Professional Documents

Culture Documents

PA12 SLS Black - CRP Technology

Uploaded by

alkhalidibaiderCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PA12 SLS Black - CRP Technology

Uploaded by

alkhalidibaiderCopyright:

Available Formats

View online product page

PA12 SLS Black

Technical DataSheet | Supplied by CRP Technology

PA12 SLS Black by CRP Technology is a black color, low density, robust PA 12 (nylon 12) grade. It is flexible, durable,

resistant to weather, abrasion, organic solvents, oils and fuels. It is used in manufacturing of complex geometries, low

volume production parts and functional prototypes with thin wall thicknesses, higher resolution details, smoother

surfaces, water- and substances resistance.

It is cost-effective and offers outstanding mechanical performances and high melting point.

It is available as fine powder for selective laser sintering technology which benefits from the absence

of supports enabling maximum precision, stability and strength.

PA12 SLS Black is suitable for replacing injection molded parts with 3D printed all-in-one

components destined to last.

It is recommended for consumer goods and industrial applications such as connectors, hinges,

housings, enclosures, jigs and fixtures.

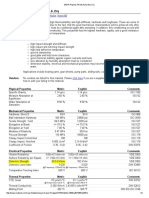

Product Type PA (Polyamide, Nylon) > PA 12 (Nylon 12)

Physical Form Powder

Appearance Black

Product Launch Date Aug 9, 2023

Product Status COMMERCIAL

Applications/ Recommended for Households products/ Consumer Goods

Electrical markets > Connectors

Key Features Abrasion resistance, Good

Cost Effective

Density, Low

Durable

Flexibility, High

Fuel Resistant

Mechanical Properties, Excellent

Oil Resistant

Solvent Resistant

Stability, Good

Strength, Good

Water Resistance, High

Weather Resistance, Good

PA12 SLS Black Properties

Thermal Value & Unit Test Condition Test Method

Lasted edited September 06, 2023 http://omnexus.specialchem.com 1

View online product page

Melting Point 181.70 °C ISO 11357

Deflection Temperature at 95.80 °C Method A ISO 75

1.8 MPa (264 psi)

Vicat Softening 177.20 °C 10N, Method A ISO 75

Temperature

Mechanical Value & Unit Test Condition Test Method

Tensile Strength 47.84 MPa At XY Axis UNI EN ISO 527-1

Tensile Strength 47.92 MPa At YX Axis UNI EN ISO 527-1

Tensile Modulus 1907.80 MPa At XY Axis UNI EN ISO 527-1

Tensile Modulus 1918.60 MPa At YX Axis UNI EN ISO 527-1

Elongation at Break 12.18 % At XY Axis UNI EN ISO 527-1

Elongation at Break 11.06 % At YX Axis UNI EN ISO 527-1

Flexural Strength 68.84 MPa UNI EN ISO 14125

Flexural Modulus 1628 MPa UNI EN ISO 14125

Impact Strength, 25.40 KJ/m2 At 23°C UNI EN ISO 179-1

Unnotched Charpy

Impact Strength, 22.60 KJ/m2 At -30°C UNI EN ISO 179-1

Unnotched Charpy

Impact Strength, Notched 4.30 KJ/m2 At 23°C UNI EN ISO 179-1

Charpy

Impact Strength, Notched 4.00 KJ/m2 At -30°C UNI EN ISO 179-1

Charpy

Lasted edited September 06, 2023 http://omnexus.specialchem.com 2

View online product page

Hardness, Shore D 78 UNI EN ISO 868

Tensile Strength 45.78 MPa At ZX Axis UNI EN ISO 527-1

Tensile Modulus 1868.20 MPa At ZX Axis UNI EN ISO 527-1

Elongation at Break 8.70 % At ZX Axis UNI EN ISO 527-1

Electrical Value & Unit Test Condition Test Method

Volume Resistivity 1.5x1014 ohm-cm ASTM D257-14

Surface Resistivity 9.3x1014 ohm ASTM D257-14

Comparative Tracking 600 V Solution A IEC 60112

Index (CTI)

Physical Value & Unit Test Condition Test Method

Density 0.99 g/cm3 At 20°C

Help us improve the Universal Selector

You can’t find what you are looking for? Please report missing products / suppliers, point out errors, or simply tell us how

we could make the Universal Selector better.

Send a Feedback

Lasted edited September 06, 2023 http://omnexus.specialchem.com 3

You might also like

- Assignment 2 Mechanics of MaterialsDocument13 pagesAssignment 2 Mechanics of MaterialsStacey SkibaNo ratings yet

- Proses Pembuatan KertasDocument124 pagesProses Pembuatan Kertasgarispante07100% (7)

- Radel® R-5900 - SolvayDocument3 pagesRadel® R-5900 - SolvayTRUONGNo ratings yet

- NG30-02JBK - Next PolymersDocument4 pagesNG30-02JBK - Next PolymersdigiarkanandNo ratings yet

- Nylon 12 Material Data: Product DescriptionDocument1 pageNylon 12 Material Data: Product DescriptionRahul SahuNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- InnoPlus LD2420D - InnoPlusDocument3 pagesInnoPlus LD2420D - InnoPlusEko SabtianNo ratings yet

- YUPLENE® R930Y - SK Geo CentricDocument2 pagesYUPLENE® R930Y - SK Geo CentricChu ChuNo ratings yet

- ImpactDocument3 pagesImpacthyper meshNo ratings yet

- Shapes BrochureDocument12 pagesShapes BrochureKhor Tze MingNo ratings yet

- PA 6.6 Nylon 6.6Document2 pagesPA 6.6 Nylon 6.6Naeem KhanNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- VESTAMID® L1670 - EvonikDocument5 pagesVESTAMID® L1670 - EvonikShikha MishraNo ratings yet

- 202-Wacker Elastosil LR 3003-80 A-B Technical Data Sheet 03-23-2021Document4 pages202-Wacker Elastosil LR 3003-80 A-B Technical Data Sheet 03-23-2021ismail hakkıNo ratings yet

- Tds Infinam RG 7100 LDocument2 pagesTds Infinam RG 7100 LKacperNo ratings yet

- Onyx - MarkforgedDocument2 pagesOnyx - MarkforgedalkhalidibaiderNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Styrolution PS 116N/L: Technical DatasheetDocument2 pagesStyrolution PS 116N/L: Technical Datasheetdrmohamed120No ratings yet

- POWERSIL 600 AB en 2019.12.05Document4 pagesPOWERSIL 600 AB en 2019.12.05Aleksandar KaplijevNo ratings yet

- LS PEKK CF HT23 Material Datasheet 201705Document1 pageLS PEKK CF HT23 Material Datasheet 201705Angel LagrañaNo ratings yet

- Technical Data SheetDocument4 pagesTechnical Data SheetHardikNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- CAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 TiconaDocument2 pagesCAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 TiconaAngererNo ratings yet

- BC245MODocument3 pagesBC245MOsudipto ranjan dassNo ratings yet

- Para - Solvay Ixef 1032Document7 pagesPara - Solvay Ixef 1032armandoNo ratings yet

- LH-3750 - Daelim IndustrialDocument2 pagesLH-3750 - Daelim IndustrialAkoyoNo ratings yet

- Ajedium Films (Solvay)Document3 pagesAjedium Films (Solvay)hyper meshNo ratings yet

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- Quadrant EPP PVC - Polyvinyl Chloride, Type I, Grade 1: Physical Properties Metric English CommentsDocument1 pageQuadrant EPP PVC - Polyvinyl Chloride, Type I, Grade 1: Physical Properties Metric English Commentsروشان فاطمة روشانNo ratings yet

- Lucene™ LC168 - LG ChemDocument2 pagesLucene™ LC168 - LG ChemTANMAY NAYAKNo ratings yet

- Nylatron® 4.6 - BoedekerDocument6 pagesNylatron® 4.6 - BoedekerMas ZuhadNo ratings yet

- Performance Properties of Corian (Dupont) PDFDocument2 pagesPerformance Properties of Corian (Dupont) PDFAdan Arribasplata SeguinNo ratings yet

- Wear Plate BrochureDocument2 pagesWear Plate Brochurec3512No ratings yet

- Ficha Tecnica Paxon As55003Document2 pagesFicha Tecnica Paxon As55003Eleannys GarciasNo ratings yet

- PaverDocument2 pagesPavershalini sivaNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Styrolution PS 495N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 495N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- GENESTAR™ GP2300S - KurarayDocument4 pagesGENESTAR™ GP2300S - KurarayRafael CastroNo ratings yet

- Celanese Corporation Celanex® 1400A Polybutylene TerephthalateDocument2 pagesCelanese Corporation Celanex® 1400A Polybutylene TerephthalateTomGaliciaNo ratings yet

- Braskem Braskem PE GP100ORXP Pead GAS PE100Document2 pagesBraskem Braskem PE GP100ORXP Pead GAS PE100weimar solizNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- Geogrid Standard Material SpecificationDocument2 pagesGeogrid Standard Material SpecificationBriccioNo ratings yet

- Polypropylene PDFDocument2 pagesPolypropylene PDFSabuj SaikiaNo ratings yet

- TDS EU G-Energy X Hydro Bio EngDocument2 pagesTDS EU G-Energy X Hydro Bio EngАлексей ДэконNo ratings yet

- Acrylic PMMA - BoedekerDocument6 pagesAcrylic PMMA - Boedekermartin sabusNo ratings yet

- Brayco Micronic™ SV/B: DescriptionDocument5 pagesBrayco Micronic™ SV/B: DescriptionAlfonsus W.M.No ratings yet

- Sikafloor®-263 SLDocument6 pagesSikafloor®-263 SLHalit Baris SertbakanNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 pagesCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNo ratings yet

- K-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsDocument1 pageK-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsPatricio Bravo CastilloNo ratings yet

- ALTECH PE-HD A 2010/506 GF10: Technical Data SheetDocument2 pagesALTECH PE-HD A 2010/506 GF10: Technical Data SheetPhung LucNo ratings yet

- Globalene ST031: Technical Data Sheet / 技術資料表Document1 pageGlobalene ST031: Technical Data Sheet / 技術資料表Ale AriasNo ratings yet

- 2.21.1 Neoprene Rubber Sheeting Flame Retardant TCDocument1 page2.21.1 Neoprene Rubber Sheeting Flame Retardant TCFerianto STNo ratings yet

- Cardolite NX-2007: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite NX-2007: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- 2024 03 06 TDS Elastollan1185ADocument4 pages2024 03 06 TDS Elastollan1185AChaker AbdellatifNo ratings yet

- Technical Data Sheet ADFLEX F 500Document2 pagesTechnical Data Sheet ADFLEX F 500leftpowtaNo ratings yet

- Cardolite NX 2016Document2 pagesCardolite NX 2016Lê TiếnNo ratings yet

- Product PDF 4956Document2 pagesProduct PDF 4956Mohammad PoostforushNo ratings yet

- TDS Nylon V3.011-EnDocument3 pagesTDS Nylon V3.011-Enmartinf090574No ratings yet

- Standard: ISO 527, ASTM D638, GB/T 1040Document1 pageStandard: ISO 527, ASTM D638, GB/T 1040alkhalidibaiderNo ratings yet

- Standard: ISO 527, ASTM D638, GB/T 1040Document1 pageStandard: ISO 527, ASTM D638, GB/T 1040alkhalidibaiderNo ratings yet

- Standard: ISO 527, ASTM D638, GB/T 1040Document1 pageStandard: ISO 527, ASTM D638, GB/T 1040alkhalidibaiderNo ratings yet

- Density: StandardDocument1 pageDensity: StandardalkhalidibaiderNo ratings yet

- Standard: DSC, 10°c/minDocument1 pageStandard: DSC, 10°c/minalkhalidibaiderNo ratings yet

- Standard: DSC, 10°c/minDocument1 pageStandard: DSC, 10°c/minalkhalidibaiderNo ratings yet

- Decomposition Temperature: StandardDocument1 pageDecomposition Temperature: StandardalkhalidibaiderNo ratings yet

- SOPs APIDocument49 pagesSOPs APIalkhalidibaiderNo ratings yet

- CantileverRetaining 6m WallsDocument10 pagesCantileverRetaining 6m WallsdsureshcivilNo ratings yet

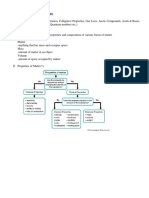

- Polymers: Classification Based On SourceDocument4 pagesPolymers: Classification Based On Sourceatulkumargaur26No ratings yet

- Acoustic Emission - Standards and Technology UpdateDocument257 pagesAcoustic Emission - Standards and Technology Updatetobby65100% (1)

- 13 Pre-Review On Chem - SrengthDocument4 pages13 Pre-Review On Chem - SrengthAl-nashreen AbdurahimNo ratings yet

- Glass Pin Post InsulatorDocument3 pagesGlass Pin Post InsulatorrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrNo ratings yet

- Air Jet Mill MicronizerDocument6 pagesAir Jet Mill MicronizerMenoddin shaikh100% (1)

- Applications of High Strength Concrete For Highway BridgesDocument30 pagesApplications of High Strength Concrete For Highway Bridgesaji raNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Freeze Dryer Lyophilisation FishDocument4 pagesFreeze Dryer Lyophilisation FishcouvrefeuNo ratings yet

- CarbonCure Technical Note - Types of Concrete CarbonationDocument4 pagesCarbonCure Technical Note - Types of Concrete CarbonationSakineNo ratings yet

- Statistical Mechanics of Liquids: Johan T. Padding Université Catholique de Louvain, BelgiumDocument79 pagesStatistical Mechanics of Liquids: Johan T. Padding Université Catholique de Louvain, Belgiumtomas guerreroNo ratings yet

- The Design, Analysis and Construction of Tensile Fabric StructuresDocument26 pagesThe Design, Analysis and Construction of Tensile Fabric Structurespradeep vermaNo ratings yet

- FoldernamesDocument10 pagesFoldernamesLEADER VISANo ratings yet

- Sirafan SpeedDocument5 pagesSirafan SpeedProsenjit76No ratings yet

- Product & Service Datasheet: Medium Voltage (6kV To 36kV) Subsea Power Cable Repair JointDocument2 pagesProduct & Service Datasheet: Medium Voltage (6kV To 36kV) Subsea Power Cable Repair Jointnader mahfoudhiNo ratings yet

- The Response of Honeycombsandwich Panels Under Low-Velocity Impact LoadingDocument25 pagesThe Response of Honeycombsandwich Panels Under Low-Velocity Impact LoadingMihaela NastaseNo ratings yet

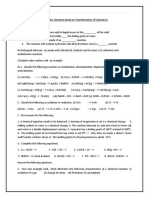

- Chemistry Question Based On Transformation of SubstanceDocument2 pagesChemistry Question Based On Transformation of SubstanceproodootNo ratings yet

- E1. Boiler Tube Failure Part 1Document54 pagesE1. Boiler Tube Failure Part 1Rajendran Srn100% (5)

- Plastic Fiber Optic Assembly Model PBT26U PBT26U: .02" Diameter Bifurcated Fiber With Threaded Sensing EndDocument2 pagesPlastic Fiber Optic Assembly Model PBT26U PBT26U: .02" Diameter Bifurcated Fiber With Threaded Sensing Endtranphuongxd369No ratings yet

- Shear CheckDocument22 pagesShear CheckAJAY SHINDENo ratings yet

- NMAT - Must Know-ChemistryDocument45 pagesNMAT - Must Know-ChemistryElise TraugottNo ratings yet

- Sa 4820M00450 00001 01 - 00Document1 pageSa 4820M00450 00001 01 - 00mohdfaridabubakarNo ratings yet

- Laboratory Rules and SafetyDocument9 pagesLaboratory Rules and SafetyMehul KhimaniNo ratings yet

- Tin Is A Chemical Element With The Symbol SNDocument1 pageTin Is A Chemical Element With The Symbol SNemieZNo ratings yet

- Dokumen - Tips - Iron Iron Carbide Phase Diagram 58ac3a092bd8dDocument16 pagesDokumen - Tips - Iron Iron Carbide Phase Diagram 58ac3a092bd8dAfrizal Adithya PNo ratings yet

- AMSOIL Synthetic Water Resistant Grease GWRDocument2 pagesAMSOIL Synthetic Water Resistant Grease GWRamsoildealerNo ratings yet

- Weldability of Austenitic Manganese Steel: J. Mendez, M. Ghoreshy, W.B.F. Mackay, T.J.N. Smith, R.W. SmithDocument7 pagesWeldability of Austenitic Manganese Steel: J. Mendez, M. Ghoreshy, W.B.F. Mackay, T.J.N. Smith, R.W. Smithนรวิชญ์ กาญจนามัยNo ratings yet

- Lab Report - Heat of CombustionDocument3 pagesLab Report - Heat of CombustionDexter ClamohoyNo ratings yet

- Photodiode Investigatory ProjectDocument25 pagesPhotodiode Investigatory ProjectNishant KumarNo ratings yet