Professional Documents

Culture Documents

Abdul Jabbar 00656815 IG2 Assignment

Uploaded by

rubentemmuaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abdul Jabbar 00656815 IG2 Assignment

Uploaded by

rubentemmuaCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/359787646

Unit IG2: Risk assessment

Technical Report · April 2022

CITATIONS READS

0 3,406

1 author:

Abdul Jabbar

University of Science and Technology Beijing

6 PUBLICATIONS 0 CITATIONS

SEE PROFILE

All content following this page was uploaded by Abdul Jabbar on 07 April 2022.

The user has requested enhancement of the downloaded file.

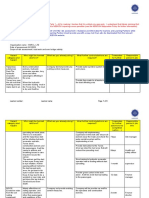

Hazard category Who might be harmed What are you already What further controls/actions are Timescales for

and hazard and how? doing? required? further actions Responsible

to be person’s job

completed title

(within …)

Work at Height Double lane yard harness is 1. Scaffolding area should be 1 Month Project

Area Supervisor mandatory while working on inspected and approved by Director

Erected Scaffolding ,Scaffolder , Scaffolder height certified inspector which is

on 36 feet height for helper , and other Periodic health monitoring of need to be deployed at the

masonry work of workers workers while working at site and proper

Building height is practicable documentation is necessary

2. Proper Safety measurement 2 Days Site Engineer

Poor Housekeeping can while erecting and (2,3)

cause slip and fall to dismantling of scaffolding

workers and scaffolder 3. PTW procedure should adopt 3 Days

before execution of work

Workers can slip on the 4. Protected edges ,Open are

object laying on the should be covered ,Proper 2 Days Site

platform Guard Railing system should Supervisor

be strictly followed (4,5)

unsafe Scaffolding can 5. Good House Keeping in 7 days

collapse and dangerous working place

for those who are 6. Pieces of pipe and Safety

climbing or working on scaffolding tool and other 1 Day Supervisor

scaffolding material remove from the

platform

Learner number: 00656815 Learner name: Abdul Jabbar Page 4 of 17

Hazard category Who might be harmed What are you already What further controls/actions are Timescales for

and hazard and how? doing? required? further actions Responsible

to be person’s job

completed title

(within …)

Noise All workers who are A noise assessment carried 1. A suitable noise meter 6 Months Finance

involved in these out Six month ago when should be installed Manager

Exposure of Noise activities and worked masonry work was under (1,2,3)

during different process 2. Barriers or absorbing 3 Months

activities without ear Exposure of noise may material of noise in the

protection cause a everlasting Old Hearing protective noisier areas

hearing loss equipment was replaced

.Suitable equipment issued to

A study data shows that those worker who are 3. Setting up health

more that 2 million working in noise exposure surveillance program to 1 Month

people are exposed to a workplace those workers who are

dangerous noise level. working in noisy areas

Those workers working 4. Carry out Noise risk 1 month Safety

in highly noise exposure assessment every month Supervisor

areas more than 80 dB (4,5)

cause NIHL

5. Provide Adequate training to 6 Month

the staff

Electricity Any skilled person using The electrical installation is in All risks are well-ordered in N/A N/A

Possible fault disorder equipment or progress meanwhile professional way so no further action

Portable electric installation on periodically inspection of required

equipment the site installed electrical facilities

like grinder after any changing in

machine The most harmful burn execution plan

,Welding ,electric shock ,lost time

plant injury or even death Main circuit breaker is

General while working with installed in the accessible

Electric disorder equipment area in case of emergency

Learner number: 00656815 Learner name: Abdul Jabbar Page 5 of 17

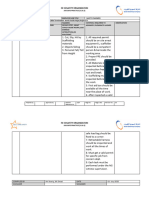

Hazard category Who might be harmed What are you already What further controls/actions are Timescales for

and hazard and how? doing? required? further actions Responsible

to be person’s job

completed title

(within …)

installation All labours received training

for whole how to respond any incident

site related to electric shock

First aider is available in the

work place to handle minor

electric shocks

Work Equipment All person involved in Proper training related to 1. Replace manual handled 14 Days Finance

and Machinery handling manually usage of work equipment is equipment with portable Manager

,power tools, and provided to all workers electric tools such as circular

Manual handled machine operators wood cutter etc.

tools ,power tools PPE to handle, manual, 2. To ensure safe condition of 7 Days Electrical

and machinery Close to worker power tool and machinery is the equipment proper Supervisor

facilitation centre provided to workers inspection and maintenance (2,3)

workers were performing is required

different activities with 3. Proper labelled instruction of 3 Days

manual handling tools the equipment should be

which is ot appropriate delivered to the workers

place to perform tasks 4. Proper space and proper 5 Days Safety

place to handle the work Supervisor

Manual operated tools equipment

without proper 5. Only Authorised person 7 Days

inspection and should allow to perform the Site

maintaince can cause task Supervisor

entrapments which may 6. Proper warning signs should 14 days (5,6

lead to ,cuts, abrasion, be available while work in

and organ damage progress

Learner number: 00656815 Learner name: Abdul Jabbar Page 6 of 17

Hazard category Who might be harmed What are you already What further controls/actions are Timescales for

and hazard and how? doing? required? further actions Responsible

to be person’s job

completed title

(within …)

Slips and trips All workers and visitors Health Surveillance of 1. Drainage system should 14 Days Site

workers develop for the water Supervisor

Hazards due to 2. Arrange the flowers to be 1 Month (1,2)

Curing plaster works water Spills on smooth Provision of PPE dried at least once a week

Concrete Slabs floor or in walking zone 3. Develop walkways by yellow 1 week

without Proper strips Safety

drainage System Wet or muddy shoes 4. Good Housekeeping 3 Days Supervisor

leads to slip and trip (3,4,5)

5. Proper indication and proper 3 days

Loose irregular surfaces inspection

such as gravels

Any kind of debris

accumulated in the

working zone

Hazardous All the skilled labour and Area Barricade and 1. Provision of Suitable PPE 7 Days Safety

Substance helpers whose are unauthorized persons are not like gloves ,masks and Supervisor

(Chemical performing paint task allowed into the working goggles

Substance areas

Fumes of paints can 2. MSDS labelled equipment 3 days Site Engineer

Paint work on grills pollute the air installed effective exhaust for should use while perfoming

and on the Building ventilation straight paint jobs

structure with Solvents vapours may

machine. It may cause damage to eyes Competent person used to

cause serious and skin perform paint and spraying 3. Appropriate safety training to 2 Weeks Site

problems of irritation works the skilled and non-skilled Supervisor

,eye damage and organic content of paints labours

may be a leading may cause allergic 4. Periodic method of tools 1 month

cause of fire reaction such as inspection should adopt Site

irritation on skin 5. Spray gun and compressor Supervisor

inspect before starting the 7 Days (4,5)

task

Learner number: 00656815 Learner name: Abdul Jabbar Page 7 of 17

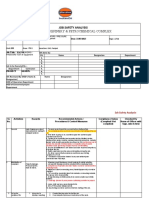

Hazard category Who might be harmed What are you already What further controls/actions are Timescales for

and hazard and how? doing? required? further actions Responsible

to be person’s job

completed title

(within …)

Ergonomics Site supervisor ,skilled Written and verbal 1. Provision of training for safe 14 days Safety

Work related upper- labour, non-skilled communication for safe manual handling supervisor

limb disorder labour and management manual loading and unloading 2. Proper Supervision while 3 Days

staff to the workers manual handling Site

Labours and helpers 3. Minimise manual handling by 7 Days supervisor

who are carrying out Manually handling of Avoid manual handling for usage of trolley or machinery (2,3,4)

the heavy objet from heavy and light material hazard substance to move the heavy materials

store to the working from store to workplace 4. Implement right angle rule 7 Days

place that can lead has a lot of risk like back Visible sign board for manual while lifting manually handled

to back injury in injury cause of heavy handling load with straight arms and

case of holding load and foot injury in right position

object or picking case of dropping down 5. Good housekeeping 3 Days Safety

object in wrong .Store keeper must know Supervisor

posture or foot injury how to handle the

in case of dropping picking up material and

material provision of pallet trolley

to handle heavy object

Fire workers, supervisor Proper Provision of PPE 1. Emergency fire drill need to 1 Month Safety

Hot work job activity ,visitors and all other related to hot work jobs. be held periodically Supervisor

like grinding and staff

welding Good Housekeeping 2. Fire Water system install and 20 Days Project

During grinding and installation of Fire Director

welding any flammable Extinguisher

material can caught fire

to lead a serious 3. introduce Permit to work 7 Days Site Engineer

explosion ,cause system and mention all the

flammable material in possible risk and their

form of wood, plastic reduction

and other related 4. Always use fire proof sheet 3 Days Site

material is present on while hot work job Supervisor

the working site

Learner number: 00656815 Learner name: Abdul Jabbar Page 8 of 17

Hazard category Who might be harmed What are you already What further controls/actions are Timescales for

and hazard and how? doing? required? further actions Responsible

to be person’s job

completed title

(within …)

Person related to 5. Inspection of Fire 7 Days Safety

welding or grinding may Extinguisher Supervisor

harm due to contact with (5,6)

fire. 6. inform supervisor if there is 3 Days

any fault in welding or

grinding electric cable

Vibration workers related to the Area barricade while working 1. Machinery related to 14 Days Site

All grinding and mixture ad grinding vibration should be used for Supervisor

concrete mixture activities Anti-vibrations gloves are limited time

machines activities Excessive use of provided

concrete mixture 2. Health surveillance program 1 Month Project

machine and grinding Workers are trained to use should be active Director

machine like disc cutter mixture machine and grinder

lead to hand arm 3. Adequate training to handle 7 Days Site

vibration such as vibrating machineries Supervisor

vibration white finger

4. Proper risk assessment carry 5 Days Safety

Vibration could cause out Supervisor

pain or permanent (4,5)

disability 5. Proper inspection of all 1 month

vibrating equipment’s

Movement of People All workers on site Proper Barricade around the No further action is required N/A N/A

and Vehicles in especially those who parking zone

Workplace load and unload the

material from the Foot path are clearly marked

Parking of the vehicles

vehicles in parking Collision may cause Only licensed holder drivers

zone and losing of serious injuries and are allowed to drive the

vehicle controls fatigue of the victim vehicle

while moving in or

Learner number: 00656815 Learner name: Abdul Jabbar Page 9 of 17

Hazard category Who might be harmed What are you already What further controls/actions are Timescales for

and hazard and how? doing? required? further actions Responsible

to be person’s job

completed title

(within …)

out in parking zone Proper maintained record of

all vehicles

All vehicles are certified by

government vehicle safety

inspector

All sign board related to

usage of vehicle placed on

the bay of Parking

Load Handling Mobile crane Operators, Visual Inspection before 1. Provision of Proper Personal 3 Days Site

Equipment Forklift truck operators operating forklift truck and protective Equipment Supervisor

and other persons mobile crane 2. Check all lifting gears and all

Forklift Truck and involved in these necessary element like 1 Week

Mobile crane is used working Helpers and operators are 3rd shekels, D shekels sling web Safety

to lift and shifting the accomplishments party certified belt etc. before execution of Supervisor

material. Mobile the work (2,3)

crane used for Mobile crane used to Provide safety Induction 3. Provide proper training to all 2 Week

roofing material. shift the roofing material before execution of work skilled labour

at height ,if it fails due to Barricade areas where

Forklift truck was mechanical fault then it operation of forklift truck and 4. Safe operations designed

using to shift the may lead to serious mobile crane occurred before implementing 14 Days Site

material on the site injury ,property loss mechanical operations Supervisor

even fatigue Separate footpath for 5. Competency of forklift truck 5 Days (4,5)

pedestrian and mobile crane operator

Forklift truck is used for must check

rd

shifting the material, Authorized persons are 6. Inspected all machines by 3 7 Days Safety

Load was not secured allowed to enter in these Party Supervisor

and according to safe areas

limit of prescribed MSDS

of forklift truck .This

Learner number: 00656815 Learner name: Abdul Jabbar Page 10 of 17

Hazard category Who might be harmed What are you already What further controls/actions are Timescales for

and hazard and how? doing? required? further actions Responsible

to be person’s job

completed title

(within …)

could lead to falling

down the material and in

this could occure injury

abrasion or death.

Learner number: 00656815 Learner name: Abdul Jabbar Page 11 of 17

Financial

Financial impact of work place injury can be described in the four ways.

1. The first thing in financial impact is that an injured person cannot work in same capacity as

he was performing the job during his fitness time period. Work can leave couple of days

according to physical injury situation .It will loss the production rate and loss of income.

2. A minor injury can be treatable with first aid kit but a severe injury may lead to

hospitalization, loss of mobility ,or any other disabilities .Employer is legally bound to pay all

medical cost

3. Financial compensation for injured person like medical bills ,lost income and other

associated loss

4. Additional Expenses in form of indirect cost due to last time injury or due to absence of the

workers ,if this take a long time then to trained other persons .Fines due to violation of

Health and Safety Rules

Direct cost is insured but indirect cost is uninsured that cannot be clearly defined.

Justification for action 1

Action Purchasing and fixing dust collector system to remain safe from excessive inhalation of dust

particles which may have chronic effect on the workers.(Hazard Category. Hazardous substance

Dust)

Specific legal arguments OSHA standard (1926.57 C - Ventilation) narrated Design and operations for exhaust fans ,jets

,ducts ,hood and Separators .A dust Collector should be designed to maintain health safety

program active for the workers who are working in dusty areas .By installation of Dust collector

sufficient purified air will be available for the workers who are exposures to the dust. Dust collector

is used for safe disposal of dust and purifies the atmosphere area of working place. Its legal

responsibilities of employer to provide safe working environment

Consideration of likelihood AND severity The likelihood of illness in working place is high because workers are working in the exposure of

dust particles .Workers are at risks without proper safety measurement The likelihood of risks

range from acute to high risks .The severity of this risk is totally dependent upon inhalation in dusty

polluted . It may be short term risk like skin irritation and visual disruption. It may be long term risk

like Asthma, lung cancer etc.

From prescription of risk the severity may be described in four stages due to dust as following :

When measuring the severity risk are categorized in 4 different phase

Learner number: 00656815 Learner name: Abdul Jabbar Page 13 of 17

The likelihood of injuries due to working at height is too high .Scaffolding erection is done step by

Consideration of likelihood AND severity

step so workers went up on for erection of scaffolding next step without following any safety rules

.The severity of the risk occurring can be in serious condition.

When measuring the severity risk are categorized in 4 different phase

5. Minimal : Any incident without No injury or damage

6. Minor : A partial injury which could be recoverable on the site or partial imbalance

7. Major : Any injury where hospitalization required or absence from the work due to illness

8. Fatal :Death or collapse of Structure or complete damaged of machinery

I have set realisation of severity on major phase. It may require hospitalization for recovering from

illness.

How effective the action is likely to be in

Third party certified scaffolding inspector will be well trained to erect scaffolding in safe manner and

controlling the risk. This should include:

inspection of temporary platform during working on Height .Its obligatory to check the PPE’’s like

the intended impact of the action; safety harness belt or safety net that can reduce the falling risks from height .Suitable Platform will

justification for the timescale that you decrease the risk to minimal amount and provide mentally satisfaction to the workers while working

indicated in your risk assessment; on height.

and I have given 1 month time frame to complete this job. This time frame is enough for Human

whether you think the action will fully resources department to advertise and hire a competent person for scaffolding erection and

control the risk. inspection.

The risk will be as low as reasonably practicable by recruiting a new incumbents cause his job

assignment will be supervision and erecting of scaffoldings

Justification for action 3

Action Fire fight equipment like fire extinguisher ,sand bucket and fire hydrant system installation required

and it should be accessible for any emergency and applying hot work permit system ( Hazard

Category -Fire)

Specific legal arguments OSHA standard for Construction (29 CFR 1926) narrates fire protection and fire managing

regulation in the construction industry. Suitable fire control equipment shall be available in the

working zone and it should be maintained for immediate use. Country Fire department adopted

OSHA slandered as part of its legislation .Banu Mukhtar has legal responsibility to fulfil the

requirement of country fire department as well as OSHA slandered to continue their working

Learner number: 00656815 Learner name: Abdul Jabbar Page 15 of 17

Consideration of likelihood AND severity During hot work if there is no fire fighting equipment available, it is more likely that spark of electric

cables or grinding can cause a explosive fire in working zone. The risk of fire always associated

with fire triangle. There is presence of fire triangle in all development projects. So there is suitable

precautions are mandatory by considering the severity factor

When measuring the severity risk are categorized in 4 different phase

1. Minimal : Any occurrence without any injury or damage

2. Minor : A limited injury which could be recoverable by First Aid treatment

3. Major : Hospitalization is mandatory or absence from the work due to illness

4. Fatal :Serious injury which result in death or collapse of Structure or complete damaged

of machinery

I have set risk severity on major category which required hospitalization treatment for recovery from

illness

How effective the action is likely to be in

Fixing of Fire protecting equipment’s like (fire extinguisher, sand bucket and fire hydrant) must be

controlling the risk. This should include:

place at accessible point in working area that can highly reduce the likelihood of ignition of fire by

the intended impact of the action; means of thoroughly inspection. Grinder cutter sparks cause of fire explosion due to poor

justification for the timescale that you housekeeping in working zone. Availability of fire fighting equipment’s can minimize the

indicated in your risk assessment; consequences or severity of fire in case of fire accident.

and I have given 20 Days timescale for fixing of Fire Protection Equipment. I will discuss Project

whether you think the action will fully Director and procurement department to purchase and install the Fire protecting equipment

control the risk. .Procurement committee meeting discussions and implementation will take 20 days for this purpose

This action will maximum reduce the risk of fire after installing of the compulsory fire protecting

equipment

Learner number: 00656815 Learner name: Abdul Jabbar Page 16 of 17

Part 4: Review, communicate and check

Suggested word counts for each section:

Planned review date or period and reasoning for this: 50 - 100 words

How the risk assessment findings will be communicated and who needs to know the information: 100 - 150 words

Follow up on the risk assessment: 100 - 150 words.

Planned review date/period with It is company policy to review all risks every year .Therefore I set risk assessment review data not

reasoning later than 6 Feburary 2023. However risk assessments have no legal time scale when you can

review your risk assessment. It is totally dependent upon organization demand and hence it can be

reviewed on following bases:

1. Risk assessment review required If there is any new working Procedure adopted by the

organization

2. Risk assessment review needed If there is any new legal procedure implemented by the

national enforcement agencies

3. Risk assessment is compulsory if there is any catastrophic event occurred organizations.

How the risk assessment findings will be I will arrange a meeting with Project Director, HSE Manager, and Site Engineer to brief about risks

communicated AND who you need to tell occurring on the sites and suggest actions about correction or minimizing the risk. I provided the

summary of all risks related to the construction sites to the Project Director .Meanwhile Agenda of

meetings, recommendations of meeting and conclusion points of the meeting will email to all

concerned person for record .Major risks should be conveyed to the all employees via tool box talk

or by posters. A summary of risk assessment and safe procedure of work place will be delivered

via social media page to all employees of firms

How you will follow up on the risk I will set a reminder of 15 days to remind the concerned department for implementation of

assessment to check that the actions suggested recommendations for corrections. I will talk to the responsible authorities about the

have been carried out status of procedure either they implemented or still the action is required .Meanwhile I will also

inquire if the actions is still pending, if the actions are still pending then I will try to know the reason

behind it .If there will be any problems to handle the situation ,I will discuss with project director

either there is any alternative solution of the actions .If these will be remain overdue for more than 3

month then an information will be conveyed to the Managing Director via Project director for

actions.

Learner number: 00656815 Learner name: Abdul Jabbar Page 17 of 17

View publication stats

You might also like

- Ig2 ProjectDocument18 pagesIg2 Projectvivek vjNo ratings yet

- Abhay Ig2 XamDocument11 pagesAbhay Ig2 Xamabhilash sureshNo ratings yet

- Amal A5Document4 pagesAmal A5Asif NNo ratings yet

- Mohammad Shahbaz Ali - IG2Document23 pagesMohammad Shahbaz Ali - IG2NIRANJANMURTHY ASST.EXECUTVIE ENGINEERNo ratings yet

- Unit IG2: Risk Assessment Part 1: Background: 00267373 Sarath Babu. RDocument9 pagesUnit IG2: Risk Assessment Part 1: Background: 00267373 Sarath Babu. RSarath Babu82% (17)

- Nixon Nikhil 00761635 Tciq ProjectDocument17 pagesNixon Nikhil 00761635 Tciq ProjectNikhil Nixon100% (4)

- 0 - Ig2 Forms Electronic SubmissionDocument17 pages0 - Ig2 Forms Electronic Submissionvishnukarukayil89% (18)

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- IG2 Project Risk Assessment RoughDocument21 pagesIG2 Project Risk Assessment RoughRemya83% (6)

- Ig2 Forms Electronic Submission v5.1 (6) (2) OldDocument9 pagesIg2 Forms Electronic Submission v5.1 (6) (2) Oldabhilash sureshNo ratings yet

- Ig2 Forms Electronic Submission v2 1 1Document15 pagesIg2 Forms Electronic Submission v2 1 1NishanthNo ratings yet

- Ig2 Forms Electronic Submission v3Document12 pagesIg2 Forms Electronic Submission v3Nowfal Habeeb100% (1)

- Risk Assessments Report PDFDocument13 pagesRisk Assessments Report PDFNishanthNo ratings yet

- Hafiz Ahmad Faraz - 00563027Document15 pagesHafiz Ahmad Faraz - 00563027vivek vj100% (1)

- Specicifc Risk AssessmentDocument5 pagesSpecicifc Risk AssessmentAejaz MujawarNo ratings yet

- 1G2 10 Engro@786Document20 pages1G2 10 Engro@786Odoka J Khan100% (1)

- Unit IG2: Risk Assessment: work/resources-library/publications/WCMS - 633233/lang - En/index - HTMDocument17 pagesUnit IG2: Risk Assessment: work/resources-library/publications/WCMS - 633233/lang - En/index - HTMRizwan HameedNo ratings yet

- Unit IG2: Risk Assessment Part 1: BackgroundDocument17 pagesUnit IG2: Risk Assessment Part 1: BackgroundStven Smith100% (6)

- JSA-002 JSA For TCFDocument4 pagesJSA-002 JSA For TCFRafeeq Ur RahmanNo ratings yet

- Ig2 Report Muhammad ArslanDocument18 pagesIg2 Report Muhammad ArslanShaheen Himalyn salt88% (8)

- Risk Assessment Ig2 Passing 003Document20 pagesRisk Assessment Ig2 Passing 003Qasim Ibrar80% (5)

- Report 1234Document13 pagesReport 1234Qaisar khanNo ratings yet

- 1ig2 Forms Electronic SubmissionDocument20 pages1ig2 Forms Electronic SubmissionAejaz MujawarNo ratings yet

- Unit IG2: Risk Assessment Part 1: BackgroundDocument9 pagesUnit IG2: Risk Assessment Part 1: BackgroundREVANTH KUMARNo ratings yet

- Part 2 Correct OneDocument8 pagesPart 2 Correct OneMock ProjectNo ratings yet

- 733.learner No - IG2. 20.08.2020.OBE, DL, SaudiArabiaDocument11 pages733.learner No - IG2. 20.08.2020.OBE, DL, SaudiArabiaMominul hoqueNo ratings yet

- Unit IG2: Risk Assessment: You Should Aim To Complete This Section in 150 - 200 WordsDocument10 pagesUnit IG2: Risk Assessment: You Should Aim To Complete This Section in 150 - 200 WordsMuhammad QureshiNo ratings yet

- Azhar Report.Document16 pagesAzhar Report.qaiserhameed360No ratings yet

- Unit IG2: Risk AssessmentDocument24 pagesUnit IG2: Risk AssessmentNowfal Habeeb85% (13)

- Risk Assesment of Workplace.Document17 pagesRisk Assesment of Workplace.Sufyan SufyanNo ratings yet

- Dyamanna Malapur - IG2Document24 pagesDyamanna Malapur - IG2NIRANJANMURTHY ASST.EXECUTVIE ENGINEER100% (1)

- Unit IG2 Risk Assessment Soap Manufacturing FactoryDocument8 pagesUnit IG2 Risk Assessment Soap Manufacturing FactoryprinceNo ratings yet

- Khan, Haider, 00733916, SaveFast Fire and SafetyDocument16 pagesKhan, Haider, 00733916, SaveFast Fire and SafetyGhazanfar Rehman67% (3)

- E&I - 13, JSA For Separation & Drying AreaDocument8 pagesE&I - 13, JSA For Separation & Drying AreaNikunja mohantyNo ratings yet

- Job Hazard Analysis of Fabrication WorkDocument7 pagesJob Hazard Analysis of Fabrication WorkBALAL AKRAMNo ratings yet

- Nebosh IG2 Risk Assessment Rigging Site PDFDocument16 pagesNebosh IG2 Risk Assessment Rigging Site PDFNishanthNo ratings yet

- Unit IG2: Risk Assessment Part 1: BackgroundDocument17 pagesUnit IG2: Risk Assessment Part 1: BackgroundNIRANJANMURTHY ASST.EXECUTVIE ENGINEERNo ratings yet

- 5.19-FO-33-JOB SAFE PRACTICE Hajer-Nujha SS - T-6Document2 pages5.19-FO-33-JOB SAFE PRACTICE Hajer-Nujha SS - T-6Shariq AhmedNo ratings yet

- Only For Reference Do No Copy 3Document17 pagesOnly For Reference Do No Copy 3Sindhi ChowkrowNo ratings yet

- Hydro TestDocument8 pagesHydro Testmozzammil saqibNo ratings yet

- Faizan Ahmed KhanDocument14 pagesFaizan Ahmed KhanFaizan Ahmed KhanNo ratings yet

- Day 3 Job Hazard Analysis (Handout)Document6 pagesDay 3 Job Hazard Analysis (Handout)mike camsNo ratings yet

- IG2 Risk Assessment Report 001Document19 pagesIG2 Risk Assessment Report 001Qasim Ibrar79% (42)

- Risk Assessment - Installation of Cable Trays & DCAC CablesDocument5 pagesRisk Assessment - Installation of Cable Trays & DCAC CablesIbrahim Esmat100% (1)

- Installation of Fence For Office Lay Dawn Area.Document6 pagesInstallation of Fence For Office Lay Dawn Area.nrphsebarauniNo ratings yet

- JSA For Scaffolding Erection and Dismentling Inside The Building Room at Accommodation Block CDocument5 pagesJSA For Scaffolding Erection and Dismentling Inside The Building Room at Accommodation Block Cnoahlungu96No ratings yet

- JSA GI Earthstrip at PTAO&M Building 05Document5 pagesJSA GI Earthstrip at PTAO&M Building 05Saiyad RiyazaliNo ratings yet

- Hadeed JSA Shearing Machine InstallationDocument11 pagesHadeed JSA Shearing Machine InstallationDhanu NikkuNo ratings yet

- JHA of Painting PDFDocument3 pagesJHA of Painting PDFTanver Ali100% (1)

- Unit NG2: Risk AssessmentDocument13 pagesUnit NG2: Risk AssessmentMyounas83% (6)

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Bar Bending & Cutting JSADocument2 pagesBar Bending & Cutting JSACharantej TejaNo ratings yet

- Scrap Material Handling & Loading Jha - 1Document2 pagesScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- Khaleel Basha Shaik, 00734394,1308-Bharat Safety Training Igc 2 - Report 3Document15 pagesKhaleel Basha Shaik, 00734394,1308-Bharat Safety Training Igc 2 - Report 3s khaleel basha100% (4)

- Risk Assessment Form: 1. Workin Gat HeightDocument3 pagesRisk Assessment Form: 1. Workin Gat HeightS.SRI KRISHNA (RA2111026020166)No ratings yet

- Scrap Material Cutting, Handling & Loading Jha - 2Document3 pagesScrap Material Cutting, Handling & Loading Jha - 2Dwitikrushna Rout100% (5)

- Menon P Ravikeerthi 00761732 Tciq ProjectDocument19 pagesMenon P Ravikeerthi 00761732 Tciq ProjectNikhil Nixon100% (7)

- Risk Assessment For Demolishing of Burnt Ware of Procurement DepartmentDocument10 pagesRisk Assessment For Demolishing of Burnt Ware of Procurement DepartmentEdmund KonoteyNo ratings yet

- JOB SAFETY ANALYSIS - Structural PaintingDocument1 pageJOB SAFETY ANALYSIS - Structural PaintingSajith C PauloseNo ratings yet

- The Agile Codex: Re-inventing Agile Through the Science of Invention and AssemblyFrom EverandThe Agile Codex: Re-inventing Agile Through the Science of Invention and AssemblyNo ratings yet

- MLS Brochure English Lowres For WebDocument12 pagesMLS Brochure English Lowres For WebAkmal AriqNo ratings yet

- Noise Metrics and Regulations: Objectives of This SectionDocument21 pagesNoise Metrics and Regulations: Objectives of This SectionSanthosh Kumar H V PESU ME DeptNo ratings yet

- Hearing ProtectionDocument1 pageHearing ProtectionRobby IrmawanNo ratings yet

- Occupational Health, Safety and Risk Analysis: August 2014Document12 pagesOccupational Health, Safety and Risk Analysis: August 2014prominceNo ratings yet

- 4 - CHECKPOINT Pengurusan BisingDocument47 pages4 - CHECKPOINT Pengurusan BisingcarolNo ratings yet

- Laney LC50-112 ManualDocument16 pagesLaney LC50-112 ManualAldo VidalNo ratings yet

- tm6260 51 99-2 September2008Document43 pagestm6260 51 99-2 September2008anil nsNo ratings yet

- Noise Code of Practice 2004Document38 pagesNoise Code of Practice 2004Tuan Suhaimi SallehNo ratings yet

- Azizi - Occupational Noise-Induced Hearing LossDocument8 pagesAzizi - Occupational Noise-Induced Hearing LossAna BrankovićNo ratings yet

- Mra Sop-Hse-01 Hse ProgramDocument17 pagesMra Sop-Hse-01 Hse ProgramFarid B. MahaliNo ratings yet

- Assessment of Noise Level and Its Impacts On Health in Different Industries Located in Khulna CityDocument7 pagesAssessment of Noise Level and Its Impacts On Health in Different Industries Located in Khulna CityAtiqur RahmanNo ratings yet

- Elacin ER BrochureDocument2 pagesElacin ER BrochurealfpercuNo ratings yet

- AV-SWP-27 Noise Management Iss 1Document3 pagesAV-SWP-27 Noise Management Iss 1Kevin DeLimaNo ratings yet

- WKS 5 HSWA Identifying Assessing Managing Work RisksDocument26 pagesWKS 5 HSWA Identifying Assessing Managing Work Risksbalkanika_1No ratings yet

- ELEMENT 5 Physical and Psychological Health1Document26 pagesELEMENT 5 Physical and Psychological Health1asn qureshiNo ratings yet

- Ig2 Example v5Document18 pagesIg2 Example v5Dhanush Nandhan50% (2)

- AbdulJabbar00656815IG2Assignment PDFDocument18 pagesAbdulJabbar00656815IG2Assignment PDFAnass BelakbirNo ratings yet

- Leq Noise CalculatorDocument7 pagesLeq Noise Calculatorjimmy tiarlinaNo ratings yet

- Hearing Loss - Ear, Nose, and Throat Disorders - MSD Manual Professional EditionDocument14 pagesHearing Loss - Ear, Nose, and Throat Disorders - MSD Manual Professional Editiondr.aliceNo ratings yet

- Mock TestDocument17 pagesMock TestSon NguyenNo ratings yet

- Hearing Conservation Resources LLWeb Feb 08Document4 pagesHearing Conservation Resources LLWeb Feb 08Joao Carlos RibeiroNo ratings yet

- Ear Hurts After Practice Piano in Small Room - Google SearchDocument1 pageEar Hurts After Practice Piano in Small Room - Google Searchp5h7ghhdw4No ratings yet

- GEOS12 EN54 System Manual Rev03Document53 pagesGEOS12 EN54 System Manual Rev03rummanhzNo ratings yet

- HSE - Guide To Controlling Noise at WorkDocument136 pagesHSE - Guide To Controlling Noise at WorkSivakumar NatarajanNo ratings yet

- Laney GS412LA ManualDocument4 pagesLaney GS412LA ManualfvillarolmedoNo ratings yet

- Model 300Scw-1: Selectone CommandDocument23 pagesModel 300Scw-1: Selectone Commandalexander vicenteNo ratings yet

- Hearing Loss - AMBOSS PDFDocument1 pageHearing Loss - AMBOSS PDFMohammedNo ratings yet

- Topic 2 - Part 2 - Work Environment Design - Auditory SenseDocument57 pagesTopic 2 - Part 2 - Work Environment Design - Auditory SenseCamille AmparoNo ratings yet

- Headphone Listening Habits and Hearing Thresholds in Swedish AdolescentsDocument14 pagesHeadphone Listening Habits and Hearing Thresholds in Swedish AdolescentsAgustina TambingNo ratings yet

- Coca Cola CompanyDocument19 pagesCoca Cola Companyubaid shahNo ratings yet