Professional Documents

Culture Documents

Service Information: July/97 II 54 - Nº: 02/97 54 10/97

Service Information: July/97 II 54 - Nº: 02/97 54 10/97

Uploaded by

Marcelo GiussaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Information: July/97 II 54 - Nº: 02/97 54 10/97

Service Information: July/97 II 54 - Nº: 02/97 54 10/97

Uploaded by

Marcelo GiussaniCopyright:

Available Formats

service information

Date: July/97 Distribution: II Substitues: Gr.: 54 - Nº: 02/97 Gr.: 54 Nr.: 10/97

Damage prevention on vehicles, when performing electric welding jobs

Considering that most of the failures occurring on electronic components are the result of excessive voltage

(burning of resistances and diodes) produced by electric welding on vehicles without taking the recommended

protection measures, we call your attention again on the precautions that must be necessary adopted, already

stated in the manuals referring to the “Instruction for installation of bodies and equipments”.

ATTENTION!

Before starting welding jobs, make sure that all the needed protection/safety equipment are available.

• Disconnect previously:

- battery cables and alternator terminals;

- electric harness of the electronic dashboard, the electronic tachygraph, electronic modules and other even-

tually installed electronic equipment.

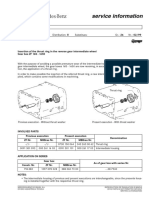

• Connect the “ground” terminal of welding equipment, directly to the part to be welded or near this one.

Remark:

To connect the “ground” terminal of the welding equipment, do not connect to vehicle’s parts or components

that received special treatment or are submitted to variable stress during vehicle operation. As for example,

the spring leaves and coil springs where any spark due to poor contact, while welding, will damage the part

surface or may conduct to rupture by fatigue.

In the same way, the wheel hub bearings may be damaged by corrosion of their races in case of sparking pro-

duced by the “ground” terminal of the welding equipment on the wheel hub.

• Do not weld on components such as: engine, gearbox, propeller shaft, front axle, rear axle housing, springs,

side members and chassis cross members.

Remark:

For the OF/OH-L vehicles, welding jobs on chassis frame side-members are accepted, except in the areas

where the chassis load is actuating such as: near the parabolic springs supports or suspension thrust ele-

ments, steering box support, etc.

• Do not weld near sending units when installed.

• When performing welding jobs near the fuel tank, remove and protect it.

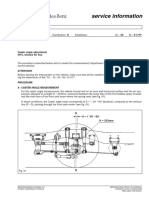

In case of O 400 UPA platforms, we have to warn about the absolute need to disconnect all the vehicle’s electron-

ic modules such as: articulation module, acceleration module, transmission module (gearbox).

We also have to mention that some articulation modules submitted to analysis present a connector/plug damage

with mishandling signals during its plugging/unplugging. In this particular, we do recommend that such opera-

tions are to be conducted with a maximum of care, paying attention to the unlocking of the connectors/plugs

when unplugging/plugging them.

MERCEDES-BENZ DO BRASIL S.A. REPRODUCTION OR TRANSLATION IN WHOLE

GERÊNCIA DE ASSISTÊNCIA TÉCNICA OR IN PARTS IS NOT PERMITTED WITHOUT

WRITTEN AUTHORIZATION

S.I. 54 - 10/97

Page 02

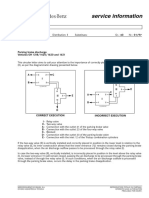

Unlocking of connectors/plugs:

• Articulation module - move laterally the red colored lock to be found on the left face of the connector;

• Acceleration module - lift the metallic lock (clip type), to be found on the frontal face of the connector.

• Transmission module - unscrew the threaded sleeve of the three connectors.

ATTENTION!

• We kindly ask to inform all the directly concerned persons about what is stated here above.

• In case of damages due to the above mentioned causes, the components replacement will not be considered

under warranty.

MERCEDES-BENZ DO BRASIL S.A.

Service

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: December/99 II 58 10/99Document2 pagesService Information: December/99 II 58 10/99Marcelo GiussaniNo ratings yet

- Service Information: December/99 II 58 09/99Document2 pagesService Information: December/99 II 58 09/99Marcelo GiussaniNo ratings yet

- Service Information: January/00 II 00 01/00Document10 pagesService Information: January/00 II 00 01/00Marcelo GiussaniNo ratings yet

- Service Information: June/98 II 26 05/98Document2 pagesService Information: June/98 II 26 05/98Marcelo GiussaniNo ratings yet

- Service Information: August/99 II 00 06/99Document2 pagesService Information: August/99 II 00 06/99Marcelo GiussaniNo ratings yet

- Service Information: Execution With CapDocument4 pagesService Information: Execution With CapMarcelo GiussaniNo ratings yet

- Service InformationDocument4 pagesService InformationMarcelo GiussaniNo ratings yet

- IS064IDocument2 pagesIS064IMarcelo GiussaniNo ratings yet

- Service Information: November/98 I 54 13/98Document14 pagesService Information: November/98 I 54 13/98Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: November/98 I 54 09/98Document14 pagesService Information: November/98 I 54 09/98Marcelo GiussaniNo ratings yet

- Service Information: November/99 I 35 01/99Document2 pagesService Information: November/99 I 35 01/99Marcelo GiussaniNo ratings yet

- Service Information: September/98 II 26 07/98Document4 pagesService Information: September/98 II 26 07/98Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: July/97 I 54 09/97Document2 pagesService Information: July/97 I 54 09/97Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: September/98 II 58 04/98Document10 pagesService Information: September/98 II 58 04/98Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: May/98 II 58 03/98Document2 pagesService Information: May/98 II 58 03/98Marcelo GiussaniNo ratings yet

- Service Information: August/96 II 54 - Nº: 0695 54 04/96Document2 pagesService Information: August/96 II 54 - Nº: 0695 54 04/96Marcelo GiussaniNo ratings yet

- Service Information: July/97 I 25 01/97Document2 pagesService Information: July/97 I 25 01/97Marcelo GiussaniNo ratings yet

- Service Information: ST ND RD ST STDocument2 pagesService Information: ST ND RD ST STMarcelo GiussaniNo ratings yet

- Service Information: May/97 II 01 01/97Document2 pagesService Information: May/97 II 01 01/97Marcelo GiussaniNo ratings yet

- Service Information: May/97 II 32 01/97Document2 pagesService Information: May/97 II 32 01/97Marcelo GiussaniNo ratings yet

- Service Information: May/97 I 41 01/97Document2 pagesService Information: May/97 I 41 01/97Marcelo GiussaniNo ratings yet

- Service Information: April/97 II 47 01/97Document2 pagesService Information: April/97 II 47 01/97Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: 08/96 07/96 58 35 November/96 IIDocument2 pagesService Information: 08/96 07/96 58 35 November/96 IIMarcelo GiussaniNo ratings yet