Professional Documents

Culture Documents

RT-flex-01 - 09 Rail Unit Box - Cracks in Side Plate Corner Weling Seams

RT-flex-01 - 09 Rail Unit Box - Cracks in Side Plate Corner Weling Seams

Uploaded by

Catalin CataOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RT-flex-01 - 09 Rail Unit Box - Cracks in Side Plate Corner Weling Seams

RT-flex-01 - 09 Rail Unit Box - Cracks in Side Plate Corner Weling Seams

Uploaded by

Catalin CataCopyright:

Available Formats

Service Letter RT-flex-01/09

12.01.2009

Technical Information to all Owners / Operators

of Wärtsilä RT-flex96C Engines

Rail unit box: Cracks in side plate corner

welding seams

Contents: Page

1. Introduction 1

2. Inspection 1

3. Countermeasure 1

4. Caution 1

5. Procedure 1

Wärtsilä Switzerland Ltd PO Box 414 Tel. +41 52 262 23 30

Wärtsilä Schweiz AG CH-8401 Winterthur Fax +41 52 212 71 03

Wärtsilä Suisse SA Switzerland E-mail: techservice.ch@wartsila.com

1 INTRODUCTION

Recent inspections have shown cracks in some rail unit boxes at their free- or driving end side

plates.

2 INSPECTION

We recommend an inspection of the free- and driving end side plates with particular effort

made to check the relevant corners and plates for cracks.

3 COUNTERMEASURE

In case of a crack, the end must be located (remove paint and use dye penetrate spray) and a

stop hole of approximately 20 mm must be drilled.

4 CAUTION

Before proceeding with the stop hole, it is essential to ensure that by drilling at this position

the stop hole will not interfere with pipes, cables or other sensitive parts.

Furthermore the hole must be drilled at a right angle with all remaining burrs and notches

removed by grinding in order to achieve a smooth surface.

5 PROCEDURE

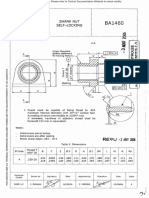

Example of a driving end crack

1. Locate the crack end

2. Drill a stop hole (Ø 20 mm)

3. Smooth grinding

1/1 Service Letter RT-flex-01/09

You might also like

- VL User Manual Rev 1.05 March 2020Document30 pagesVL User Manual Rev 1.05 March 2020Kim Reis100% (1)

- Additional Protecting Plates For Hotbox - 3216s062 - 02gbDocument3 pagesAdditional Protecting Plates For Hotbox - 3216s062 - 02gbMark ChapmanNo ratings yet

- RT-96 - Exhaust Valve Spindle LubricationDocument6 pagesRT-96 - Exhaust Valve Spindle LubricationGeorgios MariolisNo ratings yet

- Access-Door Opener Manual PDFDocument67 pagesAccess-Door Opener Manual PDFJan UngererNo ratings yet

- MM - WinGD RT Flex58t D PDFDocument498 pagesMM - WinGD RT Flex58t D PDFfaintares100% (1)

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- 2021T023 01gbDocument4 pages2021T023 01gbDenim102100% (1)

- Service Manual: General Information Care & SafetyDocument199 pagesService Manual: General Information Care & Safetyred100% (1)

- 19.10.2005 SSVV-IN: Date SignDocument33 pages19.10.2005 SSVV-IN: Date SignNguyen binhNo ratings yet

- RT-11 - 06 - Periodic Inspection of Supply Unit Cam and Roller - Size4Document3 pagesRT-11 - 06 - Periodic Inspection of Supply Unit Cam and Roller - Size4YIU KWOK KeungNo ratings yet

- Riemer Applicard2.0 - Service ManualDocument15 pagesRiemer Applicard2.0 - Service ManualGrupo FolkloricoNo ratings yet

- Technical Bulletin RT-108: Wärtsilä Low-Speed EnginesDocument6 pagesTechnical Bulletin RT-108: Wärtsilä Low-Speed EnginesKr ManuNo ratings yet

- 03.03 IFA NRV LeakagesDocument2 pages03.03 IFA NRV LeakagesGennadi JermilovNo ratings yet

- SL - WinGD - Attention - 2018 - 0005 - Operation-Instruction-to-avoid-clogging-main-fuel-injectors-nozzle-tips - XDFDocument6 pagesSL - WinGD - Attention - 2018 - 0005 - Operation-Instruction-to-avoid-clogging-main-fuel-injectors-nozzle-tips - XDFVlad FreelancerNo ratings yet

- RTA-09 Cylinder Covers With Erosion and Corrosion Resistant CladdersDocument5 pagesRTA-09 Cylinder Covers With Erosion and Corrosion Resistant CladdersCatalin CataNo ratings yet

- RTA-10 Piston Skirt in Two PartsDocument6 pagesRTA-10 Piston Skirt in Two PartsCatalin CataNo ratings yet

- RTA-46 Cracks in ColumnDocument12 pagesRTA-46 Cracks in ColumnCatalin CataNo ratings yet

- Instruction Manual: Serial No.: Voltage: 230 V Phase: 1 HZ: 50/60Document30 pagesInstruction Manual: Serial No.: Voltage: 230 V Phase: 1 HZ: 50/60Muhammad Haris BaigNo ratings yet

- RT-120 - Exhaust Valve Damper CavitationDocument6 pagesRT-120 - Exhaust Valve Damper CavitationMUKULNo ratings yet

- Operating Instructions: N - R 472C en 05.12Document42 pagesOperating Instructions: N - R 472C en 05.12Long HuynhNo ratings yet

- Service Bulletin: AB Volvo PentaDocument4 pagesService Bulletin: AB Volvo PentaDan LiamNo ratings yet

- I-32 Assessment of Connecting Rod Top End Bearing ShellDocument7 pagesI-32 Assessment of Connecting Rod Top End Bearing ShellposeidonNo ratings yet

- RTA-29 Improved Oil Supply To The Integrated Axial DetunerDocument3 pagesRTA-29 Improved Oil Supply To The Integrated Axial DetunerCatalin CataNo ratings yet

- S226-049.00 Daily Log - enDocument10 pagesS226-049.00 Daily Log - enLmf DanielNo ratings yet

- 808 - Van Driel - MOB Crane - ManualDocument221 pages808 - Van Driel - MOB Crane - ManualAmanda ViverosNo ratings yet

- Tool Maintenance - CU-Profi - Station - C - EN - 02-2022Document12 pagesTool Maintenance - CU-Profi - Station - C - EN - 02-2022RodrigoNo ratings yet

- Wartsila Rtflex58teDocument504 pagesWartsila Rtflex58teM KopNo ratings yet

- RT-270 - Cooling Water Valve Safety LoDocument6 pagesRT-270 - Cooling Water Valve Safety LoAndré MarçaloNo ratings yet

- RT-flex-07 - 07 - New Setting of Fuel Pressure Control Valve - Size4Document4 pagesRT-flex-07 - 07 - New Setting of Fuel Pressure Control Valve - Size4lijinNo ratings yet

- AZ-Operating Instructions - ENDocument4 pagesAZ-Operating Instructions - ENborodichNo ratings yet

- Printed in FranceDocument9 pagesPrinted in FranceYusron AzharyNo ratings yet

- Service Letter RT-12/09: Technical Information To All Owners / Operators of Wärtsilä RTA96C and RTA96C-B EnginesDocument4 pagesService Letter RT-12/09: Technical Information To All Owners / Operators of Wärtsilä RTA96C and RTA96C-B EnginesRaul DiazNo ratings yet

- TCD2015 PDFDocument67 pagesTCD2015 PDFRosa ChNo ratings yet

- RT-250 - Heavy Sea Mode Usage GuideDocument6 pagesRT-250 - Heavy Sea Mode Usage GuideVlad FreelancerNo ratings yet

- Instruction Manual: ISO 9001 EN 29001Document13 pagesInstruction Manual: ISO 9001 EN 29001JamesNo ratings yet

- Spreader ManualDocument176 pagesSpreader Manualhangdung19921991No ratings yet

- Service Bulletin: AB Volvo PentaDocument3 pagesService Bulletin: AB Volvo PentaArc HieNo ratings yet

- TD2015-03 EN - Installation Instruction Duresca BusbarDocument21 pagesTD2015-03 EN - Installation Instruction Duresca BusbarMarcelo Delgado100% (1)

- Centrifuga Jouan C3i Multif OpManDocument36 pagesCentrifuga Jouan C3i Multif OpManSalim AloneNo ratings yet

- 1126-17 Scanvent Type 2317 GFC Rev 1Document13 pages1126-17 Scanvent Type 2317 GFC Rev 1Ivaylo IvanovNo ratings yet

- 09.01 ICU Rail Valve LeakagesDocument11 pages09.01 ICU Rail Valve LeakagesGennadi JermilovNo ratings yet

- Instruction Manual: Butterfly Valve With HandleDocument0 pagesInstruction Manual: Butterfly Valve With HandleSohaib KhalidNo ratings yet

- En - Dren 4 40 56 97Document10 pagesEn - Dren 4 40 56 97saib.mohammed.94No ratings yet

- Sbul118 AcpowerfailureDocument1 pageSbul118 AcpowerfailureRamnept HernándezNo ratings yet

- RT60B Parts ServiceDocument39 pagesRT60B Parts Servicemetalmak ltdaNo ratings yet

- Chapter - 17 - FV 0160 9613-PicklingDocument2 pagesChapter - 17 - FV 0160 9613-PicklingAbbas PartoviNo ratings yet

- DUO CONE SEALS-install, CaterpillarDocument16 pagesDUO CONE SEALS-install, CaterpillarLuisNo ratings yet

- Shank Nut Self-Locking: REPU-2AOUT2006Document3 pagesShank Nut Self-Locking: REPU-2AOUT2006Renato WatanabeNo ratings yet

- Strapex STB-63 - ManualDocument20 pagesStrapex STB-63 - ManualembilcoNo ratings yet

- 3UL23031A Datasheet enDocument4 pages3UL23031A Datasheet enLauri OsórioNo ratings yet

- O & M Manual DLGDocument11 pagesO & M Manual DLGfaqdaniNo ratings yet

- Rease SystemDocument82 pagesRease Systemsundya100% (1)

- Installation, Operation and Maintenance Manual For Vertical Rotalock™ ClosureDocument14 pagesInstallation, Operation and Maintenance Manual For Vertical Rotalock™ ClosureMuhammad GaneshaNo ratings yet

- CV115-129 01 Interlock S226.037 01Document22 pagesCV115-129 01 Interlock S226.037 01Lmf DanielNo ratings yet

- RTA-33.1 Crank Pin Bearing ShellsDocument13 pagesRTA-33.1 Crank Pin Bearing ShellsCatalin CataNo ratings yet

- Sulzer-Moret 121 NFDDocument89 pagesSulzer-Moret 121 NFDCardoso MalacaoNo ratings yet

- Repair Instruction Corrosion Protection JacketDocument13 pagesRepair Instruction Corrosion Protection JacketIliyanPetrovNo ratings yet

- Vendor Supplied Document: ContentsDocument11 pagesVendor Supplied Document: ContentsharounNo ratings yet

- SL - Wartsila - Technical Bulletin - 2020 - Attention - RT-239 - Optimisation Jacket Cooling Water - XDFDocument14 pagesSL - Wartsila - Technical Bulletin - 2020 - Attention - RT-239 - Optimisation Jacket Cooling Water - XDFVlad FreelancerNo ratings yet

- 2012-022 - Grease - System - Emergency - Kits 17-07-2012Document3 pages2012-022 - Grease - System - Emergency - Kits 17-07-2012Jean-Jacques OuandaogoNo ratings yet

- DNV CG 0134Document158 pagesDNV CG 0134lijinNo ratings yet

- DNV CG 0063Document16 pagesDNV CG 0063lijinNo ratings yet

- DNV CG 0042Document23 pagesDNV CG 0042lijinNo ratings yet

- UIGCDocument63 pagesUIGClijinNo ratings yet

- Code of ConductDocument2 pagesCode of ConductlijinNo ratings yet

- UIFTPDocument16 pagesUIFTPlijinNo ratings yet

- REC25 DelDocument1 pageREC25 DellijinNo ratings yet

- UIPASSUBDocument3 pagesUIPASSUBlijinNo ratings yet

- UIFTPDocument16 pagesUIFTPlijinNo ratings yet

- RT-137 - Issue3 - Maintenance Concepts For RT-flex and W-X ComponentsDocument7 pagesRT-137 - Issue3 - Maintenance Concepts For RT-flex and W-X ComponentslijinNo ratings yet

- PrcdsDocument311 pagesPrcdslijinNo ratings yet

- RT-199 - Obsolescence of Baumer SVS 40 R 83 Twin-Sensor Amplifier - RTA and RT-flexDocument3 pagesRT-199 - Obsolescence of Baumer SVS 40 R 83 Twin-Sensor Amplifier - RTA and RT-flexlijinNo ratings yet

- Exhaust Valve Roller Guide: S35MC DataDocument6 pagesExhaust Valve Roller Guide: S35MC DatalijinNo ratings yet