Professional Documents

Culture Documents

Measurement System Using Coriolis

Measurement System Using Coriolis

Uploaded by

Global Metering0 ratings0% found this document useful (0 votes)

2 views28 pagesOriginal Title

Measurement system using Coriolis

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views28 pagesMeasurement System Using Coriolis

Measurement System Using Coriolis

Uploaded by

Global MeteringCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 28

Crude Oil Measurement Systems

Requirements of a crude oil measurement system:

– Accurately measure the quantity transferred

– Control operation of the system if un-manned location

– Monitor the crude oil quality and prevent transfer of non-

merchantable oil if desired for lease/produced oil

– Obtain a representative sample if required

– Eliminate air

– Provide facilities for periodic proving

– Provide back pressure for the meter and prover

Micro Motion Confidential

Page 1

The Measurement System

It is important to realize that an accurate meter is not all

that is required for an accurate measurement system.

– Temperature and pressure measurement

– Gravity measurement

– Proving methodology and meter factor validity

– Flow computer or averaging techniques for net volume

calculations

– Sampling methodology if required

– Determination of S&W for produced crude oil

Micro Motion Confidential

Page 2

API Chapter 5.6

Micro Motion Confidential

Page 3

Lease Automatic Custody Transfer

LACT systems are generally for low flow rates from an

individual producer. The components of a LACT are very

similar to any crude oil measurement system and are

sometimes referred to as ACT.

LACT systems do not have an on-site flow computer. Most

often custody transfer calculations use average values for

temperature to calculate net volume and use a flow weighted

sample to determine average gravity and S&W.

Micro Motion Confidential

Page 4

LACT Units

Components of a LACT unit

– Charge/Transfer Pump

– S&W Monitor

– Diverter Valve

– Strainer/Air Eliminator

– Sample System

– Flow Meter

– Meter Prover Loop

– Back Pressure Valve

– Check Valve

– Control Panel

A transportation or gathering pipeline measurement skid would likely

not require the pump, S&W monitor, divert valve or control panel.

Micro Motion Confidential

Page 5

LACT Units

Typical LACT configuration

Sample Cylinder

Air Eliminator Sample Probe

Strainer Block & Bleed Valve

Back Pressure

Pump

Micro Motion Confidential

Page 6

LACT Units

Charge/Transfer Pump

– The pump should produce a non-pulsating flow for the LACT unit

at a pressure compatible with the pipeline carrier

– Centrifugal pumps are typically used for LACT units requiring

medium to high volumes at low pressure.

• If high discharge pressure is required, a positive displacement pump

can act as a booster pump.

– Flow rate, pressure required and fluid properties determine the

size of the pump.

Micro Motion Confidential

Page 7

LACT Units

Strainer

– Strainers are installed upstream of

the flowmeter to protect the meter

and the other elements of the

system from being damaged by

foreign materials such as pipe

scale, pebbles, and large debris

that may be entrained.

Micro Motion Confidential

Page 8

LACT Units

S&W Probe

– S & W probes determine free water and sediment content in

crude oil by typically measuring the dielectric constant which is

the ability of the fluid to act as an insulator.

– The dielectric constant of oil is higher than that of water.

Merchantable crude oil typically contains less than 1%

water.

– This custody transfer measurement has different requirements

from production or well test applications.

– The Coriolis meter density cannot be used to detect water cut for

pipeline quality crude oil

• The typical accuracy requirement is for this measurement is ± 0.1%

water.

Micro Motion Confidential

Page 9

LACT Units

S&W Monitor

– Solid state circuitry detects changes in the

dielectric constant with sensitivity that can detect

0.1% of 1%S&W content.

– An adjustable time delay and fail-safe relays

operate the divert valve over a selectable setting

of 0-3% S&W.

– The monitor diverts flow back to a retreating

facility and returns the LACT to normal operation

as determined by the allowable S&W setting.

Micro Motion Confidential

Page 10

LACT Units

Divert Valve

– Divert valves have the primary function to fail closed when any of

the following occurs:

• Excess S&W

• Loss of power

• Loss of supply pressure

• Low level in the lease tank

• Meter failure condition

Micro Motion Confidential

Page 11

LACT Units

Air Eliminator

– Why use an air eliminator?

• Large amounts of free air

compromises meter accuracy

and can lead to overspeeding

of mechanical type meters,

which will result in damaging

the meter.

• To insure accurate liquid

measurement, it is necessary to

remove all vapor and free all

entrained air from the system.

Micro Motion Confidential

Page 12

LACT Units

Deaerator

– Float operated valve principle

– High capacity air elimination

– Vertical tank facilitates installation

– Wide variety of materials and pressure

ratings

– Various venting and connection

applications

– Low maintenance

– Generally used in higher flow rates on

pipelines

Micro Motion Confidential

Page 13

LACT Units

Sample System

– The components which make up

a typical system include

• Static mixer to insure a good

mixing of the crude oil.

• Sample probe which extends into

the pipeline

• Extraction device

• Sample Receiver/Mixer

Micro Motion Confidential

Page 14

LACT Units

Static Mixer

− The optional static mixer is installed

upstream of the sample probe.

− Rigid elements split, rearrange, and

recombine component streams into

smaller and smaller layers until one

homogeneous stream exits.

- optional static mixer installed in

the pipeline upstream of the BS&W

probe

Micro Motion Confidential

Page 15

LACT Units

Sample Probe

– The sample probe extends into the center third of the pipe facing

the flow.

– The sample probe is installed in a horizontal position in a vertical

run of pipe.

– The extraction device is pulsed by the meter to extract a fixed

quantity of sample during normal operation of the LACT unit. For

example; one pulse to the device for every barrel measured.

Micro Motion Confidential

Page 16

LACT Units

Sample Receiver/Container

– The sample container is sized to allow adequate storage

during the total transfer period.

– The fluid is stored under pressure and the container is vapor

tight to prevent evaporation.

– The fluid is tested at the end of the period to determine the

quality for custody transfer/net volume calculations.

– A mixing motor and pump are used to obtain a homogeneous

mix of crude oil before obtaining sample.

Micro Motion Confidential

Page 17

LACT Units

Centrifuge Tube

– Centrifuge tubes hold the sample

and the appropriate solvent or

demulsifier if necessary.

– The tube is heated to a specified

temperature approximately

120Degrees F. and rotated in a

centrifuge for a specific amount of

time at a specific speed. The S&W

is forced to the bottom of the tube

where the amount is read on the

scale.

Micro Motion Confidential

Page 18

LACT Units

Hydrometer

– Hydrometers are utilized to prove the

output of a densitometer or to obtain

the gravity of a sample.

− Accurate temperature measurement is

important.

− This will allow a reading of gravity and

temperature at flowing conditions.

− If light ends escape from your sample,

your hydrometer reading will not match

your densitometer reading.

Micro Motion Confidential

Page 19

LACT Units

Control Functions:

– Detects level in the lease tank and starts and stops the pump

which forces oil through the LACT unit

– Operates the solenoid which extracts a sample proportional to

flow

– Diverts flow back to the tank when S&W content is too high

– Actuate alarms as required

Micro Motion Confidential

Page 20

LACT Units

Temperature Averager

– Temperature averagers provide

a true average of the process

temperature based on volume or

time.

– Average temperature is utilized

for calculation of net volume

during a batch cycle, such as

the end of the month.

Micro Motion Confidential

Page 21

API Chapter 7.2 Temperature Determination

Micro Motion Confidential

Page 22

LACT Units

Meter Proving Loop

Micro Motion Confidential

Page 23

LACT Units

Back Pressure Valve

– The purpose of the back

pressure valve is to maintain a

constant pressure on the

flowmeter to prevent cavitation

and to control flow rate if a

centrifugal pump is used.

– The back pressure setting

should always be above the

vapor pressure of the fluid.

Micro Motion Confidential

Page 24

Back Pressure

Back Pressure Valve should be installed downstream of the prover

connections.

The amount of backpressure required is calculated as follows:

Pb = 2 P + 1.25Pe

Where, Pb = minimum backpressure required (psig)

P= pressure drop across the meter at max rate

Pe = equilibrium vapor pressure of the fluid at

operating temperature (psia)

Micro Motion Confidential

Page 25

System Design Concerns

Pressure drop

Turndown

Velocity

Access to pulses for

proving

Flow rate versus prover

capacity

Hazardous area

classification

Micro Motion Confidential

Page 26

Pressure Drop

Coriolis meters are typically several line sizes smaller

than the main pipeline.

– The sizing program calculates only the pressure drop through the

meter. More pressure drop is created by reducers.

– Back pressure valves are normally needed to keep pressure on

the meter and prevent cavitation.

Micro Motion Confidential

Page 27

Retrofit for Meter Installation

Micro Motion Confidential

Page 28

You might also like

- Kambi MWD ManualDocument39 pagesKambi MWD ManualSuraj100% (6)

- European Standard Norme Européenne Europäische NormDocument16 pagesEuropean Standard Norme Européenne Europäische NormAbey VettoorNo ratings yet

- Plunger Lift SolutionDocument24 pagesPlunger Lift SolutionojrfgmrfNo ratings yet

- IWCF Prep Refresher - Subsea Supplement - Well Control EquipmentDocument29 pagesIWCF Prep Refresher - Subsea Supplement - Well Control EquipmentAustine Ameh50% (2)

- Installation and Maintenance Manual: Steam FlowmeterDocument36 pagesInstallation and Maintenance Manual: Steam FlowmeterSans K100% (1)

- Design, Operation and Maintenance of Lact UnitsDocument3 pagesDesign, Operation and Maintenance of Lact UnitsJose gonzalezNo ratings yet

- Liquid Flow Meter Proving and LACT UnitsDocument4 pagesLiquid Flow Meter Proving and LACT UnitsDayo IdowuNo ratings yet

- Compañía Minera Suyamarca S.A.C Inmaculada Project Process Control PhilosophyDocument29 pagesCompañía Minera Suyamarca S.A.C Inmaculada Project Process Control PhilosophyHeiner PalaciosNo ratings yet

- Control & InstrumentationDocument80 pagesControl & InstrumentationDeep SYNo ratings yet

- L.A.C.T. Unit DesignDocument3 pagesL.A.C.T. Unit DesignBill Gu100% (2)

- Design Operation and Maintenance of Lact UnitsDocument12 pagesDesign Operation and Maintenance of Lact UnitsDiana Lucía Padilla0% (1)

- Instrumentation in PipelineDocument11 pagesInstrumentation in Pipelinea1137No ratings yet

- Lact UnitDocument9 pagesLact UnitBolarinwaNo ratings yet

- Control Philosophy WTPDocument12 pagesControl Philosophy WTPDIEF100% (1)

- Engineering Design LACT & Pipeline Measurement Rev 1.5Document21 pagesEngineering Design LACT & Pipeline Measurement Rev 1.5jechurchNo ratings yet

- Ch4 Drives, Actuators and ControlDocument80 pagesCh4 Drives, Actuators and ControlcactuswillsaNo ratings yet

- Section 26 - Oilgear PV Liquid MeterDocument18 pagesSection 26 - Oilgear PV Liquid MeterhammamiNo ratings yet

- Control System Training: Instruments - Part 2Document25 pagesControl System Training: Instruments - Part 2Ram Prasad SuggalaNo ratings yet

- Automation of Hydraulic Structure: Indian Institute of Technology RoorkeeDocument31 pagesAutomation of Hydraulic Structure: Indian Institute of Technology RoorkeeTerex Z. LarvexNo ratings yet

- Control Loop Hardware and TroubleshootingDocument51 pagesControl Loop Hardware and TroubleshootingAhmed ElsayedNo ratings yet

- Liquid Allocation Measurement Api Chapter 20.1: Weathered Oil Has Lost Most of Its DissolvedDocument7 pagesLiquid Allocation Measurement Api Chapter 20.1: Weathered Oil Has Lost Most of Its DissolvedSE CristobalNo ratings yet

- (TP0A016) Smith Meter® LACT UnitDocument8 pages(TP0A016) Smith Meter® LACT UnitRoberto Carlos Teixeira100% (1)

- Chapter 5 Final Control ElementsDocument84 pagesChapter 5 Final Control ElementsCaratsSVT100% (1)

- Hydraulic System DesignDocument3 pagesHydraulic System Designerrante_66No ratings yet

- Design Operation and Maintenance of LACT Units Class 2090Document7 pagesDesign Operation and Maintenance of LACT Units Class 2090Diana Lucía PadillaNo ratings yet

- Liquid Measurement Station Design 2017 ISHMDocument5 pagesLiquid Measurement Station Design 2017 ISHMMalouk CheniouniNo ratings yet

- Streamlining Water Management Operations:: Moving Beyond Mechanical To Automated Electronic ControlDocument3 pagesStreamlining Water Management Operations:: Moving Beyond Mechanical To Automated Electronic ControlHuy VuNo ratings yet

- Hydraulic Lift For Lifting Heavy Materials: Project Report OnDocument15 pagesHydraulic Lift For Lifting Heavy Materials: Project Report OnTribhuvan SharmaNo ratings yet

- Ultrasonic Liquid Level SensorDocument24 pagesUltrasonic Liquid Level Sensormadhuri12345678No ratings yet

- API 20.1 Liquid Allocation Measurement 1995Document7 pagesAPI 20.1 Liquid Allocation Measurement 1995wellington88100% (1)

- Smith Meter Lact UnitDocument8 pagesSmith Meter Lact UnitDiana Lucía PadillaNo ratings yet

- Manual ValveExpert 7.1 EnglishDocument59 pagesManual ValveExpert 7.1 EnglishMohamed SemedaNo ratings yet

- Manual ReadySoftDocument36 pagesManual ReadySoftGreg ReynekeNo ratings yet

- Manipulator Elements Sergejs BoikoDocument14 pagesManipulator Elements Sergejs BoikoСергей БойкоNo ratings yet

- Testers Ma Mul 1812 PDFDocument68 pagesTesters Ma Mul 1812 PDFJesus N RodriguezNo ratings yet

- Application of Scada For Water Treatment Plant: - by Shraddha Malve MT19ENV017Document34 pagesApplication of Scada For Water Treatment Plant: - by Shraddha Malve MT19ENV017Shraddha Malve100% (1)

- Scansteering CatDocument16 pagesScansteering CatosamaNo ratings yet

- Water Softeners Residential 9100SXT Valve Softeners US ManualDocument12 pagesWater Softeners Residential 9100SXT Valve Softeners US ManualPromagEnviro.comNo ratings yet

- Slection of Motor Starter PDFDocument4 pagesSlection of Motor Starter PDFArun GuptaNo ratings yet

- AnalizadorDocument12 pagesAnalizadorCarlos de la Torre100% (1)

- Automated IrrigationDocument12 pagesAutomated IrrigationKarthik RaitaniNo ratings yet

- OptimDocument28 pagesOptimJonathan CruzNo ratings yet

- Lab 31Document8 pagesLab 31net fliNo ratings yet

- Complete Overview of A SubstationDocument152 pagesComplete Overview of A SubstationAnish JunejaNo ratings yet

- SPE Stavanger - Level Design and ControlDocument32 pagesSPE Stavanger - Level Design and ControlSushil KunduNo ratings yet

- Report - Pump Room AutomationDocument12 pagesReport - Pump Room AutomationtanujgateNo ratings yet

- Hydraulic and Pneumatic Systems by Batch1 17M101,102,107,108,109,110Document49 pagesHydraulic and Pneumatic Systems by Batch1 17M101,102,107,108,109,110Agash ChellappaNo ratings yet

- Meter Out Circuit For Speed Control in Hydraulic CircuitsDocument12 pagesMeter Out Circuit For Speed Control in Hydraulic CircuitsThe Information TreeNo ratings yet

- FlowmwterDocument68 pagesFlowmwterjimmjimNo ratings yet

- Visco Pro 2000Document63 pagesVisco Pro 2000Luz Stella Calixto GomezNo ratings yet

- Condition Monitoring Notes-Unit 2Document11 pagesCondition Monitoring Notes-Unit 2MaheswariRVNo ratings yet

- Control Loop Hardware and TroubleshootingDocument51 pagesControl Loop Hardware and Troubleshootingrosita61100% (1)

- Implementation of Scada in Gas PipelineDocument50 pagesImplementation of Scada in Gas PipelinenwabukingzNo ratings yet

- Pure Water: Installation, Operation and Maintenance ManualDocument32 pagesPure Water: Installation, Operation and Maintenance ManualhectorNo ratings yet

- Auxiliary TransformerDocument22 pagesAuxiliary TransformerعليفاضلNo ratings yet

- Conveyer Brake SystemsDocument4 pagesConveyer Brake SystemsTran DucNo ratings yet

- SATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFDocument20 pagesSATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFuserscribd2011No ratings yet

- Water Source Heat Pump Axiom™ Water-to-Water - EXW: Product CatalogDocument52 pagesWater Source Heat Pump Axiom™ Water-to-Water - EXW: Product CatalogImran AzizNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Orifice Meters For Liquid MeasurementDocument8 pagesOrifice Meters For Liquid MeasurementGlobal MeteringNo ratings yet

- PO1604039Document2 pagesPO1604039Global MeteringNo ratings yet

- SKETCH DRAWING Level GaugeDocument1 pageSKETCH DRAWING Level GaugeGlobal MeteringNo ratings yet

- 1BAF S6R 0.5to6 ACHECHDocument1 page1BAF S6R 0.5to6 ACHECHGlobal MeteringNo ratings yet

- Additional Info To Be Add in ProcedureDocument1 pageAdditional Info To Be Add in ProcedureGlobal MeteringNo ratings yet

- Mill Cert15052018Document1 pageMill Cert15052018Global MeteringNo ratings yet

- S38 130-G Flange UnionDocument1 pageS38 130-G Flange UnionGlobal MeteringNo ratings yet

- Ga DWG - Ifa - 0Document1 pageGa DWG - Ifa - 0Global MeteringNo ratings yet

- TensileDocument3 pagesTensileGlobal MeteringNo ratings yet

- Po1701066 - GMSDocument1 pagePo1701066 - GMSGlobal MeteringNo ratings yet

- Jpoj Split 4Document1 pageJpoj Split 4Global MeteringNo ratings yet

- Stud Bolt MtoDocument1 pageStud Bolt MtoGlobal MeteringNo ratings yet

- Sogt P&idDocument344 pagesSogt P&idGlobal Metering0% (1)

- Po1702080 - GMSDocument2 pagesPo1702080 - GMSGlobal MeteringNo ratings yet

- PM Blanket DeuignDocument13 pagesPM Blanket DeuignGlobal MeteringNo ratings yet

- 1986 13 The NEL Orifice Plate Project Hobbs NEL - Split - 4Document1 page1986 13 The NEL Orifice Plate Project Hobbs NEL - Split - 4Global MeteringNo ratings yet

- 3Document1 page3Global MeteringNo ratings yet

- Jpoj Split 2Document1 pageJpoj Split 2Global MeteringNo ratings yet

- PDFSB Company ProfileDocument19 pagesPDFSB Company ProfileGlobal MeteringNo ratings yet

- 1986 13 The NEL Orifice Plate Project Hobbs NEL - Split - 3Document1 page1986 13 The NEL Orifice Plate Project Hobbs NEL - Split - 3Global MeteringNo ratings yet

- 1986 13 The NEL Orifice Plate Project Hobbs NELDocument13 pages1986 13 The NEL Orifice Plate Project Hobbs NELGlobal MeteringNo ratings yet

- Fuel Injection & TurbochargingDocument4 pagesFuel Injection & Turbocharging6 avinashNo ratings yet

- Fluid Mechanics (ECH3113) - Chapter 3 Flow in PipesDocument110 pagesFluid Mechanics (ECH3113) - Chapter 3 Flow in PipesTalal B. Osman100% (1)

- OdmeDocument2 pagesOdmeHotnCrispy CrispyNo ratings yet

- Instrumentation Devices Ans Systems - 1 by K.c.bhuyanDocument70 pagesInstrumentation Devices Ans Systems - 1 by K.c.bhuyanAman SrivastavaNo ratings yet

- 纯液压技术 英文版讲义 PDFDocument236 pages纯液压技术 英文版讲义 PDFWeeLun TanNo ratings yet

- D V 5-l C o C: Service ManualDocument44 pagesD V 5-l C o C: Service Manualwillycoyote1990-1No ratings yet

- Blender BrochureDocument2 pagesBlender BrochureLily Villalobos MelgarejoNo ratings yet

- 2017 APMP TCFF Workshop Dr. SHIV KUMAR JAISWAL Flow Lab Details INDIA PDFDocument58 pages2017 APMP TCFF Workshop Dr. SHIV KUMAR JAISWAL Flow Lab Details INDIA PDFfarhanNo ratings yet

- Brochure Echometer Well AnalyzerDocument3 pagesBrochure Echometer Well AnalyzermiguelNo ratings yet

- Mud Hopper: User ManualDocument13 pagesMud Hopper: User ManualAli Ali50% (2)

- Manual Promass 84fDocument74 pagesManual Promass 84fPedro A. Santana H.No ratings yet

- A F C A A: Utomatic LOW Ontrol FOR Erial PplicationsDocument8 pagesA F C A A: Utomatic LOW Ontrol FOR Erial PplicationsJavier EncaladaNo ratings yet

- D1-160 LEWA Ecoflow-Metering-Pumps enDocument19 pagesD1-160 LEWA Ecoflow-Metering-Pumps encandra trisilawatiNo ratings yet

- Applied Energy: SciencedirectDocument11 pagesApplied Energy: SciencedirectjulianrcoNo ratings yet

- Ansi+isea+z358 1-2009Document28 pagesAnsi+isea+z358 1-2009iplaruffNo ratings yet

- Fluid Mechanics Lab Project ReportDocument9 pagesFluid Mechanics Lab Project ReportMuhammad AbdullahNo ratings yet

- VENTURIDocument3 pagesVENTURIfathima camangianNo ratings yet

- 1.5in PX4 Higienica EOMDocument43 pages1.5in PX4 Higienica EOMWalter CastilloNo ratings yet

- P&IDs (Piping & Instrumentation Diagrams) and P&ID Valve Symbol LibraryDocument7 pagesP&IDs (Piping & Instrumentation Diagrams) and P&ID Valve Symbol LibraryJames JohnNo ratings yet

- Syllabus Unit-VDocument27 pagesSyllabus Unit-Vmuskan sNo ratings yet

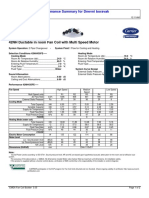

- Performance Summary For Dnevni Boravak: 42NH Ductable in Room Fan Coil With Multi Speed MotorDocument2 pagesPerformance Summary For Dnevni Boravak: 42NH Ductable in Room Fan Coil With Multi Speed Motorvelikimag87No ratings yet

- A Method To Calculate Pressure Drop For Gas-Liquid Flow in Long Horizontal Transmission LinesDocument84 pagesA Method To Calculate Pressure Drop For Gas-Liquid Flow in Long Horizontal Transmission Linesantonio alvaradoNo ratings yet

- Sludge Sampling Guidance DocumentDocument100 pagesSludge Sampling Guidance DocumentAndreea GabrielaNo ratings yet

- Flow Through Chokes Choke PerformanceDocument25 pagesFlow Through Chokes Choke PerformanceAli KiasariNo ratings yet

- Megabloc 050-032-200.1 10 HP 3600rpm (Roscada)Document5 pagesMegabloc 050-032-200.1 10 HP 3600rpm (Roscada)Alexander GiraudNo ratings yet

- Foxboro Vortex Flow MetersDocument24 pagesFoxboro Vortex Flow Metersmuhammad naufal anisNo ratings yet

- Agitation and Mixing PDFDocument84 pagesAgitation and Mixing PDFLeso Sasa Damljanovic100% (1)

- JT 121 PP PDFDocument2 pagesJT 121 PP PDFRāĦul LuĦārNo ratings yet