Professional Documents

Culture Documents

Eye Injuries and Prevention

Uploaded by

Sher DilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eye Injuries and Prevention

Uploaded by

Sher DilCopyright:

Available Formats

1TB02-011C44 Doc No: AMT-HS-F-004

TOOL BOX TALK ATTENDANCE

DATE TIME LOCATION CONDUCTED BY:

TOPIC EYE INJURIES AND PREVENTION

DISCUSS:

Common Hazards that Cause Eye Injuries on the Job

Flying dust

Flying debris

Chemicals

Blunt trauma to the eye

Burns due to UV exposure, such as welder’s flash

Best Practices to Avoid Injuries to the Eyes

Identify all of the potential eye hazards in your work area and for your specific work tasks. Ensure there are

proper safeguards in place to prevent an eye injury. If there is a safeguard missing, stop the work task and

correct the problem.

Eliminate or lessen the chance of getting something into your eye by avoiding being in the line of fire. One

quick example is standing upwind of debris or dust blowing around the work area.

Always wear approved safety glasses, face shield, or goggles when needed. The type of PPE needed will

depend on the work task. Three out of every five victims of eye injuries on the job were not wearing any

eye protection.

If there are welding activities going on, wear proper eye protection and ensure there is a protective barrier

in place to protect other employees in the area from UV exposure.

If you get something in your eye, do not rub or scratch it. Rubbing the eye can cause scratching of the

cornea resulting in injury. Find an eyewash station or saline bottle to rinse out the object.

If you get a chemical in your eyes, remove your contacts if there is any in and begin to rinse your eyes out.

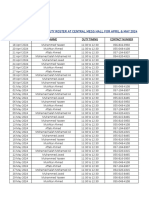

S/N NAME POSITION SIGNATURE

1

2

3

4

5

6

7

8

9

10

11

Rev. 00 Effective 27/07/2023

1TB02-011C44 Doc No: AMT-HS-F-004

TOOL BOX TALK ATTENDANCE

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Attendees comment: By signing above, I hereby acknowledge that I have fully understand the training

conducted.

Language used: Translated by:

Prepared by: Conducted by:

Rev. 00 Effective 27/07/2023

You might also like

- 17 Samss 518Document20 pages17 Samss 518Mohamed H. ShedidNo ratings yet

- Maruti FinalDocument23 pagesMaruti FinalYash MangeNo ratings yet

- Safety Talk For Painting WorkDocument3 pagesSafety Talk For Painting WorkBashir KhanNo ratings yet

- 5 Min ProtectingSight 10Document3 pages5 Min ProtectingSight 10Ani videozNo ratings yet

- Five Common Eye HazardsDocument5 pagesFive Common Eye HazardsMahamiNo ratings yet

- Eye Injuries: Worksafe Western AustraliaDocument5 pagesEye Injuries: Worksafe Western AustraliaaezeadNo ratings yet

- 10-TBT-07 Eye Injury Protection Week-7Document4 pages10-TBT-07 Eye Injury Protection Week-7saad aliNo ratings yet

- Personal Protective Equipment - Eye and Face Protection: Risk Control Resources, LLC Printed On: 01/29/2009Document71 pagesPersonal Protective Equipment - Eye and Face Protection: Risk Control Resources, LLC Printed On: 01/29/2009M_E_AdamsNo ratings yet

- ST073 - Text - Eye Damage Prevention 010301Document13 pagesST073 - Text - Eye Damage Prevention 010301malik jahanNo ratings yet

- Eye SafetyDocument4 pagesEye Safetymnkoanyane16No ratings yet

- Eye and Face Protection Toolbox Talks: Shops Web PageDocument2 pagesEye and Face Protection Toolbox Talks: Shops Web PageEko SusantoNo ratings yet

- Eye and Face Protection For Welding and Cutting OperationsDocument5 pagesEye and Face Protection For Welding and Cutting OperationsCamilo Sanchez VanegasNo ratings yet

- Toolbox Safety Talks - Eye ProtectionDocument3 pagesToolbox Safety Talks - Eye ProtectionHtoo Htoo KyawNo ratings yet

- Toolbox Topics - Eye Injury ProtectionDocument1 pageToolbox Topics - Eye Injury ProtectionIsmail AliNo ratings yet

- Eye Safety TBTDocument2 pagesEye Safety TBTRaza salaut RehmatNo ratings yet

- Hav Ext Hs Gen 0254 BDocument25 pagesHav Ext Hs Gen 0254 Bum erNo ratings yet

- TB 21 Eye Safety EngDocument1 pageTB 21 Eye Safety EngHSE 1No ratings yet

- Eye Protection in The WorkplaceDocument3 pagesEye Protection in The WorkplaceVel MuruganNo ratings yet

- (G) Eye Safety 99Document5 pages(G) Eye Safety 99tipuNo ratings yet

- Eye ProtectionDocument8 pagesEye ProtectionRaad AljuboryNo ratings yet

- Construction Safety Talks HBDocument58 pagesConstruction Safety Talks HBjayaramanrathnamNo ratings yet

- Eye Safety: A Safety Talk For Discussion LeadersDocument3 pagesEye Safety: A Safety Talk For Discussion LeadersrajNo ratings yet

- Weekly Safety Topic - 03-Dic-2012 - Eye Protection-Seeing Is BelievingDocument5 pagesWeekly Safety Topic - 03-Dic-2012 - Eye Protection-Seeing Is BelievingNeder Antonio Alcala DiazNo ratings yet

- Module 13 - Eye Injuries: Speaker NotesDocument5 pagesModule 13 - Eye Injuries: Speaker NotesSae TumNo ratings yet

- Module 13 - Eye Injuries: Speaker NotesDocument5 pagesModule 13 - Eye Injuries: Speaker NotesSae TumNo ratings yet

- Ppe Eye and Face ProtectionDocument2 pagesPpe Eye and Face ProtectionMunaku TafadzwaNo ratings yet

- Eye Protection: Remember ThisDocument2 pagesEye Protection: Remember ThisNiraNo ratings yet

- SOS-Saving Our Sight: Safety EyewearDocument3 pagesSOS-Saving Our Sight: Safety EyewearSantos RexNo ratings yet

- Eye Protection Training Refresher: March 2010Document37 pagesEye Protection Training Refresher: March 2010Balasubramaniamkamaraj100% (1)

- Eye Safety At-a-Glance: Protecting Your Vision at WorkDocument8 pagesEye Safety At-a-Glance: Protecting Your Vision at WorkEtibar AliyevNo ratings yet

- Eyesafety Not IncludDocument17 pagesEyesafety Not IncludEnxhinyer Aamir KhanNo ratings yet

- Eye and Face Protection PFDocument31 pagesEye and Face Protection PFAwalludin Pandu NegaraNo ratings yet

- Eye Protection: Toolbox Meeting GuideDocument1 pageEye Protection: Toolbox Meeting GuideIwan MsNo ratings yet

- Personal Protective EquipmentDocument14 pagesPersonal Protective EquipmentAbhiyan Anala ArvindNo ratings yet

- Toolbox Talk Eye Protection HS - TBT.04Document3 pagesToolbox Talk Eye Protection HS - TBT.04binczykagNo ratings yet

- PPE GuidanceDocument13 pagesPPE Guidancesjorgundson17No ratings yet

- Personal Protection Face EyesDocument30 pagesPersonal Protection Face EyesDantikaNo ratings yet

- Eye ProtectionDocument2 pagesEye ProtectionZeeshan BajwaNo ratings yet

- ARC Welding Safety: Because There's So Much More To EnjoyDocument16 pagesARC Welding Safety: Because There's So Much More To EnjoyScott NorrisNo ratings yet

- Safety MeasuresDocument30 pagesSafety MeasuresAthar Habib ShahaniNo ratings yet

- Tool Box Talk: Eye ProtectionDocument1 pageTool Box Talk: Eye ProtectionEtibar AliyevNo ratings yet

- 3m Eyewear Catalog Full LoResDocument40 pages3m Eyewear Catalog Full LoResMuhammad RaHadian Wiranata100% (1)

- Eye and Face Protection PDFDocument2 pagesEye and Face Protection PDFSajid HussainNo ratings yet

- Eye Protection at WorkDocument4 pagesEye Protection at WorkHarits PamitranNo ratings yet

- Eye Injuries - Causes and Treatment: Safety TalkDocument2 pagesEye Injuries - Causes and Treatment: Safety TalkmjbotelhoNo ratings yet

- Eye Injury Prevention: WWW - Worksafesask.caDocument20 pagesEye Injury Prevention: WWW - Worksafesask.cafrancisNo ratings yet

- Chapter 4 - Personal Protective Equipment: Use, Responsibility, and CostDocument7 pagesChapter 4 - Personal Protective Equipment: Use, Responsibility, and CostGiovanni Paolito YodicoNo ratings yet

- Mod-1 - SJ - Val May 2020 - Ppe & Chemical SafetyDocument16 pagesMod-1 - SJ - Val May 2020 - Ppe & Chemical SafetyL JayanthiNo ratings yet

- Eye Protection Safety TrainingDocument32 pagesEye Protection Safety TrainingImthiyaz MulkiNo ratings yet

- Eye ProtectionDocument1 pageEye ProtectionDjole GeorgeNo ratings yet

- Protect Your EyeballsDocument1 pageProtect Your EyeballsnorwalkreadymixNo ratings yet

- Cosh Construction Occupational Safety & Health Course: Personal Protective Equipment (PPE)Document57 pagesCosh Construction Occupational Safety & Health Course: Personal Protective Equipment (PPE)Ralph John ColomaNo ratings yet

- What Is PPE (Personal Protective Equipment) - The PM HQ PDFDocument18 pagesWhat Is PPE (Personal Protective Equipment) - The PM HQ PDFshreyas100% (1)

- Eye and Face ProtectionDocument2 pagesEye and Face ProtectionAbu LeoNo ratings yet

- CARPENTRY 10 - Q1 - W8 - Mod8Document18 pagesCARPENTRY 10 - Q1 - W8 - Mod8Vilma Dela Cruz PenaNo ratings yet

- Safety Data Sheet: SECTION 1. Product and Business InformationDocument3 pagesSafety Data Sheet: SECTION 1. Product and Business Informationpatt430% (1)

- Imcasf09 03 PDFDocument7 pagesImcasf09 03 PDFPepe PompinNo ratings yet

- Eye Protection For Infection Control: US CDC/NIOSH RecommendationsDocument5 pagesEye Protection For Infection Control: US CDC/NIOSH RecommendationsPriskilla Grace TicoaluNo ratings yet

- Eye SafetyDocument15 pagesEye SafetyVictor Moreno NavarreteNo ratings yet

- Eye and Face ProtectionDocument34 pagesEye and Face ProtectionDriss EddeniaNo ratings yet

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- Basic Guide to Dental InstrumentsFrom EverandBasic Guide to Dental InstrumentsRating: 2.5 out of 5 stars2.5/5 (3)

- AMT Medical Emergency Drill - 21.03.2024Document5 pagesAMT Medical Emergency Drill - 21.03.2024Sher DilNo ratings yet

- Emrgency ExitDocument1 pageEmrgency ExitSher DilNo ratings yet

- Amt-Hs-F-004 - Tool Box Talk Attendance SheeDocument2 pagesAmt-Hs-F-004 - Tool Box Talk Attendance SheeSher DilNo ratings yet

- TBT - 16 - 03 - 2024 - Cable ManagementDocument1 pageTBT - 16 - 03 - 2024 - Cable ManagementSher DilNo ratings yet

- First Aid ChecklistDocument2 pagesFirst Aid ChecklistSher DilNo ratings yet

- Confined Space Material ListDocument1 pageConfined Space Material ListSher DilNo ratings yet

- MOBCO - Safety Staff Duty Roster During Lunch TimeDocument1 pageMOBCO - Safety Staff Duty Roster During Lunch TimeSher DilNo ratings yet

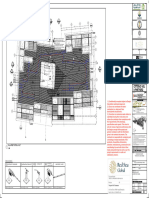

- 1TB02011 011C44 Amp FC R1 SDW Ar 10001Document1 page1TB02011 011C44 Amp FC R1 SDW Ar 10001Sher DilNo ratings yet

- 109-RR-AMT-ITP-02-Fall Arrest SystemDocument1 page109-RR-AMT-ITP-02-Fall Arrest SystemSher DilNo ratings yet

- Mechanical Ventilation: Available at SiteDocument1 pageMechanical Ventilation: Available at SiteSher DilNo ratings yet

- Actual MPDocument16 pagesActual MPSher DilNo ratings yet

- Site Safety DeclarationDocument4 pagesSite Safety DeclarationSher DilNo ratings yet

- Experience Letter - Az Abdullah JameelDocument1 pageExperience Letter - Az Abdullah JameelSher DilNo ratings yet

- Mohammad Hamsho2021.pdf001Document3 pagesMohammad Hamsho2021.pdf001Sher DilNo ratings yet

- Monthly Report - March 2024Document2 pagesMonthly Report - March 2024Sher DilNo ratings yet

- 011C44 - Daily Work Report (28-2-2024) - RosewoodDocument8 pages011C44 - Daily Work Report (28-2-2024) - RosewoodSher DilNo ratings yet

- Analisis Perencanaan Rekrutmen Aparatur Sipil Negara Kabupaten Mamuju UtaraDocument11 pagesAnalisis Perencanaan Rekrutmen Aparatur Sipil Negara Kabupaten Mamuju UtarafitriNo ratings yet

- Lecture # 3 Introduction To JqueryDocument88 pagesLecture # 3 Introduction To JqueryDanial AhmadNo ratings yet

- 2015.15009.fundamental Principles of Physical Chemistry - Text PDFDocument782 pages2015.15009.fundamental Principles of Physical Chemistry - Text PDFAnoif Naputo Aidnam100% (1)

- Popis Na OK KoziDocument325 pagesPopis Na OK KoziViktor ArsovNo ratings yet

- Ecological Pyramids WorksheetDocument3 pagesEcological Pyramids Worksheetapi-26236818833% (3)

- 3500 Ha027988 7Document384 pages3500 Ha027988 7Gigi ZitoNo ratings yet

- Effect of Different Laser Texture Configurations On Improving Surface Wettability and Wear Characteristics of Ti6Al4V Implant MaterialDocument14 pagesEffect of Different Laser Texture Configurations On Improving Surface Wettability and Wear Characteristics of Ti6Al4V Implant Materialnitish kumar100% (1)

- Opening StrategyDocument6 pagesOpening StrategyashrafsekalyNo ratings yet

- SPE-171076-MS The Role of Asphaltenes in Emulsion Formation For Steam Assisted Gravity Drainage (SAGD) and Expanding Solvent - SAGD (ES-SAGD)Document14 pagesSPE-171076-MS The Role of Asphaltenes in Emulsion Formation For Steam Assisted Gravity Drainage (SAGD) and Expanding Solvent - SAGD (ES-SAGD)Daniel FelipeNo ratings yet

- Definition of Surface Texture and Stylus InstrumentDocument5 pagesDefinition of Surface Texture and Stylus InstrumenthosseinNo ratings yet

- Noten - Detective Conan - Case ClosedDocument2 pagesNoten - Detective Conan - Case ClosedBLU-NYTE GamingNo ratings yet

- Yemen Companies Contact DetailsDocument5 pagesYemen Companies Contact DetailsYAGHMOURE ABDALRAHMAN78% (9)

- Jackson R. Lanning: Profile StatementDocument1 pageJackson R. Lanning: Profile StatementJacksonLanningNo ratings yet

- What Is NanoWatt TechnologyDocument1 pageWhat Is NanoWatt Technologyfolk_sharathNo ratings yet

- Packet Tracer - VLSM Design and Implementation Practice TopologyDocument3 pagesPacket Tracer - VLSM Design and Implementation Practice TopologyBenj MendozaNo ratings yet

- Book2Chapter10 and 11 EvaluationDocument55 pagesBook2Chapter10 and 11 EvaluationEmmanuel larbiNo ratings yet

- The Exchange Student (Dedicated To Rotary International)Document163 pagesThe Exchange Student (Dedicated To Rotary International)Nikita100% (1)

- Getting Started HANADocument86 pagesGetting Started HANAAr RazaNo ratings yet

- SFA TRAINING MODULE Week 1Document14 pagesSFA TRAINING MODULE Week 1Ivan Perez100% (1)

- Oil RussiaDocument8 pagesOil RussiaAyush AhujaNo ratings yet

- Prayer For Protection PDFDocument3 pagesPrayer For Protection PDFtim100% (1)

- Congenital Abnormalities of The Female Reproductive TractDocument14 pagesCongenital Abnormalities of The Female Reproductive TractMary SheshiraNo ratings yet

- AI LabDocument17 pagesAI LabTripti JainNo ratings yet

- Osssc JR Clerk Odia Paper 2015 - 20171207 - 0001Document7 pagesOsssc JR Clerk Odia Paper 2015 - 20171207 - 0001songspk100No ratings yet

- Monster Energy v. Jing - Counterfeit OpinionDocument9 pagesMonster Energy v. Jing - Counterfeit OpinionMark JaffeNo ratings yet

- 5CT PDVSA em - 18!00!05 EnglishDocument27 pages5CT PDVSA em - 18!00!05 EnglishJuan Gutierrez100% (1)

- Revised Implementing Rules and Regulations Ra 10575Document79 pagesRevised Implementing Rules and Regulations Ra 10575Rodel D. LuyaoNo ratings yet

- 16.3 - Precipitation and The Solubility Product - Chemistry LibreTextsDocument14 pages16.3 - Precipitation and The Solubility Product - Chemistry LibreTextsThereNo ratings yet