Professional Documents

Culture Documents

Ajay Kumar: Profile Summary Core Competencies

Uploaded by

Chetan HinganeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ajay Kumar: Profile Summary Core Competencies

Uploaded by

Chetan HinganeCopyright:

Available Formats

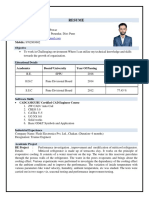

AJAY KUMAR

Achievement-driven professional targeting assignments in Engineering

Design & Manufacturing with a leading organization of repute in

Manufacturing / IT (Mechanical Design) Industry

ajaykr2529@out look.com 08282821202/ 08777845198

& 09123929760

Profile Summary

Core Competencies

Mechanical Design (CAD) Engineer offering nearly 3 years of rich

experience in Drilling Tools in Manufacturing Industry 3D Solid Assembling &

Experience in 3D Solid Modelling, Assembling, Detailing, Sheet Metal Modelling

Detailing

Process, Drawing Creation in Creo 4.0 , GD&T and Sheet Metal process

Possess knowledge of welding and bending process

Skilled in Reverse Engineering, Large Assembly Management Design

Reverse

and Design Optimization using Top Down A pproach Concepts &

Engineering

Expert in creating cost effective designs, simplifying tooling, reducing Drawings

number of parts, assigning proper material, improving appearance &

scope across sites and models Material Drawings

Capable of maintaining business relationship with vendors and clients by Planning Creation in Creo

resolving their design related issues

Attained understanding of Tolerance Standards of UNI- ISO 2768/ 1

and UNI- ISO 2768/2 on design drawings

An innovative & result-oriented professional with strong leadership, Project Concept Selection

negotiation & interpersonal skills Management & Feasibility

Analysis

Work Experience

Soft Skills

Since Jun’17 with Soilmec Foundation Equipment Pvt. Ltd., Thane

as CAD Engineer

Key Result Areas:

Reviewing the project and the physical procedures for the process of

Reverse Engineering

Providing engineering solutions to Solid Modelling, Sheet Metal,

Welding and Bending using the tool Creo 4.0

Soft

Planning material for tool requirement; examining the interference in Skills

assembly process

Creating error-free manufacturing drawings as per the set standards of the

organization

Developing 3D model of assemblies and parts of various components

Supervising order planning and execution as per the target deadline

Transforming 2D models into 3D models and making the drawings as per

the fabrication procedures

Generating large assemblies and sub-assemblies models and drawings to

make the preassembly for welding purpose; releasing final drawings after IT Skills

making changes

Devising various configuration models and developing projects through

Creo 4.0 and managing revisions of assemblies & drawings CAD Packages: Creo Parametric-4.0,

Developing PFEP (Plan For Every Part) based on Design & Development AutoCAD 2014, CATIA v6, SolidWorks

aspect and product development till PPAP (Production Part Approval 2014 & Delcam

Process) Platforms: Windows XP (7 & 10)

Participating in Quality and Velocity Improvement of services by process Professional

improvement & data management Application Software: MS Office &

Internet Applications

Highlights:

Localization of Product: Designed Soilmec rig machine parts & structure;

added local vendors to manufacture it locally which helped in reducing time

and the cost of these parts import from Italy

Reduction of Material Cost: Reduced 18% of overall material cost from

making changes by selecting cost effective material and the machining

process

Organizational Projects

Desander: Designed SMD-250 with reverse engineering and made all

possible modification in the existing Desanders

Drilling Tools: Customized the design of the drilling tools as per the

requirement

Grout Pump: Engineered project of GIET-2 Grout in collaboration with

Global Purchasing Team for supplier finalization and strategy sourcing

Education

2017: B.Tech. (Mechanical Engineering) from Brainware Group of Institutions (West Bengal University of

Technology), Kolkata with 7.2 CGPA

2013: Diploma (Mechanical Engineering) from JLD College of Engineering and Management, Kolkata with

65.80%

2010: 10th from Khanna High School (West Bengal Board of Secondary Education), Kolkata

Certification

Tool Designing & Manufacturing from MSME Tool Room, Kolkata in 2014

Extracurricular Activities

Visited BAUMA Exhibition with Soilmec India in Mumbai and Bangalore

Visited various sites in Chennai and Bangalore, for performance and condition of Tools, Mixers, Delta Pump,

Desanders and Kelly Bars

Personal Details

Date of Birth: 30th October 1995

Languages Known: English, Hindi & Bengali

Permanent Address: 44/48 Debendra Chandra Dey Road, Kolkata - 700015, WB

Current Address: Flat No.104, Tata Housing, Boisar - 401501, Maharashtra

You might also like

- CAD Engineering Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #3From EverandCAD Engineering Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #3Rating: 4.5 out of 5 stars4.5/5 (4)

- Karthikraja S: Personal InfoDocument1 pageKarthikraja S: Personal InfoSampathvasan SNo ratings yet

- Karthikraja S: Personal InfoDocument1 pageKarthikraja S: Personal InfoSampathvasan SNo ratings yet

- BIT Baroda Institute of Technology: Creo (Pro/ENGINEER) Training atDocument4 pagesBIT Baroda Institute of Technology: Creo (Pro/ENGINEER) Training atNIRALINo ratings yet

- Ashish Shirsat 9 YRDocument2 pagesAshish Shirsat 9 YRvattipalli murariNo ratings yet

- Aditya Kastwar - RLDocument1 pageAditya Kastwar - RLmohammed rafi shaikhNo ratings yet

- Karthic SengottaiyanDocument5 pagesKarthic SengottaiyanKarthic MannarNo ratings yet

- course_summary_brochure_webDocument8 pagescourse_summary_brochure_webiwillkeeplovingu08No ratings yet

- Trinadh Resume DesignDocument4 pagesTrinadh Resume DesignDrew LadlowNo ratings yet

- Yenuguthala Chandra Sekhar: Cad EngineerDocument4 pagesYenuguthala Chandra Sekhar: Cad Engineerchandrasekhar y47No ratings yet

- AJINKYA NIGADE (Mechanical Design Engineer) 1Document3 pagesAJINKYA NIGADE (Mechanical Design Engineer) 1Rahul PatankarNo ratings yet

- CAD EngineerDocument3 pagesCAD EngineerBhuvan YzagNo ratings yet

- Pratheepraj TDocument3 pagesPratheepraj TvenkyymdNo ratings yet

- Linda Harris' Design Engineer CVDocument1 pageLinda Harris' Design Engineer CVSHREE RAVVANo ratings yet

- Ravi Kaninde ResumeDocument2 pagesRavi Kaninde Resumeapi-357519222No ratings yet

- Chaitanya. Kulkarni: Cyient, Hyderabad - Senior Design EngineerDocument3 pagesChaitanya. Kulkarni: Cyient, Hyderabad - Senior Design Engineerchaitanya kulkarniNo ratings yet

- ChandrasekaranDocument5 pagesChandrasekaransk2324No ratings yet

- Andhavarapu Ramu: ObjectiveDocument4 pagesAndhavarapu Ramu: ObjectiveRao SriNo ratings yet

- Trainer ProfileDocument2 pagesTrainer ProfileSandeep RaoNo ratings yet

- CAD Product Development Pro-EDocument1 pageCAD Product Development Pro-EHasham ZaidiNo ratings yet

- Sagar DhumalDocument2 pagesSagar Dhumalranaware ajinkyaNo ratings yet

- 2yrs As Design EngDocument5 pages2yrs As Design Engpadmanabha14No ratings yet

- Rahul Kohinkar Old OnwardDocument6 pagesRahul Kohinkar Old OnwardRahul KohinkarNo ratings yet

- Pranav Jadhav Resume YoE 3.3 Design EnggDocument2 pagesPranav Jadhav Resume YoE 3.3 Design EnggRahul PatankarNo ratings yet

- CV TemplateDocument2 pagesCV TemplateMiriam AdlyNo ratings yet

- CV-TemplateDocument2 pagesCV-TemplateAhmed GamalNo ratings yet

- Naukri PrasadShrotri (7y 0m)Document3 pagesNaukri PrasadShrotri (7y 0m)Ayushee TiwariNo ratings yet

- Aravinda KumarDocument2 pagesAravinda KumarposttopictomotiveNo ratings yet

- CV TemplateDocument2 pagesCV Templateasmaa0712269No ratings yet

- John Gabriel BenoliraoDocument1 pageJohn Gabriel BenoliraoTrending JuanNo ratings yet

- Ashutosh CVDocument5 pagesAshutosh CVChintan ShahNo ratings yet

- Speed Engineering Solutions PVT LTD - D18 - Product Engineer - Mechanical - Design & Development in Pune CityDocument2 pagesSpeed Engineering Solutions PVT LTD - D18 - Product Engineer - Mechanical - Design & Development in Pune CityKautilNo ratings yet

- Gomathi Nayagam - CV 2023Document5 pagesGomathi Nayagam - CV 2023mathinayakNo ratings yet

- Resume Nairu RathodDocument2 pagesResume Nairu RathodSarang BhongNo ratings yet

- CV TemplateDocument2 pagesCV Templateabdellah gestionNo ratings yet

- JD-Lead - Application EngineeringDocument3 pagesJD-Lead - Application EngineeringShubham PardeshiNo ratings yet

- Experienced Architectural Drafter with 10+ Years in CADDocument4 pagesExperienced Architectural Drafter with 10+ Years in CADMT JasonNo ratings yet

- Harpreet SinghDocument2 pagesHarpreet SinghNAVNEET THAKURNo ratings yet

- Mechanical Engineer Ravi Babaladi's 6+ Years Product Design ExperienceDocument3 pagesMechanical Engineer Ravi Babaladi's 6+ Years Product Design ExperienceRavi BabaladiNo ratings yet

- Engineering Intern Seeks New ChallengesDocument2 pagesEngineering Intern Seeks New ChallengesJak ObNo ratings yet

- Lebenslauf Von Harsh BhimaniDocument2 pagesLebenslauf Von Harsh BhimaniHarsh BhimaniNo ratings yet

- AutoCAD Draftsman (Samad)Document4 pagesAutoCAD Draftsman (Samad)samadNo ratings yet

- Anurag B. Landage: Profile SummaryDocument2 pagesAnurag B. Landage: Profile SummaryAbhishek MNNo ratings yet

- Bangalore-+91-9900520910.: Pradeepa GDocument5 pagesBangalore-+91-9900520910.: Pradeepa Gvattipalli murariNo ratings yet

- RESUME UPD - 1670820102755 - Chinmay Vithal ChavanDocument3 pagesRESUME UPD - 1670820102755 - Chinmay Vithal ChavanRahul PatankarNo ratings yet

- Expert Manufacturing Engineer Seeks New ChallengeDocument4 pagesExpert Manufacturing Engineer Seeks New ChallengeSudhir KulkarniNo ratings yet

- Akash ResumeDocument3 pagesAkash ResumeAkashNo ratings yet

- Vigneshwaran.S: Areas of ExposureDocument2 pagesVigneshwaran.S: Areas of Exposuremamillapalli sri harshaNo ratings yet

- Pursue challenging Design Engineering careerDocument3 pagesPursue challenging Design Engineering careerAhmed ShariffNo ratings yet

- CV Template11Document2 pagesCV Template11Mohamed KoranyNo ratings yet

- Chapter # 1Document27 pagesChapter # 1Anonymous N73Nk4RwsNo ratings yet

- Skills Required For A Mechanical JobDocument18 pagesSkills Required For A Mechanical JobAbhishek Tanguturi100% (1)

- February 5, 1999 R/L 2/2000: Standard SoftwareDocument3 pagesFebruary 5, 1999 R/L 2/2000: Standard SoftwareMEGAN ASBROCKNo ratings yet

- Sathishkumar M - 033814Document3 pagesSathishkumar M - 033814SATHISHKUMAR MNo ratings yet

- KARAN KHODE RESUME E4yearsDocument2 pagesKARAN KHODE RESUME E4yearswooden makersNo ratings yet

- Mahesh Kumar - Vallakati, B.Tech Mechanical Engineering: (CAD Design Engineer)Document1 pageMahesh Kumar - Vallakati, B.Tech Mechanical Engineering: (CAD Design Engineer)Vallakati Mahesh kumarNo ratings yet

- Bhavik Suthar - CV - AJDocument3 pagesBhavik Suthar - CV - AJmohammed rafi shaikhNo ratings yet

- JD - CAD Design Engineer - ConFormsDocument1 pageJD - CAD Design Engineer - ConFormscricninja09No ratings yet

- ShivaRam ResumeDocument4 pagesShivaRam ResumeVishnu TejaNo ratings yet

- Which Software Is Best For Sheet Metal Design ? Dhyan AcademyDocument4 pagesWhich Software Is Best For Sheet Metal Design ? Dhyan Academydhyanacademy engineersNo ratings yet

- Mechanical Seal Performance and Related Calculations: by Tom ArnoldDocument15 pagesMechanical Seal Performance and Related Calculations: by Tom ArnoldLucaNo ratings yet

- Alif Enterprises Samriddhi Industrial Product QTY Rate Discount Rate Discount Final Price Final PriceDocument2 pagesAlif Enterprises Samriddhi Industrial Product QTY Rate Discount Rate Discount Final Price Final PriceChetan HinganeNo ratings yet

- 47147Document14 pages47147Chetan HinganeNo ratings yet

- Alignment of PumpsDocument10 pagesAlignment of PumpsChetan HinganeNo ratings yet

- CH 9Document6 pagesCH 9rammech85No ratings yet

- Shambhu Pawar ResumeDocument2 pagesShambhu Pawar ResumeChetan HinganeNo ratings yet

- Rohan Ramesh Shinde Mobile No: +91 8652216517 Linkedin Link: 9/ Ratan Maya Chawl, Majasgaon Tekdi, Jogeshwari (E), Mumbai-400060Document3 pagesRohan Ramesh Shinde Mobile No: +91 8652216517 Linkedin Link: 9/ Ratan Maya Chawl, Majasgaon Tekdi, Jogeshwari (E), Mumbai-400060Chetan HinganeNo ratings yet

- Vikas Prakash Todkar: ObjectiveDocument4 pagesVikas Prakash Todkar: ObjectiveChetan HinganeNo ratings yet

- Z:/Engg Drawings/PRO - E - 08 - 2008/STANDARD - COMPONENTSDocument1 pageZ:/Engg Drawings/PRO - E - 08 - 2008/STANDARD - COMPONENTSChetan HinganeNo ratings yet

- Rohan Ramesh Shinde Mobile No: +91 8652216517 Linkedin Link: 9/ Ratan Maya Chawl, Majasgaon Tekdi, Jogeshwari (E), Mumbai-400060Document3 pagesRohan Ramesh Shinde Mobile No: +91 8652216517 Linkedin Link: 9/ Ratan Maya Chawl, Majasgaon Tekdi, Jogeshwari (E), Mumbai-400060Chetan HinganeNo ratings yet

- Vikas Prakash Todkar: ObjectiveDocument4 pagesVikas Prakash Todkar: ObjectiveChetan HinganeNo ratings yet

- Ajay Kumar: Profile Summary Core CompetenciesDocument2 pagesAjay Kumar: Profile Summary Core CompetenciesChetan HinganeNo ratings yet

- Akash Babar Resume - Mechanical Engineer with 1 Year Blast Furnace ExperienceDocument2 pagesAkash Babar Resume - Mechanical Engineer with 1 Year Blast Furnace ExperienceChetan HinganeNo ratings yet

- Shubham Kshirsagar ResumeDocument2 pagesShubham Kshirsagar ResumeChetan HinganeNo ratings yet

- Curriculam Vitae: Metal & ForgingDocument2 pagesCurriculam Vitae: Metal & ForgingChetan HinganeNo ratings yet

- Krushikesh Ravindra SanasDocument3 pagesKrushikesh Ravindra SanasChetan HinganeNo ratings yet

- Rectangular Wire Compression SpringsDocument2 pagesRectangular Wire Compression SpringsChetan HinganeNo ratings yet

- Value Engineering Nagre 918Document6 pagesValue Engineering Nagre 918Chetan HinganeNo ratings yet

- Presentaion FlowDocument4 pagesPresentaion FlowChetan HinganeNo ratings yet

- INDUCTION SCHEDULE - Design EngineersDocument4 pagesINDUCTION SCHEDULE - Design EngineersChetan HinganeNo ratings yet

- Dhruv Patidar: Product Design Engineer - MechanicalDocument1 pageDhruv Patidar: Product Design Engineer - MechanicalChetan HinganeNo ratings yet

- Shambhu Pawar ResumeDocument2 pagesShambhu Pawar ResumeChetan HinganeNo ratings yet

- Shambhu Pawar ResumeDocument2 pagesShambhu Pawar ResumeChetan HinganeNo ratings yet

- Hemantkumar Z Patel: Design Engineer - Mechanical Career SummaryDocument3 pagesHemantkumar Z Patel: Design Engineer - Mechanical Career SummaryChetan HinganeNo ratings yet

- Ajinkya S NigadeDocument2 pagesAjinkya S NigadeChetan HinganeNo ratings yet

- Ajinkya S NigadeDocument2 pagesAjinkya S NigadeChetan HinganeNo ratings yet

- Abhay Nivrutii Shinde: BASED MNC, May 2019-Till Date, As A Junior Design EngineerDocument3 pagesAbhay Nivrutii Shinde: BASED MNC, May 2019-Till Date, As A Junior Design EngineerChetan HinganeNo ratings yet

- Abhay Nivrutii Shinde: BASED MNC, May 2019-Till Date, As A Junior Design EngineerDocument3 pagesAbhay Nivrutii Shinde: BASED MNC, May 2019-Till Date, As A Junior Design EngineerChetan HinganeNo ratings yet

- Shambhu Pawar ResumeDocument2 pagesShambhu Pawar ResumeChetan HinganeNo ratings yet

- How To Build A Robot SimulationDocument26 pagesHow To Build A Robot SimulationRafael SchroerNo ratings yet

- Artcam Prevod FinalDocument16 pagesArtcam Prevod FinalDarko SekulicNo ratings yet

- CAD CAM and CNC Training at Goregaon Mumbai India With Softwares Like Unigraphics NX Mastercam and Delcam PowermillDocument2 pagesCAD CAM and CNC Training at Goregaon Mumbai India With Softwares Like Unigraphics NX Mastercam and Delcam PowermillAlimgarh MalikNo ratings yet

- Delcam Footwear - Solutions PDFDocument11 pagesDelcam Footwear - Solutions PDFYlle UntNo ratings yet

- Apostila PowerMILL 5.5 - 5 EixosDocument126 pagesApostila PowerMILL 5.5 - 5 EixosRoberto SilvaNo ratings yet

- ArtCAM Pro Jewellery Edition User Guide by Delcam PDFDocument130 pagesArtCAM Pro Jewellery Edition User Guide by Delcam PDFLys StilosNo ratings yet

- Basic - Concepts POWER SHAPEDocument154 pagesBasic - Concepts POWER SHAPEconsdesproy75% (4)

- Powerful, Versatile, Easy To Use CAD Software For The Design of Complex 3D PartsDocument9 pagesPowerful, Versatile, Easy To Use CAD Software For The Design of Complex 3D PartspatgigNo ratings yet

- Stitch TecDocument2 pagesStitch TecNery LopezNo ratings yet

- GTMA News Issue 2 2011Document44 pagesGTMA News Issue 2 2011GTMAAdminNo ratings yet

- Delcam - PowerMILL 9.0 FiveAxis Training Course en - 2008Document148 pagesDelcam - PowerMILL 9.0 FiveAxis Training Course en - 2008भागराज राज100% (1)

- Delcam - PowerINSPECT 2010 FaroScanning EN - 2009Document22 pagesDelcam - PowerINSPECT 2010 FaroScanning EN - 2009phạm minh hùngNo ratings yet

- Desktop Engineering 2010-03Document82 pagesDesktop Engineering 2010-03PerryShopsNo ratings yet

- Brosur - Autodesk Solutions (New) - CompressedDocument4 pagesBrosur - Autodesk Solutions (New) - CompresseddelcamdmiNo ratings yet

- Getting Started With Featurecam 2008: Delcam UsaDocument135 pagesGetting Started With Featurecam 2008: Delcam UsaDijmarescu SiminaNo ratings yet

- Manual CrispinDocument71 pagesManual CrispinMarco Corona67% (6)

- Ortho MILLDocument2 pagesOrtho MILLMiguel Angel SNo ratings yet

- Composites UK Directory 2016 Low ResDocument16 pagesComposites UK Directory 2016 Low ResMbamali ChukwunenyeNo ratings yet

- Fast, Accurate Multi-Axis Programming For RobotsDocument5 pagesFast, Accurate Multi-Axis Programming For RobotspatgigNo ratings yet

- PowerINSPECT BrochureDocument11 pagesPowerINSPECT BrochureJosephRomeraloNo ratings yet

- Technicut and Delcam Revolutionise Blisk MachiningDocument8 pagesTechnicut and Delcam Revolutionise Blisk MachiningjimNo ratings yet

- Delcam - PowerSHAPE 2013 R1 WhatsNew EN - 2012Document92 pagesDelcam - PowerSHAPE 2013 R1 WhatsNew EN - 2012hhoready tube100% (1)

- Delcam - PowerMILL 2017 MTD UserGuide ENDocument63 pagesDelcam - PowerMILL 2017 MTD UserGuide ENdaocongdablNo ratings yet

- Lecture 8 CADCAMDocument31 pagesLecture 8 CADCAMAnand P DwivediNo ratings yet

- Powerinspect Manual CmmsDocument2 pagesPowerinspect Manual CmmsFelipe Cordeiro100% (1)

- FeatureCAM 2014 Whats NewDocument89 pagesFeatureCAM 2014 Whats NewDaniel JimenezNo ratings yet

- Custom Orthotic InsolesDocument8 pagesCustom Orthotic InsolesgailNo ratings yet

- Tomorrow's Materials TodayDocument2 pagesTomorrow's Materials TodayShantanu SinghaNo ratings yet

- PowerMILL 2015 Whats New enDocument74 pagesPowerMILL 2015 Whats New enNaveen KumarNo ratings yet

- Delcam - PowerMILL 2012 Whats New EN - 2011Document100 pagesDelcam - PowerMILL 2012 Whats New EN - 2011phạm minh hùngNo ratings yet