Professional Documents

Culture Documents

Seetharaman 2004

Uploaded by

SQF PractitionerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seetharaman 2004

Uploaded by

SQF PractitionerCopyright:

Available Formats

Role of Water in Pretzel Dough Development and Final Product Quality

K. Seetharaman,1,2 N. Yao,1 and M. K. Rout3

ABSTRACT Cereal Chem. 81(3):336–340

The relationship between flour quality or processing conditions and tinization. The structural and functional attributes of dough and pretzels

pretzel quality has not been extensively investigated. The objective of this were significantly different for the three treatments. The degrees of gluten

study was to elucidate the role of water in pretzel dough development and development during mixing and starch gelatinization during baking were

the consequent impact on pretzel integrity. Control pretzel and pretzels influenced by the levels of water added and consequently influenced pretzel

made with lower or higher levels of added water in the dough were pro- quality. Pretzels made using low-water treatment were brittle due to a

duced under standard processing conditions at Reading Bakery Systems’ lack of gluten development in the dough and inadequate starch gelatini-

pilot plant in Robesonia, PA. Dough samples were evaluated for their zation during baking, while pretzels made using high water treatment were

appearance, moisture content, and extensibility and were viewed under a unacceptable due to extensive gelatinization and retrogradation of starch.

microscope to evaluate the gluten network. Pretzels before and after the Pretzel quality therefore appeared to be a function of appropriate gluten

kiln were evaluated for moisture content, pasting properties, and hardness development and starch gelatinization in the product.

and were viewed under a microscope to evaluate the extent of starch gela-

Pretzels are a popular snack food. Researchers, however, have MATERIALS AND METHODS

not investigated the relationship between the processing parameters

of pretzel and the subsequent impact on quality under modern Treatments and Pretzel Production

processing conditions. Shollenberger and Marshall (1927) reported Control pretzel dough was produced by adding 7.65 kg (42.5%

on the influence of flour cultivars and the effects of chemical and water on flour basis) of water to 18 kg of flour, 0.45 kg of oil,

viscosity properties of flour on pretzel quality. They reported that 0.45 kg of sugar, and 0.05 kg of yeast. The dry ingredients were

both high- and low-protein flours were unacceptable for pretzel mixed for 1 min in a Hobart mixer (model M802) before the addi-

production, while straight and patent-grade flours containing 8– tion of water and the mixture was further mixed for 4 min to form

10.5% protein were most satisfactory for pretzel making. This the dough. The resulting dough was allowed to rest for 20 min

study, however, does not translate to pretzel production under before extrusion and shaping. The low- and high-water doughs

modern production conditions that utilize high-speed extruders were made under conditions similar those for control dough with

and production operations. the exception of the amount of water added to the dough. The low-

Pretzel production is a simple process requiring few ingredients water treatment and high-water treatment had 6.75 and 8.37 kg of

including flour, oil, sugar, and yeast. During pretzel processing, water added (37.5 and 46.5% water, flour wieght basis, respec-

the dough is shaped by an extruder at relatively low pressures, tively). The levels of water added were selected based on the least

treated with hot-alkali solution, salted, and baked. The baking is and highest amounts of water that could be added to make a

divided into two parts: a quick rapid initial bake at high tem- dough and produce pretzels. Furthermore, the lower level of water

perature, followed by a slow drying process at a lower temper- was selected because it was identified by the industry as a level of

ature. While the general effects of the cooking in a hot alkali bath water addition that caused pretzel breakage.

and baking and drying on pretzel quality are known (Groff 2001), Pretzels were made at the Reading Bakery Systems (RBS) pilot

the specific influences of components on pretzel structure, and plant at Robesonia, PA. The processing parameters for pretzel baking

thereby quality, have received little attention from researchers. are listed in Table I.

For example, a common quality issue encountered by the pretzel

industry is pretzel breakage wherein pretzels lack integrity after Flour Properties

baking. Pretzel industry experts and line operators can predict Protein content of the flour was analyzed using a protein analyzer

pretzel breakage after baking by looking at the shaped dough (FP-528L, Leco Corp., St. Joseph, MI). A factor of 5.7 was used to

after low-pressure extrusion because shaped dough lacks integrity convert nitrogen content to wheat flour protein content. Moisture

and breaks after extrusion when picked off the conveyor belt. content was determined by drying 1 g of flour at 130°C for 15 min

Pretzel industry experts list several causes for this problem: addi- using a moisture analyzer (MB45, Ohaus Corp., Pine Brook, NJ).

tion of lower levels of water to the dough, higher extrusion pres-

sures (>80 psi), higher levels of yeast addition, and increased rest Dough Properties

time of the dough. After several preliminary experiments, we deter- The farinograph properties of pretzel flour and pretzel formu-

mined that higher extrusion pressure was more a symptom of lation, including water absorption, development time, stability,

dough viscosity but not a cause of pretzel breakage in itself. Further- and breakdown time were determined by using a Farinograph E

more, we also determined that yeast level and rest time were (C. W. Brabender Instruments, S. Hackensack, NJ) according the

secondary factors that did not directly influence product quality. Approved Method 54-21 using constant flour method in a 50-g

Therefore, the objective of this study was to elucidate the role of test bowl (AACC 2000).

water in pretzel dough development and the mechanism by which

it affected pretzel integrity. TABLE I

Pretzel Processing Parameters

1 Assistant professor and graduate student, respectively, Department of Food Science,

Pennsylvania State University, University Park, PA 16802.

Temperature (°C) Time (min)

2 Corresponding author. Phone: 814-865-5644. Fax: 814-863-6132. E-mail: Cooker 88 0.5–1

Koushik@psu.edu Oven zone 1 254 4.4a

3 Dept. of Botany, University of Hong Kong, Pokfulam Road, Hong Kong. ...

Oven zone 2 218

Kiln 112 14

Publication no. C-2004-0310-06R.

© 2004 American Association of Cereal Chemists, Inc. a Baking time includes the time in both zones 1 and 2.

336 CEREAL CHEMISTRY

Pasting Properties (w/v) (Evans 2002) on microscope slide then sealed with nail

The pasting properties of pretzels before and after the kiln were polish after covering with a cover slip.

determined by using a Rapid Visco Analyzer (RVA) (Newport Sci-

entific, Warriewood, Australia). Pretzels were ground using a coffee Statistical Analysis

grinder (Braun model KSM2 (4), Naucalpan, Mexico) at full speed All measurements were conducted at least twice. Data for texture

for 1 min. Slurry (28 g, 14% db) of ground pretzels and water was analysis is the average of more than 10 individual observations

mixed at 960 rpm for 10 sec and the test was conducted at 160 rpm for each treatment. Data were analyzed by using one-way analysis

using the preset protocol for extrusion without alcohol. The RVA of variance (ANOVA) and Tukey’s Studentized Range test

software was used to analyze peak, trough, final, breakdown, and procedure using Statistical Analysis System v. 8.3 (SAS institute,

setback viscosities. Cary, NC). Significance was defined at the 5% level.

Textural Properties RESULTS

The textural properties of extruded shaped dough and pretzels

before and after kiln were measured by using a texture analyzer The pretzel industry generally recognizes that the addition of

(TA.XT2i; Texture Technologies Corp., Scarsdale, NY/Stable Micro lower amounts of water to dough results in pretzel breakage.

Systems, Godalming, Surrey, UK). Extruded dough (10 pieces, 2 g Therefore, in this study, we evaluated the functional properties of

each) and 15 pretzel samples before or after the kiln were randomly dough and pretzels made using higher or lower levels of added

selected from each treatment and tested according to settings listed water in the dough compared with the standard (control) formu-

in Table II. Data reported are the average of 10 values for the lation. Key differences between the products were identified using

dough samples and 15 values for the pretzel samples. a variety of analytical tools to understand the causes of pretzel

breakage. The observations also helped define the optimal struc-

Confocal Microscopy of Dough tural attributes required for good quality pretzels.

Observations of dough gluten structure were made using laser

scanning confocal microscopy (Olympus FV-300, Hitech Instru- Dough Characterization

ments, Edgemont, PA). Samples stained with fluorescein (Sigma, Visually, the shaped control dough had a shiny white appear-

St. Louis, MO) were excited with a blue argon ion laser (488 nm) ance, rounded edges, and the dough piece retained its integrity

and images were collected through a 510 LP and 530 SP filter. DIC when picked up from the conveyor belt. In contrast, the low-water

transmitted light images were collected simultaneously. Fluorescein dough had a dull grayish appearance with tiny cracks visible on

solution (1 mg/mL in 70% ethanol) diluted 100× was used to soak the surface and the dough lacked integrity when picked off the

a small piece of dough cut by surgical blade. The dough piece was conveyor belt. The high-water dough, on the other hand, was

allowed to stand for 10 min then washed 3× with distilled water to elastic and did not break when picked off the conveyor belt. The

remove excess dye and observed with the confocal microscope. high-water dough did not retain its shape after extrusion, resulting

in a flattened product that was not desired.

Polarized Light Microscopy of Pretzel Pretzel flour used in this study had a protein content of 9.1%

Starch granule morphology and degree of starch gelatinization and moisture content of 11.2%. The farinograph curves for the

were observed by using a polarized light microscope. Ground pretzel pretzel flour, control dough formulation, and dough formulations

samples of control, low-, or high-water formula pretzels were viewed made with low or high levels of added water are shown in Fig. 1.

by using a light microscope equipped with polarizing filters (BX The water absorption of the flour was 55.9% based on a 500 FU

50, Olympus, New York, NY) connected to a digital camera (SPOT consistency. The water added to all three dough formulations was

II Bioscan, Pittsburg, PA). Images were captured by autoexposure. lower compared to water required for the flour gluten to be fully

A small amount of pretzel powder was dispersed with 0.08% (w/v) developed. Thus, pretzel doughs are typically developed under

I2 (diluted from stock solution of 0.2% I2 and 2.0% KI in water limiting water conditions, resulting in suboptimal gluten devel-

opment. Furthermore, gluten formation is even more limited in

the low-water dough, thus affecting the functionality of this dough.

TABLE II This observation was further supported by confocal microscopic

Test Settings for Texture Analysis of Dough and Pretzelsa

observations of the gluten network of the three dough formulations

Pretzel Dough Force Pretzel

Probe TA-96 Double Clamp TA-41 Knife Blade

Probe ending point Return to start Return to start

Pretest speed (mm/sec) 2.0 10

Test speed (mm/sec) 3.3 1

Post speed (mm/sec) 10.0 10

Test time (sec) na na

Probe distance (mm) 40.0 3

Trig force (g) 5 5

a When measured with a TA.XT2i texture analyzer.

TABLE III

Moisture Contents of Extruded Dough and of Pretzels

Before and After Kiln

Added Dough Pretzel Moisture (%)

Formulation a

Water (%) Moisture (%) Before Kiln After Kiln

Low-water 37.5 28.93bb 8.19b 4.52a

Control 42.5 31.29a 9.32a 4.45a

High-water 46.5 38.66c 11.05c 7.04b

a Based on flour (%).

b Values followed by the same letter in the same column are not significantly Fig. 1. Farinograms of pretzel flour, low-water, control, and high-water

different (P < 0.05). formula doughs (% water, flour basis).

Vol. 81, No. 3, 2004 337

(Fig. 2). The fibrils of the gluten network were visible in the control zels made using low-water addition were not as swollen, showing

dough and the high-water dough formulations, whereas the gluten a higher proportion of ungelatinized starch granules (arrows in

network did not have a continuous structure in the low-water Fig. 6A). On the other hand, pretzels made using high-water addition

dough. Similar observations have been reported for pasta dough, were the most swollen and almost no ungelatinized granules were

which is also typically extruded under limiting water conditions observed.

(Matsuo et al 1978).

The extensibility of the three dough samples was also signi- DISCUSSION

ficantly different as measured by using a TA.XT2i (Fig. 3). The

low-water dough was not extensible and broke, while the control The physicochemical characteristics that define pretzels and the

and high-water doughs retained their extensibility throughout the impact of water on dough development and pretzel quality have

test time. The limited gluten formation and the absence of gluten not been investigated before. This study aims to understand the

network in the low-water pretzel dough contributed to its decreased impact of water on pretzel dough properties and gluten network for-

extensibility. This observation is supported by results obtained from mation. The study further explores the subsequent impact of moisture

confocal microscopy. content in dough on pretzel quality by documenting changes that

occur in starch matrix as influenced by baking. These obser-

Pretzel Characterization vations will aid the industry in improving pretzel quality, as well

Pretzel samples were characterized by using rapid viscosity anal- in quality assurance to consistently produce good quality pretzels.

ysis, texture analyses, and microscopic techniques after baking but Gluten development in dough was significantly influenced by

before the kiln, and at the end of the kiln (final product). The interior the water content in the formulation. In typical bread doughs, the

cross-section of control baked pretzels appeared white and opaque, level of water added is determined based on the flour water absorp-

while pretzels made with either low-water or high-water had dull tion measured using the farinograph or similar tools. In pretzel

color and a glassy interior cross-section. dough, the level of water in the formulation was significantly lower

The moisture contents of extruded dough and pretzels before than that determined for the flour using a farinograph (Fig. 1).

and after the kiln are listed in Table III. When measured before Thus, gluten development in pretzel dough would be limited by the

the kiln, the moisture content of low-water pretzels was lowest and lower level of water added compared with that required for the

high-water pretzels were highest. The moisture content of the flour from which the dough is made. Matsuo et al (1978) reported

finished product was higher in high-water pretzels compared with that the protein matrix in pasta dough became more ordered as the

the other two treatments. Roughly the same amount of moisture dough approached the end of the extruder augur without achieving

(≈70.5%) was removed from the dough during baking for all three

treatments. However, the proportion of moisture removed from

the half-baked products during drying in the kiln was significantly

different. About 52.3% of the moisture was removed from the control

product; 44.8% was removed from the low-water pretzel; and

only 36.3% was removed from the high-water pretzels.

Pretzels sampled before and after the kiln exhibited signi-

ficantly different (P < 0.05) pasting properties when measured by

using RVA (Fig. 4). Low-water pretzels sampled before the kiln

had higher pasting properties compared with control pretzels sam-

pled before the kiln, while the reverse trend was observed in pretzels

sampled at the end of the kiln. High-water pretzels had the lowest

pasting properties when sampled before or after the kiln.

The force required to break pretzel samples before and after the

kiln are shown in Fig. 5 (P < 0.001). The force required to break

low-water pretzels was highest before the kiln and lowest after the

kiln, while the force required breaking high-water pretzels exhibited

the opposite trend.

Observations of pretzel samples under polarized light microscopy

reveal different degrees of starch swelling and gelatinization as

shown in Fig. 6. Starch granules in control pretzels were swollen Fig. 3. Dough extensibility of low-water, control and high-water extruded

and partially gelatinized. In contrast, starch granules in the pret- dough samples. Data reported average of 10 values for dough samples.

Fig. 2. Confocal microscopy of low-water (A), control (B), and high-water (C) pretzel doughs. Gluten network formation in control and high-water

pretzel doughs indicated by arrows.

338 CEREAL CHEMISTRY

a continuous network of protein sheets and fibrils, suggesting a microscopy of low-water pretzels showed starch granules that

lack of optimal gluten development. The amount of water added have minimal swelling compared with that observed in control or

to control pretzel dough and the subsequent mixing time of 4 min high-water pretzels (Fig. 6A). The peak viscosity of pretzels made

is well suited for the required gluten development and functionality using low-water dough was higher before drying in the kiln, while

to produce good quality pretzels with desired texture. However, if the peak viscosity was lower after the drying operation compared

the amount of water added was lower than that for control dough, with control pretzels. In contrast, starch granules in pretzels made

then gluten development was minimal (Fig. 2A), resulting in a using the high-water dough were swollen and gelatinized (Fig.

dough that lacked desired extensibility after shaping. Dough with 6C), and their peak viscosities were the lowest when measured by

higher levels of water added had good gluten development but using the RVA. It is likely that the gelatinized or partially gela-

flowed easily through the extruder and did not maintain the desired tinized granules retrograded, while the ungelatinized partially

shape after extrusion. Thus optimal gluten functionality is desired swollen starch granules annealed during the baking process, thus

in pretzel doughs to provide the necessary elasticity needed to influencing viscosity development in the RVA. The degree of

maintain the integrity of the shaped dough piece. starch swelling and gelatinization possibly also contributed to the

Based on the loss of moisture in the baking oven and the kiln, it internal matrix of the pretzels. Data on the force required to break

is evident that the extent of starch gelatinization in the oven, the pretzels using a texture analyzer showed that pretzels made using

degree of annealing/retrogradation in the kiln and the subsequent the low-water dough required less force to break after baking and

amount of water held by the matrix was significantly different for

the three treatments. The rapid loss of moisture from the low-

water dough probably minimized starch swelling and gelatinization,

while the higher moisture levels present in the high-water dough

potentially facilitated starch swelling and gelatinization during

the baking operation. This observation was further supported by

data from microscopy and pasting properties. The results from

Fig. 4. Pasting properties of low-water, control, and high-water pretzels

before and after kiln (P < 0.05). Data reported average of two replicates.

Fig. 5. Peak cutting force of low-water, control, and high-water pretzels Fig. 6. Polarized light microscopy (10× magnification) of low-water (A),

before and after kiln (P < 0.001). Data reported average of 15 replicates control (B), and high-water (C) pretzels. Arrows indicate ungelatinized

pretzel samples. starches in low-water pretzel.

Vol. 81, No. 3, 2004 339

drying. This was probably due to limited gluten development in ACKNOWLEDGEMENTS

the dough and the subsequent limited contribution of gelatinized

starch in setting the internal matrix. Pretzels made using high- We thank the Pennsylvania Department of Agriculture for the grant that

water dough, on the other hand, required greater force to break supported this research (contract no. ME442307) and also the Snack Food

Association for partial funding in support of this project. We also thank

after baking and drying, probably due to a stronger gluten matrix

Terry Groff, President, Reading Bakery System, Inc., and the staff for assis-

in the dough and the gelatinized and retrograded starch matrix tance and the use of the pilot plant for this research project.

established during baking and drying. Therefore, the overall quality

of pretzels appear to be related to the level of water added and its LITERATURE CITED

consequent impact on the gluten development during dough mixing

and extrusion, and the subsequent rate of moisture removal during American Association of Cereal Chemists. 2000. Approved Methods of

the baking process which affects starch swelling and gelatinization. the AACC, 10th Ed. Method 54-21. The Association: St. Paul, MN.

Therefore, an optimal balance between gluten and starch func- Evans, A. 2002. Resistant starch from four native high-amylose maize

tionality is desired for pretzels of good quality. When less water starches. M.S. thesis. The Penn State University: University Park, PA.

was added to the dough, gluten development was limited; starch Groff, E. T. 2001. Perfect pretzel production. Pages 369-383 in: Snack

appeared to anneal and form a glassy matrix, resulting in a pretzel Foods Processing. E. W. Lusas and L. W. Rooney, eds. Technomic

Publishing: Lancaster, PA.

that was brittle. In contrast, while gluten development was better in Matsuo, R. R., Dexter, J. E., and Dronzek, B. L. 1978. Scanning electron

doughs with high levels of added water, the extent of starch gelatin- microscopy study of spaghetti processing. Cereal Chem. 55:744-753.

ization was also higher in the pretzels, resulting in a harder, more Seetharaman, K., Yao, N., and Groff, T. 2002. Quality assurance for hard

unacceptable pretzel with a retrograded starch matrix. Further studies pretzel production. Cereal Foods World 47:361-364.

are underway to determine the influence of flour properties on Shollenberger, J. H., and Marshall, W. K. 1927. Flour for pretzels. USDA

pretzel quality. Tech. Bull. 46:1-16.

[Received May 5, 2003. Accepted November 17, 2003.]

340 CEREAL CHEMISTRY

You might also like

- Advances in Dairy ProductsFrom EverandAdvances in Dairy ProductsFrancesco ContoNo ratings yet

- 5Document16 pages5Herbert BassNo ratings yet

- Tugas 3 Desy Bing IndDocument7 pagesTugas 3 Desy Bing IndDesi LestariNo ratings yet

- Improve Cookie Quality with Protease EnzymeDocument7 pagesImprove Cookie Quality with Protease EnzymeMichelle RomeroNo ratings yet

- Ipomoea Batatas Ipomoea Batatas: Jl. Bandara Sultan Iskandar Muda Blang Bintang Aceh Besar - 23372, IndonesiaDocument6 pagesIpomoea Batatas Ipomoea Batatas: Jl. Bandara Sultan Iskandar Muda Blang Bintang Aceh Besar - 23372, IndonesiaNi Made Candra GusatyanaNo ratings yet

- Cereal Chem - 1998 - Wehrle - Rheological Changes in Wheat Sourdough During Controlled and Spontaneous FermentationDocument5 pagesCereal Chem - 1998 - Wehrle - Rheological Changes in Wheat Sourdough During Controlled and Spontaneous Fermentationmohamed.alkadour96No ratings yet

- Shakeel Biscuit Paper 2014Document10 pagesShakeel Biscuit Paper 2014Trung HuynhNo ratings yet

- Noodle Quality As Related To Sorghum Starch Properties: Cereal Chemistry July 2001Document5 pagesNoodle Quality As Related To Sorghum Starch Properties: Cereal Chemistry July 2001Starla CintaNo ratings yet

- Influence of Fermentation Time On Characteristics of Sourdough BreadDocument7 pagesInfluence of Fermentation Time On Characteristics of Sourdough BreadPolluxitoNo ratings yet

- FP 07 023 Zheng Final 23nov2007Document9 pagesFP 07 023 Zheng Final 23nov2007Esa Ghanim FadhallahNo ratings yet

- N Dyfnw 6 XBN QZ 6 SM 8 KXYks DyDocument10 pagesN Dyfnw 6 XBN QZ 6 SM 8 KXYks DyRara AmeliaNo ratings yet

- Current Research in Nutrition and Food ScienceDocument9 pagesCurrent Research in Nutrition and Food ScienceDiba BasarNo ratings yet

- 2010 Article 155Document6 pages2010 Article 155Chandrima JashNo ratings yet

- Bài Báo 6-1Document10 pagesBài Báo 6-1Lê Văn HòaNo ratings yet

- RVA Lab ReportDocument7 pagesRVA Lab ReportZahid AnwarNo ratings yet

- Effect of Hydrophilic Gums On The Quality of Frozen Dough: II. Bread CharacteristicsDocument8 pagesEffect of Hydrophilic Gums On The Quality of Frozen Dough: II. Bread CharacteristicsRoxy PeñalozaNo ratings yet

- Effect of Lactic Acid and UV Irradiation On The Cassava and Corn StarchesDocument12 pagesEffect of Lactic Acid and UV Irradiation On The Cassava and Corn StarchesElok KurniaNo ratings yet

- Amarantus CaudatusDocument8 pagesAmarantus CaudatusJherson Gustavo SánchezNo ratings yet

- 1 s2.0 S0268005X18303035 MainDocument9 pages1 s2.0 S0268005X18303035 MainMd GiyasuddinNo ratings yet

- Spaghetti - Paste FainoaseDocument7 pagesSpaghetti - Paste FainoaseEder IzakiNo ratings yet

- Sourdough Fermented by BALDocument9 pagesSourdough Fermented by BALPalupi Cahyaning RatriNo ratings yet

- Quality of Jelly Candy Made of Acid-Thinned Starch Added With Different Non-Starch PolysaccharidesDocument9 pagesQuality of Jelly Candy Made of Acid-Thinned Starch Added With Different Non-Starch PolysaccharidesjeffersonNo ratings yet

- Pareyt 2010Document8 pagesPareyt 2010Ruth Noemy Ruiz MangandiNo ratings yet

- naumenko et al 2021Document9 pagesnaumenko et al 2021Bianca LeyvaNo ratings yet

- Pengaruh Lama Fermentasi Yang Berbeda Pada Pembuatan Tepung Telur Pan DryingDocument8 pagesPengaruh Lama Fermentasi Yang Berbeda Pada Pembuatan Tepung Telur Pan DryingselvianiNo ratings yet

- Chemical Implications and Time Reduction of On-Farm Cocoa Fermentation byDocument10 pagesChemical Implications and Time Reduction of On-Farm Cocoa Fermentation byLeonardo Ramos GNo ratings yet

- Effect of Sodium Lauryl Sulphate On The Texture of Sponge CakeDocument6 pagesEffect of Sodium Lauryl Sulphate On The Texture of Sponge CakeronaldyuncosaNo ratings yet

- Effect of Process Variables On Spaghetti Quality': Durum Wheat and PastaDocument5 pagesEffect of Process Variables On Spaghetti Quality': Durum Wheat and PastatawfikNo ratings yet

- 1 s2.0 S0733521012001701 MainDocument7 pages1 s2.0 S0733521012001701 MainLUIS EDUARDO CIRO PARRANo ratings yet

- Cookies From Composite Wheat-Mesquite Flours: Characterization During Storage R.P. Gusmão, T.A.S. GusmãoDocument1 pageCookies From Composite Wheat-Mesquite Flours: Characterization During Storage R.P. Gusmão, T.A.S. GusmãoEliasNo ratings yet

- Effect of Sucrose On The Mixolab, Alveograph Charactersitics and Breadmaking Properties of Strong Wheat FlourDocument9 pagesEffect of Sucrose On The Mixolab, Alveograph Charactersitics and Breadmaking Properties of Strong Wheat FlourDanaNo ratings yet

- Characterization of the Rheological Properties of Yoghurt-A ReviewDocument26 pagesCharacterization of the Rheological Properties of Yoghurt-A Review伊利亚斯尼亚佐夫No ratings yet

- DRAFT PAPER PROSIDING 3 Rev (3) - TranslatedDocument7 pagesDRAFT PAPER PROSIDING 3 Rev (3) - TranslatedSyifa AuliaNo ratings yet

- Cereal Chem - 2002 - Clarke - Effect of Single Strain and Traditional Mixed Strain Starter Cultures On RheologicalDocument8 pagesCereal Chem - 2002 - Clarke - Effect of Single Strain and Traditional Mixed Strain Starter Cultures On Rheologicalmohamed.alkadour96No ratings yet

- Jurnal Pasta 2Document8 pagesJurnal Pasta 2hendy vidianaNo ratings yet

- Repeated PH-stat Fed-Batch Fermentation For RhamnolipidDocument9 pagesRepeated PH-stat Fed-Batch Fermentation For Rhamnolipidsidikmar1425No ratings yet

- Effect of Extrusion Process Conditions On The Physical Properties of Tef-Oat Healthy Snack ExtrudatesDocument9 pagesEffect of Extrusion Process Conditions On The Physical Properties of Tef-Oat Healthy Snack ExtrudatesfaustounivalleNo ratings yet

- LWT - Food Science and TechnologyDocument6 pagesLWT - Food Science and TechnologyAnderson Widmer Morales VillarrealNo ratings yet

- Impact of Different Beer Yeasts On Wheat Dough and Bread Quality ParamtersDocument8 pagesImpact of Different Beer Yeasts On Wheat Dough and Bread Quality ParamtersIonuț NeaguNo ratings yet

- Pengaruh Fasilitator Fermentasi Dan Suhu Pengeringan Terhadap Kualitas Biji KakaoDocument9 pagesPengaruh Fasilitator Fermentasi Dan Suhu Pengeringan Terhadap Kualitas Biji KakaoLulu FransiskaNo ratings yet

- Pengaruh Fasilitator Fermentasi Dan Suhu Pengeringan Terhadap Kualitas Biji KakaoDocument9 pagesPengaruh Fasilitator Fermentasi Dan Suhu Pengeringan Terhadap Kualitas Biji KakaoAbdus SananNo ratings yet

- Cereals Alcohol Yield Process Conditions EffectDocument6 pagesCereals Alcohol Yield Process Conditions EffectDavidNo ratings yet

- 1 50733 2 10 20180502 PDFDocument14 pages1 50733 2 10 20180502 PDFAwalytaNo ratings yet

- 1 s2.0 S096399699800091X MainDocument7 pages1 s2.0 S096399699800091X Mainlarrain lsdNo ratings yet

- 1 s2.0 S0144861720305452 MainDocument9 pages1 s2.0 S0144861720305452 MainErel Bar-IlanNo ratings yet

- Physicochemical Properties of Rice Analogs Based On Multi-Level: Influence of The Interaction of Extrusion ParametersDocument18 pagesPhysicochemical Properties of Rice Analogs Based On Multi-Level: Influence of The Interaction of Extrusion ParametersDita MegaNo ratings yet

- Sweet Potato Starches Compared by Processing MethodDocument10 pagesSweet Potato Starches Compared by Processing MethodYanuar PramanaNo ratings yet

- Physical Quality of Snacks and Technological Properties ofDocument8 pagesPhysical Quality of Snacks and Technological Properties ofjenifer montoyaNo ratings yet

- Calidad Del Cocinado de Pasta AACC66-50Document3 pagesCalidad Del Cocinado de Pasta AACC66-50ZacariasNo ratings yet

- Pengaruh Penambahan Ragi Tape Dan Waktu Fermentasi Terhadap Karakteritik Pulpa Biji KakaoDocument4 pagesPengaruh Penambahan Ragi Tape Dan Waktu Fermentasi Terhadap Karakteritik Pulpa Biji KakaoAsnyta NytaNo ratings yet

- Effects of Fermentation in Saltine Cracker ProductionDocument5 pagesEffects of Fermentation in Saltine Cracker ProductionValéria BritoNo ratings yet

- 9010 24979 1 SM PDFDocument6 pages9010 24979 1 SM PDFLogi MarpaungNo ratings yet

- Optimasi Pembuatan Sohun Ubi Jalar Menggunakan Ekstruder Pemasak-PencetakDocument10 pagesOptimasi Pembuatan Sohun Ubi Jalar Menggunakan Ekstruder Pemasak-PencetakPutri Zahra AulidhaNo ratings yet

- Physical-Chemical Characteristics Determination of Potato (Solanum Phureja Juz. & Bukasov) StarchDocument8 pagesPhysical-Chemical Characteristics Determination of Potato (Solanum Phureja Juz. & Bukasov) StarchCamilo MartinezNo ratings yet

- Annealing ModificationDocument8 pagesAnnealing ModificationAnonymous NZHwrtNo ratings yet

- Optimization of Non-Fermented Gluten-Free Dough Composition Based On Rheological Behavior For Industrial Production of "Empanadas" and Pie-CrustsDocument8 pagesOptimization of Non-Fermented Gluten-Free Dough Composition Based On Rheological Behavior For Industrial Production of "Empanadas" and Pie-CrustsDiana Gz-BsNo ratings yet

- Water Sorption and The Plasticization Effect in WafersDocument8 pagesWater Sorption and The Plasticization Effect in WafersElkin G ArcosNo ratings yet

- Wheat Sourdough Fermentation - Effects of Time and Acidification On Fundamental Rheological PropertiesDocument9 pagesWheat Sourdough Fermentation - Effects of Time and Acidification On Fundamental Rheological PropertiesmaurodiloretoNo ratings yet

- Effect of Hydrophilic Gums On The Quality of Frozen Dough: Electron Microscopy, Protein Solubility, and Electrophoresis StudiesDocument7 pagesEffect of Hydrophilic Gums On The Quality of Frozen Dough: Electron Microscopy, Protein Solubility, and Electrophoresis StudiesRoxy PeñalozaNo ratings yet

- Rheological Monitoring of Structure Evolution and Development in Stirred YoghurtDocument9 pagesRheological Monitoring of Structure Evolution and Development in Stirred YoghurtAzizah MunitaNo ratings yet

- TortillasandDoughExtensibilityBAKERpaper_finalDocument6 pagesTortillasandDoughExtensibilityBAKERpaper_finalSQF PractitionerNo ratings yet

- ObjectiveBreadAnalysisBAKERpaper_2022Document7 pagesObjectiveBreadAnalysisBAKERpaper_2022SQF PractitionerNo ratings yet

- SGC - Specification Guarsar-501Document1 pageSGC - Specification Guarsar-501SQF PractitionerNo ratings yet

- Understanding Baking PDFDocument289 pagesUnderstanding Baking PDFAlexandra Soares100% (1)

- Step by Step Traceability for the RMDocument1 pageStep by Step Traceability for the RMSQF PractitionerNo ratings yet

- R.R.O. 1990, Reg. 347_ GENERAL - WASTE MANAGEMENTDocument134 pagesR.R.O. 1990, Reg. 347_ GENERAL - WASTE MANAGEMENTSQF PractitionerNo ratings yet

- Sanitizer Effects On ATP SurfacesDocument2 pagesSanitizer Effects On ATP SurfacesSQF PractitionerNo ratings yet

- Safe Food Handling Standards - FINAL - Revnov2012 1Document55 pagesSafe Food Handling Standards - FINAL - Revnov2012 1SQF PractitionerNo ratings yet

- Food Safety - Quality Audit Expectations - V2 - April 2023Document39 pagesFood Safety - Quality Audit Expectations - V2 - April 2023Lutviana Ema100% (3)

- Cereal Foods World 2018Document3 pagesCereal Foods World 2018SQF PractitionerNo ratings yet

- PB Ptps - Dansensor Preventative Maintenance Program - en - WebDocument2 pagesPB Ptps - Dansensor Preventative Maintenance Program - en - WebSQF PractitionerNo ratings yet

- PB Ptps Dansensor Checkpoint 3 - en 11Document2 pagesPB Ptps Dansensor Checkpoint 3 - en 11SQF PractitionerNo ratings yet

- Validation MD Critical LimitDocument1 pageValidation MD Critical LimitSQF PractitionerNo ratings yet

- Reference Database For Hazard Identification - Physical Hazards (Metal 2.0 MM)Document1 pageReference Database For Hazard Identification - Physical Hazards (Metal 2.0 MM)SQF PractitionerNo ratings yet

- Guia FDA LsiteriaDocument85 pagesGuia FDA LsiteriaLeticia Gallardo100% (1)

- Environmental Monitoring Risk AssessmentDocument27 pagesEnvironmental Monitoring Risk AssessmentAwais Qureshi100% (1)

- Horticulturae 08 00731 v2Document29 pagesHorticulturae 08 00731 v2SQF PractitionerNo ratings yet

- User Instructions of Ultrasonic Equipments Revision 1Document36 pagesUser Instructions of Ultrasonic Equipments Revision 1SQF PractitionerNo ratings yet

- Glass Registry & Inspection Checklist FORMATDocument2 pagesGlass Registry & Inspection Checklist FORMATSQF PractitionerNo ratings yet

- WaterDocument5 pagesWaterSQF PractitionerNo ratings yet

- Brooks 2021Document15 pagesBrooks 2021SQF PractitionerNo ratings yet

- Vegan+Egg+Replacement+BAKERpaper FinalDocument7 pagesVegan+Egg+Replacement+BAKERpaper FinalSQF PractitionerNo ratings yet

- Understanding Product Defence - Techni-KDocument5 pagesUnderstanding Product Defence - Techni-KSQF PractitionerNo ratings yet

- WS P2 TradeDocument4 pagesWS P2 Tradearyan mehtaNo ratings yet

- 1.6 Growth and EvolutionDocument28 pages1.6 Growth and EvolutionTita RachmawatiNo ratings yet

- Unit 8: Celebrations: ReadingDocument23 pagesUnit 8: Celebrations: ReadingPhạm Kim HiềnNo ratings yet

- Muhammad Alhady (Identifying The Topic Sentences (Main Idea) )Document4 pagesMuhammad Alhady (Identifying The Topic Sentences (Main Idea) )Euthana siaNo ratings yet

- Indian Vegetarian Buffet MenusDocument7 pagesIndian Vegetarian Buffet MenusTo The Tee CafeNo ratings yet

- Stl-Emergency Situation Report-21.06.2023Document14 pagesStl-Emergency Situation Report-21.06.2023Mohamad Samer S. ALYASAKINo ratings yet

- BMTRTJLRTRTNBTRBRTLBKTRNNGGTDocument24 pagesBMTRTJLRTRTNBTRBRTLBKTRNNGGTSecret filesNo ratings yet

- Signed Off - Food and Beverages11 - q4 - m5 - Provide Room Services - v3Document42 pagesSigned Off - Food and Beverages11 - q4 - m5 - Provide Room Services - v3Jellane Señora85% (13)

- Exclusively Coke - Babak Ebrahimi PDFDocument5 pagesExclusively Coke - Babak Ebrahimi PDFBabak EbrahimiNo ratings yet

- Global Dairy Market 1700832803122Document69 pagesGlobal Dairy Market 1700832803122butmalai valentinaNo ratings yet

- Practice (Present Progressive As Future) : A. B. C. D. E. F. GDocument3 pagesPractice (Present Progressive As Future) : A. B. C. D. E. F. GJesús R.B.No ratings yet

- Matrix RDO MarinduqueDocument195 pagesMatrix RDO MarinduqueKimber Lee0% (1)

- Dairy production evidence in ancient Indus Valley potsDocument2 pagesDairy production evidence in ancient Indus Valley potsகாட்டு வாசிNo ratings yet

- Food Menu - Dunedin New Zealand EatsDocument1 pageFood Menu - Dunedin New Zealand EatsLourdes M IbarraNo ratings yet

- RA-Z - Ants Ants and More Ants - CLR PDFDocument7 pagesRA-Z - Ants Ants and More Ants - CLR PDFPaula LeeNo ratings yet

- Use The Gerund: Use The Infinitive With ToDocument2 pagesUse The Gerund: Use The Infinitive With ToKarolina PopławskaNo ratings yet

- Camiguin ItineraryDocument2 pagesCamiguin ItineraryJoyce Antoinette LagatNo ratings yet

- Soal Present Past TenseDocument6 pagesSoal Present Past TenseSupri HandokoNo ratings yet

- UntitledDocument136 pagesUntitledAdam RaflyNo ratings yet

- Key English collocations documentDocument4 pagesKey English collocations documentNguyễn Ngọc Mỹ AnhNo ratings yet

- Soal Persiapan UNBK 2018Document2 pagesSoal Persiapan UNBK 2018robi ganyongNo ratings yet

- How lack of sleep hurts college students' health and gradesDocument14 pagesHow lack of sleep hurts college students' health and gradesfran_10jessica7825% (8)

- The Plastic Planet: Understanding and Reducing Plastic FootprintDocument26 pagesThe Plastic Planet: Understanding and Reducing Plastic FootprintEnosh100% (1)

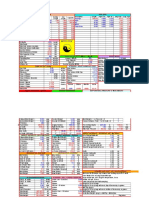

- Anup Calculation SheetDocument33 pagesAnup Calculation SheetAziz AndriyantoNo ratings yet

- Writting b1 1Document24 pagesWritting b1 1Thanh ThảoNo ratings yet

- Lesson 5 - Writing Part 3 & Part 4 (Informal Email) I. Sample QuestionsDocument11 pagesLesson 5 - Writing Part 3 & Part 4 (Informal Email) I. Sample QuestionsPhương Thanh VũNo ratings yet

- Cleaning Schedule - Equipment TemplateDocument2 pagesCleaning Schedule - Equipment TemplateEduyNo ratings yet

- The Den Happy HourDocument1 pageThe Den Happy HourFarley ElliottNo ratings yet

- Avocados: LACTUCARIUM, Which Is A Sleep Inducing NutrientDocument2 pagesAvocados: LACTUCARIUM, Which Is A Sleep Inducing Nutrientjoseph brownNo ratings yet

- Marketing Management 1st Edition Iacobucci Solutions Manual 1Document14 pagesMarketing Management 1st Edition Iacobucci Solutions Manual 1beulah100% (49)