Professional Documents

Culture Documents

Access To Work Platform

Uploaded by

ferielvpkOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Access To Work Platform

Uploaded by

ferielvpkCopyright:

Available Formats

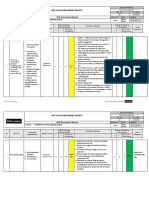

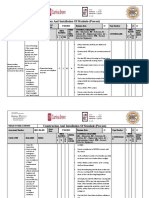

NAWARA GAS TREATMENT PLANT (NAWGTP)

OMV (TUNESIEN) GMBH DATE:07/08/2018

Description of the work to be undertaken TASK RISK ASSESSMENT FORM TRA N. 404 Risk Assessment Team

Welding and grinding, pipe prefabrication and installation in unit 220/590 Med Trabelsi

ABDERRAZZEK BOUABDELLI

Method Statement / Work Procedure etc. Ref. No (If applicable)

SAFE WORKING PRACTICES NAWGTP-ABB-NGTP-000-HS-PLA-00017

TASK RISK ASSESSMENT PROCEDURE NAWGTP-ABB-NGTP-000-HS-PLA-00018

PTW: 2892

Initial Further recommendations

Residual Risk Actioned

Major Steps Hazards Identified Existing Control Measures Risk (Mitigation measures)

L S R person

L S R

Supervision and advice

- Fall from height Ensure safe access way to platform

- Contact with sharp TBT before commencing of activities

parts Reduce number of persons involved

1. Access to work Staff provided with mandatory PPE Ensure work platform are inspected Technicians +

platform Staff trained for working at height and tagged accordingly Job

Certified safety harness B 3 B3 Identification and cover of all sharp B 1 B1 Supervisor

parts

Maintain always three points contact

when climbing to platform

Safety harness to be worn (if require)

anchored to fixed strong point

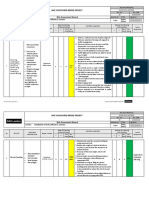

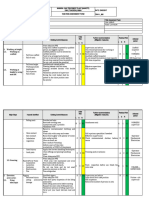

Initial Further recommendations

Residual Risk Actioned

Major Steps Hazards Identified Existing Control Measures Risk (Mitigation measures)

L S R person

L S R

Supervision and advice

Barrication

PTW to be issue and available in work

location

Daily visual inspection of tolls and

equipment

Use only inspected and color coded tolls

and equipment

Ensure that safety guard protection is

installed for each tools

Use grinding disk according to speed

Staff provided with mandatory PPE rotation of grinding machine

Specific PPE available Staff to weak additional PPE (face

- Personnel injury Trained staff shield, mechanical gloves, apron…) Technicians,

- Fire Quarterly inspection of tools Hold tools with both hands Job

C 4 C4 C 2 C2

- Electrocution Fire extinguisher available Do not use force and do not exert Supervisor,

2. Preparation of - Slips/trips excessive pressure on the tool HSE SPV

welding joint Fire watch man stand by in work area

Remove all combustible materials

Protect all flammable parts by fire

retardant blanket

Earthing of electrical equipment’s

Protect electrical cables

Reduce number of person involved

Housekeeping and materials

arrangement

Proper cable management

HSE area inspection

Safe distance to rotating tools parts to

be maintained at all time”.

Involved team to wear ear protection

Technicians,

Information all neighboring staff

- Noise B 2 B2 B 1 B1 Job

Ear protection available Reduce exposure time

Supervisor

Reduce number of person involved

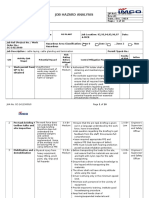

Initial Further recommendations

Residual Risk Actioned

Major Steps Hazards Identified Existing Control Measures Risk (Mitigation measures)

L S R person

L S R

Supervision and advice

Daily visual inspection of tolls and

equipment

Staff to weak additional PPE (welding

- Personnel injury shield, welding gloves, apron…)

- Exposure to Staff provided with mandatory PPE Fire watch man stand by in work area

Welders,

ultraviolet radiation Specific PPE available Remove all combustible materials

3. Welding activities Job

- Burns Trained staff B 4 B4 Protect all flammable parts by fire B 2 B2

Supervisor,

- Fire Quarterly inspection of tools retardant blanket

HSE SPV

- Exposure to welding Fire extinguisher available Protection of power cables

fume Ventilation of welding area

Reduce number of person involved

Rotate persons involved

Regular health surveillance

HSE area inspection

Supervision and advice

- Personnel injury Daily visual inspection of tread machine

- Electrocution Only qualified and trained person is

- Slips/trips authorized to use this machine

Do not wear loose clothes

Do not exert a force higher than

capacity of tread machine

Staff provided with mandatory PPE Earthing of tread machine Fabricator,

4. Cutting / fitting pipe Staff trained for using treading machine Protection of electrical cables Job

by threading Quarterly inspection of equipment C 4 C4 Prohibit access to work area for C 2 C2 Supervisor,

machine unauthorized person HSE SPV

Housekeeping and materials

arrangement in work area

Safety device of machine must be

available and operational

Reduce number of persons involved

HSE area inspection

safe distance to rotating tools parts to

be maintained at all time”.

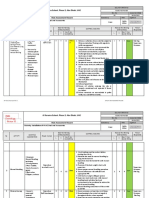

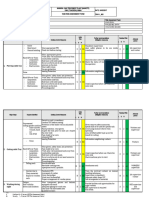

Initial Further recommendations

Residual Risk Actioned

Major Steps Hazards Identified Existing Control Measures Risk (Mitigation measures)

L S R person

L S R

Supervision and advice

Ensure safe access to trailer

Second person to hold the ladder

Install ladder only on level and stable

5. Rigging of pipes and - Fall form height ground Rigger,

Staff provided with mandatory PPE

accessories on trailer - Struck between B 3 B3 Do not work close to extremities of A 1 A1 Job

Staff trained for rigging

- Personnel injuries trailer Supervisor

Never put hands between pipes and/or

supports

Daily inspection of lifting accessories

Reduce number of persons involved

- Personnel injury Supervision and advice

- Fall of load Daily visual inspection of lifting

- Collision with equipment’s and accessories

obstacles Barrication of lifting area

Nobody enter under suspended load

Safety distance to be maintained to

obstacles

Reduce number of persons involved

Staff provided with mandatory PPE Assessment of load weight before to Operator,

Qualified crane operator proceed Job

6. Lifting of pipe and Certified lifting equipment’s Do not exceed maximum load capacity Supervisor,

accessories Tag lines available C 4 C4 of equipment(s) B 2 B2 HSE SPV

Ensure good stability of lifting

equipment’s and stable ground

conditions

Permanent banksman communication

with operator

Check weather conditions

Using of two taglines for guiding the

load

Attention when working close to

electrical lines

HSE area inspection

Initial Further recommendations

Residual Risk Actioned

Major Steps Hazards Identified Existing Control Measures Risk (Mitigation measures)

L S R person

L S R

Supervision and advice

- Personnel Awareness for correct manual handling

lumbago injury Reduce exposure of staff, always try to

- Sharp material avoid any manual lifting by the use of

mechanical lifting equipment

- Hands Injury

7. Manual handling of Take regular breaks

C 4 C4 Rotate persons involved on manual Job

pipes and accessories C 1 C1

handling Supervisor,

Staff provided with mandatory PPE Apply safe manual handling techniques Technicians

Assess load prior to manual handling

Involve more persons when necessary

Identification and cover of all sharp

parts

Do not put hands under load

Supervision and advice

- Falling from PTW mandatory

the man Man basket daily inspection to be done

basket Barrication of work area

- Injury Ensure that all guardrail of man basket

- Man lift are in place

rollover Respect the load chart

- Fall of objects Respect the safe work limit

Staff provided with mandatory PPE Ensure that all the switch are functional Technicians,

8. Working at height Equipment TP certified Do not over load man lift Job

using man lift Safety harness certified C 3 C3 Ensure stable and level ground for B 1 B1 Supervisor,

using man basket Operator,

Wear helmet with chain strap HSE SPV

Only trained and qualified staff can be

involved

No work outside the man basket is

authorized

Ensure safety harness attached at all

time by basket anchor point

Tools attachment

HSE area inspection

Initial Further recommendations

Residual Risk Actioned

Major Steps Hazards Identified Existing Control Measures Risk (Mitigation measures)

L S R person

L S R

Supervision and advice

- Fatigue Take regular breaks

- Animal’s hazards Avoid to work long hours during night

- Slips/trips Reduce number of people involved

Rotate person involved in night shift

- Poor visibility

activities

No lone working are allowed

Reporting of fatigue signs

Stop work and release person

immediately when fatigue signs

observed Technicians,

Staff provided with mandatory PPE Transparent glasses to be wear by all Job

9. Working during the Light torch available involved staff Supervisor

night shift Walk ways lighten C 3 C3 Torch light to be wear by all staff A 1 A1 HSE

Use only safe walkway Supervisor

Assess lighting conditions, sufficient Electrician

light shall be ensured Mechanical

Housekeeping and materials

arrangement

Avoid sitting near materials storage

areas

Communication means to be ensured

Ensure mandatory presence of

ambulance and medical staff during the

night activities

HSE area inspection

Helmet torch, clean glasses

10. Rigging and erection Rigger to attach lifting C 3 C3 Supervision and advice A 1 A1 Rigger,

using man lift accessories to the Maintaining free safe access Job

beam lift on the Only authorized person to be involved Supervisor,

ground: Staff provided with mandatory PPE Clear instruction to crane operator to Operator

- Personnel Trained and qualified rigger not operate the crane until rigging

injury Valid third party inspection of the lifting completed

- Slip and trip accessories Do not put hand between load and

hazards supports/cable/sling/chain

Inspection of equipment’s and

accessories before to start

Initial Further recommendations

Residual Risk Actioned

Major Steps Hazards Identified Existing Control Measures Risk (Mitigation measures)

L S R person

L S R

Rigger to remove sling Supervision and advice

using man basket: Man basket daily inspection to be done

Barrication of working area

- Falling from Ensure that all guardrail of man basket

the height are in place

- Falling objects Respect the load chart

- Personnel Respect the safe work limit

injury Ensure that all the switch are functional

Ensure stable and level ground for

Staff provided with mandatory PPE C 3 C3 using man basket B 1 B1 Technicians,

TP certified man basket Do not overload man basket Job

Certified safety harness Wearing helmet with chain strap Supervisor,

Only qualified operator can be involved Operator,

No work outside of man basket is HSE SPV

authorized

Wear safety harness always connected

to basket anchor point

Tools attachment

HSE area inspection

Supervision and advice

Only trained personnel for working at

height can be involved

Daily visual inspection of scaffold

Barrication of working area

- Fall from height Staff provided with mandatory PPE Do not exceed the maximum load

- Fall of tools Certified harness provided capacity of scaffold

- Collapse of Certified scaffolding materials Use only scaffold green tagged

scaffold Trained staff for working at height and Scaffold shall be erected by certified Technicians,

11. Work on scaffold

scaffold erection scaffolders Job

C 3 C3 B 1 B1

Tools attachment Supervisor,

Materials arrangement HSE SPV

Nobody enter under working at height

activities

Do not drop tools and materials from

platform

Safety harness attached to strong

anchor point to be wear when require

Do not work outside of scaffolding

HSE area inspection

Initial Further recommendations

Residual Risk Actioned

Major Steps Hazards Identified Existing Control Measures Risk (Mitigation measures)

L S R person

L S R

Barrier off under the working area

PTW to be available Prohibit person access under the

Staff wear mandatory PPE working area

Only qualified and trained person for Effective and close supervision

working at height Wear safety helmet with chain strap

Working on Midrail of Safety harness with double lanyard and fall Tools to be attached or use tools belt

12. Working outside the manbasket arrestor (more than 6m) Do not operate man lift close to Job

manbasket - Fall from height Reduce working time outside of manbasket C 3 C3 working persons B 1 B1 Supervisor

- Falling objects 100% hook up of harness 100% of During the work basket shall be parked Technicians

- Injury the time in the close position near the erector Operator

Superposed work is prohibit Jumping on the steel structure is HSE SPV

prohibited

HSE area inspection

Reduce number of people involved

Mandatory PTW Supervision and advice

- Falling from Wear adequate PPE Man basket daily inspection to be done.

the man Wearing helmet with chin strap Barrication of area

13. Working at height basket Only trained and qualified staff can be Ensure that all guardrail of man basket

- Injury involved are in place SUPERVISOR

using manlift C 3 C3 B 1 B1

No work outside the man basket is Respect the load chart WORKER +

authorized Respect the safe work limit OPERATOR

Use only certified man basket Ensure that all the switch are functional

Wearing certified harness with double

lanyard always connected

Initial Further recommendations

Residual Risk Actioned

Major Steps Hazards Identified Existing Control Measures Risk (Mitigation measures)

L S R person

L S R

- Personnel injury Supervision and advice

- Equipment rollover Barrication of work area

Assess ground condition, ensure stable

and level ground

Banksmen to escort equipment’s

14. Arrangement of Staff provided with mandatory PPE Daily visual inspection of equipment’s

pipes and boxes by Qualified equipment operator Ensure adequate load store position Operator,

using Telescopic/ TP certified equipment’s C 4 C4 Telescopic/forklift do not lift more than B 2 B2 Banksman

forklift 6 meter length pipe Job

Lashing of load by equipment forks (if Supervisor,

unstable) HSE SPV

Reduce number of persons involved

Maintain safe distance to operated

equipment

HSE area inspection

Note:

L Likelihood A – E (as per HSE Risk Assessment Matrix)S Severity 1 – 5 (as per HSE Risk Assessment Matrix)R Risk = L S Very Low - Low - Medium - High (as per HSE Risk Assessment Matrix)

Approved by ___ _____

For additional information please refer to document NAWGTP-ABB-NGTP-000-HS-PLA-00018 - Task Risk Assessment Procedure Signature ____________________

You might also like

- Risk Assessment For Installation of Drainage PipesDocument17 pagesRisk Assessment For Installation of Drainage PipesAnandu Ashokan94% (35)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 pagesRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan91% (32)

- Risk Assessment For Installation of Water Supply PipeDocument18 pagesRisk Assessment For Installation of Water Supply PipeAnandu Ashokan86% (28)

- Risk Assessment For Structured CablingDocument7 pagesRisk Assessment For Structured CablingAnandu Ashokan71% (7)

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsAnandu Ashokan88% (8)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument7 pagesRisk Assessment For Testing and Commissioning of Electrical Systemvo100% (3)

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDocument13 pagesRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan94% (17)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument8 pagesRisk Assessment For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (8)

- Road Marking WorksDocument5 pagesRoad Marking Workstariq1987100% (2)

- Risk Assessment For Installation of Grill, Diffuser and LouversDocument13 pagesRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- JHA For Cable Laying, Cable Glanding and TerminationDocument12 pagesJHA For Cable Laying, Cable Glanding and TerminationFrancis Enriquez Tan100% (2)

- DNV Rules For Planning and Execution of Marine Operations - Scanned Version PDFDocument228 pagesDNV Rules For Planning and Execution of Marine Operations - Scanned Version PDFCees van Zandvliet100% (3)

- Risk Assessment For Flushing of Chilled Water PipingDocument9 pagesRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanNo ratings yet

- Risk Assessment For Installation of Toilet Exhaust FanDocument11 pagesRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment of Installation of Chilled Water PipesDocument19 pagesRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- JSA Appendix Cutting, Grinding ConcreteDocument8 pagesJSA Appendix Cutting, Grinding ConcreteĐặng Quang Huy100% (1)

- Coring: Job Safety Analysis (JSA)Document2 pagesCoring: Job Safety Analysis (JSA)Nishad Muhammed100% (1)

- Amc Concourse Bridge Project: Activity: Flushing of Chilled Water PipelineDocument8 pagesAmc Concourse Bridge Project: Activity: Flushing of Chilled Water PipelineEm Niax100% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- RA For MPI TestDocument3 pagesRA For MPI TestLu Min Han100% (1)

- JHA For Manual Excavation Near On Control RoomDocument9 pagesJHA For Manual Excavation Near On Control RoomFrancis Enriquez Tan100% (1)

- JHA For Loop CheckDocument8 pagesJHA For Loop CheckFrancis Enriquez Tan83% (6)

- JSA For Rope Access Services (24-Sep-14)Document8 pagesJSA For Rope Access Services (24-Sep-14)TomasPavlovic100% (1)

- Crane, Rigging & LiftingDocument100 pagesCrane, Rigging & LiftingMarlon Arq100% (14)

- LEEA 039a Accreditation Scheme Appendix 1Document25 pagesLEEA 039a Accreditation Scheme Appendix 1Irshad Akhter100% (1)

- Hoisting and Rigging - Basic Safety Training: Want To Receive A Wallet Card?Document36 pagesHoisting and Rigging - Basic Safety Training: Want To Receive A Wallet Card?xharpreetxNo ratings yet

- 781 Prject Area Its BTPDocument7 pages781 Prject Area Its BTPferielvpkNo ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- QRC-RA-001-Construction and Installation of Manhole (Precast)Document10 pagesQRC-RA-001-Construction and Installation of Manhole (Precast)Kallem RajashekarNo ratings yet

- Adjusment Diesel GeneratorDocument6 pagesAdjusment Diesel GeneratorferielvpkNo ratings yet

- Cathodic 2 ProtectionDocument2 pagesCathodic 2 ProtectionferielvpkNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- Assemble TentDocument2 pagesAssemble TentferielvpkNo ratings yet

- Barrier Garde de Corps 642Document2 pagesBarrier Garde de Corps 642ferielvpkNo ratings yet

- JSA Appendix Backfilling Soil, Welding HDPEDocument8 pagesJSA Appendix Backfilling Soil, Welding HDPEĐặng Quang HuyNo ratings yet

- Barrier FenceDocument2 pagesBarrier FenceferielvpkNo ratings yet

- Hydroseeding WorkDocument26 pagesHydroseeding WorkSamsiah TolaNo ratings yet

- Assembly FromworkDocument3 pagesAssembly FromworkferielvpkNo ratings yet

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 pagesNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemabbasNo ratings yet

- Risk-Assessment Ducts & AccessoriesDocument13 pagesRisk-Assessment Ducts & AccessoriesMohammed Amer PashaNo ratings yet

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Adjusment DEHYDRATORSDocument3 pagesAdjusment DEHYDRATORSferielvpkNo ratings yet

- JSA For Cleaning Boiler, SCR & ESP InternalDocument18 pagesJSA For Cleaning Boiler, SCR & ESP InternalThái Đạo Phạm LêNo ratings yet

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Document3 pagesZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilNo ratings yet

- Cable Dray ATRDocument3 pagesCable Dray ATRferielvpkNo ratings yet

- Risk Assessment of Installation of Chilled Water PipesDocument20 pagesRisk Assessment of Installation of Chilled Water PipesJomy JohnyNo ratings yet

- 03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressDocument16 pages03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressSavio SunnyNo ratings yet

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNo ratings yet

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- Tra 002Document6 pagesTra 002Bilal0% (1)

- Jsa Mobilization ExcavatorDocument8 pagesJsa Mobilization Excavatormalimsaidi_160040895100% (1)

- Concrete Pumping Risk AssessmentDocument5 pagesConcrete Pumping Risk AssessmentlenindraNo ratings yet

- Appendix 3 Risk Assessment of Post Fixed Rebar Drill & Fix With Chemical AnchorDocument13 pagesAppendix 3 Risk Assessment of Post Fixed Rebar Drill & Fix With Chemical Anchormohsin.meizaNo ratings yet

- ELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaDocument12 pagesELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaYuva samaj sewa TrustNo ratings yet

- Pre-Job Safety Meeting Form: Netcore Management SystemDocument10 pagesPre-Job Safety Meeting Form: Netcore Management SystemAniekan AkpaidiokNo ratings yet

- Risk Assessment For Installation of Fire Fighting SystemDocument14 pagesRisk Assessment For Installation of Fire Fighting SystemMohamed Elhadad100% (5)

- Risk Assessment For Dismantling of Temporary ServicesDocument17 pagesRisk Assessment For Dismantling of Temporary ServicesAnandu AshokanNo ratings yet

- Risk Assessment For Installation of A New AC UnitDocument9 pagesRisk Assessment For Installation of A New AC Unitservice.amepNo ratings yet

- Risk Assessment For Installation of Cooling TowersDocument19 pagesRisk Assessment For Installation of Cooling TowersVlad Karo100% (1)

- Site Safety Plan / Job Safety Analysis: Work Group: Work Reference: Site OrganizationDocument3 pagesSite Safety Plan / Job Safety Analysis: Work Group: Work Reference: Site Organizationfadli.lpgNo ratings yet

- Risk Assessment For Concrete Repair WorkDocument11 pagesRisk Assessment For Concrete Repair WorkSaeed AhmadNo ratings yet

- Blasting 001 Abb WarehouseDocument2 pagesBlasting 001 Abb WarehouseferielvpkNo ratings yet

- Cathodic 2 ProtectionDocument2 pagesCathodic 2 ProtectionferielvpkNo ratings yet

- CUTTING Wood PROJECT AREA RAFIKDocument2 pagesCUTTING Wood PROJECT AREA RAFIKferielvpkNo ratings yet

- Blasting 001 Abb WarehouseDocument2 pagesBlasting 001 Abb WarehouseferielvpkNo ratings yet

- Assemble TentDocument2 pagesAssemble TentferielvpkNo ratings yet

- Adjusment DEHYDRATORSDocument3 pagesAdjusment DEHYDRATORSferielvpkNo ratings yet

- Lifting Devices and Rigging: CPC-ALL-HSE-PRC-SOP-178Document15 pagesLifting Devices and Rigging: CPC-ALL-HSE-PRC-SOP-178Zico PutraNo ratings yet

- Online RB Study NotesDocument9 pagesOnline RB Study Notesenjazco.rsgNo ratings yet

- Technical Policy Board Guidelines For Marine Lifting OperationsDocument42 pagesTechnical Policy Board Guidelines For Marine Lifting Operationscostantin2100% (1)

- Guidebook For Lifting Supervisors PDFDocument13 pagesGuidebook For Lifting Supervisors PDFBeste Ardıç Arslan100% (1)

- Hse JsaDocument22 pagesHse JsaAnonymous y1pIqcNo ratings yet

- Air Handling Units 39HQMDocument8 pagesAir Handling Units 39HQMAhmadNo ratings yet

- Planning A Conference CentreDocument65 pagesPlanning A Conference CentreAdnan EsmailNo ratings yet

- 3-Pre-Lift Checklist Rev A 06302015Document2 pages3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- Lifting A Pressure Vessel With Two Main Lift Cranes and One Tail CraneDocument12 pagesLifting A Pressure Vessel With Two Main Lift Cranes and One Tail Cranezeusvares100% (1)

- FM-OHS-1300-09 Rigging Diagram BG Rev ADocument3 pagesFM-OHS-1300-09 Rigging Diagram BG Rev ARakan PierwszyNo ratings yet

- Tadano GT 550e 2 - O1 1eDocument214 pagesTadano GT 550e 2 - O1 1eMuhammad100% (12)

- JHADocument8 pagesJHARayyan ramosNo ratings yet

- Crane SafetyDocument166 pagesCrane Safetymordidomi100% (2)

- Gin Wheels or Pulley WheelsDocument1 pageGin Wheels or Pulley WheelsNanang RizalNo ratings yet

- Terminology For Additional Support Risk Management: User'S Guide LiftingDocument16 pagesTerminology For Additional Support Risk Management: User'S Guide LiftingakhmadbayNo ratings yet

- ClampRings InstallDocument23 pagesClampRings InstallGunawanNo ratings yet

- Hordern Pavillion Venue PackDocument8 pagesHordern Pavillion Venue PackNeill Douglas - AndrewsNo ratings yet

- Steel Structure SafetyDocument23 pagesSteel Structure SafetyMohamed AtefNo ratings yet

- SOP For Hydra RepairingDocument13 pagesSOP For Hydra RepairingMD AbdullahNo ratings yet

- 17 05 02 CCA SG Rev03Document57 pages17 05 02 CCA SG Rev03Александър ПухлевNo ratings yet

- Safety Guidelines For The Entertainment IndustryDocument31 pagesSafety Guidelines For The Entertainment Industryhans777hansNo ratings yet

- THE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4Document21 pagesTHE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4RosalyNo ratings yet

- BSG - Benedicto Steel GroupDocument8 pagesBSG - Benedicto Steel Groupallyssa monica duNo ratings yet

- 3 Green Lift Checklist FormDocument2 pages3 Green Lift Checklist FormHưng Hoàng DuyNo ratings yet

- Rigging Training Workshop - Off-Level Pick Points (Uneven Elevation)Document6 pagesRigging Training Workshop - Off-Level Pick Points (Uneven Elevation)Alex Sandro Borges PereiraNo ratings yet

- Jamshed Bhabha Theatre 1Document7 pagesJamshed Bhabha Theatre 1vasundhara chakkaNo ratings yet