Professional Documents

Culture Documents

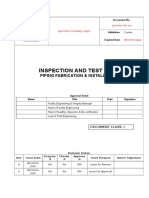

Inspection Test Plan

Inspection Test Plan

Uploaded by

gelsongustavoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Test Plan

Inspection Test Plan

Uploaded by

gelsongustavoCopyright:

Available Formats

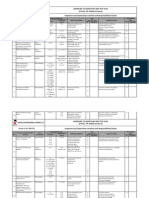

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

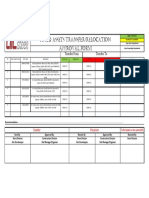

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 1

1.0 JOB SPECIFIC DATA : -

CUSTOMER :

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

CONSULTANT : - PROJECT NO:

INSP. AGENCY: DESIGN CODE :

2.0 QUALITY STAGES & INSPECTION :

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

CHARACTERISTICS METHOD EXTENT TL CLI

1 MATERIAL IDENTIFICATION H H

Review & Verification of Material Test Certs. & Drawing Review 100% Drawing, ASME Sec-II

Correlation of MTC with Material Visual 100% Mill Test

Certificate

Dimensional Inspection Measurement 5% Drawing/ Mill Test

Certificate

Identification-Boiler/Heat/Plate/ Part/Shell No.& Mat.Specs. Visual 100% Identification

Punching

IA Stamp Transfer Verify 100% Stamp Transfer

Verify UT Testing for Plate & Nozzle Forgings in MTC Review 100% Material Spec.

HOT ROLLED DRUM:Simulated Heat Treatment & PWHT test coupon Review 1 Sample HT Cycle & Material

/Heat Specs./Code

Identification & Dimensional Inspection of Dished Ends Measurement 100% Drawing

Document review for Dished Ends & Manhole Rims Review 100% Drawing & Code

Identification & Dimensional Inspection of Manhole Rims Measurement 100% Drawing

2 SETUP OF L-SEAMS OF SHELL ALONGWITH TEST COUPON H H

Production Test Coupon with L-Seam Verify One PTC / IBR-1950

Heat/Drum

Intermediate SR (if D/T<20 for CS & <18 for AS) Review of 100% IBR-1950/HT

HT chart Procedure

Ovality, (Inside dia. Min & Max.) Measurement 100% 1% of Nominal ID or

5mm max.

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 2

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Shell length, Outside circumference Measurement 100% Drawing

Profile D/4 100% Drawing, IBR 1950

Template

Weld Preparation Template 100% Drawing

Offset / Mismatch Measurement 100% 10%of Nominal plate

thickness or 3mm max

Flaw detection on weld edges PT/MT 100% Free from

Lamination, Crack &

Liner Indications

Tack Weld Soundness PT 100% Procedure PT(Refer

Note No.3)

Shell identification/IA Stamp Visual 100% Drawing, IA Stamp

3 L-SEAM WELDING H R

Backgauging after 1st side welding PT/MT 100% Procedure PT/MT

Inspection after both side welding Visual 100% Procedure VT

Weld reinforcement - Flush ground from Outside Visual 100% IBR-1950

Inspection after Re-rolling of shell:

Profile D/4 100% Within 0.3% of ID

Tempelate

Ovality Measurement 100% 1%of ID or 5mm Max.

Welder/Welding Operator ID Visual 100% Qualified welder

list/IBR Certificate

Weld soundness RT & MT 100% Procedure RT, MT

NDE for CS Drum thk. >&= 100 mm & AS Drum thk. >&=50mm UT 100% Procedure UT

4 PWHT & TESTING OF PTC H H

Heat-Treatment Cycle Review 100% IBR-1950

Heat-Treatment Compliance to Code Review of 100% IBR-1950

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 3

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

HT chart

Mech. Properties of PTC Mechanical One PTC / Material

Testing Heat /Dru Specifications

5 C-SEAM SETUP H H

Orientation Visual 100% Drawing

Total length Measurement 100% Drawing

Alignment of shell courses Visual & 100% 1mm/mtr, 5mm max.

Measureme

Weld preparation Template 100% Drawing

Alignment / Root offset. Measurement 100% 10% of Nominal plate

thickness + 1mm or

4mm max.

Flaw detection on weld edges. PT/MT 100% Free from

Lamination, Crack &

Liner Indications

Tack Weld Soundness PT 100% Procedure PT(Refer

Note No.3)

IF WELD PROCESS & HT IS DIFFERENT THAN L-SEAM WELDING :

Production Test Coupon with C-seam Verify One PTC / IBR-1950

Heat/Drum

6 C-SEAM WELDING H R

Backgauging after 1st side welding PT/MT 100% Procedure PT/MT

Inspection after both side welding Visual 100% Procedure VT

Weld reinforcement -Flush ground from outside Visual 100% IBR-1950

Welder/Welding Operator ID Verify 100% Qualified welder

list / IBR Certifica

te

Weld soundness RT & MT 100% Procedure RT, MT

*INSP.BY /TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 4

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

NDE for CS Drum thk. >&= 100 mm & AS Drum thk. >&=50mm UT 100% Procedure UT

7 BUTT WELD SETUPS FOR NOZZLES/STUBS H H

Alignment Measurement 10% Drawing

Orientation Visual 100% Drawing

Setup Dimensions Measurement 10% Drawing

Tackweld Soundness by PT PT 100% Procedure PT(Refer

Note No.3)

8 WELDING OF BUTT WELDS OF NOZZLES/STUBS H R

Weld Soundness RT 100% Procedure RT

9 NOZZLES,STUBS,MH RIM & OTHER OPENINGS ON SHELL/D'END H -

MARKING ON SHELL :

Four Quadrant distribution & Punching Combination 100% Within 2 mm

set, W.L

Drum Centreline punching Measurement 100% Equidistant within 1

mm

-No. & size of holes Count & 100% Drawing

Visual

-Distance from reference, Tangential Distance Measurement 100% Drawing

-Orientation Visual 100% Drawing

MARKING ON D'END :

-Four Quadrant distribution & Punching Measurement 100% Within 2 mm

- No. & size of holes Count & 100% Drawing

Visual

- Distance from reference, Tangential Distance Measurement 100% Drawing

- Orientation Visual 100% Drawing

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 5

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

10 INSPECTION OF OPENINGS H -

1) Opening on shell

Number of holes count 100% Drawing

Distance from reference Measurement 100% Drawing

Orientation Visual 100% Drawing

Size of holes Measurement 100% Drawing

Visual Inspection Visual 100% No surface

defects(Refer Note N

o.3)

- Nozzle Openings >&=10NPS PT/MT 100% Procedure PT/MT

2) Opening on D'end

Number of holes Count 100% Drawing

Distance from reference Measurement 100% Drawing

Orientation. Visual 100% Drawing

Size of holes Measurement 100% Drawing

Visual Inspection Visual 100% No surface

defects(Refer Note N

o.3)

Flaw detection on M/H Opening PT/MT 100% Procedure PT/MT

11 SETUP OF NOZZLES,STUBS,MH RIM & OTHER BRANCH CONNECTIONS ON SHELL/D'END H H

SETUP OF MH RIM WITH D'END

-Projection from shell Measurement 100% Drawing

-Alignment & Squareness. Measurement 100% Within 1 Degree/ 3mm

max.

-Weld preparation. Template 100% Drawing

-Tackweld soundness. PT 100% Procedure PT(Refer

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 6

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Note No.3)

SETUP OF NOZZLES WITH D'END

- Identification & Orientation. Visual 100% Drawing

- Alignment & Squareness. Measurement 100% Within 1 Degree/ 3mm

max.

- CTC distance/Projection Measurement 100% Drawing

- Weld preparation Template 100% Drawing

- Tackweld soundness PT 100% Procedure PT(Refer

Note No.3)

SETUP OF NOZZLES WITH SHELL:

-Identification & Orientaion Visual 100% Drawing

-Alignment & Squareness Measurement 100% Within 1 Degree/ 3mm

max.

-CTC distance/Projection Measurement 100% Drawing

-Weld preparation Template 100% Drawing

-Tackweld soundness PT 100% Procedure PT(Refer

Note No.3)

12 WELDING OF NOZZLES,STUBS,MH RIM & OTHER BRANCH CONNECTIONS ON SHELL/D'END H R

I) WELDING OF MANHOLE RIM WITH D'END

-Backgauging after 1st side welding PT 100% Procedure PT

-Weld visual Inspection Visual 100% Procedure VT(Refer

Note No.3)

-Weld size Measurement 100% Drawing

-Weld soundness UT & MT 100% Procedure UT, MT

-Welder ID. Verify 100% Qualified welder

list

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 7

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

II) WELDING OF NOZZLES WITH D'END

- Weld visual inspection Visual 100% Procedure VT(Refer

Note No.3)

- Weld size Measurement 100% Drawing

- Welder ID. Verify 100% Qualified welder

list

- MT of all Nozzle Welds MT 100% Procedure MT

Full penetration welds >=10 NPS or above 25 thk UT/RT 100% Procedure UT/RT

Full penetration set through nozzle welds UT/RT 100% Procedure UT/RT

III) WELDING OF NOZZLES WITH SHELL:

-Weld Visual inspection Visual 100% Procedure VT(Refer

Note No.3)

-Weld Size Measurement 100% Drawing

-Welder ID Verify 100% Qualified welder

list

-Full penetration Nozzle welds>=10NPS & Safety valve nozzle UT/RT 100% Procedure UT/RT

& Full penetration Nozzle welds> 25mm thick UT/RT 100% Procedure UT/RT

-Full penetration set through nozzle welds UT/RT 100% Procedure UT

-MT of All Nozzle welds MT 100% Procedure MT

13 IDENTIFICATION AND DIMENSIONS OF MANHOLE COVER PLATE & PLACING INSIDE THE DRUM H R

Identification Visual 100% Drawing

Dimensions Measurement 100% Drawing

14 SETUP OF DISHED END TO SHELL H H

Orientation & Alignment of shells Visual & 100% Drawing

Measureme

Weld preparation Template 100% Drawing

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 8

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Alignment / Root offset Measurement 100% 10% of Nominal plate

thickness + 1mm or

4mm max.

Flaw detection on weld edges PT/MT 100% Free from

Lamination, Crack &

Liner Indications

Tack Weld Soundness PT 100% Procedure PT(Refer

Note No.3)

Performance Qualification for Welding Operator Verify 100% Qualified welder

list

15 WELDING OF DISHED END TO SHELL H R

Backgauging after 1st side welding PT/MT 100% Procedure PT/MT

Inspection after both side welding Visual 100% Procedure VT

Weld reinforcement- Flush ground from outside Measurement 100% Drawing, IBR-1950

Welding Operator ID Visual 100% Qualified welder

list

Weld soundness RT & MT 100% Procedure RT, MT

NDE for CS Drum thk. >&= 100 mm & AS Drum thk. >&=50mm UT 100% Procedure UT

16 CLEARANCE FOR PWHT H H

Compliance of all Welding,including Ext./Inetrnal attachment Verify 100% Drawing

Overall Major Dimensions Measurement 100% Drawing

NDE Clearance Verify 100% NDT Reports

Nozzle Butt Welds RT 100% Procedure RT

Lifting Lug UT 100% Procedure UT

**NDE of all accessible Pressure Retaining Welds MT 100% Procedure MT

**If not covered earlier

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 9

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

All attachment Welds MT/PT 100% Procedure MT/PT

Removal of all temporory attachment Welds MT/PT 100% Procedure MT/PT

Traceability of weld joints Review 100% Completed weldmap

17 PWHT H R

Heat-Treatment Cycle Review 100% Heat Treatment

Procedure

Heat-Treatment Compliance to Code Review of 100% Heat Treatment

HT chart Procedure

18 INSPECTION & NDE AFTER PWHT H R

Major Dimensions Measurement 100% Drawing

Flange facing Visual 100% Drawing

LSeam, CSeam, Nozzle Welds PT/MT 10% Procedure PT/MT

All T-joints PT/MT 100% Procedure PT/MT

MT of MH rim to D'end welds, accessible area MT 100% Procedure MT

Safety valve nozzle welds MT 100% Procedure MT

Nozzle Welds >=10NPS or above 25thk MT 100% Procedure MT

NDE for CS Plate thk >&= 100mm & AS Plate thk. >&=50mm **

**UT/RT of Shell seams (L & C Seams) UT/RT 100% Procedure UT/RT

**All accesible pressure retaining welds(LS,CS,Nozzle Welds) PT/MT 100% Procedure PT/MT

19 HYDROSTATIC TEST H H

Hydro Test Verify 100% Drawing, Hydrostatic

test Procedure

Recording Deformation : Measurement Every Shell No Permenant

Deformation

Outside Circumference at 0 Kg/SqCm

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 10

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Outside Circumference at MAWP

Outside Circumference at HTP

Outside Circumference at 0 Kg/SqCm

Pressure test result Record 100% Satisfactory

IA Stamp/Code punching on satisfactory Pressure test Visual / 100% IBR-1950, Legible

Rub-off Stamping & Rub-off

20 DRAINING & DRYING AFTER HYDRO TEST H -

Draining, Drying & Cleaning Visual 100% Inside surface shall

be Dry & Clean

21 MARKING FOR DRILLING H -

Distance from reference Measurement 100% Drawing

Orientation of rows Measurement 100% Drawing

No.of rows count 100% Drawing

No.of Openings/Holes per row Count 100% Drawing

Pitch Measurement 100% Drawing

Hole size Visual 100% Drawing

22 DRILLING INSPECTION H -

Orientation of rows Visual 100% Drawing

No.of rows count 100% Drawing

No.of Holes per row Count 100% Drawing

Distances from refernce lines Measurement 100% Drawing

Linear Ligament (minimum) Measurement 100% Drawing

Circumferencial Ligament (minimum) Measurement 100% Drawing

Hole Diameter Plug gauge 100% Drawing

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 11

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Groove dimensions Measurement 100% Drawing

Surface Finish of Drilled Holes Visual 10% 125 to 250 RMS

Quadrant Line Punching for Reference Measurement 100% Drawing

NDE on Holes coming on shell welds ** PT/MT 100% Procedure PT/MT

** Note :Both side flush grinding to be done before NDT

23 FINAL INSPECTION H H

Fitment of Drum Internals Verify 100% Drawing

Attachments of all non pr.parts internal/exteral Visual 100% Drawing

Compliance to Drg for Scope Verify 100% Drawing BOM

Traceability of weld joints Review 100% Completed Weldmap

Centreline punching Visual 100% Drawing

Code Compliance Certificati 100% Compillation of

on / Docum stage IR's & MTC's,

Code

24 PAINTING INSPECTION H -

Surface Preparation Visual 100% Drawing, Painting

Specs.

Paint Shade, Make, Batch No. Visual 100% Drawing, Painting

Specs.

Visual Inspection after painting Visual 100% Complete coverage of

area, No rundowns,

Peel-offs, Cracks

Paint-Dry Film Thickness (DFT) Measurement Random Drawing, Painting

Specs.

Application of rust prevention oil on inside surface Visual 100% Drawing/Specs.

Capping / Blanking of all Openings Visual 100% All Openings Shall

be Covered /Capped

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 12

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Identification Visual 100% Drawing

Marking of C/L punching Visual 100% All drum centreline

marked

25 INSPECTION RELEASE NOTE H -

Final Document Review Review 100% Drawing, Compilation

of document

Inspection Release Note Issuance of

IRN

3.0 NOTES :

1) Following documents, as applicable are to be reviewed during inspection.

1. WPS,PQR,WPQ and Welding Technology sheet(WTS)

2. Material Test Certificates

3. Manufacturing Records

4. All the required Inspection Records.

Following Documents shall be referred for this QAP (As Applicable) :

1) NDE Procedures

+---+-----------+-------------------------------------------+

|Sr.|Control No.|Procedure Description |

+---+-----------+-------------------------------------------+

|1) |RT12 |Radiographic Examination of Welded Joints |

+---+-----------+-------------------------------------------+

|2) |PT1 |Liquid Penetrant Examination |

+---+-----------+-------------------------------------------+

|3) |MT3 |Magnetic Particle Examination |

+---+-----------+-------------------------------------------+

|4) |UT2 |Ultrasonic Examination Of Butt Welds |

+---+-----------+-------------------------------------------+

|5) |UT4 |Straight Beam Ultrasonic Examination of |

| | |Rolled Steel Plates |

+---+-----------+-------------------------------------------+

2) RECORD NOT REQUIRED TO GENERATE FOR VISUAL INSPECTION AND

TACK WELD SOUNDNESS AS MENTIONED IN THIS ITP.

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P01

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER DRUMS DATE : 28-05-2011

PAGE : 13

4.0 INSPECTION POINTS

INSPECTION POINTS ARE INDICATED BY :

R Record Review Point RECORD REVIEW POINT is a recording operation in the operation / production

cycle marked by the AI/Customer/TPI. Record of inspection is maintained

and will be made available to AI/Customer/TPI for review during next

HOLD/WITNESS stage Inspection,as applicable.

W Witness Point WITNESS POINT is defined as a notification operation in operation / production

cycle marked by the AI/Customer/TPI to excercise their option to witness

and verify a specific operation. Further processing shall proceed where the

AI/Customer/TPI do not validate their option. The notification shall be

documented in a manner acceptable to AI/Customer/TPI, as applicable.

H Hold Point HOLD POINT is defined as a verification of the operation by the requesting

authority AI,Customer/TPI.Further processing is prohibited until acceptance

of the operation & documentation is completed by the requesting authority.

- - Inspection option will not be exercised

5.0 RECORD OF REVISIONS :

REV NO. DATE CHANGES

PREPARED BY CHECKED BY APPROVED BY ACCEPTED BY CLIENT/CONSULTANT/TPI

*INSP.BY TL -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN)

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P02

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

DISHED ENDS FOR BOILER DRUM DATE : 15-09-2011

PAGE : 1

1.0 JOB SPECIFIC DATA : -

CUSTOMER :

CONSULTANT : - PROJECT NO:

INSP. AGENCY: DESIGN CODE :

2.0 QUALITY STAGES & INSPECTION :

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

CHARACTERISTICS METHOD EXTENT TL CLI

1 MATERIAL IDENTIFICATION H H

Material Test Certificates Review 100% Drawing, ASME Sec-II

Correlation of MTC with Material Visual 100% Mill Test

Certificate

Dimensional Inspection Measurement 5% Drawing/Mill Test

Certificate

Identification & Stamp Transfer Visual 100% Identification

Punching & Stamp Tra

nsfer

UT of Plates UT 100% ASTM A578 Level B

2 INSPECTION OF DISHED ENDS AFTER FORMING H R

Surface Finish Visual 100% Spinning/Die Marks

to be ground smooth

Inspection of template on layout Measurement 100% Proper matching

Inside Circumference Measurement 100% Drawing

Inside Circumference-For a Pair of Dished End Measurement 100% Within +/- 5mm

Ovality Measurement 100% 1% of ID or 5mm max.

Thinning Measurement 5Spots Min. Drawing, IBR-1950

Profile-Increase in Depth, Decrease in Depth Template 100% Drawing, IBR-1950

Height Measurement 100% Drawing

Knuckle Radius Template 100% Decrease not

Permissible

*INSP.BY -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P02

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

DISHED ENDS FOR BOILER DRUM DATE : 15-09-2011

PAGE : 2

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Straight Face(Lesser of Inside & Outside readings) Measurement 100% Drawing

PT from Inside,Outside on Knuckle Portion & On Edge PT 100% Procedure PT

Heat-Treatment (As Applicable) Review of 100% Drawing, IBR-1950

HT chart

Lamination Check UT 100% No Laminations

/Procedure UT

Identification & Stamping on D/E Visual 100% Legible

3 INSPECTION RELEASE NOTE H -

Final Document Review Review 100% Drawing, Compilation

of document

Inspection Release Note Issuance of 100%

IRN

3.0 NOTES :

1) Following documents, as applicable are to be reviewed during inspection.

1. WPS,PQR,WPQ and Welding Technology sheet(WTS)

2. Material Test Certificates

3. Manufacturing Records

4. All the required Inspection Records.

Following Documents shall be referred for this QAP (As Applicable) :

1) NDE Procedures

+---+-----------+-------------------------------------------+

|Sr.|Control No.|Procedure Description |

+---+-----------+-------------------------------------------+

|1) |RT12 |Radiographic Examination of Welded Joints |

+---+-----------+-------------------------------------------+

|2) |PT1 |Liquid Penetrant Examination |

+---+-----------+-------------------------------------------+

|3) |MT3 |Magnetic Particle Examination |

+---+-----------+-------------------------------------------+

|4) |UT2 |Ultrasonic Examination Of Butt Welds |

*INSP.BY TL -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P02

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

DISHED ENDS FOR BOILER DRUM DATE : 15-09-2011

PAGE : 3

+---+-----------+-------------------------------------------+

|5) |UT4 |Straight Beam Ultrasonic Examination of |

| | |Rolled Steel Plates |

SAUDI ARAMCO

+---+-----------+-------------------------------------------+ WELDING PROCEDURE SPECIFICATIONS

2) RECORD NOT REQUIRED TO GENERATE FOR VISUAL INSPECTION AND

TACK WELD SOUNDNESS AS MENTIONED IN THIS ITP.

4.0 INSPECTION POINTS

INSPECTION POINTS ARE INDICATED BY :

R Record Review Point RECORD REVIEW POINT is a recording operation in the operation / production

cycle marked by the AI/Customer/TPI. Record of inspection is maintained

and will be made available to AI/Customer/TPI for review during next

HOLD/WITNESS stage Inspection,as applicable.

W Witness Point WITNESS POINT is defined as a notification operation in operation / production

cycle marked by the AI/Customer/TPI to excercise their option to witness

and verify a specific operation. Further processing shall proceed where the

AI/Customer/TPI do not validate their option. The notification shall be

documented in a manner acceptable to AI/Customer/TPI, as applicable.

H Hold Point HOLD POINT is defined as a verification of the operation by the requesting

authority AI,Customer/TPI.Further processing is prohibited until acceptance

of the operation & documentation is completed by the requesting authority.

- - Inspection option will not be exercised

5.0 RECORD OF REVISIONS :

REV NO. DATE CHANGES

PREPARED BY CHECKED BY APPROVED BY ACCEPTED BY CLIENT/CONSULTANT/TPI

*INSP.BY TL -THERMAX LI IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN)

SAUDI ARAMCO

THERMAX LIMITED WELDING PROCEDURE SPECIFICATIONS

BOILER & HEATER GROUP

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P03

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

MEMBRANE PANELS DATE : 15-09-2011

PAGE : 1

1.0 JOB SPECIFIC DATA : -

CUSTOMER :

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

CONSULTANT : - PROJECT NO:

INSP. AGENCY: DESIGN CODE :

2.0 QUALITY STAGES & INSPECTION :

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

CHARACTERISTICS METHOD EXTENT TL CLI

1 MATERIAL IDENTIFICATION H H

Material Test Certificates Review 100% Drawing, Material

Spec.

Correlation of MTC with Material Visual 100% Mill Test

Certificate

Dimensional Inspection Measurement 5% Drawing/Mill Test

Certificate

Identification Visual 100% Punching/Stencilling

2 PREPRODUCTION SAMPLE OF SWAGED TUBE ENDS H R

Surface Defects PT 100% Procedure PT

Normalising of swage tube ends Review of 100% HT Procedure /

HT Chart IBR-1950

Dimensional Insp - Ovality, Thickness, Concentricity, Length Measurement 100% Drawing

Hardness after Normalising Measurement 100% Drawing / Specs.

Physical Testing :(Flattening-1, Flaring-1) Mech. 1Set of IBR-1950

Testing Test/Heat

3 INSPECTION OF SWAGED TUBE ENDS H -

Inspection after Swaging Visual 2% Drawing

Surface Defects PT 2% Procedure PT

Dimensional Insp -Ovality, Thickness, Concentricity, Length Measurement 2% Drawing

Hardness after Normalising Measurement 5% Drawing / Specs.

*INSP.BY TL -THERMAX IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P03

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

MEMBRANE PANELS DATE : 15-09-2011

PAGE : 2

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

4 HEAT-TREATMENT OF SWAGED TUBE ENDS H R

Heat-Treatment Cycle Review 100% HT Procedure /

IBR-1950

Heat-Treatment Compliance to Code Review of 100% HT Procedure /

HT Chart IBR-1950

5 WELDING OF MEMBRANE STRIP TO TUBE H -

Cleaning of Tubes Shot 100% Free from Mill Scale

Blasting & Clean from Inside

Pitches of Tubes Measurement 1st Panel Drawing

Segment

Weld Inspection Visual & 100% Drawing

Measureme

6 INSPECTION OF PANEL AFTER PACK BENDING H -

Inspection for Layout On layout *1Segment / Within 3mm

Boiler

*Most Restricted Bend of Total Panels

Ovality on Outer Tubes Measurement 2% Within 10%

Thinning on Outer Tubes Measurement 2% Drawing/

100/(4R/D+2) max.

Flow Area O.D less than 3" * Ball Test 100% Ball Size= {(0.9

OD-2.3SWT)-1.6mm}

*Note:Not applicable for Single & Both end swaging

7 SETUP OF BUTT JOINTS H H

Panel tube,Spools,Opening tubes & Loose tube joints

Orientation Visual 100% Drawing

Setup Dimensions Measurement 10% Drawing

Alignment Measurement 10% Drawing

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P03

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

MEMBRANE PANELS DATE : 15-09-2011

PAGE : 3

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

8 WELDING OF BUTT WELD JOINTS H R

Visual Inspection Visual 100% Procedure VT

Panel Tube Butt Welds for Length Built-up RT 5% per Procedure RT

welder

Spool Butt Welds RT 5% per Procedure RT

welder

Opening Tubes Butt Welds RT 5% per Procedure RT

welder

Loose Tubes Butt Welds RT 5% per Procedure RT

welder

9 SAMPLE/FIRST PRODUCTION BEND FOR PANEL OPENING/LOOSE TUBES H R

Identification Visual 100% Drawing

Dimensions on Layout Layout 100% Within 3mm

Matching

Ovality Measurement 100% 10% Max.

Minimum Thickness Measurement 100% Drawing/

100/(4R/D+2) max.

Flow Area for Tubes O.D less than 3" Ball Test 100% Ball Size(Cold Bend)

={(0.9 OD-2.3SWT)-

1.6mm}

Bore Inspection Visual 100% No Score Marks, if

Mandrel is used

10 INSPECTION OF PANEL OPENING/LOOSE TUBES AFTER BENDING H R

Orientation Visual 100% Drawing

Dimensions on Layout Layout 5% Within 3mm

Matching

Flow Area for Tubes O.D less than 3" Ball Test 100% Ball Size(Cold Bend)

={(0.9 OD-2.3SWT)-

1.6mm}

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P03

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

MEMBRANE PANELS DATE : 15-09-2011

PAGE : 4

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

11 FINAL INSPECTION OF LOOSE TUBES H H

Identification Marking Visual 5% Drawing

Site Weld Preperation (If Applicable) Visual 5% Drawing

End Identification Visual 5% Drawing

Document Review Review 100% Compillation of

stage IR's & MTC's,

Code

12 SETUP OF PANEL TUBES TO HEADER/S H H

Cleaning of Tubes from inside Air blowing 100% Free from foreign

material

Cleaning of header from inside Air blowing 100% Free from foreign

material

Orientation Visual 100% Drawing

Setup Inspection Measurement 100% Drawing

Alignment & Squareness Measurement 10% Drawing

13 WELDING OF PANEL TUBES TO HEADER/S H -

Squareness of Header with Panel Measurement 100% Drawing

Straightness of Header Measurement 100% 1mm/mtr or 5mm max.

Weld Inspection Visual & 100% Drawing & Procedure

Measureme

NDE after full welding PT/MT 10% Procedure PT/MT

14 STRUCTURALS & ATTACHMENTS H -

Identification & Orientaion Visual 100% Drawing

Dimensional Inspection Measurement 100% Drawing

Alignment & Squareness Measurement 100% Drawing

Inspection of Strip cutout with Template/ Gauge as appl. Verify 100% Drawing

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P03

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

MEMBRANE PANELS DATE : 15-09-2011

PAGE : 5

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Weld Inspection Visual 100% Drawing

Stud Welding on Tubes Stud Layout 100% Drawing

Stud Weld Soundness Torque Test 10 Studs 2 Breakage in 10

min. Studs for 30ftlb Tor

que is Acceptable

15 MOCK UP OF PANEL WITH RESPECTIVE HEADER-FOR SITE ASSEMBLED HEADER ONLY

Orientation Visual 100% Drawing

Alignment & overall major Dimensions Measurement 100% Drawing

Identification Punching / Marking of Header Verify 100% Drawing

16 CLEARANCE FOR PWHT OF PANEL TO HEADER JOINTS H -

Overall Dimensions Measurement 100% Drawing

Distortion / Flatness Visual 100% Drawing

Weld Inspection (Size & Finish) Measurement 100% Drawing

& Visual

NDE Clearance Review of 100% NDE Procedures

NDE Repor

Completion of all Welding Visual 100% Drawing

Identification Punching Rub-off 100% Drawing

17 PWHT OF PANEL TO HEADER JOINTS H R

Heat-Treatment Cycle Review 100% HT Procedure /

IBR-1950

Heat-Treatment Compliance to Code Review of 100% HT Procedure /

HT Chart IBR-1950

18 FINAL INSPECTION H H

Compliance to Drawing for Scope Review 100% Drawing-BOM

Major Dimensions Measurement Critical Drawing

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P03

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

MEMBRANE PANELS DATE : 15-09-2011

PAGE : 6

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Dimension

IA Stamp & Final Rub off Visual 100% IBR-1950, Legibility

of Stamp & Rub off

19 PAINTING INSPECTION H -

Surface Preparation Visual 100% Drawing, Painting

Specs.

Paint Shade, Make, Batch No. Visual 100% Drawing, Painting

Specs.

Visual Inspection after painting Visual 100% Complete coverage of

area, No rundowns,

Peel-offs, Cracks

Paint-DFT Measurement Random Drawing, Painting

Specs.

Cleaning of headers from inside Air blowing 100% Free from foreign

material

Capping / Blanking of all Openings Visual 100% All Openings Shall

be Covered /Capped

Identification Marking Visual 100% Drawing

20 INSPECTION RELEASE NOTE H -

Final Document Review Review 100% Drawing, Compilation

of document

Inspection Release Note Issuance of

IRN

3.0 NOTES :

1) Following documents, as applicable are to be reviewed during inspection.

1. WPS,PQR,WPQ and Welding Technology sheet(WTS)

2. Material Test Certificates

3. Manufacturing Records

4. All the required Inspection Records.

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P03

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

MEMBRANE PANELS DATE : 15-09-2011

PAGE : 7

Following Documents shall be referred for this QAP (As Applicable) :

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

1) NDE Procedures

+---+-----------+-------------------------------------------+

|Sr.|Control No.|Procedure Description |

+---+-----------+-------------------------------------------+

|1) |RT12 |Radiographic Examination of Welded Joints |

+---+-----------+-------------------------------------------+

|2) |PT1 |Liquid Penetrant Examination |

+---+-----------+-------------------------------------------+

|3) |MT3 |Magnetic Particle Examination |

+---+-----------+-------------------------------------------+

|4) |UT2 |Ultrasonic Examination Of Butt Welds |

+---+-----------+-------------------------------------------+

|5) |UT4 |Straight Beam Ultrasonic Examination of |

| | |Rolled Steel Plates |

+---+-----------+-------------------------------------------+

2) RECORD NOT REQUIRED TO GENERATE FOR VISUAL INSPECTION AND

TACK WELD SOUNDNESS AS MENTIONED IN THIS ITP.

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P03

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

MEMBRANE PANELS DATE : 15-09-2011

PAGE : 8

4.0 INSPECTION POINTS

INSPECTION POINTS ARE INDICATED BY :

SAUDI ARAMCO

R Record Review Point RECORD REVIEW POINT is a recording operation in the operation / production WELDING PROCEDURE SPECIFICATIONS

cycle marked by the AI/Customer/TPI. Record of inspection is maintained

and will be made available to AI/Customer/TPI for review during next

HOLD/WITNESS stage Inspection,as applicable.

W Witness Point WITNESS POINT is defined as a notification operation in operation / production

cycle marked by the AI/Customer/TPI to excercise their option to witness

and verify a specific operation. Further processing shall proceed where the

AI/Customer/TPI do not validate their option. The notification shall be

documented in a manner acceptable to AI/Customer/TPI, as applicable.

H Hold Point HOLD POINT is defined as a verification of the operation by the requesting

authority AI,Customer/TPI.Further processing is prohibited until acceptance

of the operation & documentation is completed by the requesting authority.

- - Inspection option will not be exercised

5.0 RECORD OF REVISIONS :

REV NO. DATE CHANGES

PREPARED BY CHECKED BY APPROVED BY ACCEPTED BY CLIENT/CONSULTANT/TPI

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN)

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P04

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER SIDE/BAFFLE/FURNACE SIDE/REAR WALL (FM) DATE : 11-06-2011

PAGE : 1

1.0 JOB SPECIFIC DATA : -

CUSTOMER :

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

CONSULTANT : - PROJECT NO:

INSP. AGENCY: DESIGN CODE :

2.0 QUALITY STAGES & INSPECTION :

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

CHARACTERISTICS METHOD EXTENT TL CLI

1 MATERIAL IDENTIFICATION H H

Material Test Certificates Review 100% Drawing, Material

Spec.

Correlation of MTC with Material Visual 100% Mill Test

Certificate

Dimensional Inspection Measurement 5% Drawing/Mill Test

Certificate

Identification Visual 100% Punching/Stencilling

2 PREPRODUCTION SAMPLE OF SWAGED TUBE ENDS H R

Surface Defects PT 100% Procedure PT

Normalising of swage tube ends Review of 100% HT Procedure /

HT Chart IBR-1950

Dimensional Insp - Ovality, Thickness, Concentricity, Length Measurement 100% Drawing

Hardness after Normalising Measurement 100% Drawing / Specs.

Physical Testing :(Flattening-1, Flaring-1) Mech. 1Set of IBR-1950

Testing Test/Heat

3 INSPECTION OF SWAGED TUBE ENDS H -

Inspection after Swaging Visual 2% Drawing

Surface Defects PT 2% Procedure PT

Dimensional Insp -Ovality, Thickness, Concentricity, Length Measurement 2% Drawing

Hardness Measurement 2% Drawing / Specs.

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P04

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER SIDE/BAFFLE/FURNACE SIDE/REAR WALL (FM) DATE : 11-06-2011

PAGE : 2

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

4 NORMALISING OF SWAGED TUBE ENDS H R

Heat-Treatment Cycle Review 100% HT Procedure/

IBR-1950

Heat-Treatment Compliance to Code Review of 100% HT Procedure /

HT Chart IBR-1950

Hardness Measurement 5% Drawing / Specs.

5 WELDING OF MEMBRANE STRIP TO TUBE H -

Cleaning of Tubes Shot 100% Free from Mill Scale

Blasting & Clean from Inside

Pitches of Tubes Measurement 1st Panel Drawing

Segment

Weld Inspection Visual & 100% Drawing

Measureme

6 INSPECTION OF PANEL AFTER PACK BENDING H -

Inspection for Layout On layout *1Segment / Within 3mm

Boiler

*Most Restricted Bend of Total Panels

Ovality on Outer Tubes Measurement 2% Within 10%

Thinning on Outer Tubes Measurement 2% 100/(4R/D+2) Max.

Flow Area O.D less than 3" * Ball Test 100% Ball Size= {(0.9

OD-2.3SWT)-1.6mm}

*Note:Not applicable for Single & Both end swaging

7 SETUP OF BUTT JOINTS H H

Panel tube joints, Spool joints & Opening tubes joints

Orientation Visual 100% Drawing

Setup Dimensions Measurement 10% Drawing

Alignment Measurement 10% Drawing

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P04

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER SIDE/BAFFLE/FURNACE SIDE/REAR WALL (FM) DATE : 11-06-2011

PAGE : 3

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

8 NDT SCHEDULE H R

Panel Tube Butt Welds for Length Built-up RT 5% per Procedure RT

welder

Spool Butt Welds RT 5% per Procedure RT

welder

Opening Tubes Butt Welds RT 5% per Procedure RT

welder

9 STRUCTURALS & ATTACHMENTS H -

Identification & Orientaion Visual 100% Drawing

Dimensional Inspection Measurement 100% Drawing

Alignment & Squareness Measurement 100% Drawing

Inspection of Strip cutout with Template/ Gauge as appl. Verify 100% Drawing

Weld Inspection Visual 100% Drawing

Stud Welding on Tubes Stud Layout 100% Drawing

Stud Weld Soundness Torque Test 10 Studs 2 Breakage in 10

min. Studs for 30ftlb Tor

que is Acceptable

10 FINAL INSPECTION H H

Compliance to Drawing for Scope Review 100% Drawing-BOM

Overall Dimensions Measurement Critical Drawing

Dimension

Site Weld Preparation (If Applicable) Template 10% Random Drawing

IA Stamp & Rub Off Visual 100% IBR-1950, Legibility

Document Review Review 100% Compillation of

stage IR's & MTC's,

Code

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P04

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER SIDE/BAFFLE/FURNACE SIDE/REAR WALL (FM) DATE : 11-06-2011

PAGE : 4

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

11 PAINTING INSPECTION H -

Surface Preparation Visual 100% Drg/Painting Specs.

Paint Shade Visual 100% Drawing, Painting

Specs.

Visual Inspection after painting Visual 100% Complete coverage of

area, No rundowns,

Peel-offs, Cracks

Paint-DFT Measurement random Drawing, Painting

Specs.

Cleaning of Tubes from Inside before capping Air blowing 100% Free from foreign

material

Capping / Blanking of all Openings Visual 100% All Openings Shall

be Covered /Capped

Identification Marking Visual 100% Drawing

12 INSPECTION RELEASE NOTE H -

Final Document Review Review 100% Drawing, Compilation

of document

Inspection Release Note Issuance of 100%

IRN

3.0 NOTES :

1) Following documents, as applicable are to be reviewed during inspection.

1. WPS,PQR,WPQ and Welding Technology sheet(WTS)

2. Material Test Certificates

3. Manufacturing Records

4. All the required Inspection Records.

Following Documents shall be referred for this QAP (As Applicable) :

1) NDE Procedures

+---+-----------+-------------------------------------------+

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P04

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER SIDE/BAFFLE/FURNACE SIDE/REAR WALL (FM) DATE : 11-06-2011

PAGE : 5

|Sr.|Control No.|Procedure Description |

+---+-----------+-------------------------------------------+

|1) |RT12 |Radiographic Examination of Welded Joints |

SAUDI ARAMCO

+---+-----------+-------------------------------------------+ WELDING PROCEDURE SPECIFICATIONS

|2) |PT1 |Liquid Penetrant Examination |

+---+-----------+-------------------------------------------+

|3) |MT3 |Magnetic Particle Examination |

+---+-----------+-------------------------------------------+

|4) |UT2 |Ultrasonic Examination Of Butt Welds |

+---+-----------+-------------------------------------------+

|5) |UT4 |Straight Beam Ultrasonic Examination of |

| | |Rolled Steel Plates |

+---+-----------+-------------------------------------------+

2) RECORD NOT REQUIRED TO GENERATE FOR VISUAL INSPECTION AND

TACK WELD SOUNDNESS AS MENTIONED IN THIS ITP.

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P04

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER SIDE/BAFFLE/FURNACE SIDE/REAR WALL (FM) DATE : 11-06-2011

PAGE : 6

4.0 INSPECTION POINTS

INSPECTION POINTS ARE INDICATED BY :

SAUDI ARAMCO

R Record Review Point RECORD REVIEW POINT is a recording operation in the operation / production WELDING PROCEDURE SPECIFICATIONS

cycle marked by the AI/Customer/TPI. Record of inspection is maintained

and will be made available to AI/Customer/TPI for review during next

HOLD/WITNESS stage Inspection,as applicable.

W Witness Point WITNESS POINT is defined as a notification operation in operation / production

cycle marked by the AI/Customer/TPI to excercise their option to witness

and verify a specific operation. Further processing shall proceed where the

AI/Customer/TPI do not validate their option. The notification shall be

documented in a manner acceptable to AI/Customer/TPI, as applicable.

H Hold Point HOLD POINT is defined as a verification of the operation by the requesting

authority AI,Customer/TPI.Further processing is prohibited until acceptance

of the operation & documentation is completed by the requesting authority.

- - Inspection option will not be exercised

5.0 RECORD OF REVISIONS :

REV NO. DATE CHANGES

PREPARED BY CHECKED BY APPROVED BY ACCEPTED BY CLIENT/CONSULTANT/TPI

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN)

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P05

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER TUBES DATE : 28-05-2011

PAGE : 1

1.0 JOB SPECIFIC DATA : -

CUSTOMER :

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

CONSULTANT : - PROJECT NO:

INSP. AGENCY: DESIGN CODE :

2.0 QUALITY STAGES & INSPECTION :

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

CHARACTERISTICS METHOD EXTENT TL CLI

1 MATERIAL IDENTIFICATION H H

Material Test Certificates Review 100% Drawing, Material

Spec.

Correlation of MTC with Material Visual 100% Mill Test

Certificate

Dimensional Inspection Measurement 5% Drawing/Mill Test

Certificate

Identification Visual 100% Punching/Stencilling

2 PREPRODUCTION SAMPLE OF SWAGED TUBE ENDS H R

Surface Defects PT 100% Procedure PT

Normalising of swage tube ends Review of 100% HT Procedure /

HT Chart IBR-1950

Dimensional Insp - Ovality, Thickness, Concentricity, Length Measurement 100% Drawing

Hardness after Normalising Measurement 100% Matl. Specs.

Physical Testing :(Flattening-1, Flaring-1) Mech. 1Set of IBR-1950/Matl.

Testing Test/Heat Specs.

3 INSPECTION OF SWAGED TUBE ENDS H -

Inspection after Swaging Visual 2% Drawing

Surface Defects PT 2% Procedure PT

Dimensional Insp -Ovality, Thickness, Concentricity, Length Measurement 2% Drawing

Hardness after Normalising Measurement 2% Matl. Specs.

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P05

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER TUBES DATE : 28-05-2011

PAGE : 2

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

4 NORMALISING OF SWAGED TUBE ENDS H R

Heat-Treatment Cycle Review 100% HT Procedure /

IBR-1950

Heat-Treatment Compliance to Code Review of 100% HT Procedure /

HT Chart IBR-1950

5 FLAT STUD WELDING - PREPRODUCTION SAMPLE H -

Dimensions : Tube Size, Stud-Location, Spacing & Width Measurement 5% Drawing

& Visual

Stud Weld Soundness Torque Test 10 Studs 2 Breakage in 10

min. Studs for 30ftlb Tor

que is Acceptable

Concentricity Measurement 5% Drawing/Specs.

Bore Inspection Visual 100% Burnthrough Not

Acceptable

Undercut, Crack Visual 5% Procedure VT

Metal Splash Visual 5% Metal Splash upto

5mm Acceptable

6 FLAT STUD WELDING - INPROCESS INSPECTION H -

Undercut, Crack Visual 5% Procedure VT

Metal Splash Visual 5% Metal Splash 5mm Acc

Stud Weld Soundness Torque Test 10 Studs 2 Breakage in 10

min. Studs for 30ftlb Tor

que is Acceptable

Bore Inspection Visual 100% Burnthrough Not

Acceptable

7 TUBE BENDING-PREPRODUCTION SAMPLE (WITH MAX.DEGREE BEND) H R

Identification Visual 100% Drawing

Dimensions on Layout Layout 100% Within 3mm

Matching

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P05

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER TUBES DATE : 28-05-2011

PAGE : 3

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Ovality Measurement 100% 10% Max.

Minimum Thickness Measurement 100% Drawing /

100/(4R/D+2) max.

Flow Area for Tubes O.D less than 3" Ball Test 100% Ball Size(Cold Bend)

={(0.9 OD-2.3SWT)-1

.6mm}

Bore Inspection Visual 100% No Score Marks, if

Mandrel is used

Surface defects, Die Marks Visual 100% 0.5 mm deep max.

without sharp notche

s

Cracks, Wrinkles Visual 100% No cracks, wrinkles

8 TUBE BENDING - INPROCESS/FINAL INSPECTION H -

Layout Inspection Measurement 100% Drawing

& Visual

Dimensions on Layout Layout 5% Within 3mm

Matching

Ovality Measurement 5% Within 10%

Thinning Measurement 5% Drawing,

100/(4R/D+2) Max.

Surface defects, Die Marks Visual 100% 0.5 mm deep max

without sharp notche

s

Cracks, Wrinkles Visual 100% No Cracks, Wrinkles

9 SETUP OF BUTT JOINTS (TUBE TO TUBE) H -

Set up dimensions Measurement 10% Drawing

Edge preparation Template 10% Drawing

Orientation Visual 100% Drawing

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P05

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER TUBES DATE : 28-05-2011

PAGE : 4

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Alignment Measurement 10% Drawing

10 NDT SCHEDULE H R

Butt Welds RT 5% per Procedure RT

welder

11 STRUCTURALS & ATTACHMENTS H -

Identification & Orientaion Visual 100% Drawing

Dimensional Inspection Measurement 100% Drawing

Alignment & Squareness Measurement 100% Drawing

Weld Inspection Visual 100% Drawing

Stud Welding on Tubes Stud Layout 100% Drawing

& Orient

Stud Weld Soundness Torque Test 10 Studs 2 Breakage in 10

min. Studs for 30ftlb Tor

que is Acceptable

Mock up of mating tubes of soot blower attach. with jig rod Verify 100% Drawing.

12 FINAL INSPECTION H H

Identification Marking Visual 5% Drawing

Dimensions on Layout Layout 5% Within 3mm

Matching

Flow Area for Tubes O.D less than 3" Ball Test 100% Ball Size ={(0.9

OD-2.3SWT)-1.6mm}

Site Weld Preperation (If Applicable) Visual 5% Drawing

End Identification Visual 5% Drawing

Document Review Review 100% Drawing, Compilation

of stage IR's/ MTC

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P05

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER TUBES DATE : 28-05-2011

PAGE : 5

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

13 SURFACE PREPARATION H -

Surface Preparation Visual 100% Drawing, Painting

Specs.

14 PAINTING INSPECTION H -

Paint Shade Visual 100% Drawing, Painting

Specs.

Visual Inspection after painting Visual 100% Complete coverage of

area, No rundowns,

Peel-offs, Cracks

Paint-DFT Measurement Random Drawing, Painting

Specs.

Cleaning of tubes from inside before capping Air blowing 100% Free from foreign

material

Capping / Blanking of all Tubes Visual 100% All Tubes Shall be

Covered /Capped

ID Marking (Boiler No./Drawing No./Mark/ Part No.) Visual 100% Drawing

End Identification Visual 100% Drawing

15 INSPECTION RELEASE NOTE H -

Final Document Review Review 100% Drawing, Compilation

of document

Inspection Release Note Issuance of

IRN

3.0 NOTES :

1) Following documents, as applicable are to be reviewed during inspection.

1. WPS,PQR,WPQ and Welding Technology sheet(WTS)

2. Material Test Certificates

3. Manufacturing Records

4. All the required Inspection Records.

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P05

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER TUBES DATE : 28-05-2011

PAGE : 6

Following Documents shall be referred for this QAP (As Applicable) :

1) NDE Procedures

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

+---+-----------+-------------------------------------------+

|Sr.|Control No.|Procedure Description |

+---+-----------+-------------------------------------------+

|1) |RT12 |Radiographic Examination of Welded Joints |

+---+-----------+-------------------------------------------+

|2) |PT1 |Liquid Penetrant Examination |

+---+-----------+-------------------------------------------+

|3) |MT3 |Magnetic Particle Examination |

+---+-----------+-------------------------------------------+

|4) |UT2 |Ultrasonic Examination Of Butt Welds |

+---+-----------+-------------------------------------------+

|5) |UT4 |Straight Beam Ultrasonic Examination of |

| | |Rolled Steel Plates |

+---+-----------+-------------------------------------------+

2) RECORD NOT REQUIRED TO GENERATE FOR VISUAL INSPECTION AND

TACK WELD SOUNDNESS AS MENTIONED IN THIS ITP.

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P05

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

BOILER TUBES DATE : 28-05-2011

PAGE : 7

4.0 INSPECTION POINTS

INSPECTION POINTS ARE INDICATED BY :

SAUDI ARAMCO

R Record Review Point RECORD REVIEW POINT is a recording operation in the operation / production WELDING PROCEDURE SPECIFICATIONS

cycle marked by the AI/Customer/TPI. Record of inspection is maintained

and will be made available to AI/Customer/TPI for review during next

HOLD/WITNESS stage Inspection,as applicable.

W Witness Point WITNESS POINT is defined as a notification operation in operation / production

cycle marked by the AI/Customer/TPI to excercise their option to witness

and verify a specific operation. Further processing shall proceed where the

AI/Customer/TPI do not validate their option. The notification shall be

documented in a manner acceptable to AI/Customer/TPI, as applicable.

H Hold Point HOLD POINT is defined as a verification of the operation by the requesting

authority AI,Customer/TPI.Further processing is prohibited until acceptance

of the operation & documentation is completed by the requesting authority.

- - Inspection option will not be exercised

5.0 RECORD OF REVISIONS :

REV NO. DATE CHANGES

PREPARED BY CHECKED BY APPROVED BY ACCEPTED BY CLIENT/CONSULTANT/TPI

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN)

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P09

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

CONVECTION BANK MODULE ASSEMBLY DATE : 04-11-2011

PAGE : 1

1.0 JOB SPECIFIC DATA : -

CUSTOMER :

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

CONSULTANT : - PROJECT NO:

INSP. AGENCY: DESIGN CODE :

2.0 QUALITY STAGES & INSPECTION :

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

CHARACTERISTICS METHOD EXTENT TL CLI

1 GROUND INSPECTION OF PRESSURE PARTS H H

Identification of Tubes & Headers Visual 100% Drg

2 MATERIAL IDENTIFICATION H H

Review & Verification of Test Certificates & Drawing Review 100% Drawing, Material

Spec.

Correlation of MTC with Material Visual 100% Mill Test

Certificate

Dimensional Inspection Measurement 5% Drawing/Mill Test

Certificate

Identification Visual 100% Punching/Stencilling

3 WELDING OF BUTT JOINTS, (IF APPLICABLE) H R

Weld Inspection Visual 100% Drawing, Procedure

VT

Weld Soundness RT 100% Procedure RT

4 SETUP OF TUBES TO HEADER H H

Identification & Orientation Measurement 100% Drawing

Cleaning of tubes from inside Air blowing 100% free from foreign

material

Cleaning of Header from inside Air Blowing 100% free from foreign

material

Setup Dimensions Measurement 100% Drawing

Tube Alignment Measurement 100% Drawing

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P09

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

CONVECTION BANK MODULE ASSEMBLY DATE : 04-11-2011

PAGE : 2

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Overall Dimensions Measurement 100% Drawing

5 WELDING OF TUBES TO HEADER H -

NDT on Root Run Weld PT/MT 100% Procedure PT/MT

Weld Inspection (Size & Finish) Measurement 100% Drawing / Procedure

& Visual VT

NDT after full weld PT/MT 100% Procedure PT/MT

6 CLEARANCE FOR PWHT H H

Overall Major Critical Dimensions Measurement 100% Drawing

Welding Insp.of Pressure Parts & Structural Attachments Visual 100% Drawing

NDE Clearance Review of 100% NDE Procedure

NDE Repor

7 PWHT H R

Heat-Treatment Compliance to Code Review of 100% IBR-1950

HT chart

8 HYDROSTATIC TEST, (IF APPLICABLE) H H

Hydro Test Verify 100% Drawing, Procedure

Pressure test result Record 100% Satisfactory

9 DRAINING & DRYING AFTER HYDRO TEST H -

Draining, Drying & Cleaning Visual 100% Inside surface shall

be Dry & Clean

10 FINAL INSPECTION H H

Overall Major Critical Dimensions Measurement 100% Drawing

Overall Assembly Inspection Visual 100% Drawing

Cleaning of header from inside before capping Air blowing 100% free from foreign

material

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P09

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

CONVECTION BANK MODULE ASSEMBLY DATE : 04-11-2011

PAGE : 3

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Code Stamping Visual 100% IBR-1950

I.A.Stamp, Date & Rub-off Visual 100% IBR-1950, Legibility

Document Review Review 100% Compillation of

stage IR's & MTC's,

Code

11 PAINTING INSPECTION H -

Surface Preparation Visual 100% Drawing, Painting

Specs.

Paint Shade, Make, Batch No. Visual 100% Drawing, Painting

Specs.

Visual Inspection after painting Visual 100% Complete coverage of

area, No rundowns,

Peel-offs, Cracks

Paint-DFT Measurement Random Drawing, Painting

Specs.

Cleaning of header from inside before capping Air blowing 100% free from foreign

material

Capping / Blanking of all Tubes, Pipes, Openings Visual 100% All Tubes, Pipes,

Openings Shall be Co

vered /Capped

Identification Marking Visual 100% Drawing

12 INSPECTION RELEASE NOTE H -

Final Document Review Review 100% Drawing, Compilation

of document

Inspection Release Note Issuance of

IRN

3.0 NOTES :

1) Following documents, as applicable are to be reviewed during inspection.

1. WPS,PQR,WPQ and Welding Technology sheet(WTS)

2. Material Test Certificates

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P09

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

CONVECTION BANK MODULE ASSEMBLY DATE : 04-11-2011

PAGE : 4

3. Manufacturing Records

4. All the required Inspection Records.

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

Following Documents shall be referred for this QAP (As Applicable) :

1) NDE Procedures

+---+-----------+-------------------------------------------+

|Sr.|Control No.|Procedure Description |

+---+-----------+-------------------------------------------+

|1) |RT12 |Radiographic Examination of Welded Joints |

+---+-----------+-------------------------------------------+

|2) |PT1 |Liquid Penetrant Examination |

+---+-----------+-------------------------------------------+

|3) |MT3 |Magnetic Particle Examination |

+---+-----------+-------------------------------------------+

|4) |UT2 |Ultrasonic Examination Of Butt Welds |

+---+-----------+-------------------------------------------+

|5) |UT4 |Straight Beam Ultrasonic Examination of |

| | |Rolled Steel Plates |

+---+-----------+-------------------------------------------+

2) RECORD NOT REQUIRED TO GENERATE FOR VISUAL INSPECTION AND

TACK WELD SOUNDNESS AS MENTIONED IN THIS ITP.

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P09

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

CONVECTION BANK MODULE ASSEMBLY DATE : 04-11-2011

PAGE : 5

4.0 INSPECTION POINTS

INSPECTION POINTS ARE INDICATED BY :

SAUDI ARAMCO

R Record Review Point RECORD REVIEW POINT is a recording operation in the operation / production WELDING PROCEDURE SPECIFICATIONS

cycle marked by the AI/Customer/TPI. Record of inspection is maintained

and will be made available to AI/Customer/TPI for review during next

HOLD/WITNESS stage Inspection,as applicable.

W Witness Point WITNESS POINT is defined as a notification operation in operation / production

cycle marked by the AI/Customer/TPI to excercise their option to witness

and verify a specific operation. Further processing shall proceed where the

AI/Customer/TPI do not validate their option. The notification shall be

documented in a manner acceptable to AI/Customer/TPI, as applicable.

H Hold Point HOLD POINT is defined as a verification of the operation by the requesting

authority AI,Customer/TPI.Further processing is prohibited until acceptance

of the operation & documentation is completed by the requesting authority.

- - Inspection option will not be exercised

5.0 RECORD OF REVISIONS :

REV NO. DATE CHANGES

PREPARED BY CHECKED BY APPROVED BY ACCEPTED BY CLIENT/CONSULTANT/TPI

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN)

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P10

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

FINNED ECONOMISER ASSLY(FM) DATE : 09-09-2011

PAGE : 1

1.0 JOB SPECIFIC DATA : -

CUSTOMER :

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

CONSULTANT : - PROJECT NO:

INSP. AGENCY: DESIGN CODE :

2.0 QUALITY STAGES & INSPECTION :

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

CHARACTERISTICS METHOD EXTENT TL CLI

1 GROUND INSPECTION OF PRESSURE PARTS H H

Identification of Coils/Headers Visual 100% Drg

2 MATERIAL IDENTIFICATION H H

Review & Verification of Test Certificates & Drawing Review 100% Drawing, Material

Spec.

Correlation of MTC with Material Visual 100% Mill Test

Certificate

Dimensional Inspection Measurement 5% Drawing/Mill Test

Certificate

Identification Visual 100% Punching/Stencilling

3 GROUND INSPECTION OF ECONOMISER CASING & STRUCTURE H -

Identification Visual 100% Drawing

Visual Inspection Visual Random Drawing

Overall Assembly Inspection Measurement Random Drawing, free from

damage

Overall Dimensions , Diagonal Measurement Random Drawing

4 STRUCTURE & CASING H -

Compliance to Drg/ITP Review of 100% Drg/ITP No.N56 or

Insp.reco N59

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P10

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

FINNED ECONOMISER ASSLY(FM) DATE : 09-09-2011

PAGE : 2

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

5 INSPECTION OF COIL BENDS H -

Identification Visual 10% Drawing

Dimensions on Layout On layout 10% Within 2mm

Ovality Measurement 10% Max.10%

Thinning Measurement 10% Drawing,

100/(4R/D+2) Max.

Flow Area, (Cold Bending) Ball Test 100% Ball Size(Cold Bend)

(0.9OD-2.3SWT)-1.6mm

Flow Area, (Hot Bending) Ball Test 100% Ball Size(Hot Bend)(

0.85OD-2.3SWT)-3.2mm

Surface Defects, Die Marks VIsual 100% 0.5mm deep max.

(merge sharp notches

if any

Cracks, Wrinkles VIsual 100% No Cracks, Wrinkles

Post Bend Heat-Treatment If applicable Review of 100% Procedure

HT Chart Heat-Treatment

6 SETUP OF COIL BENDS TO FIN TUBES H H

Inspection Clearance of Coil Bends Verify 100% Drawing/IR

Alignment Measurement 100% Drawing

Dimensions on Layout Layout 100% Within 1mm

Matching

Setup Dimensions Measurement 100% Drawing

Tackweld Soundness PT 10% Procedure/Code

7 WELDING OF BUTT JOINTS H R

Weld Inspection (Size & Finish) Visual 100% Drawing & Procedure

VT

Excess Penetration (Flow area- Cold bending) Ball Test 100% Ball Size(0.9OD-2.3S

WT)-1.6mm

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P10

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

FINNED ECONOMISER ASSLY(FM) DATE : 09-09-2011

PAGE : 3

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

Excess Penetration (Flow area- hot bending) Ball Test 100% Ball Size(0.85OD-2.3

SWT)-3.2mm

Weld Soundness RT Code or Procedure RT

Min.5% **

** Min. 5% per Welder

8 ALIGNMENT OF HEADERS ON STRUCTURE H -

Identification & Orientaion Visual 100% Drawing

Alignment Water level 100% Within 2mm

, Plumb

Dimensions Measurement 100% Drawing

9 SETUP OF HEADER STUBS TO COILS H H

Cleaning of coils from inside Air blowing 100% free from foreign

material

Cleaning of Header from inside Air blowing 100% free from foreign

material

Setup Dimensions, Alignment Measurement 100% Drawing

10 WELDING OF HEADER STUBS TO COILS H R

Weld Inspection (Size & Finish) Visual 100% Drawing & Procedure

VT

Weld Soundness RT Code or Procedure RT

Min.5% **

** Min. 5% per Welder

11 HYDROSTATIC TESTING H H

Hydro Test pressure Verify 100% Drawing

Pressure gauges range Verify 100% 1.5 to 2.5 times of

test pressure

Calibration validity of Pressure gauges Verify 100% Calibration report &

*INSP.BY IBR -IBR CLI -CLIENT/TPI

Session : tccom9420m040 INSPECTION & TEST PLAN (QA PLAN) Contd...

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

INSPECTION & TEST PLAN (QA PLAN) FOR CONTROL NO. : ITP/ERPLN /P10

SAUDI ARAMCO

REVISION NO.: 0

WELDING PROCEDURE SPECIFIC

FINNED ECONOMISER ASSLY(FM) DATE : 09-09-2011

PAGE : 4

SR. INSPECTION STAGES ACCEPTANCE * INSP. BY

NO. STANDARD

SAUDI ARAMCO

CHARACTERISTICS METHOD EXTENT TL IBR CLIWELDING PROCEDURE SPECIFICATIONS

due date

Pressure Gauges Verify 100% Record id.numbers

Cleaning of weld joints Visual 100% No rust or

extraneous mat.

Test pressure (on Pressure gauge) Visual 100% Test Pressure Shall

not exceed more than

6% at any time

Test Duration (Holding time) Measurement 100% Min.30 Minutes

Leakage Visual 100% No leakages

Pressure drop Visual 100% No Pressure drop