Professional Documents

Culture Documents

Flushing Pump BOQ 20.02.2020

Uploaded by

pprateek18Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flushing Pump BOQ 20.02.2020

Uploaded by

pprateek18Copyright:

Available Formats

Flushing Water Supply Pumps BOQ THINK BIM

TECHNICAL

Doc. No.: TB/15280/P/C-01 Rev. No.: 00

SERVICES

Project No. 15280 Prepared By: MKS PVT. LTD.

Issue Date: 20.02.2020 Approved By: DKT Ashiana Tarang, Bhiwadi

Rate Amount

S.NO. DESCRIPTION Unit Qty

(Rs.) (Rs.)

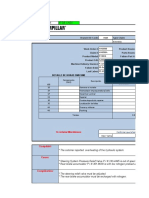

I Flushing Water Supply Pumps

1.0 Variable Speed Hydropneumatic System For Flushing OHT

filling:

Supply, installation, testing & commissioning of Compact self

contained Hydro pneumatic system comprising of following :

i) Vertical, In-line, multistage, centrifugal clear water pumps with SS-

304 casing, S.S 304 impeller and SS-316 shaft, C.I. Base & head

TEFC motor (with mechanical seal) Vendor to submit performance

curves, dimension detail and technical data sheet catalogue of the

proposed model for review and approval.

ii) Panel mounted microprocessor PID controller and variable

frequency drive (VFD) integrated in a single body or as separate

components with pressure sensor transmitter (one dedicated to

each pump) minimum two lined LCD display, diodes to indicate

pump ready, pump running and fault and capable to communicate

with other controllers following MODBUS-RTU or BACNET Class-2

protocol through RS485 port. System should be capable to

compensate for frictional losses at lower flows. All alarms should be

displayed in the controller. System should be equipped with dry

running protection. (Quantity of VFD = 1 No.)

iii) Pre-charged diaphragm pressure vessel with interchangeable

membrane, charging connection, connected to outlet header with

necessary flanges, gaskets, isolating valves, nuts/bolts etc.

complete (size of pressure vessel shall be of suitable capacity or as

per manufacturer calculation/recommendation).

iv) Set of accessories such as pressure switches, pressure

transducers,valve (butterfly / ball valve, NRV of PN 16.00 rating)

Vibration Isolator, GI "heavy class" suction & delivery header &

interconnection piping, level controller, pressure gauge inter

connecting power and control cabling etc. complete with Vibration

eliminator of required quantities.

● Capacity/Flow rate

of each pump - 270 lpm (16.2 m3 /Hr)

● Pumping Head - 70m

● Motor (kw) - 5.5 KW or as per manufacture recommendation

● Location - STP plant room

● 1 Set = 3 Nos. Pump (2 Working+1 Standby)

Note: As of now 1w+1s has to be installed and 1w has to be

added when all the phases shall be operational.

a) Supply Set 1

b) Installation, testing & commissioning Set 1

Page 1

You might also like

- BOQ Water TreatmentDocument3 pagesBOQ Water TreatmentYawar Qureshi100% (2)

- T10107 YR02 P0ZEN 140001 - Rev.0 - Electrical System Design CriteriaDocument89 pagesT10107 YR02 P0ZEN 140001 - Rev.0 - Electrical System Design CriteriaRahul SrivastavaNo ratings yet

- Etp - 30 KLDDocument18 pagesEtp - 30 KLDsubramanyam kumarNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- 2000 Parts Catalog: ABB Offshore Systems IncDocument111 pages2000 Parts Catalog: ABB Offshore Systems IncRafael Charry Andrade50% (2)

- Fire Fighting Course Uploaded by Hady HabibDocument148 pagesFire Fighting Course Uploaded by Hady HabibparthivNo ratings yet

- Data Sheet R0.xlsx - 1Document2 pagesData Sheet R0.xlsx - 1Dharam SharmaNo ratings yet

- Bill of Quantities Sewage Treatment PlanDocument11 pagesBill of Quantities Sewage Treatment PlanMiguel ChanNo ratings yet

- Ahmedabad Municipal CorporationDocument40 pagesAhmedabad Municipal Corporationkishore vpNo ratings yet

- Boq of Electrification of Package-02 - 30092021Document128 pagesBoq of Electrification of Package-02 - 30092021SHANTANU PATHAKNo ratings yet

- SCG 2423 19B - 20B Boq LliDocument7 pagesSCG 2423 19B - 20B Boq LliAnsaf AskyNo ratings yet

- Part BDocument1,080 pagesPart BgovindharajaluNo ratings yet

- P-G-0101 - CWBP01 Pump Head CAlculationsDocument54 pagesP-G-0101 - CWBP01 Pump Head CAlculationsJonery NabablitNo ratings yet

- Indian Oil Corporation LTD,: Petreco International (Me) LTDDocument11 pagesIndian Oil Corporation LTD,: Petreco International (Me) LTDDark KnightNo ratings yet

- Pavetest DivisionDocument46 pagesPavetest DivisionjohanNo ratings yet

- PCV Data Sheet PDFDocument5 pagesPCV Data Sheet PDFveenaNo ratings yet

- Guide For Instrumenting The P&I / Flow Diagram: Tata Consulting EngineersDocument36 pagesGuide For Instrumenting The P&I / Flow Diagram: Tata Consulting EngineersswatkoolNo ratings yet

- 60-F8451S-H0101-01 RevD DBR of CPPDocument19 pages60-F8451S-H0101-01 RevD DBR of CPPK R Kumar RanjanNo ratings yet

- BOQ MergedDocument4 pagesBOQ Mergedfakir mohammadNo ratings yet

- Conny Tech Pte LTD: Progress Claims: No.1 LOA Ref: SCCCI/LOI/CH/012 Dated 7 September 2020Document1 pageConny Tech Pte LTD: Progress Claims: No.1 LOA Ref: SCCCI/LOI/CH/012 Dated 7 September 2020Zawhtet WinNo ratings yet

- Tyagi Ji - STPDocument17 pagesTyagi Ji - STPShine Water ExpertsNo ratings yet

- Drinking-Cooking Water Treatment and Distribution SystemDocument3 pagesDrinking-Cooking Water Treatment and Distribution Systemdb.jcrs2022No ratings yet

- Quality Assurance Plan: Manufacturer'S Name & AddressDocument1 pageQuality Assurance Plan: Manufacturer'S Name & AddressEWTRNo ratings yet

- BOQ 70000 Utility (AD4+AD7+AD9 AD10 AD11)Document33 pagesBOQ 70000 Utility (AD4+AD7+AD9 AD10 AD11)Md Imran Khan SohanNo ratings yet

- Movitec BDocument64 pagesMovitec BJohnyNo ratings yet

- HubantDocument3 pagesHubantAr Aditya SagarNo ratings yet

- SL No. Description Unit QTY: or 10mm ArmasoundDocument4 pagesSL No. Description Unit QTY: or 10mm ArmasoundAnkit JainNo ratings yet

- N2 Generator CalculationDocument9 pagesN2 Generator CalculationBagus PrambudiNo ratings yet

- Tender Enquiry No. Bhe/Fp/Cvl/024 Section-IV Bill of QuantitiesDocument16 pagesTender Enquiry No. Bhe/Fp/Cvl/024 Section-IV Bill of QuantitiesjeevanNo ratings yet

- 90383800B CMP 200 DR LSS External Capacitor PDFDocument6 pages90383800B CMP 200 DR LSS External Capacitor PDFbajarNo ratings yet

- 8 NCC Etp Vol II Sec C1-ADocument4 pages8 NCC Etp Vol II Sec C1-AShanjiNo ratings yet

- Inst & AutoDocument2 pagesInst & AutohadiNo ratings yet

- Indian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)Document3 pagesIndian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)kkaranagNo ratings yet

- 7770865e - 6187064 - 01 Technical Specification Ros 6180 Rev 00Document10 pages7770865e - 6187064 - 01 Technical Specification Ros 6180 Rev 00bondsivamaniNo ratings yet

- BOQ HVAC SYSTEM Sector 21 22122016Document5 pagesBOQ HVAC SYSTEM Sector 21 22122016Tuesou MachereNo ratings yet

- Fuller Factory#PricingDocument39 pagesFuller Factory#PricingkkkhattabbbNo ratings yet

- t21041-CD-000-Ins-mto-002 Mto For Mov Master Station - Rev. 1Document3 pagest21041-CD-000-Ins-mto-002 Mto For Mov Master Station - Rev. 1Bally JanNo ratings yet

- UntitledDocument29 pagesUntitledIwan HerawanNo ratings yet

- Tspart Bsub Section Iiic 02 FinalDocument11 pagesTspart Bsub Section Iiic 02 Finalpradeep.selvarajanNo ratings yet

- Commercial Offer Letter No. 1001-20Document7 pagesCommercial Offer Letter No. 1001-20Mourad AhmadNo ratings yet

- B Waste Water Drainage (Soil, Waste & Vent System) (Option 01)Document4 pagesB Waste Water Drainage (Soil, Waste & Vent System) (Option 01)Arjun BharambeNo ratings yet

- Material SubmittalDocument66 pagesMaterial SubmittalmodvillamancaNo ratings yet

- KiddeDocument3 pagesKiddeRaduNo ratings yet

- Boq LGDocument5 pagesBoq LGAshutosh Kumar DubeyNo ratings yet

- Calculation ReportDocument29 pagesCalculation Reportvictor.sNo ratings yet

- Automation EstimateDocument13 pagesAutomation EstimateJitesh KumarNo ratings yet

- NDB Manuals (06 NDB) PDFDocument121 pagesNDB Manuals (06 NDB) PDFLe HienNo ratings yet

- SBT 19-075R3Document6 pagesSBT 19-075R3Mourad AhmadNo ratings yet

- Specifications For Transmitters-R1pdfDocument6 pagesSpecifications For Transmitters-R1pdfVirgilioNo ratings yet

- GB Vapour RecoveryDocument17 pagesGB Vapour RecoveryrobertwinwoodNo ratings yet

- Approved - 4977-AVBOT-Approval For Procurement of ATMSHTMS Accessories - NE-1Document3 pagesApproved - 4977-AVBOT-Approval For Procurement of ATMSHTMS Accessories - NE-1Rajesh DeyNo ratings yet

- HT Amot Valve CalibrationDocument3 pagesHT Amot Valve CalibrationWAQAS ASHIQNo ratings yet

- HvacDocument48 pagesHvacmohamed adelNo ratings yet

- BOQ - 500 KLD Prefabricated STP - R00Document5 pagesBOQ - 500 KLD Prefabricated STP - R00tnd tbecNo ratings yet

- F 36 Arrangement of Aux Connection & Temp Indicating Devices Rev 01 14.12.2022Document2 pagesF 36 Arrangement of Aux Connection & Temp Indicating Devices Rev 01 14.12.2022Jagan TnNo ratings yet

- Shindo Hydro Booster SystemDocument8 pagesShindo Hydro Booster SystemJLD RESOURCESNo ratings yet

- Well Stimulation Job ProgramDocument36 pagesWell Stimulation Job Programmuhammad anasNo ratings yet

- 51Q-BU-0008 - Rev.1 Sanitary Works Inspection ReportDocument1 page51Q-BU-0008 - Rev.1 Sanitary Works Inspection Reportnazim7No ratings yet

- Sl. No. Short Description: 1 Central AC Material Rate 2 Installation Rate Total AmountDocument23 pagesSl. No. Short Description: 1 Central AC Material Rate 2 Installation Rate Total AmountSofiqNo ratings yet

- WTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDocument26 pagesWTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDeepak Patil100% (1)

- SABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingDocument15 pagesSABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingAbdelaziz EldeebNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Pump Technical SpecDocument9 pagesPump Technical Specpprateek18No ratings yet

- Broadband BillDocument1 pageBroadband Billpprateek18No ratings yet

- Domestic Claim Report - 34021Document3 pagesDomestic Claim Report - 34021pprateek18No ratings yet

- Domestic Claim Report - 34023Document1 pageDomestic Claim Report - 34023pprateek18No ratings yet

- Kenr9408kenr9408-01 SisDocument4 pagesKenr9408kenr9408-01 SisBruno ArteagaNo ratings yet

- WW Ordering Guide 700 SeriesDocument4 pagesWW Ordering Guide 700 SeriesEdwin BautistaNo ratings yet

- Flow in Pipe - Manning FormulaDocument1 pageFlow in Pipe - Manning FormulaBahtiar YudhistiraNo ratings yet

- Pipeline Pigging Handbook 8Document1 pagePipeline Pigging Handbook 8Bruno GonçalvesNo ratings yet

- Uh2002a12en 1Document5 pagesUh2002a12en 1MARTIN GONZALEZNo ratings yet

- Manual HydraulicVentValveDocument4 pagesManual HydraulicVentValvebentsopoNo ratings yet

- Action Plan (M 19)Document8 pagesAction Plan (M 19)lukikhoNo ratings yet

- List of BooksDocument9 pagesList of BooksQaxim ShahNo ratings yet

- Titan Flow Control, Inc.: Installation, Operation, and MaintenanceDocument5 pagesTitan Flow Control, Inc.: Installation, Operation, and MaintenanceAHMEDMALAHYNo ratings yet

- 2 Flow in Closed Conduits Lecture Probs PDFDocument14 pages2 Flow in Closed Conduits Lecture Probs PDFRobi TanyagNo ratings yet

- KSB Selecting Centrifugal Pumps En, Property FileDocument92 pagesKSB Selecting Centrifugal Pumps En, Property Filevisitabhinav100% (7)

- Materials For HSN Codes (Sales)Document6 pagesMaterials For HSN Codes (Sales)Sachin SinghNo ratings yet

- Nfpa 25 2002 IndexDocument5 pagesNfpa 25 2002 Indexsaladin1977No ratings yet

- Centrifugal Pump ExperimentsDocument18 pagesCentrifugal Pump ExperimentssamadonyNo ratings yet

- 1.7 Vane Pumps 1. Unbalanced Vane Pump: Unbalanced Vane Pumps Are of Two VarietiesDocument12 pages1.7 Vane Pumps 1. Unbalanced Vane Pump: Unbalanced Vane Pumps Are of Two VarietiesSUNDARRAJAN KNo ratings yet

- Hydraulic and Pneumantic Machine 1 Basic 8Document14 pagesHydraulic and Pneumantic Machine 1 Basic 8Valentine NwankwoNo ratings yet

- Comfort PU FlyerDocument5 pagesComfort PU FlyeruginpNo ratings yet

- Request Form KH08588Document4 pagesRequest Form KH08588nelsonNo ratings yet

- Pump Head CalculationDocument12 pagesPump Head CalculationIrfan Siddiqui100% (1)

- Sanyi Gate Valve Spare PartsDocument18 pagesSanyi Gate Valve Spare PartsAnonymous MxwCc4No ratings yet

- Chiller Piping SystemDocument12 pagesChiller Piping Systemsundarhvac67% (3)

- BOQ Pemas Jar Pipa Dist GCA CandiDocument3 pagesBOQ Pemas Jar Pipa Dist GCA CandiRasyid7 SurabayaNo ratings yet

- A and F v-10 Simplex Pump ModelsDocument112 pagesA and F v-10 Simplex Pump ModelsPromagEnviro.comNo ratings yet

- System Rated Plus W Sub 150Document2 pagesSystem Rated Plus W Sub 150Martin Roberto GarciaNo ratings yet

- Liebherr Technical Data DpvoDocument86 pagesLiebherr Technical Data DpvoІгор Веселов100% (1)

- Compression Fittings: Technical Helpline: +44 (0) 1473 277 460 Technical Helpline: +44 (0) 1473 277 460Document56 pagesCompression Fittings: Technical Helpline: +44 (0) 1473 277 460 Technical Helpline: +44 (0) 1473 277 460thingsneededforNo ratings yet

- R K Bansal-A Textbook of Fluid Mechanics and Hydraulic Machines - by EasyEngineering - Net-1101-1125Document25 pagesR K Bansal-A Textbook of Fluid Mechanics and Hydraulic Machines - by EasyEngineering - Net-1101-1125Shanawas Abdul RazakNo ratings yet