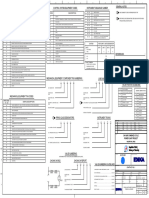

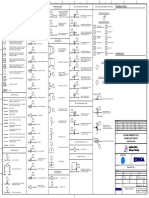

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

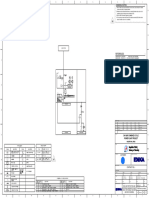

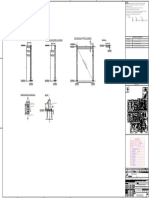

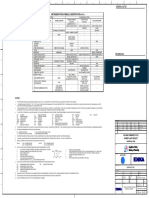

DWG Number 132T9047 Rev - Released 3/4/2019 Page 1 of 2

REVISION HISTORY

THIS DOCUMENT SHALL BE REVISED IN DATE

NOTES: REV DESCRIPTION APPROVED

ITS ENTIRETY. ALL SHEETS OF THIS (YYYY-MM-DD)

1. REFER TO DEVICE SUMMARY (MLI 0414) FOR DEVICE SETTINGS AND DESCRIPTION. DOCUMENT ARE THE SAME REVISION

A LEVEL AS INDICATED. A

2. REFER TO OUTLINE DRAWING (MLI 0313) AND NOTES (MLI 0314) FOR GAS TURBINE PC

CONNECTION POSITIONS AND CHARACTERISTICS.

3. REFER TO DOCUMENTS 334A7731 AND GEK101944 FOR WATER INJECTION

RECOMMENDATIONS.

4. IT IS RECOMMENDED TO VERIFY THE CLEANLINESS OF THE PIPINGS BEFORE INSTALLATION

PER 362A2412

B 5. EXPOSED WATER PIPING AND COMPONENTS MUST BE INSULATED AND HEAT TRACED TO B

PREVENT WATER FROM FREEZING IF THE SKID IS INSTALLED IN AREA WHERE SURROUNDING

TEMPERATURE COULD FALL BELOW 32°F (0°C).

6. THE RECIRCULATION FLOW SHOULD BE RETURNED TO THE STORAGE TANK AND NOT SHORT-

CIRCUITED TO THE PUMP INLET. IT IS RECOMMENDED THAT NO VALVES BE INSTALLED IN THIS

LINE. YET, IF IT IS REQUIRED TO INSTALL ANY VALVE IN THE LINE, IT MUST BE TAGGED OR

LOCKED OPENED DURING OPERATION TO PREVENT SERIOUS DAMAGE TO THE PUMP.

C 7. THE CONICAL FILTER UPSTREAM OF THE PUMP MUST BE CLEANED AFTER 500 HOURS OF C

RUNNING HOURS AND AFTER THAT EVERY 3 YEARS.

8. IF IT IS NOT WRITTEN (NC) THE DEFAULT POSITION OF ALL THE VALVES IS NORMALLY OPEN

(NO).

9. SCHEMATICS AND P&ID SPECIFICATION PER 372A3671.

10. EXTRA RULES FOR 04* SCHEM REFER 379A9908.

D D

E E

F F

G G

H H

THIS DRAWING MODIFIES EXISTING ML ITEM 0462 DRAWING

J J

SIMILAR TO FIRST MADE FOR IEC61355 No. MLI NO.

110T6528 367A7464G025 - 0462

CREATED BY APPROVED BY DOCUMENT TYPE REVISION

GE CLASS II (IN TERNAL NON-CRITICAL) /NOT EXPORT CONT ROLLED P.SANTHIYAGU G, RAVIKUMAR SCHEMATIC -

K C 2 01 9 General El ectri c Company (USA) TITLE

K

THIRD ANGLE PROJECTION

All rights reserved. The information herein is Proprietary and Technically Exclusive content that is solely owned by General Electric Company

and/or its affiliates. Thus, it is being provided with the explicit expectation of restricted and privileged use. All persons or legal entities

WATER INJECTION SYSTEM- MOD

receiving this information shall be deemed by the act of its receipt to have contractually agreed to make no duplications, reproductions of GE POWER

any nature by any means, modifications, disclosures, or use any portion of this material; except as is expressly authorized in writing by CREATION DATE (YYYY-MM-DD) SHEET SIZE DRAWING NO. SHEET

General Electric Company and/or its legitimate affiliates. 2019-02-23 D 132T9047 1 OF 2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

GE Proprietary Information - Class II (Internal) US EAR - NLR

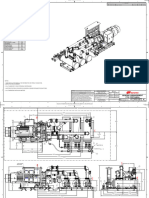

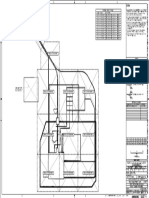

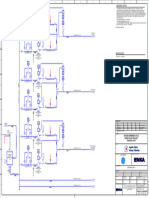

DWG Number 132T9047 Rev - Released 3/4/2019 Page 2 of 2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

WJ10

PC

A A

(FA8-2)

HOLE DIA. 0.03 inch 79mm

LOW POINT CONTINUOUS DRAIN

WD

TO VS2-4

SH-2, ZONE H-3

B B

CONTROL STOP VALVE

VALVE ASSEMBLY

ASSEMBLY

FROM MLI 0477

( VPR62-1 ) Regulates the air pressure ( VPR62-11) Regulates the air pressure

(VCK8-1 TO 14)

C C

VTA

C B (20WN-1) Allows water injection in the combustion chambers

VTA

A

D D C

( VQE1-1 ) Allows quick closing of the stop valve

( 90WN-1 ) Converts 4-20mA signal into a pneumatic signal for valve position setting

I

P

(33WN-1)

ZSH (96WF-1) (96WF-2)

(33WN-2) (33WN-4)

E ZSL FT FT

(33WN-3)

E

ZSL ZSH HV134

WD WI2

WJ2

PC PC

FC FC NO

(VS2-1)

(VC4-1) (FM1-1)

Regulates the water flow Measures the injection water flow Cuts off the injection water low flow

HV113

PURGE

F (96WN-1) WATER DRAIN F

HV148

FROM WATER SUPPLY

PIT TURBINE BASE

TURBINE ON-BASE PIPING MLI 0968

HV102

VTA HV131

HV133

SEE NOTE 3

G HV101 (96WN-2) (96WN-3) G

WD HV111

HV100 (VCK101) PIT PDIT

(FW1-2) HV110 (PW1-1) (FW1-1) Filters the injection water flow

WJ1 WATER INLET WD

PC HV132

HV127

NO WD HV121

HV130

RECIRCULATION STOP VALVE

ASSEMBLY

H

FROM SH-2,

HV120 HV147

H VTA VTA

ZONE B-9

NT NT

M

(88WN-1)

(23WN-1)

( 20WN-18 ) Water Injection

Pump

(FO-1)

(33WN-11)

J J

ZSH

DRAIN

WATER INJECTION MODULE MLI A035

(VCK100) WD WJ5

PC

PC

WJ3 FO (VS2-4)

CREATED BY APPROVED BY DOCUMENT TYPE REVISION

P.SANTHIYAGU G, RAVIKUMAR SHEMATIC -

K Recirculation Stop Valve GE CLASS II (IN TERNAL NON-CRITICAL) /NOT EXPORT CONT ROLLED TITLE

K

(to tank) C 2 01 9 General El ectri c Company (USA)

All rights reserved. The information herein is Proprietary and Technically Exclusive content that is solely owned by General Electric Company WATER INJECTION SYSTEM- MOD

and/or its affiliates. Thus, it is being provided with the explicit expectation of restricted and privileged use. All persons or legal entities

receiving this information shall be deemed by the act of its receipt to have contractually agreed to make no duplications, reproductions of GE POWER

any nature by any means, modifications, disclosures, or use any portion of this material; except as is expressly authorized in writing by CREATION DATE (YYYY-MM-DD) SHEET SIZE DRAWING NO. SHEET

General Electric Company and/or its legitimate affiliates. 2019-02-23 D 132T9047 2 OF 2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

GE Proprietary Information - Class II (Internal) US EAR - NLR

You might also like

- REV Description Date Approval: RevisionsDocument2 pagesREV Description Date Approval: RevisionsLONG Trương MinhNo ratings yet

- Detail A: PT Assy, Layout - JB34GDocument3 pagesDetail A: PT Assy, Layout - JB34GmatiasNo ratings yet

- 0420 - 118T3440 - Cooling WaterDocument2 pages0420 - 118T3440 - Cooling WaterfaisalnadimNo ratings yet

- Installation InstructionDocument1 pageInstallation InstructionmmNo ratings yet

- Gas Fuel Conditionning Skid 1021776 2g0 Ek PFB 0001Document5 pagesGas Fuel Conditionning Skid 1021776 2g0 Ek PFB 0001faisalnadimNo ratings yet

- Power Supply Board (Tantalum Less) : Solidworks Drawing: All Changes Must Be Done in Solidworks DatabaseDocument2 pagesPower Supply Board (Tantalum Less) : Solidworks Drawing: All Changes Must Be Done in Solidworks DatabasezizouhicheNo ratings yet

- General Arrangement V 90-160KW 23800766 A: This View Is Shown For Reference OnlyDocument2 pagesGeneral Arrangement V 90-160KW 23800766 A: This View Is Shown For Reference OnlyVăn HùngNo ratings yet

- 550 Gallon Stainless Steel Ibc Center Discharge SheetDocument1 page550 Gallon Stainless Steel Ibc Center Discharge SheetGioNo ratings yet

- DECAL, WIRING SCHEMATIC (Xe), VFD, SD, WATER COOLEDDocument4 pagesDECAL, WIRING SCHEMATIC (Xe), VFD, SD, WATER COOLEDMarcos LunaNo ratings yet

- File 1326132307Document1 pageFile 1326132307Rodrigo KrammNo ratings yet

- ARV-HII-ELECT-038 - XA - 28VDC Aux PWRDocument2 pagesARV-HII-ELECT-038 - XA - 28VDC Aux PWRArmando CastellanosNo ratings yet

- Original-Approved-Building-Plan 2 PDFDocument23 pagesOriginal-Approved-Building-Plan 2 PDFAndrew EllisonNo ratings yet

- Envases 2 Oz SQ B Shot 8 75g 2042 14 BD C 02 2oz Shot SQ B 26mm Customer EnvasesDocument1 pageEnvases 2 Oz SQ B Shot 8 75g 2042 14 BD C 02 2oz Shot SQ B 26mm Customer EnvasesSalvador CardenasNo ratings yet

- P92-4998 Harness Aftertreatment PDFDocument4 pagesP92-4998 Harness Aftertreatment PDFDiego LiraNo ratings yet

- 1595 GadDocument1 page1595 GadAnonymous X3PnFL6No ratings yet

- C125D6D, C150D6D, C175D6D, C200D6D: Outline, GensetDocument3 pagesC125D6D, C150D6D, C175D6D, C200D6D: Outline, GensetTheronNo ratings yet

- This Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedDocument1 pageThis Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedR- Md Masud Rana B-110No ratings yet

- Listado de Instrumentos - DescripciónDocument33 pagesListado de Instrumentos - DescripciónDaniel Camargo Perez100% (1)

- One Line Protection and Metering Diagram For 400v MCCS With Single Bus Bar and One IncomingDocument1 pageOne Line Protection and Metering Diagram For 400v MCCS With Single Bus Bar and One Incomingmustafa1989ocNo ratings yet

- Ilb 0300Document1 pageIlb 0300Gary Tarqui MagneNo ratings yet

- DECAL, WIRING SCHEMATIC (Xe), VFD, SD, AIR COOLEDDocument4 pagesDECAL, WIRING SCHEMATIC (Xe), VFD, SD, AIR COOLEDMarcos LunaNo ratings yet

- Lower Housing, R/A II, PB540/560: Solidworks Drawing: All Changes Must Be Done in Solidworks DatabaseDocument1 pageLower Housing, R/A II, PB540/560: Solidworks Drawing: All Changes Must Be Done in Solidworks DatabasezizouhicheNo ratings yet

- System 55 55x HDGDocument1 pageSystem 55 55x HDGCarsten KrentscherNo ratings yet

- ULR CL17sc - TD - 979000087 - RevADocument1 pageULR CL17sc - TD - 979000087 - RevAEmanuel GamboaNo ratings yet

- SGC 233 Coupling Data SheetDocument1 pageSGC 233 Coupling Data SheetMohammad yasinNo ratings yet

- 26071-203-M6-341-30002 - P&ID Fire Water System Building Area - Rev. 002Document1 page26071-203-M6-341-30002 - P&ID Fire Water System Building Area - Rev. 002MAHMUDNo ratings yet

- Tech 1469 ManDocument25 pagesTech 1469 ManRiski KurniawanNo ratings yet

- V9616-7 - EN051 - General Arrangement Drawing - ADocument3 pagesV9616-7 - EN051 - General Arrangement Drawing - Asunnudwi10No ratings yet

- TKG 002 Uha CDR Cea 003 - 3Document2 pagesTKG 002 Uha CDR Cea 003 - 3HARSHARANNo ratings yet

- SMH RBG TD ST 03B 00 El S631Document1 pageSMH RBG TD ST 03B 00 El S631hemanthsridharaNo ratings yet

- Treehouse, Waiheke Island: Structural Steelwork NotesDocument12 pagesTreehouse, Waiheke Island: Structural Steelwork NotesKesavan DhuraiNo ratings yet

- General Arrangement Up-Series (80 Gal.) 22431829 G: R.Redmond W.SorahDocument3 pagesGeneral Arrangement Up-Series (80 Gal.) 22431829 G: R.Redmond W.SorahRogerNo ratings yet

- 118T3448 - Fuel Gas ChromatographDocument2 pages118T3448 - Fuel Gas ChromatographfaisalnadimNo ratings yet

- Approved - 400kV LADocument22 pagesApproved - 400kV LAGuru MishraNo ratings yet

- G.V & AIR VALVE-ModelDocument1 pageG.V & AIR VALVE-ModelAnand KP100% (1)

- 3U141-149447 Rev C ELSDocument132 pages3U141-149447 Rev C ELSGAS PLANTNo ratings yet

- Koc Approvals Contractor Revision: GL. EL. +87.670 NotesDocument1 pageKoc Approvals Contractor Revision: GL. EL. +87.670 NotesSivaram KumarNo ratings yet

- Koc Approvals Contractor Revision: GL. EL. +87.670 NotesDocument1 pageKoc Approvals Contractor Revision: GL. EL. +87.670 NotesSivaram KumarNo ratings yet

- Installation Instructions: Harley-Davidson Sportster Mini Grenades PART# 16874 / 46874Document6 pagesInstallation Instructions: Harley-Davidson Sportster Mini Grenades PART# 16874 / 46874raymond malletNo ratings yet

- 4124 Ai Du 21110S006S01 Is01 - CheckprintDocument1 page4124 Ai Du 21110S006S01 Is01 - CheckprintamitNo ratings yet

- G.V & AIR VALVE-ModelDocument1 pageG.V & AIR VALVE-ModelAnand KPNo ratings yet

- Section A-A: General NotesDocument1 pageSection A-A: General NotesADRIAN SILVESTRE HERNANDEZNo ratings yet

- Koc Approvals Contractor Revision: GL. EL. +87.670 NotesDocument1 pageKoc Approvals Contractor Revision: GL. EL. +87.670 NotesSivaram KumarNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Construction Notes: CASE-1Document1 pageConstruction Notes: CASE-1Cyril AleaNo ratings yet

- Especificaciones Compresor Centac C700Document2 pagesEspecificaciones Compresor Centac C700Ascencio RubenNo ratings yet

- TN1002 OdDocument1 pageTN1002 Odgaetan.boehlyNo ratings yet

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 pagesTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopPastor VelasquezNo ratings yet

- TKG 002 Uha CDR Cea 002 - 3Document2 pagesTKG 002 Uha CDR Cea 002 - 3HARSHARANNo ratings yet

- Revisions C: AG9 REDRAWN PER ECO-19-005708 BKW SFDocument1 pageRevisions C: AG9 REDRAWN PER ECO-19-005708 BKW SFMarcos MoraisNo ratings yet

- Rfa Mep M 129Document2 pagesRfa Mep M 129kinidudissaNo ratings yet

- 78AC6y6NJKvRJuXAcMcmqw2Document1 page78AC6y6NJKvRJuXAcMcmqw2Quality AviationNo ratings yet

- JB5000 Drawing-SK3015-1067 RoundDocument1 pageJB5000 Drawing-SK3015-1067 Roundcarloncho1980No ratings yet

- J414201001PADocument1 pageJ414201001PASehna SerajNo ratings yet

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 pagesTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopRiski KurniawanNo ratings yet

- NWB 100 HCDocument1 pageNWB 100 HCKen ShaffnerNo ratings yet

- Preliminary: Configuration Management Controlled ReferenceDocument1 pagePreliminary: Configuration Management Controlled ReferenceJesus Villoria GarciaNo ratings yet

- Amphenol: Advanced SensorsDocument1 pageAmphenol: Advanced SensorsTesoro HonNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- Iq360 000 M6J Ya 00003 00Document1 pageIq360 000 M6J Ya 00003 00mustafa1989ocNo ratings yet

- Iq360 000 M6J Ya 00006 00Document1 pageIq360 000 M6J Ya 00006 00mustafa1989ocNo ratings yet

- Iq360 000 M6J Ya 00007 00Document1 pageIq360 000 M6J Ya 00007 00mustafa1989ocNo ratings yet

- Iq360 000 M6J Ya 00005 00Document1 pageIq360 000 M6J Ya 00005 00mustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Washing Skid - IQ361-100-V1A-MUTC-01028Document1 pageWashing Skid - IQ361-100-V1A-MUTC-01028mustafa1989ocNo ratings yet

- One Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR IncomingsDocument1 pageOne Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR Incomingsmustafa1989ocNo ratings yet

- Flow DiagramDocument1 pageFlow Diagrammustafa1989ocNo ratings yet

- One Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR IncomingsDocument1 pageOne Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR Incomingsmustafa1989ocNo ratings yet

- One Line Protection and Metering Diagram For 400v MCCS With Single Bus Bar and One IncomingDocument1 pageOne Line Protection and Metering Diagram For 400v MCCS With Single Bus Bar and One Incomingmustafa1989ocNo ratings yet

- One Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR IncomingsDocument1 pageOne Line Protection and Metering Diagram For 400v Switchgears With Double Bus Bar and Two XFMR Incomingsmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Water Injection System - IQ361-100-V1A-MUTC-01073Document2 pagesWater Injection System - IQ361-100-V1A-MUTC-01073mustafa1989ocNo ratings yet

- Removal of CO in The Production of Demineralized Water With Reverse Osmosis and ElectrodeionizationDocument2 pagesRemoval of CO in The Production of Demineralized Water With Reverse Osmosis and ElectrodeionizationAbdiel AlonsoNo ratings yet

- Clinoptilolite (Natural Zeolite)Document4 pagesClinoptilolite (Natural Zeolite)Hamed HpNo ratings yet

- Microbiological Analysis of Pharmaceutical Products.Document40 pagesMicrobiological Analysis of Pharmaceutical Products.Ayush KesriNo ratings yet

- PURELAB Chorus Range Brochure LITR40040-04Document16 pagesPURELAB Chorus Range Brochure LITR40040-04Luis Luna CruzNo ratings yet

- SPE 154567 Polymer Flooding A 500-cp OilDocument13 pagesSPE 154567 Polymer Flooding A 500-cp OilBichara DjimetNo ratings yet

- Crude Oil DesaltingDocument25 pagesCrude Oil DesaltingNaumanNo ratings yet

- Final Report On Lakhwar DamDocument14 pagesFinal Report On Lakhwar DamAkash BhartiNo ratings yet

- Preparation of ReagentsDocument4 pagesPreparation of ReagentskvictoNo ratings yet

- Rid Out 2.5 Ec MSDSDocument6 pagesRid Out 2.5 Ec MSDSADMIN IIINo ratings yet

- W2-SITUATION ANALYSIS CLJIP 2023-25 Barangay MangagoyDocument4 pagesW2-SITUATION ANALYSIS CLJIP 2023-25 Barangay MangagoySammy CoderaNo ratings yet

- Lecture 07 What Is Drought and What Are The Causes CSS PMS General Science and AbilityDocument14 pagesLecture 07 What Is Drought and What Are The Causes CSS PMS General Science and Abilityabdul samiNo ratings yet

- Demulsifier For Water OilDocument5 pagesDemulsifier For Water OilCesar Augusto Pineda GomezNo ratings yet

- Science 4 Week 5 Pivot 4a Lesson PlanDocument7 pagesScience 4 Week 5 Pivot 4a Lesson PlanPia PrenroseNo ratings yet

- This Thesis/field Practice Manuscript Can Be AccessedDocument54 pagesThis Thesis/field Practice Manuscript Can Be AccessedEmelyn DecenillaNo ratings yet

- Smart Water Quality Monitoring System Based On Iot: Journal Critical ReviewsDocument6 pagesSmart Water Quality Monitoring System Based On Iot: Journal Critical ReviewsrajyamgarNo ratings yet

- Plant Desin Report For Spice ProductionDocument7 pagesPlant Desin Report For Spice ProductionUmar Mohammad Mir0% (1)

- Pryophoric Iron FiresDocument3 pagesPryophoric Iron FiresJeremy CiminiNo ratings yet

- Technical Guidance Document Quality MonitoringDocument27 pagesTechnical Guidance Document Quality MonitoringtalhaNo ratings yet

- Low-Chloride and Low-Chlorate Disinfection - Effective and SafeDocument8 pagesLow-Chloride and Low-Chlorate Disinfection - Effective and SafeAndres Ezequiel PalarinoNo ratings yet

- Siemens NF-RO O&M ManualDocument55 pagesSiemens NF-RO O&M ManualMfundo DlaminiNo ratings yet

- 1.4.1 Drainage Requirement: CET 3414 Irrigation and DrainageDocument2 pages1.4.1 Drainage Requirement: CET 3414 Irrigation and DrainagentirugiribambeNo ratings yet

- Total Solids in Water and Wastewater SamplesDocument3 pagesTotal Solids in Water and Wastewater SamplesAmit VishwakarmaNo ratings yet

- S T P DesignDocument70 pagesS T P DesignvijaykumarlambaNo ratings yet

- Tsunami EssayDocument5 pagesTsunami EssayChong TanNo ratings yet

- The Life Cycle of Plants MST UnitDocument26 pagesThe Life Cycle of Plants MST UnitNancy CárdenasNo ratings yet

- Sikaswell s-2 DatasheetDocument3 pagesSikaswell s-2 DatasheetJoshua HobsonNo ratings yet

- T155Document4 pagesT155Katerin HernandezNo ratings yet

- B353-OL3-018 KBF Pres RevCDocument67 pagesB353-OL3-018 KBF Pres RevCvrajakisoriDasiNo ratings yet

- Water and Wastewater References, Models, and Terminology: 3.1 Setting The StageDocument10 pagesWater and Wastewater References, Models, and Terminology: 3.1 Setting The StageAymene Salah BendrihemNo ratings yet

- Coliform Standards in India PDFDocument9 pagesColiform Standards in India PDFKHUSHBOONo ratings yet