0% found this document useful (0 votes)

46 views14 pagesMechanical Systems: Flywheels, Pulleys, and Governors

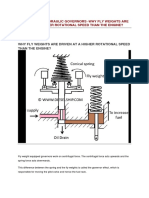

The document discusses several mechanical components and systems including flywheels, pulleys, crank mechanisms, governors, and linkages. Flywheels store kinetic energy to reduce speed fluctuations in machines. Pulleys can change speed and torque via differences in pulley wheel diameters. Crank mechanisms convert circular to reciprocal motion. Governors use centrifugal or inertia forces to regulate engine speed under varying loads. Four-bar linkages are the simplest movable closed chain mechanical linkage.

Uploaded by

uzairCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

46 views14 pagesMechanical Systems: Flywheels, Pulleys, and Governors

The document discusses several mechanical components and systems including flywheels, pulleys, crank mechanisms, governors, and linkages. Flywheels store kinetic energy to reduce speed fluctuations in machines. Pulleys can change speed and torque via differences in pulley wheel diameters. Crank mechanisms convert circular to reciprocal motion. Governors use centrifugal or inertia forces to regulate engine speed under varying loads. Four-bar linkages are the simplest movable closed chain mechanical linkage.

Uploaded by

uzairCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd