Professional Documents

Culture Documents

Yeonsang Rhee Resume 02092024

Uploaded by

sahilalex25Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yeonsang Rhee Resume 02092024

Uploaded by

sahilalex25Copyright:

Available Formats

Yeonsang Rhee Phone: +1 (818) 439-8789

E-mail: rheeyeonsang@gmail.com

Mechanical Engineer Address: San Diego, CA

URL: LinkedIn.com/in/rheeyeonsang

Highly motivated and detail-oriented Mechanical Engineer with 5+ years of experience in design and manufacturing,

seeking a challenging position in the aerospace & defense industry. Possesses a strong understanding of engineering

principles, materials, and manufacturing processes relevant to the sector. Track record of success in designing,

analyzing, and developing complex mechanical systems while adhering to rigorous quality standards. Adept at utilizing

CAD software and proficient in project management methodologies. Thrives in collaborative environments and

possesses excellent communication and problem-solving skills.

EXPERIENCE HI TECH HONEYCOMB (San Diego, CA)

Manufacturing Engineer 03/2022 – 11/2023

Ensured purchase orders, technical drawings, and traveler instructions aligned with customer requirements through ERP

system analysis.

Provided floor operators with comprehensive support, addressing questions regarding traveler instructions and technical

drawings.

Identified and tackled issues hindering operators from achieving desired production results.

Performed root cause analyses for product quality deviations, implementing optimal solutions to minimize future

occurrences.

Investigated limitations of the current chamfer machining process and presented an alternative design for enhanced

productivity.

Consistently identified opportunities for process optimization, proactively raising concerns and proposing solutions to

drive continuous improvement.

5TH AXIS (San Diego, CA)

Mechanical Engineer 10/2020 – 01/2022

Conceptualized and designed innovative new products using SolidWorks, bringing groundbreaking ideas to life.

Transformed design concepts into tangible prototypes, rigorously testing and validating their performance and reliability.

Led the automation of a crucial manufacturing process, leveraging six-axis robots to achieve faster, more efficient part

and fixture interchange in CNC machines by making the machine run 48 hours un-attended.

Sales Engineer 12/2017 – 09/2020

Collaborated closely with customers to seamlessly integrate our products into their systems, ensuring optimal

performance.

Resolved customer issues swiftly and effectively, diagnosing problems and implementing solutions to maximize product

utilization.

Organized and documented valuable customer feedback, translating it into actionable insights for the engineering team.

DOOSAN ELECTRO-MATERIALS (San Jose, CA)

Technical Intern 07/2016 – 08/2016

Proactively researched and compiled daily industry news briefs, keeping superiors informed of relevant trends and

developments.

Facilitated effective communication by attending client meetings, taking meticulous notes, and distributing

comprehensive minutes to all attendees.

Successfully navigated language and technical barriers, acting as a vital communication link between Korean

headquarters and American colleagues.

EDUCATION NATIONAL UNIVERSITY (San Diego, CA) 10/2020 – 03/2022

Master of Science in Engineering Management

Project Management, Operations & Supply Chain Management, Skills Management, Quality Management, Financial

Management, Manufacturing Management, Risk Management

UNIVERSITY OF CALIFORNIA, SAN DIEGO (La Jolla, CA) 09/2013 – 12/2018

Bachelor of Science in Engineering Science

Mechanics, Vibrations, Thermodynamics, Fluid Flow, Heat Transfer, Materials, Control Theory, Mechanical Design

SKILLS Languages: Fluent English, Korean, and Japanese

Software:

o CAD / CAM: SolidWorks, AutoCAD, Inventor, Fusion360

o Finite Element Analysis: ANSYS

o Analysis: MATLAB, Python, LabView

o Microsoft Office Suite: Word, Excel, PowerPoint, Project, Teams

Mechanical Design: 3D Modeling, engineering drawings, GD&T, tolerance analysis, kinematics, dynamics, materials

selection, stress analysis, design for manufacturability and assembly (DFMA)

Manufacturing: CNC Machining, additive manufacturing (3D Printing), welding (MIG, laser, spot), EDM, other fabrication

methods (cutting, chamfering, rolling, hand-forming, brazing)

Workholding design, experience with typical aerospace-defense sector metals (aluminum, steel, titanium, nickel-based

alloy), manufacturing cell design

Problem-solving: root-cause analysis, critical thinking, analytical skills

Communication: written and verbal communication, technical writing, presentations, interpersonal skills

Organization and Time Management: prioritization, meeting deadlines, planning and scheduling, multitasking

Engineering in Training (FE Mechanical), Certified SolidWorks Professional (CSWP)

You might also like

- Ravi Kaninde ResumeDocument2 pagesRavi Kaninde Resumeapi-357519222No ratings yet

- Resume of Anandakumar - T - May2023Document3 pagesResume of Anandakumar - T - May2023AKT InvestmentNo ratings yet

- Natalia G Kassa-Resume 2-2-20210-EngDocument2 pagesNatalia G Kassa-Resume 2-2-20210-EngDaniel HooperNo ratings yet

- Vigneshwaran.S: Areas of ExposureDocument2 pagesVigneshwaran.S: Areas of Exposuremamillapalli sri harshaNo ratings yet

- Mahesh Thalkar-Design & Manufacturing Engineer-July-22 PDFDocument3 pagesMahesh Thalkar-Design & Manufacturing Engineer-July-22 PDFrahulpillai91No ratings yet

- Umesh Ahirrao: Personal ProfileDocument2 pagesUmesh Ahirrao: Personal ProfileUmesh AhirraoNo ratings yet

- Achieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivateDocument12 pagesAchieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivatestrganeshkumarNo ratings yet

- Karthic SengottaiyanDocument5 pagesKarthic SengottaiyanKarthic MannarNo ratings yet

- Skills Required For A Mechanical JobDocument18 pagesSkills Required For A Mechanical JobAbhishek Tanguturi100% (1)

- Steven L. Henderson, CPM: Mechanical Design & Manufacturing EngineerDocument2 pagesSteven L. Henderson, CPM: Mechanical Design & Manufacturing EngineerShort Term Equity IdeasNo ratings yet

- Document 2Document2 pagesDocument 2Zeke YurixoNo ratings yet

- Joshua Pilkin Resume 022124Document2 pagesJoshua Pilkin Resume 022124Joshua PilkinNo ratings yet

- Gelacio Guevara CVDocument1 pageGelacio Guevara CVMiguel GuevaraNo ratings yet

- Entry - Eng: ProfileDocument4 pagesEntry - Eng: ProfileKwalar KingNo ratings yet

- Resume (Archit Sharma) .PO - UpdatedDocument3 pagesResume (Archit Sharma) .PO - UpdatedAnupam DashNo ratings yet

- Aditya Kastwar - RLDocument1 pageAditya Kastwar - RLmohammed rafi shaikhNo ratings yet

- Ernesto Ndjoli Roku: Design EngineerDocument1 pageErnesto Ndjoli Roku: Design EngineerErnest RokouNo ratings yet

- Ample Esume: BjectiveDocument1 pageAmple Esume: BjectiveJoy JohnNo ratings yet

- JOB DESCRIPTION: Mechanical Design Engineer: OverviewDocument2 pagesJOB DESCRIPTION: Mechanical Design Engineer: OverviewAspire SuccessNo ratings yet

- Expert Manufacturing Engineer Seeks New ChallengeDocument4 pagesExpert Manufacturing Engineer Seeks New ChallengeSudhir KulkarniNo ratings yet

- William R Townson ResumeDocument2 pagesWilliam R Townson ResumeWill TownsonNo ratings yet

- CV TemplateDocument2 pagesCV Templateabdellah gestionNo ratings yet

- Akash ResumeDocument3 pagesAkash ResumeAkashNo ratings yet

- Abhishek CVDocument2 pagesAbhishek CVsaiabhishekd.me19No ratings yet

- TeresDocument1 pageTeresvibush VarshanNo ratings yet

- Shreyash Ghodke CVDocument2 pagesShreyash Ghodke CVseanNo ratings yet

- Resume 08 26 2023Document2 pagesResume 08 26 2023api-608970005No ratings yet

- John Cedric Ortego: ExperienceDocument3 pagesJohn Cedric Ortego: ExperiencedarnaNo ratings yet

- Prathamesh Patil ResumeDocument2 pagesPrathamesh Patil ResumeVaibhav GhargeNo ratings yet

- Swinburne University Mechanical Engineer PortfolioDocument6 pagesSwinburne University Mechanical Engineer PortfolioDaniel TanNo ratings yet

- Naukri PranavMs 9052057 - 05 00 - 1Document2 pagesNaukri PranavMs 9052057 - 05 00 - 1HR DirectorNo ratings yet

- Saravanan ResumeDocument5 pagesSaravanan ResumeRamkishore ChelvinMurugeshNo ratings yet

- Product Design Engineering Manager in TN Resume David EvansDocument2 pagesProduct Design Engineering Manager in TN Resume David EvansDavidEvans2No ratings yet

- Cost Out Vave JDDocument2 pagesCost Out Vave JDelamukil.sensacoreNo ratings yet

- Jass Bikic-ResumeDocument3 pagesJass Bikic-ResumedrbikicNo ratings yet

- Suggested KeywordsDocument6 pagesSuggested KeywordsHomer Texido FrangioniNo ratings yet

- ShivaRam ResumeDocument4 pagesShivaRam ResumeVishnu TejaNo ratings yet

- Naukri PrasadShrotri (7y 0m)Document3 pagesNaukri PrasadShrotri (7y 0m)Ayushee TiwariNo ratings yet

- Essig Pitch Slide DeckDocument12 pagesEssig Pitch Slide DeckraedNo ratings yet

- PDF 20221125 213424 0000Document1 pagePDF 20221125 213424 0000ImranNo ratings yet

- Venkatesh - Manavaddar (Technical Writting) - 2014Document4 pagesVenkatesh - Manavaddar (Technical Writting) - 2014Venkatesh ManavaddarNo ratings yet

- Resume Mohit PatelDocument1 pageResume Mohit PatelJas RandheyNo ratings yet

- Abigail Moadab Resume 2023Document1 pageAbigail Moadab Resume 2023api-538604468No ratings yet

- Sachin Raval: Senior Technical Project Manager - PMP & CSM CertifiedDocument3 pagesSachin Raval: Senior Technical Project Manager - PMP & CSM CertifiedmanasNo ratings yet

- 2.resume - Santhosh Kumar TDocument2 pages2.resume - Santhosh Kumar TAbhishek MNNo ratings yet

- Anurag B. Landage: Profile SummaryDocument2 pagesAnurag B. Landage: Profile SummaryAbhishek MNNo ratings yet

- CV-TemplateDocument2 pagesCV-TemplateAhmed GamalNo ratings yet

- Kumaravel Resume 14+ Lead Mechanical Designer - TLDocument3 pagesKumaravel Resume 14+ Lead Mechanical Designer - TLKumarNo ratings yet

- CV TemplateDocument2 pagesCV Templateasmaa0712269No ratings yet

- Sagar DhumalDocument2 pagesSagar Dhumalranaware ajinkyaNo ratings yet

- Ajay Kumar: Profile Summary Core CompetenciesDocument2 pagesAjay Kumar: Profile Summary Core CompetenciesChetan HinganeNo ratings yet

- Gelacio Guevara Quintero: Mexican / 23 Years OldDocument1 pageGelacio Guevara Quintero: Mexican / 23 Years OldMiguel GuevaraNo ratings yet

- File 000Document1 pageFile 000PRAVEEN ENo ratings yet

- bhanuprakash kosarajuDocument2 pagesbhanuprakash kosarajuapi-730921223No ratings yet

- Resume-Chetan-Dhuri-Mechanical Design FEADocument4 pagesResume-Chetan-Dhuri-Mechanical Design FEAChetan DhuriNo ratings yet

- Mechanical Engineer ResumeDocument3 pagesMechanical Engineer ResumeDeepak SharmaNo ratings yet

- Shaheer AnzakDocument3 pagesShaheer AnzakMusheeza LiaqatNo ratings yet

- Smart Design Solutions PDFDocument6 pagesSmart Design Solutions PDFDeepak Raj ChauhanNo ratings yet

- Muhammad-Tariq CVDocument4 pagesMuhammad-Tariq CVMuhammad TariqNo ratings yet

- Offshore Piping Design: Technical Design Procedures & Mechanical Piping MethodsFrom EverandOffshore Piping Design: Technical Design Procedures & Mechanical Piping MethodsNo ratings yet

- ABB Lummus Global B.V. Piling SpecificationDocument25 pagesABB Lummus Global B.V. Piling SpecificationRama Krishna Reddy DonthireddyNo ratings yet

- Influence of curing conditions on mechanical properties of recycled concreteDocument11 pagesInfluence of curing conditions on mechanical properties of recycled concreteBasil Baby-PisharathuNo ratings yet

- The Retrofitting of Reinforced Concrete Column-To-Beam ConnectionsDocument9 pagesThe Retrofitting of Reinforced Concrete Column-To-Beam ConnectionssakthistructNo ratings yet

- Pre PHD ANU-SyllabusDocument8 pagesPre PHD ANU-SyllabuskishorebabNo ratings yet

- China AeroDocument18 pagesChina AeroCheung ReggieNo ratings yet

- Physics - General Knowledge Questions and Answers Page 9Document3 pagesPhysics - General Knowledge Questions and Answers Page 9surya123sNo ratings yet

- BTEC Engineering Project AssessmentDocument16 pagesBTEC Engineering Project Assessmentnabeel hassan ali100% (1)

- Day 2 Human Centered Design-1Document28 pagesDay 2 Human Centered Design-1John TauloNo ratings yet

- Questionnaire Survey - MEP Design GuidelinesDocument5 pagesQuestionnaire Survey - MEP Design GuidelineskhaledmiNo ratings yet

- 30GX Wiring 533-084 30HX Chiller CarrierDocument34 pages30GX Wiring 533-084 30HX Chiller Carrieryamamoto_san100% (5)

- Marine BoilersDocument29 pagesMarine BoilersAshish YadavNo ratings yet

- Lesson - CepdeDocument1 pageLesson - Cepdearun aryaNo ratings yet

- Structural DynamicsDocument79 pagesStructural DynamicsJunnaz BalacuitNo ratings yet

- Deck Design Project ReportDocument23 pagesDeck Design Project ReportOzzoman DukeNo ratings yet

- Process MetricsDocument3 pagesProcess MetricspeejayNo ratings yet

- Lab Manual 1 of Digital ElectronicsDocument4 pagesLab Manual 1 of Digital ElectronicsQuqan TahirNo ratings yet

- Value Engineering References, 2020-11-06Document2 pagesValue Engineering References, 2020-11-06swhuntNo ratings yet

- Comprehensive Range of Pilot PlantsDocument22 pagesComprehensive Range of Pilot PlantsKannan RamanNo ratings yet

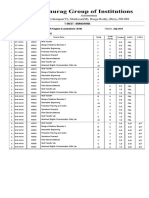

- Mechanical Engineering III Sem II ResultsDocument63 pagesMechanical Engineering III Sem II ResultsLE 335 P NAVEENNo ratings yet

- 60A Automatic Power Changeover System DesignDocument7 pages60A Automatic Power Changeover System DesignVictor Temitope OwokoleNo ratings yet

- UG-37 F FactorDocument7 pagesUG-37 F FactorjamesNo ratings yet

- NX Machining: A Complete Solution For Machine Tool ProgrammingDocument20 pagesNX Machining: A Complete Solution For Machine Tool ProgrammingAhmad SaepuddinNo ratings yet

- Modeling Transport 4th Edition de Dios Ortuzar J ADocument3 pagesModeling Transport 4th Edition de Dios Ortuzar J AAlfredo ReyesNo ratings yet

- CSP Application GuideDocument16 pagesCSP Application Guidernp246000No ratings yet

- NWfall08 LautenschlagerDocument3 pagesNWfall08 LautenschlagerMukesh Kumar BhandekarNo ratings yet

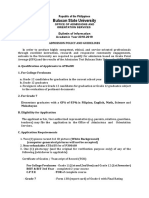

- ATBulSUDocument5 pagesATBulSUJohn Rester DemerinNo ratings yet

- E & CE TimeTable W.E.F 19 Feb, 2024Document8 pagesE & CE TimeTable W.E.F 19 Feb, 2024mannnn014No ratings yet

- Excavation and FoundationDocument1 pageExcavation and FoundationBH12010No ratings yet

- December 2012 Wire Rope ExchangeDocument84 pagesDecember 2012 Wire Rope ExchangeWire Rope ExchangeNo ratings yet

- Plate Fin Vs Annular FinDocument1 pagePlate Fin Vs Annular FinzlajaviNo ratings yet