Professional Documents

Culture Documents

WINCH and DRUM WINDER Design and Analysi

Uploaded by

petrone.andrea20Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WINCH and DRUM WINDER Design and Analysi

Uploaded by

petrone.andrea20Copyright:

Available Formats

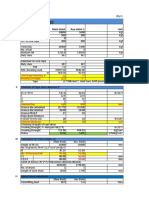

WINCH & DRUM WINDER

Design and Analysis of Single Drum

Refer : Handbook WINCH, WIRE AND CABLE TECHNOLOGY (2001) & Guideline for Design Commissioning and Maintenance of Drum Winders.

Calculate by moon.near76@gmail.com

DATA INPUT

Load / Line Pull = 17714.1 Lb 8035 Kg 78796.4 N

Line Speed (V) = 58 Ft/min 0.29 m/s

Output Torque = 2256.0 In.Lb 2599.2 Kg.cm 254.9 N.m

Ø Head Drum = 99 Inch 2520 mm

Input Speed = 1420 Rpm

Output Speed = 2.2 Rpm

SPEED CALCULATION

Selection of the Gear unit & V = speed = 0.29 m/s

the variable speed gear unit. Ø Head Pulley = 2520 mm

Refer to CEMA

nN Input speed = 1420 rpm

na Output speed = 2.2 rpm

Output speed na = V.60000 . iv

π.D = 2.2 min⁻¹ (rpm)

WINCH DRIVES

Power Determination

With the pulls and speeds selected, the basic “drum output power” comes from the two well-known relationships:

H.P. out = Line Pull (lb.) x Line Speed (ft/min) = 31.13 Hp 22.90 kW

33,000

H.P. out = Output torque (in-lb.) x Output Speed (rev/min) = 0.08 Hp 0.06 kW

63,000

Mechanical efficiencies for machines with spur or planetary reducers and fairleaders will range between 80% and 85%.

If worm gearing is involved, an efficiency of 70% to 75% is appropriate.

Each manufacturer will have his own design values, ranging from hopeful to conservative.

H.P. Input = H.P. out x overall winch efficiency = 26.53 Hp 19.51 kW

ROPE SELECTION

A vertical single drum winder is required to carry 20 persons from the surface to an underground seam located at 400 metres deep.

High of head sheave 15 meter

Select a rope suitable for the winder :

Mass of a miner and equipment = 88 Kg

Factor of Safety required on rope = 10 10

Mass of personnel in cage = 1760 Kg

Estimated cage = 4000 Kg

Estimated attachments mass = 200 Kg

Estimated rope mass 5 Kg/M = 2075 Kg

∴ Mass on rope at drum = 8035 Kg

78.8 kN

∴ Minimum rope breaking strain = Mass on rope x Safety factor

788.2 kN

For shaft over 400 metres deep. use Non-rotating rope

(Ref section 2.3.1)

From AS1426 Steel wire ropes for mines Select ø 36 Gd 1770 Non-rotating rope.

Breaking Strain 891 kN

Mass 5.49 kg/M.

Recalculate with actual rope mass = 2278.35 Kg

Difference of rope mass 203.35 Kg

Mass on rope at drum = 8238.4 Kg

Total static load at drum = 80.82 kN

∴ Rope Factor of Safety = Breaking Strain / Static load

11.02 > 10

DRUM PARAMETER SELECTION

For a vertical single drum winder with a surface to underground seam depth of 400 metres

Select the drum dimensions necessary to correctly coil and store the rope.

Assume a rope diameter of 36 mm

Assume a rope angle from drum to sheave of 45 °

Assume the drum will have parallel rope grooves.

Fleet angle required = 1.5° 1.5 ° Tan 14.10

Distance from drum to sheave = 17 m 17 m

Drum Width = 2*(Distance to sheave*Tan 1.5) 479448 mm 34000 479448

2* 17* Tan1.5* 1000 = 890.4 mm

Drum to Rope Ratio = 70

Minimum Drum Diameter = 70*36 2520 mm

Pitch of rope groove = Ø + Ø *0.04 37.44 mm 6.69 0.1787

Number grooves = Drum width / pitch of rope groove 23.78 24 groove

Drum width = 24*37.44 890.4 mm

= 898.56 mm

Actual fleet angle = Tan-1 (449.28/17000) 14.1014 °

= 1.514°

Allow 3 dead coils on drum at all times

1st Layer

Working rope Dia = 2556 mm

Working rope length = 166.9 m

2nd Layer

Working rope Dia = 2617.5 mm 2569.4 mm

Working rope length = 187.4 m 183.9 m

3rd Layer

Working rope Dia = 2679.0 mm 2630.9

Working rope length = 200.1 m 196.5 m

Total drum capacity with 3 Layers = 559.75 metres 554.3 m 547.3 m

Capacity required = 400+50 449 m < 554.3

You might also like

- Idn - 4Document5 pagesIdn - 4Anh KyNo ratings yet

- Crane & CorbelDocument3 pagesCrane & CorbelWangTFNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Rating: 3 out of 5 stars3/5 (2)

- 10 Ton SIngle Girder 7.62 M Span DesignDocument4 pages10 Ton SIngle Girder 7.62 M Span DesignAdeeb ShahzadaNo ratings yet

- Calculations For The Power Consumption of ImpellerDocument2 pagesCalculations For The Power Consumption of ImpellerNiui NagarNo ratings yet

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- 20 5T PDFDocument3 pages20 5T PDFMUBASHSHIR HELALNo ratings yet

- Mullion AnalysisDocument4 pagesMullion AnalysisganeshNo ratings yet

- Question 1 SolutionDocument4 pagesQuestion 1 SolutionKazeem YusuffNo ratings yet

- Deck Girder - Top GirderDocument3 pagesDeck Girder - Top GirdervibishnanNo ratings yet

- Trunnion DesignDocument2 pagesTrunnion DesignsachinNo ratings yet

- 238 239 240 Pile Load AND LATERAL LOAD CalculationDocument10 pages238 239 240 Pile Load AND LATERAL LOAD CalculationSHARDA CHANDRAKANTNo ratings yet

- Beam Cantiliever CalculationDocument16 pagesBeam Cantiliever CalculationAnonymous sfkedkymNo ratings yet

- Staging DesignDocument8 pagesStaging DesignAbhinandan Jasrotia0% (1)

- Lifting Lug Excel SheetDocument8 pagesLifting Lug Excel Sheetshazan67% (3)

- Calculation Leading To Equipment Selection and SpecificationDocument12 pagesCalculation Leading To Equipment Selection and SpecificationJohn Louie PimentelNo ratings yet

- Coba JembatanDocument28 pagesCoba JembatanAbdi Septia PutraNo ratings yet

- EP For Monorail For Ammonium Nitrate Management Area 1Document4 pagesEP For Monorail For Ammonium Nitrate Management Area 1Nitish TakalkarNo ratings yet

- 30m Anchor and Base Plate MonopoleDocument6 pages30m Anchor and Base Plate MonopoleEhtesham AliNo ratings yet

- Staircase: CharateristicDocument5 pagesStaircase: CharateristicJacky TiongNo ratings yet

- Pedestal Design 3, 4,5 & 6Document2 pagesPedestal Design 3, 4,5 & 6munishant10% (1)

- Anchor BTD DefgDocument5 pagesAnchor BTD DefgAKSHAY BHATKARNo ratings yet

- Design v. PasteDocument4 pagesDesign v. PasteAnonymous sfkedkymNo ratings yet

- Calculation For Temporary Staging of PSC 45.1mDocument10 pagesCalculation For Temporary Staging of PSC 45.1mzieq72100% (9)

- 4.1.5.SP ConnectionDocument30 pages4.1.5.SP ConnectionAnh KyNo ratings yet

- 10T SWL Spreader Bar R2-Fos2.0Document8 pages10T SWL Spreader Bar R2-Fos2.0Snr Designer JayaNo ratings yet

- Rubber Belt Conveyor Calculations (ISO 5048: 1989 E) : BC 2304 NDDocument8 pagesRubber Belt Conveyor Calculations (ISO 5048: 1989 E) : BC 2304 NDmah moudNo ratings yet

- Purlin and Wall Girt Design-Span 9mDocument16 pagesPurlin and Wall Girt Design-Span 9mNarasimha AkkammagariNo ratings yet

- JEROME M. GUETA QUIZ 3 - Advance Steel DesignDocument105 pagesJEROME M. GUETA QUIZ 3 - Advance Steel DesignJerome M. GuetaNo ratings yet

- Pile Cap Check For PE7PTC-15,30 15-07-20 (Shear Enhancement)Document5 pagesPile Cap Check For PE7PTC-15,30 15-07-20 (Shear Enhancement)mayoo1986No ratings yet

- I. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Document30 pagesI. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Anh KyNo ratings yet

- I. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Document30 pagesI. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Anh KyNo ratings yet

- Lift Calculation DemoDocument4 pagesLift Calculation Demoa_toups0% (1)

- Gantry CraneDocument20 pagesGantry Cranekushaljp8989No ratings yet

- Jis G-3444Document10 pagesJis G-3444Maulana YusufNo ratings yet

- Insert Plate CheckDocument6 pagesInsert Plate CheckSatish KumarNo ratings yet

- Agitator-Batch Size-JacketDocument6 pagesAgitator-Batch Size-JacketSagarNo ratings yet

- Calculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesDocument7 pagesCalculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesYunizar Putra MahardikaNo ratings yet

- Vertical Lift Hydraulic Gate DesignDocument40 pagesVertical Lift Hydraulic Gate Designmesam100% (3)

- Water Supply Projects Pertaining To Sambalpur & Jharsuguda BlockDocument2 pagesWater Supply Projects Pertaining To Sambalpur & Jharsuguda BlockvenuNo ratings yet

- Travelling Tripper CalculationDocument5 pagesTravelling Tripper CalculationHarshGuptaNo ratings yet

- Lifting Lug For Vessel calculation-FInalDocument17 pagesLifting Lug For Vessel calculation-FInalSiva baalan100% (1)

- Kabilan S Karunakaran P Nikhil Anand T Ragesh T CB - EN.U4EEE16115 CB - EN.U4EEE16121 CB - EN.U4EEE16131 CB - EN.U4EEE16144Document2 pagesKabilan S Karunakaran P Nikhil Anand T Ragesh T CB - EN.U4EEE16115 CB - EN.U4EEE16121 CB - EN.U4EEE16131 CB - EN.U4EEE16144KabilanNo ratings yet

- Design Document of 24m Guyed MastDocument26 pagesDesign Document of 24m Guyed Mastdheeraj SureshNo ratings yet

- SdasdasdDocument18 pagesSdasdasddheeraj SureshNo ratings yet

- Design Conveyor CalculationDocument1 pageDesign Conveyor CalculationThành ChíNo ratings yet

- Axera 7260t Sandvik Mining and ConstructionDocument4 pagesAxera 7260t Sandvik Mining and ConstructiondaniloNo ratings yet

- AISC2005 Anchor Bolt Version22042015 FixDocument8 pagesAISC2005 Anchor Bolt Version22042015 FixThuyTranNo ratings yet

- Fillet Weld Strength (AISC)Document8 pagesFillet Weld Strength (AISC)shadab521No ratings yet

- Anchor Bolts DesignDocument6 pagesAnchor Bolts DesignAKSHAY BHATKARNo ratings yet

- Catalogue - HDD ServicesDocument16 pagesCatalogue - HDD Servicesbagus handokoNo ratings yet

- Bridge DesignDocument11 pagesBridge DesignIyœ Møsisæ100% (1)

- Beam, Column DesignDocument6 pagesBeam, Column DesignDhanush M.R.No ratings yet

- AgitatorDocument6 pagesAgitatorSung Woong MoonNo ratings yet

- Design of Square Footing For A Recta Sloped Footing: Check For Development LengthDocument44 pagesDesign of Square Footing For A Recta Sloped Footing: Check For Development LengthSwarna LathaNo ratings yet

- Gantry CraneDocument31 pagesGantry Cranekushaljp8989No ratings yet

- 10m Slab BridgeDocument20 pages10m Slab BridgeYosef Kiros100% (1)

- Eye Washes G1808: Guardian EquipmentDocument2 pagesEye Washes G1808: Guardian Equipmenteisenbarger5607No ratings yet

- Lambda Sensors: Quick and Easy Testing and ReplacementDocument12 pagesLambda Sensors: Quick and Easy Testing and ReplacementChinh HuuNo ratings yet

- White Outdoor Parts Manual 13CO616G190 LT 1650 Year 2002Document17 pagesWhite Outdoor Parts Manual 13CO616G190 LT 1650 Year 2002Anonymous cPSmlINA30% (1)

- Module 2 - Flywheels Part 2Document5 pagesModule 2 - Flywheels Part 2Johnlloyd BarretoNo ratings yet

- Crc-p-600 Welding Machine Spec. Brochure 2Document4 pagesCrc-p-600 Welding Machine Spec. Brochure 2gdgfd100% (1)

- 4th Generation Subaru Legacy Rear Wheel Bearing Replacement Walk-Through (Final With Pics)Document11 pages4th Generation Subaru Legacy Rear Wheel Bearing Replacement Walk-Through (Final With Pics)pausenotNo ratings yet

- Ford 2003 My Obd System OperationDocument2 pagesFord 2003 My Obd System OperationBeverly100% (56)

- Ichill 200cx Evo GBDocument40 pagesIchill 200cx Evo GBNikola NikolovNo ratings yet

- Failure Analysis of An Overhead Travelin PDFDocument11 pagesFailure Analysis of An Overhead Travelin PDFRadit and bambangNo ratings yet

- NISSAN 997PE-53000 1F1 - 1F2 Pneumatic LP EFI K21 - GK21 For North America - 01-2020Document533 pagesNISSAN 997PE-53000 1F1 - 1F2 Pneumatic LP EFI K21 - GK21 For North America - 01-2020Socma Reachstackers100% (5)

- Penthouse Spring 1984Document2 pagesPenthouse Spring 1984John M. CavoteNo ratings yet

- Mechanical WIP Test Forms - Air Balancing - Randys Donut - Okada - With Temp - SignedDocument1 pageMechanical WIP Test Forms - Air Balancing - Randys Donut - Okada - With Temp - SignedJovani G. BallonNo ratings yet

- Martin Yale 959 ManualDocument16 pagesMartin Yale 959 ManualnapoleanpintoNo ratings yet

- D475a BulldozerDocument1,548 pagesD475a Bulldozertincho_0026100% (3)

- Tpi 008 de en PDFDocument116 pagesTpi 008 de en PDFMikel1020No ratings yet

- Wheel Loaders VocabularyDocument10 pagesWheel Loaders VocabularyLyanHyangNo ratings yet

- A4vg125hwdl232r-Nzf02f021s-S R902189541 StaraDocument34 pagesA4vg125hwdl232r-Nzf02f021s-S R902189541 StaraRodrigues de OliveiraNo ratings yet

- Daikin Split System BrochureDocument11 pagesDaikin Split System BrochureLasitha WiNo ratings yet

- Strategy Diagram ExamplesDocument8 pagesStrategy Diagram ExamplesmanuelNo ratings yet

- A Comprehensive Review On Process and Engineering Aspects of Pharmaceutical Wet GranulationDocument31 pagesA Comprehensive Review On Process and Engineering Aspects of Pharmaceutical Wet GranulationManuel AlemanNo ratings yet

- v1 Quiz 3 PDFDocument2 pagesv1 Quiz 3 PDFParam Veer ChoudharyNo ratings yet

- The Laws of Motion Worksheet: InstructionsDocument3 pagesThe Laws of Motion Worksheet: Instructionsmariela75% (8)

- Absolute CEDocument2 pagesAbsolute CEhaan luuNo ratings yet

- WRC Loadings and Sign ConventionDocument9 pagesWRC Loadings and Sign ConventionGovindan KrishnamoorthybashyamNo ratings yet

- 4sthead Insight PDFDocument4 pages4sthead Insight PDFGuilherme PfeilstickerNo ratings yet

- Aerofoil SelectionDocument3 pagesAerofoil SelectionAlaa AhmedNo ratings yet

- Hyster 3 TONDocument738 pagesHyster 3 TONahmedaljamel433No ratings yet

- Atomic Term SymbolsDocument4 pagesAtomic Term SymbolsM IkhsanNo ratings yet

- Truss and Gridder RoofDocument37 pagesTruss and Gridder RoofYashi GuptaNo ratings yet