Professional Documents

Culture Documents

Step Turning in Lathe

Uploaded by

devmarineacademyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Step Turning in Lathe

Uploaded by

devmarineacademyCopyright:

Available Formats

PRACTICAL---STEP TURNING IN LATHE

MATERIAL-USE A STARIGHT TURNING JOB

TIME-4Hour

TOOL NECESSARY- 1- Right hand turning tool

2-Facing tool

3-Surface gauge

4- Chuck key

5- Tool post Key

6- Vernier Caaliper

Procedure

1. First loosen the jaw in the chuck key to position the work piece, and then tighten the jaws.

2. Fix the cutting tool in the toolpost.

3. Switch on the lathe and move the carriage near to the workpiece. Give it a small cross feed, and

then move carriage longitudinally to the required length slowly.

4. Bring the carriage to the original position, give a small cross feed and move

carriage longitudinally. Repeat this step until required diameter is obtained.

5. To get smooth surface give a very small feed when the diameter is nearing the required value.

6. To face the end surface of the workpiece, move the carriage to make the tool touch the end

surface of the work piece.

7. Give a small feed in longitudinal direction, and then move the tool towards the axis of the

workpiece using the cross slide to complete the workpiece.

8. The turning operation is done with cutting tool to reduce the diameter upto the required

dimension for the two steps of various diameters.

9. The workpiece is removed from the chuck and the dimensions of workpiece are checked for the

requirements.

___________________________________________________________prc________________

You might also like

- Various Types of Operations Performed in Lathe Machine - Education Discussion PDFDocument13 pagesVarious Types of Operations Performed in Lathe Machine - Education Discussion PDFtinku meenaNo ratings yet

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- PDF File of Machine Shop Report PDFDocument8 pagesPDF File of Machine Shop Report PDFNur Akmal100% (1)

- Machine Tools Lab ManualDocument51 pagesMachine Tools Lab ManualCharan KumarNo ratings yet

- Drilling Boring Reaming and TappingDocument24 pagesDrilling Boring Reaming and TappingAgnivesh SharmaNo ratings yet

- Taper Turning PDFDocument10 pagesTaper Turning PDFMaria Mehar0% (1)

- Machine Shop Lab Manual 2018Document16 pagesMachine Shop Lab Manual 2018S B MALLURNo ratings yet

- BME Unit IV Machine ToolsDocument41 pagesBME Unit IV Machine ToolsArvind BhosaleNo ratings yet

- Facetron Adjustment & Alignment: Zeroing The Cheater "Sighting The Rifle"Document8 pagesFacetron Adjustment & Alignment: Zeroing The Cheater "Sighting The Rifle"Alexey KurennoyNo ratings yet

- Machine Shop ReportDocument8 pagesMachine Shop ReportNazib Ul Islam Sazib78% (9)

- ME2207 Lab ManualDocument45 pagesME2207 Lab ManualchristadcrNo ratings yet

- Intermediate Guide to Free Motion Quilting: The 4-Step FMQ System to Gain Confidence and Get Better Quilts + 8 Projects for Intermediate QuiltersFrom EverandIntermediate Guide to Free Motion Quilting: The 4-Step FMQ System to Gain Confidence and Get Better Quilts + 8 Projects for Intermediate QuiltersNo ratings yet

- Beginner's Guide to Free Motion Quilting: What Beginners Should Know Before Starting FMQ + 4 Projects for Beginners to Quilt with ConfidenceFrom EverandBeginner's Guide to Free Motion Quilting: What Beginners Should Know Before Starting FMQ + 4 Projects for Beginners to Quilt with ConfidenceNo ratings yet

- 4 - Sem Lab Manual: Spur Gear MillingDocument10 pages4 - Sem Lab Manual: Spur Gear MillingPRASSAN SHAHNo ratings yet

- AAAAAAAAAAAAAADocument13 pagesAAAAAAAAAAAAAAArslanNo ratings yet

- Report of Machining Workshop-Group2004Document8 pagesReport of Machining Workshop-Group2004حسن كميت hassankomeit lNo ratings yet

- Mohsin Ali MTMDocument24 pagesMohsin Ali MTMasgharali202jbNo ratings yet

- MTM Lab Report..517Document78 pagesMTM Lab Report..517Furqan AhmadNo ratings yet

- me8361-MT 1 LabmanualDocument37 pagesme8361-MT 1 LabmanualHOD ITNo ratings yet

- MACHINE TOOLS LabDocument40 pagesMACHINE TOOLS LabFarhan KhanNo ratings yet

- Instructions ReportDocument5 pagesInstructions Reportapi-516031423No ratings yet

- Ex. No. Date Name of The Experiment Page No. Remarks Staff SignatureDocument18 pagesEx. No. Date Name of The Experiment Page No. Remarks Staff SignatureDivin Kumar MNo ratings yet

- Bme222 - Project Plan - Ballpeen Hammer HandleDocument5 pagesBme222 - Project Plan - Ballpeen Hammer HandleeleonortablingonNo ratings yet

- 9 Unit 4: Turning: Search in BookDocument26 pages9 Unit 4: Turning: Search in BookArslanNo ratings yet

- Machine Tool and Maching Lab ReportDocument20 pagesMachine Tool and Maching Lab ReportFurqan AhmadNo ratings yet

- Manufacturing Process-Ii: Lab Manual 8Document11 pagesManufacturing Process-Ii: Lab Manual 8Abdul Rehman FaisalNo ratings yet

- Machining ProcessDocument23 pagesMachining ProcessAshish KatariaNo ratings yet

- 4th Sem Dme Machine Shop Records c20Document8 pages4th Sem Dme Machine Shop Records c20TRILOK KUMAR REDDYNo ratings yet

- ME2258 Manufacturing Technology Lab I Lab Manual PDFDocument40 pagesME2258 Manufacturing Technology Lab I Lab Manual PDFTim BryantNo ratings yet

- Machine Shop: C C C C C C C CDocument23 pagesMachine Shop: C C C C C C C CLakhvir SinghNo ratings yet

- Experiment Fi1 PDFDocument33 pagesExperiment Fi1 PDFrajamanickam sNo ratings yet

- All Lab Reports of Manufacturing ProcessesDocument28 pagesAll Lab Reports of Manufacturing ProcessesZia JanNo ratings yet

- MTM FinalDocument59 pagesMTM FinalQasim AliNo ratings yet

- 2018-Me-33 (MTM Lab Report)Document68 pages2018-Me-33 (MTM Lab Report)Humayun ArifNo ratings yet

- Lathe ReportDocument11 pagesLathe ReportWan Syafiq Wan Syamsulbahri100% (2)

- C7 - ShaperDocument11 pagesC7 - ShaperHans PinonNo ratings yet

- Lathe MachineDocument8 pagesLathe MachineMarc Augustus GarciaNo ratings yet

- Manufacturing Technology Lab - I ManualDocument45 pagesManufacturing Technology Lab - I ManualSakthivelNo ratings yet

- Presentation On Lathe and Shaper MachineDocument13 pagesPresentation On Lathe and Shaper Machinemukul anand jhaNo ratings yet

- ME2258 Manufacturing Technology Lab IIDocument14 pagesME2258 Manufacturing Technology Lab IIதியாகராஜன் அரிதாஸ்No ratings yet

- Krar Unit 58Document21 pagesKrar Unit 58AkashNo ratings yet

- Shop Practice No. 7 Off Hand Method: Ball-Peen HammerDocument13 pagesShop Practice No. 7 Off Hand Method: Ball-Peen HammerEriane Garcia100% (2)

- Drilling Boring Reaming and TappingDocument24 pagesDrilling Boring Reaming and TappingjohnNo ratings yet

- Unit 2 Machine ToolsDocument11 pagesUnit 2 Machine ToolsMemes TechnicalNo ratings yet

- Mashop Theory and PracticeDocument38 pagesMashop Theory and PracticeCel Caren MakidatoNo ratings yet

- Drilling, Boring, Reaming, and Tapping To Spot and Drill Work in A ChuckDocument3 pagesDrilling, Boring, Reaming, and Tapping To Spot and Drill Work in A ChuckMoid Aretaño MesaNo ratings yet

- Hand ToolsDocument15 pagesHand ToolsNaethan VelardeNo ratings yet

- Haide EeeeeeDocument32 pagesHaide Eeeeeeusmaniqbal15No ratings yet

- Drilling Boring Reaming and TappingDocument24 pagesDrilling Boring Reaming and TappingPuneeth KumarNo ratings yet

- Mechanical Work Shop Lab ReportDocument9 pagesMechanical Work Shop Lab ReportOG HackNo ratings yet

- c1 PDFDocument56 pagesc1 PDFAnjaana PrashantNo ratings yet

- Drilling Boring Reaming and TappingDocument24 pagesDrilling Boring Reaming and TappingsumikannuNo ratings yet

- Experiment No. 7: To Perform Drilling Operation On LatheDocument3 pagesExperiment No. 7: To Perform Drilling Operation On LatheHasnain Ashraf100% (2)

- Grinding ReportDocument5 pagesGrinding ReportSteady Bunny100% (2)

- ACFrOgBo6Ox3g06ZxeiCrCoUDBHsMSAOD8Z-4pR8DuGGt1ubF33vpbe0ymRER8wI KUnd39t UJPAF1hwbp 5 3 FgyxR9Zvi16mHKP XDGdJl-R9L321jMxjXcOqCHSh5bR1hzRGUD3iwHrwzeeDocument5 pagesACFrOgBo6Ox3g06ZxeiCrCoUDBHsMSAOD8Z-4pR8DuGGt1ubF33vpbe0ymRER8wI KUnd39t UJPAF1hwbp 5 3 FgyxR9Zvi16mHKP XDGdJl-R9L321jMxjXcOqCHSh5bR1hzRGUD3iwHrwzeeKashif SultanNo ratings yet

- Shaper, Planer, Slotter and Boring MachineDocument10 pagesShaper, Planer, Slotter and Boring Machinemuhammad umarNo ratings yet

- Manufacturing Technology Lab IDocument43 pagesManufacturing Technology Lab IMECHANICAL SMCETNo ratings yet

- Manufacturing Science Lab ManualDocument29 pagesManufacturing Science Lab Manualranjeet singh100% (1)

- Grinding Overview: Machinist Grinder Interview Questions and AnswersFrom EverandGrinding Overview: Machinist Grinder Interview Questions and AnswersNo ratings yet

- 02 Audit PlanDocument1 page02 Audit PlandevmarineacademyNo ratings yet

- 04 - List of Machines & EquipmentDocument2 pages04 - List of Machines & EquipmentdevmarineacademyNo ratings yet

- 03 Breakdown HistoryDocument2 pages03 Breakdown HistorydevmarineacademyNo ratings yet

- 04 Change Request RegisterDocument1 page04 Change Request RegisterdevmarineacademyNo ratings yet

- 03 Plan For Suppliers AuditsDocument1 page03 Plan For Suppliers AuditsdevmarineacademyNo ratings yet

- 02 SupplierEvaluationDocument1 page02 SupplierEvaluationdevmarineacademyNo ratings yet

- 03 - FRM - Induction PlanDocument1 page03 - FRM - Induction PlandevmarineacademyNo ratings yet

- 05 Internal Quality AuditDocument2 pages05 Internal Quality AuditdevmarineacademyNo ratings yet

- 02 Customer Complaint Handling FormDocument1 page02 Customer Complaint Handling FormdevmarineacademyNo ratings yet

- 04 Quality Objectives Tracking SheetDocument1 page04 Quality Objectives Tracking SheetdevmarineacademyNo ratings yet

- Responsibilities and AuthoritiesDocument1 pageResponsibilities and AuthoritiesdevmarineacademyNo ratings yet

- 06 Record ControlDocument1 page06 Record ControldevmarineacademyNo ratings yet

- 04 - FRM - Training Feedback FormDocument1 page04 - FRM - Training Feedback FormdevmarineacademyNo ratings yet

- GSK, Paper-3, 02-20Document4 pagesGSK, Paper-3, 02-20devmarineacademyNo ratings yet

- G S K PaperDocument1 pageG S K PaperdevmarineacademyNo ratings yet

- PassportDocument3 pagesPassportdevmarineacademyNo ratings yet

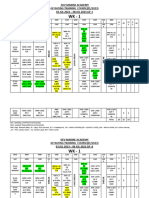

- GP Time Table Jul - Dec 2023Document19 pagesGP Time Table Jul - Dec 2023devmarineacademyNo ratings yet

- GP Rating Online Question BankDocument506 pagesGP Rating Online Question BankdevmarineacademyNo ratings yet

- 10TH MarksheetDocument1 page10TH MarksheetdevmarineacademyNo ratings yet

- Manisha Charitable Trust: Registered Office: Pin: 380013, GujaratDocument1 pageManisha Charitable Trust: Registered Office: Pin: 380013, GujaratdevmarineacademyNo ratings yet

- QR 09 - Training Plan & Schedule - ParmarDocument2 pagesQR 09 - Training Plan & Schedule - ParmardevmarineacademyNo ratings yet

- Marine WorkshopDocument3 pagesMarine WorkshopdevmarineacademyNo ratings yet

- Sewage Treatment Plant On A Ship Marpol Annex Iv: Derleyen: Nejat Öztezcan Chief EngineerDocument84 pagesSewage Treatment Plant On A Ship Marpol Annex Iv: Derleyen: Nejat Öztezcan Chief EngineerdevmarineacademyNo ratings yet

- Mek TopicDocument5 pagesMek TopicdevmarineacademyNo ratings yet

- CCMC (Hygiene) PPT Jan22Document13 pagesCCMC (Hygiene) PPT Jan22devmarineacademyNo ratings yet

- Types of ShipDocument60 pagesTypes of ShipdevmarineacademyNo ratings yet

- Sanjay and Mahasagar, PrasenjitDocument6 pagesSanjay and Mahasagar, PrasenjitdevmarineacademyNo ratings yet

- HaldiramDocument5 pagesHaldiramdevmarineacademyNo ratings yet

- Grinding MachineDocument10 pagesGrinding MachinedevmarineacademyNo ratings yet

- Larthe AccessoriesDocument17 pagesLarthe AccessoriesdevmarineacademyNo ratings yet