Professional Documents

Culture Documents

Date

Uploaded by

erik0007Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Date

Uploaded by

erik0007Copyright:

Available Formats

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

For more information contact Engineering Standards Group at email engstds@fcagroup.com and/or Normazione Group at normazione@fcagroup.c

COMPONENTS FOR

7.N0007

VEHICLE INTERIOR/EXTERIOR TRIMS

OFF-VEHICLE NOISE Page: 1/14

Date: 20-FEB-2020

LATTUADA ALBERTO - alberto.lattuada@fcagroup.com

GLOMSKI DENNIS - dennis.glomski@fcagroup.com

PCA

Code

5 PM

-

:0

07

Ch.

0

02

11

2

6,

y0

Edition

Co-Author

l

For information, please contact Author and Co-author in the lateral label of this document

Ju

Author

For APAC, LATAM and Maserati contacts, please consult SD.00130

on

m

co

p.

ou

Ch. Date Description

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE

gr

FCA ITALY -- V. C. & I. - NOISE VIBRATION HARSHNESS PCC

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THIRD PARTIES WITHOUT PRIOR

fc

- 12/10/97 Edition 1 – New; drawn up in accordance with standard 7-G0020.

.

th

- 11/19/99 Edition 2 – Fully revised. (AN)

IN CASE OF DISPUTE, THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

au

- 11/15/00 Edition 3 – Revised for update of test standard. (AN)

@

FCA US -- NVH TEST DEV & LAB OPS - 5660

3D

- 05/15/02 Edition 4 – Standard application criteria (§ 1) and test preparation

module (§ 5) revised. (AN)

54

WRITTEN CONSENT BY FCA ITALY S.p.A.

Edition 5 –

19

- 10/28/03 Name of Supervisor changed (previously Amort). (AN)

W

- 07/15/05 Edition 6 – Revised and updated. (AN)

CONFIDENTIAL

by

- 04/14/10 Edition 7 – Changed and revised title completely. (VG)

d

- 15 FEB 2012 Edition 8 – Revised and updated. (VG)

te

in

- 11 MAR 2014 Edition 9 – Added chapter named “Component with electric actuator”

Pr

Added test SETUP in the chapter “Data processing” (LL)

- 06-MAR-2017 Edition 10 – Revised and updated (LL)

- 20-FEB-2020 Edition 11 – Revised and updated (LL)

Co-Author Department

Author Department

ANY PRINTED COPY IS TO BE DEEMED AS UNCHECKED; THEREFORE THE UPDATED COPY MUST BE CHECKED IN THE APPROPRIATE WEB SITE

COPYRIGHT FCA ITALY SPA

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

PageStandards

2

7.N0007

For more information contact Engineering Group at email engstds@fcagroup.com and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

CRITERIA FOR USING THE STANDARD

The purpose of the standard is to measure the objective and subjective noise (knocking, creaking,

tinkling) of a component subject to vertical vibrational excitation and, in the case of components with

electric actuator, during handling too.

PM

The standard applies to all body components: radio, navigation system, CD player, NIT, air intake

vents, instrument panel, steering wheel interface, steering wheel airbag, seatbelt reels, sun blind and

5

luggage compartment reels, fuse boxes, switch panels (lights controls, climate control, windows etc.),

:0

courtesy lights, lights and headlights, tyre repair kit supplied in module, sunroof, climate control unit.

0 07

02

2

2

REFERENCE STANDARDS

6,

y0

7-G0030 Calculating the significance of test items (PGE)

l

Ju

7-G0112 Tightness check for threaded connections on vehicle (PGE)

on

LP.7R006 Vehicle level NVH - Full vehicle buzz, squeak and rattle (PGE)

7-T0250 Quality profile from customer's viewpoint (PTS)

m

co

LP.7R014 Vehicle level NVH – DC motor noise assessment (PGE)

p.

ou

gr

3

a

EQUIPMENT REQUIRED FOR THE TEST

fc.

th

Soundproof chamber

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

WRITTEN CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

au

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR

1 electrodynamic excitation unit that supports a static load of at least 20 kg

@

1 control system complete with vibration controller for sweep sine and random signal

3D

2 B&K type 4384 accelerometers (0 – 50 g)

2 load amplifiers for B&K type 2635 accelerometers

54

1 B&K 4291 type accelerometer calibrator

19

1 1/2” B&K type 4190 / 2669 microphone capsule

W

1 B&K 5935 microphone amplifier

by

1 B&K 4231 pistonphone

d

1 Stabilized power supply

te

CONFIDENTIAL

Analyser for signal processing and analysis (e.g. Lms Test Lab)

in

Pr

Scale for weights from 0 - 10 kg with accuracy of ± 10 g

Torque wrenches

Body part fixed to rigid structure, for anchorage to shaker

NOTE: The measurement chain indicated may be replaced by another equivalent. A maximum error

of 0.5 dB(A) is permitted.

COPYRIGHT FCA ITALY SPA

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

Page 3/14

FCA Italy S.p.A

For more information contact Engineering Standards Group at email engstds@fcagroup.com

7.N0007

and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

PM

5

:0

007

202

6,

l y0

Ju

on

m

co

p.

ou

a gr

fc.

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR WRITTEN

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

au

CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

@

3D

54

19

W

by

d

te

CONFIDENTIAL

in

Pr

PUBLISHED BY FGA - NORMAZIONE

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

PageStandards

4

7.N0007

For more information contact Engineering Group at email engstds@fcagroup.com and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

DESCRIPTION OF TEST COMPONENT

PM

Test component accompanying sheet

5

:0

07

Component type :

0

02

Build level :

2

Supplier :

6,

y0

Production date :

l

Drawing n. : Ju

on

Notes :

m

co

p.

ou

a gr

. fc

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

WRITTEN CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

au

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR

TEST COMPONENT BUILD LEVEL descriptive table

3D

54

Level A Only geometric dimensional part

19

W

Level B Part partly level A and partly level C, i.e. only fit for its own purpose

by

d

Part to design specifications, final material, operational; 100% suitable

te

CONFIDENTIAL

Level C

for experimental design approval

in

Pr

Level D Industrialised part, i.e. produced using final production process

Date: ....................................................................... Exemption: NO [ ] YES [ ]

Test Engineer: ........................................................ Signature ......................................

COPYRIGHT FCA ITALY SPA

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

Page 5/14

FCA Italy S.p.A

For more information contact Engineering Standards Group at email engstds@fcagroup.com

7.N0007

and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

TEST PREPARATION

PM

5.1

5

Secure the interface and body part to the excitation unit [Help 1]. Test Op. []

:0

07

5.2

Position 1 3-axis accelerometer to monitor any resonances on the structure

0

02

[Help 1]:

No structural resonances are permitted in the range of frequencies lower

2

than 100 Hz (inertia measurement) Test Op. []

6,

y0

5.3

Secure test component to the body part. Test Op. []

l

5.4 Ju

on

Position microphone 100 mm from the issuer face of the test component

[Help 1]. Test Op. []

m

5.5

co

Remove test component from the body part. Test Op. []

p.

5.6

ou

Measure background noise in soundproof chamber with vibrator off (spectrum

gr

1/3 of weighted octave (A)) [Help 2]. Test Op. []

a

fc

5.7

.

Excite the vibrator with a random signal detected on the vehicle, in the

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR WRITTEN

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

component application point, during the test according to standard LP.7R006

au

CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

(paragr. 12.1.D and 12.1.F). If the signal is not available, ask R&D – PD –

@

Vehicle Integration – NVH. Test Op. []

3D

5.8

54

Measure noise produced by interface/body part (spectrum 1/3 of weighted

octave (A)) [Help 2]. Test Op. []

19

W

by

d

te

CONFIDENTIAL

in

Pr

Date: ....................................................................... Exemption: NO [ ] YES [ ]

Test Operative: .......................................................

Test Engineer: ........................................................ Signature ......................................

PUBLISHED BY FGA - NORMAZIONE

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

PageStandards

6

7.N0007

For more information contact Engineering Group at email engstds@fcagroup.com and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

TEST METHOD

6.1

PM

Fit the component by securing to the body part, tightening the fastenings to the

minimum torque specified in the design (Standard 7-G0112). Test Op. []

5

6.2

:0

Excite with the random signals used in point 5.7. Test Eng. []

07

6.3

0

02

Measure noise produced by component (spectrum 1/3 of weighted octave (A))

[Help 2]. Test Eng.. []

2

6,

6.4

y0

Also evaluate the noise produced subjectively, with evaluation on SAE scale in

accordance with Standard 7-T0250 [Help 3]. Test Eng. []

l

6.5 Ju

on

Leave to vibrate for 10 minutes and repeat the subjective and objective noise

measurements, as indicated in points 6.3 and 6.4. Test Eng. []

m

6.6

co

Enter subjective/objective evaluation summary as indicated in [Help 4]. Test Eng. []

p.

ou

6.7

When possible, apply a solution to eliminate component noise and repeat the

gr

subjective and objective noise measurements, as indicated in points 6.3 and 6.4. Test Eng. []

a

. fc

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

WRITTEN CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

au

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR

@

3D

54

19

W

by

d

te

CONFIDENTIAL

in

Pr

Date: ....................................................................... Exemption: NO [ ] YES [ ]

Test Operative: .......................................................

Test Engineer: ........................................................ Signature ......................................

COPYRIGHT FCA ITALY SPA

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

Page 7/14

FCA Italy S.p.A

For more information contact Engineering Standards Group at email engstds@fcagroup.com

7.N0007

and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

7

COMPONENT WITH ELECTRIC ACTUATOR

7.1

In case of component with electric actuator, in addition to the vibrational

characterization on the shaker and the characterization of electric actuator in

PM

according with LP.7R014 procedure, is also necessary to perform test during

electric motion

5

:0

7.2

07

Test preparation

0

02

7.2.1

2

Position component inside soundproof chamber Test Op.. []

6,

7.2.2

y0

Connect the electrical actuator to the stabilized power supply trough appropriate

l

cable with on/off switch being sure that the power supply is located outside the

soundproof chamber and set to 12,5 V

Ju Test Op. []

on

7.2.3

Position microphone 100 mm from the issuer face of the test component

m

[Help 1]. Test Op. []

co

7.2.4

p.

Measure background noise of the soundproof chamber (spectrum 1/3 of

ou

weighted octave (A)) [Help 2]. Test Eng. []

gr

7.2.5

a

fc

Subjectively evaluation of a component that have no noise (knocking, creaking,

tinkling, rattling, buzzing) during its electric motion, than perform noise

.

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR WRITTEN

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

measurement [Target Curve] Test Eng. []

au

CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

@

7.3

3D

Test method

54

7.3.1

19

Switch on the stabilized power supply and set it to 12,5 V Test Eng.. []

W

7.3.2

by

Start the component’s electric motion by the switch and perform 3 complete

cycles Test Eng. []

d

te

CONFIDENTIAL

7.3.3

in

Perform the subjective and objective noise measurements, as indicated in points

Pr

6.3, 6.4 and 6.6 . Test Eng. []

7.3.4

If you experience noise apply, when possible, a solution to eliminate component

issue and repeat the subjective and objective noise measurements, as indicated

in points 6.3, 6.4 and 6.6, to verify the re-alignment with target curve. Test Eng. []

Data:…………………………………………………….. Deroga: NO [ ] SI [ ]

Nome Addetto Prova:…………………………..………

Nome Tecnico:………………………………….……… Firma……………………………………..

PUBLISHED BY FGA - NORMAZIONE

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

PageStandards

8

7.N0007

For more information contact Engineering Group at email engstds@fcagroup.com and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

DATA PROCESSING

8.1

PM

Processing data of an acoustic effect that recurs on several occasions over time

5

:0

8.1.1

07

Set up the LMS analyser with the following parameters: Test Eng. []

0

02

TRACKING SET UP

2

Measurement Mode: Stationary

6,

Tracking Method: Time

y0

Duration: 30 s

l

Ju

N° of averages: 8

Averaging type: Linear average

on

m

ACQUISITION SET UP

co

Bandwidth: 12800 Hz

p.

Resolution: 1 Hz

ou

gr

8.1.2

a

Extract from the complete Time History the linear average A-weighted 1/3 Test Eng. []

fc

Octave spectrum

.

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

WRITTEN CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

8.1.3

au

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR

Superimpose the 1/3 octave spectra obtained in points: Test Eng. []

@

5.6 (soundproof chamber background noise)

3D

5.8 (noise produced by interface/body part) [TARGET CURVE]

54

6.3 (noise produced by test component)

19

as the example shown in [Help 2].

W

by

In the case of electrical handling measurement superimpose the 1/3 Octave spectra obtained in

points:

d

7.2.4 (soundproof background noise)

te

CONFIDENTIAL

in

7.2.5 [TARGET CURVE]

Pr

7.3.3 (noise produced by components during electric motion)

8.2

Processing data for a transient acoustic effect

8.2.1

Listen to the Time History again to highlight the section during which the Test Eng. []

recorded effect is present, as the example shown in figure 2.

COPYRIGHT FCA ITALY SPA

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

Page 9/14

FCA Italy S.p.A

For more information contact Engineering Standards Group at email engstds@fcagroup.com

7.N0007

and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

PM

5

:0

Figure 1

007

8.2.2

02

Set up the LMS analyser with the following parameters: Test Eng. []

2

6,

TRACKING SET UP

y0

Measurement Mode: Stationary

l

Ju

Tracking Method: Time

Duration: n° of seconds of the section of the selected time history

on

N° of averages: 8

m

Averaging type: Linear average

co

p.

ACQUISITION SET UP

ou

Bandwidth: 12800 Hz

gr

Resolution: 1 Hz

a

fc

8.2.3

.

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR WRITTEN

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

Extract the linear average A-weighted 1/3 Octave spectrum from the section of Test Eng. []

au

CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

the selected Time History.

@

8.2.4

3D

Superimpose the 1/3 octave spectra obtained in points: Test Eng. []

54

5.6 (soundproof chamber background noise)

19

5.8 (noise produced by interface/body part)

W

7.2.2 (noise produced by test component)

by

as per the example shown in [Help 2].

d

te

CONFIDENTIAL

In the case of electrical handling measurement superimpose the 1/3 Octave

in

spectra obtained in points:

Pr

7.2.4 (soundproof background noise)

7.2.5 [TARGET CURVE]

7.3.3 (noise produced by components during electric motion)

PUBLISHED BY FGA - NORMAZIONE

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

PageStandards

10

7.N0007

For more information contact Engineering Group at email engstds@fcagroup.com and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

8.3

At the end of the subjective and objective noise measurements, if they had Test Eng. []

encountered noises coming from the test component, compile an issue detailed

card as shown in (help 4), writing:

component data (draw number and production data)

description of the detected noise and 1° and 2° level diagnosis

PM

description of the action for eliminate noise

timeline for implementing action

5

:0

owner responsible for implementing action

0 07

Inside the issue card must be insert a detailed picture of the component and its

02

noise graphic.

2

6,

If they had not encountered any noises, compile the issue card only with noise

y0

graphic to certify the no noise of the component

l

Ju

on

m

co

p.

ou

gr

a

fc.

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

WRITTEN CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

au

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR

@

3D

54

19

W

by

d

te

CONFIDENTIAL

in

Pr

COPYRIGHT FCA ITALY SPA

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

Page 11/14

FCA Italy S.p.A

For more information contact Engineering Standards Group at email engstds@fcagroup.com

7.N0007

and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

HELP

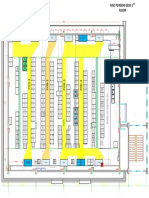

Help 1

PM

5

:0

07

COMPONENT TRIAXIAL ACCELEROMETER

0

202

6,

y0

10 cm BODY

l

MICROPHONE Ju

on

(oriented towards emitting face)

m

INTERFACE

co

p.

ou

gr

SHAKER

a

fc.

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR WRITTEN

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

au

CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

@

3D

54

19

W

by

d

te

CONFIDENTIAL

in

Pr

PUBLISHED BY FGA - NORMAZIONE

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

PageStandards

12

7.N0007

For more information contact Engineering Group at email engstds@fcagroup.com and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

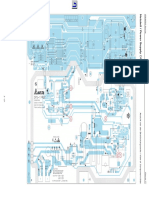

Help 2

1/3 Octave Band Spectrum

X axis (abscissa)

PM

Central band of frequencies from 100 to 25 kHz appear on the abscissa (each 1/3 octave

corresponds to 5 mm; each octave is 15 mm).

5

:0

Y axis (ordinates)

07

The 1/3 octave band spectrum appears in the ordinate, 20 mm every 10 dB (A) with scale

from 20 to 90.

0

2 02

90

6,

Soundproof chamber background noise

y0

Noise produced by interface/body part

80

Noise produced by component

l

Ju

dB/(A) on

70

NB: NOT TO SCALE

m

co

60

p.

ou

50

gr

a

fc

40

.

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

WRITTEN CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

au

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR

30

@

3D

20

54

19

Hz

W

by

This graphic must be only consider as example.

d

te

NB : - the noise produced by “interface/body part” must be at least 10 Dba lower than the

CONFIDENTIAL

in

values measured during the test, regarding both the level and the spectrum, above the

Pr

1/3 octave band 500 Hz.

COPYRIGHT FCA ITALY SPA

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

Page 13/14

FCA Italy S.p.A

For more information contact Engineering Standards Group at email engstds@fcagroup.com and/or Normazione Group at normazione@fcagroup.c

Ch. 7.N0007

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

Help 3

SAE evaluation scale (customer's perspective) – Standard 7-T0250

PM

NOT ACCEPTABLE ACCEPTABLE

compared to parameter to be evaluated

Judgement Very Bad Less than Mediocre Acceptable Acceptable Fair Good Very good Excellent

5

unacceptable mediocre limit

:0

CUSTOMER PERCEPTION

07

Detectability All Average customers Critical customers Expert customers

customers

0

02

Perceptibility HIGH MODERATE LOW VERY NONE

LOW

2

6,

Sensation Intolerability Major Annoyance Slight Small disturbance Slight No disturbance

annoyance annoyance annoyance

y0

Reaction Rejection Protest Complaint Acceptance Appreciation Enthusiasm

l

Alphanumeric Score Ju

on

scale

m

Corrective actions Radical and immediate Timely improvement action To be Requires attention OK

action improved

co

p.

ou

a gr

. fc

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR WRITTEN

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

au

CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

@

3D

54

19

W

by

d

te

CONFIDENTIAL

in

Pr

PUBLISHED BY FGA - NORMAZIONE

FCA standards and specifications are subject to frequent revisions. It is the user's responsibility to comply with current versions.

PageStandards

14

7.N0007

For more information contact Engineering Group at email engstds@fcagroup.com and/or Normazione Group at normazione@fcagroup.c

Ch.

Build level: A[ ] - B[ ] - C[ ] - D[ ] - E[ ] Job:

Component Type: Drawing N.:

Supplier: Last change:

Help 4

Test report

PM

5

:0

0 07

02

2

6,

ly0

Ju

on

m

co

p.

ou

gr

a

fc.

th

IF THE ITALIAN EDITION IS NOT AVAILABLE OR NOT UPDATED, THE ENGLISH EDITION IS THE VALID REFERENCE.

WRITTEN CONSENT BY FGA S.P.A. IN CASE OF DISPUTE THE ONLY VALID REFERENCE IS THE ITALIAN EDITION.

au

THIS DOCUMENT MUST NOT BE REPRODUCED OR CIRCULATED TO THE THIRD PARTIES WITHOUT PRIOR

@

3D

54

19

W

by

d

te

CONFIDENTIAL

in

Pr

COPYRIGHT FCA ITALY SPA

You might also like

- Performance, Acoustical and Insulators, Interior Assemblies WSS-M99P32-E1 1. ScopeDocument6 pagesPerformance, Acoustical and Insulators, Interior Assemblies WSS-M99P32-E1 1. Scopeerik0007No ratings yet

- Worldwide Engineering Standards: Label Design CriteriaDocument20 pagesWorldwide Engineering Standards: Label Design Criteriaerik0007No ratings yet

- Global Performance Requirements For Labels: Worldwide Engineering StandardsDocument17 pagesGlobal Performance Requirements For Labels: Worldwide Engineering Standardserik0007100% (1)

- Astm D 903Document3 pagesAstm D 903rajupetalokeshNo ratings yet

- TL 52608 enDocument6 pagesTL 52608 enerik00070% (1)

- PMM Shipyard DirectoryDocument9 pagesPMM Shipyard DirectoryHarisNo ratings yet

- Be Mechanical Engineering Semester 3 2023 May Strength of Materials Rev 2019 C SchemeDocument2 pagesBe Mechanical Engineering Semester 3 2023 May Strength of Materials Rev 2019 C SchemeAditya PatilNo ratings yet

- Commerce Bcom Financial Markets Semester 5 2022 November Marketing in Financial Services Mfs CbcgsDocument2 pagesCommerce Bcom Financial Markets Semester 5 2022 November Marketing in Financial Services Mfs CbcgsNaman GalaNo ratings yet

- BE 18CS731 7sem Feb March 2022Document2 pagesBE 18CS731 7sem Feb March 2022Mohanned AttamimiNo ratings yet

- Characteristics Standard Pagina: 1/10 DataDocument14 pagesCharacteristics Standard Pagina: 1/10 Dataerik0007No ratings yet

- Be Chemical Engineering Semester 7 2022 December Chemical Engineering Equipment Design Rev 2019 C SchemeDocument3 pagesBe Chemical Engineering Semester 7 2022 December Chemical Engineering Equipment Design Rev 2019 C SchemeMitesh ThakurNo ratings yet

- BE 15CS52 5 Sem July August 2021Document1 pageBE 15CS52 5 Sem July August 2021YashmithaNo ratings yet

- MS 5393Document7 pagesMS 5393erik0007No ratings yet

- Be - Mechanical Engineering - Semester 5 - 2023 - May - Mechanical Measurements and Controlsrev 2019 C SchemeDocument2 pagesBe - Mechanical Engineering - Semester 5 - 2023 - May - Mechanical Measurements and Controlsrev 2019 C Schemebottomfragger993No ratings yet

- CSD PyqDocument9 pagesCSD PyqGourav PalNo ratings yet

- 18ME751_unlockedDocument2 pages18ME751_unlockedabhishekNo ratings yet

- 15ec42 Dec18-Jan19Document2 pages15ec42 Dec18-Jan19Mohammed ZeeshanNo ratings yet

- DSA Model Question PaperDocument2 pagesDSA Model Question PaperRoopa NNo ratings yet

- Be - Electrical Engineering - Semester 6 - 2023 - May - Energy Storagerev 2019 C SchemeDocument1 pageBe - Electrical Engineering - Semester 6 - 2023 - May - Energy Storagerev 2019 C SchemeHarsh BaswantNo ratings yet

- CS 00018Document13 pagesCS 00018Diego FerreiraNo ratings yet

- Update Layout Pondok Gede 9oct2020Document1 pageUpdate Layout Pondok Gede 9oct2020Benny S PutraNo ratings yet

- AOS software versions and release datesDocument3 pagesAOS software versions and release datesWK OngNo ratings yet

- Wagner ManualDocument22 pagesWagner ManualwghazaliNo ratings yet

- IP May 2023 Questio PaperDocument1 pageIP May 2023 Questio Papergpmumbai123No ratings yet

- Grundig-Beko Delta dps-174bp PsuDocument3 pagesGrundig-Beko Delta dps-174bp PsuMy USERNAME100% (1)

- J5 CON2 battery monitor and protection circuitDocument1 pageJ5 CON2 battery monitor and protection circuitAbdulraouf Defnany100% (3)

- Proyecto Relizado Por: Jonny Grisales Juan Verbel Juan GonzalesDocument1 pageProyecto Relizado Por: Jonny Grisales Juan Verbel Juan GonzalesAlex GrisalesNo ratings yet

- Proyecto Relizado Por: Jonny Grisales Juan Verbel Juan GonzalesDocument1 pageProyecto Relizado Por: Jonny Grisales Juan Verbel Juan GonzalesAlex GrisalesNo ratings yet

- 6153 ProblemDocument1 page6153 ProblemNy ChenqNo ratings yet

- BE17IS72 - 7 Sem - Feb - March 2022Document2 pagesBE17IS72 - 7 Sem - Feb - March 2022Sana KhanNo ratings yet

- G21LAHL1377 - A - ICA Fluor Ethenol GADocument2 pagesG21LAHL1377 - A - ICA Fluor Ethenol GAYadir SánchezNo ratings yet

- Site Plan and LocationDocument1 pageSite Plan and Locationjamis1i09No ratings yet

- Six Flags Qiddiya: ClientDocument1 pageSix Flags Qiddiya: ClientAlbert NajjarNo ratings yet

- 4710-MDB-9520 FDR TO MAINT BLD SWBD-4710-RMU-9522 CUBICLE-1: LFF (Scotland) Ltd. Tco Ib Moa ProjectDocument20 pages4710-MDB-9520 FDR TO MAINT BLD SWBD-4710-RMU-9522 CUBICLE-1: LFF (Scotland) Ltd. Tco Ib Moa ProjectрусланNo ratings yet

- 18CV71 UnlockedDocument3 pages18CV71 Unlockedshaheed jafarNo ratings yet

- RC Structural Elements Design ExamDocument2 pagesRC Structural Elements Design ExamTanzeem AhmedNo ratings yet

- ZBHH 2Document1 pageZBHH 2FF XNo ratings yet

- 123-Smart Locker FingerprintDocument1 page123-Smart Locker FingerprintzulNo ratings yet

- AEIL-1-8-6-3-001 DrawingDocument2 pagesAEIL-1-8-6-3-001 DrawingJohn AlexanderNo ratings yet

- 15CS52 Dec18-Jan19Document1 page15CS52 Dec18-Jan19bhavyaraikotiNo ratings yet

- Twin Villa-Sc001Document1 pageTwin Villa-Sc001vigneshNo ratings yet

- SMD Engineering soot blower wiring diagramDocument25 pagesSMD Engineering soot blower wiring diagramChan Shiaw SyanNo ratings yet

- AtcDocument39 pagesAtcSAWAN J KOTIANNo ratings yet

- Floor Plans: Analysi S AND Zoni NGDocument1 pageFloor Plans: Analysi S AND Zoni NGSwezen DesuzaNo ratings yet

- Special Electrical Machines Course QPDocument1 pageSpecial Electrical Machines Course QPOmkar GuptaNo ratings yet

- Sensor mounting bracket dimensionsDocument1 pageSensor mounting bracket dimensionsChandru ChristurajNo ratings yet

- Be - Mechanical Engineering - Semester 5 - 2023 - May - Dynamics of Machineryrev 2019 C SchemeDocument2 pagesBe - Mechanical Engineering - Semester 5 - 2023 - May - Dynamics of Machineryrev 2019 C Schemebottomfragger993No ratings yet

- FM Noel - SCOREDocument2 pagesFM Noel - SCOREHechamaya compositeurNo ratings yet

- A-1.3 Arqui 3Document1 pageA-1.3 Arqui 3Luis OcejoNo ratings yet

- Harmonized "Cluster" Document: Amine Contamination ResistanceDocument4 pagesHarmonized "Cluster" Document: Amine Contamination Resistanceerik0007No ratings yet

- Ubicacion BañosDocument1 pageUbicacion BañosPaz Carrasco MellaNo ratings yet

- Dogpatch Market ReportDocument4 pagesDogpatch Market ReportDunja GreenNo ratings yet

- 15CV72 Dec18-Jan19Document2 pages15CV72 Dec18-Jan19KushiNo ratings yet

- Gambar Micrometer StandDocument4 pagesGambar Micrometer Standcakim.anhNo ratings yet

- Like_im_gonna_lose_you_-_Meghan_TrainorDocument3 pagesLike_im_gonna_lose_you_-_Meghan_TrainorGrecia Villarreal MoránNo ratings yet

- Report On Substandard Floor Tiling Work in B6 Male BathroomDocument3 pagesReport On Substandard Floor Tiling Work in B6 Male BathroomYasith AbeywickramaNo ratings yet

- G026a-Pv-15001 String Wiring Layout Block 1-15001Document1 pageG026a-Pv-15001 String Wiring Layout Block 1-15001Daniel BanawaNo ratings yet

- Be - Information Technology - Semester 3 - 2023 - May - Paradigms Computer Programming Faoundationrev 2019c SchemeDocument1 pageBe - Information Technology - Semester 3 - 2023 - May - Paradigms Computer Programming Faoundationrev 2019c SchemeNitin VisheNo ratings yet

- Architectural Specification DetailsDocument1 pageArchitectural Specification DetailsZaw Hlaing AungNo ratings yet

- R2 SECTION: Sta. 0+000 - Sta. 1+100: Scale A1: 1/1500, A3: 1/3000 Ring 2 - 1Document12 pagesR2 SECTION: Sta. 0+000 - Sta. 1+100: Scale A1: 1/1500, A3: 1/3000 Ring 2 - 1ကိုနေဝင်းNo ratings yet

- FRB01A011107Document1 pageFRB01A011107Chandru ChristurajNo ratings yet

- Suzume No Tojimari Unknown Composer Suzume No Tojimari Trailer OSTDocument4 pagesSuzume No Tojimari Unknown Composer Suzume No Tojimari Trailer OSTGrandadamNo ratings yet

- P2Document1 pageP2manescankaye2No ratings yet

- AIDS Question Paper - RemovedDocument8 pagesAIDS Question Paper - RemovedPriyadarshini ChavanNo ratings yet

- A01 PDFDocument1 pageA01 PDFShariah MelonNo ratings yet

- Qrupd) LRQH 83757: 3DJH 'DWHDocument8 pagesQrupd) LRQH 83757: 3DJH 'DWHerik0007No ratings yet

- Determining The Resistance To Combustion of The Non-Metallic Materials For Parts Inside Vehicle Passenger CompartmentDocument17 pagesDetermining The Resistance To Combustion of The Non-Metallic Materials For Parts Inside Vehicle Passenger Compartmenterik0007No ratings yet

- Harmonized "Cluster" Document: Amine Contamination ResistanceDocument4 pagesHarmonized "Cluster" Document: Amine Contamination Resistanceerik0007No ratings yet

- Keur 00822-107 201210Document2 pagesKeur 00822-107 201210erik0007No ratings yet

- Pre-Formed Textile Material Mats: Mat Bonding Tensile Strength Determination Performance StandardDocument6 pagesPre-Formed Textile Material Mats: Mat Bonding Tensile Strength Determination Performance Standarderik0007No ratings yet

- Keur 00821-029 201906Document5 pagesKeur 00821-029 201906erik0007No ratings yet

- Keur 00821-024 201710Document2 pagesKeur 00821-024 201710erik0007No ratings yet

- Coating Adhesion and Heat Tests Performance Standard: Change Level Date Description of ChangeDocument4 pagesCoating Adhesion and Heat Tests Performance Standard: Change Level Date Description of Changeerik0007No ratings yet

- Corrosion Resistance Water Immersion TestDocument4 pagesCorrosion Resistance Water Immersion Testerik0007No ratings yet

- Keur 00822-108 200601Document3 pagesKeur 00822-108 200601erik0007No ratings yet

- Iso 1765 1986Document4 pagesIso 1765 1986erik0007No ratings yet

- Keur 00822-117 200601Document2 pagesKeur 00822-117 200601erik0007No ratings yet

- Keur 00822-106 200601Document2 pagesKeur 00822-106 200601erik0007No ratings yet

- WSS M8P16 BDocument16 pagesWSS M8P16 Berik0007No ratings yet

- Standard Report: Search CriteriaDocument5 pagesStandard Report: Search Criteriaerik0007No ratings yet

- Keur 00824-401 201505Document4 pagesKeur 00824-401 201505erik0007No ratings yet

- PV 3919 enDocument6 pagesPV 3919 enerik0007No ratings yet

- PV 3909 enDocument4 pagesPV 3909 enerik0007No ratings yet

- Burning behavior test for insulating materialsDocument7 pagesBurning behavior test for insulating materialserik0007No ratings yet

- Mass Per Unit Area (Weight) of Fabric: Standard Test Method ForDocument5 pagesMass Per Unit Area (Weight) of Fabric: Standard Test Method ForTimmi Timmi ChoiceNo ratings yet

- PV 3950engDocument13 pagesPV 3950engerik0007No ratings yet

- Vehicle Parts PV 2005: Klass.-Nr. 50 32 1 September 2000Document3 pagesVehicle Parts PV 2005: Klass.-Nr. 50 32 1 September 2000erik0007No ratings yet

- Iso 2411 PDFDocument18 pagesIso 2411 PDFerik0007No ratings yet

- Trim Assembly, Enclosed Luggage WSS-M15P32-D Compartment Covering 1. ScopeDocument11 pagesTrim Assembly, Enclosed Luggage WSS-M15P32-D Compartment Covering 1. Scopeerik0007No ratings yet

- Astm 3574 2003Document23 pagesAstm 3574 2003irwanchemNo ratings yet

- Hager Wiring Accessories Catalogue 1120Document64 pagesHager Wiring Accessories Catalogue 1120lizukyNo ratings yet

- Conplast P509: Water Reducing AdmixtureDocument2 pagesConplast P509: Water Reducing AdmixtureBalasubramanian Ananth100% (1)

- Ass02 - Querying The Movie Ratinsg DataDocument6 pagesAss02 - Querying The Movie Ratinsg Data10bicsesaliNo ratings yet

- Sieve AnalysisDocument17 pagesSieve AnalysisWan Radhiah100% (1)

- Osi-Nist Ofs Test ReportDocument4 pagesOsi-Nist Ofs Test ReportWidodo MuisNo ratings yet

- BS 5977 - 1 Lintels PDFDocument14 pagesBS 5977 - 1 Lintels PDFTom YeeNo ratings yet

- Fyp ProjectDocument5 pagesFyp ProjectUsman PashaNo ratings yet

- Catalogo HDessault 2024 GB WebDocument32 pagesCatalogo HDessault 2024 GB Webcyntia.dujsikovaNo ratings yet

- IMS Protocol Reference GuideDocument31 pagesIMS Protocol Reference Guideparimipavan_794176No ratings yet

- FV/FRV Series Throttle Valves/Throttle Check Valves: SymbolDocument2 pagesFV/FRV Series Throttle Valves/Throttle Check Valves: SymbolThyago de PaulaNo ratings yet

- CXC - CSEC Mechanical Eng Technology Paper 2 (May 2010)Document12 pagesCXC - CSEC Mechanical Eng Technology Paper 2 (May 2010)Marie Henry0% (1)

- Engineering Mechanics Tutorial Question BankDocument13 pagesEngineering Mechanics Tutorial Question Bankrajeev_kumar365No ratings yet

- Patent Application Publication (10) Pub. No.: US 2011/0210008 A1Document9 pagesPatent Application Publication (10) Pub. No.: US 2011/0210008 A1AblaqNo ratings yet

- 4500PS Series, 60 HP - 50 HZ Horsepower Rated Model 4507PS 4509PSDocument2 pages4500PS Series, 60 HP - 50 HZ Horsepower Rated Model 4507PS 4509PSJesus SilvaNo ratings yet

- How Does An Escalator Work - mp4Document2 pagesHow Does An Escalator Work - mp4gfgfNo ratings yet

- VTU Engineering Physics Practical (Lab) - 3.Transistor-CharacteristicsDocument4 pagesVTU Engineering Physics Practical (Lab) - 3.Transistor-CharacteristicsGaurav SharmaNo ratings yet

- Unigear 550: 12 - 17.5 KV, Arc-Proof, Air Insulated Switchgear For Power ApplicationsDocument48 pagesUnigear 550: 12 - 17.5 KV, Arc-Proof, Air Insulated Switchgear For Power ApplicationsMohd Nawawi Ab AzizNo ratings yet

- Load Classification of CranesDocument4 pagesLoad Classification of CranesNarayan Prasad100% (3)

- SyncBackFree PDFDocument446 pagesSyncBackFree PDFdoug24elNo ratings yet

- HUADA LW Decanter CentrifugesDocument5 pagesHUADA LW Decanter CentrifugesАндрей МанышкинNo ratings yet

- Brazing and SolderingDocument18 pagesBrazing and SolderingbendutsNo ratings yet

- Records and TimesheetDocument2 pagesRecords and TimesheetKazim NawazNo ratings yet

- User Manual: Opening Using The Opening Code Generally StructureDocument1 pageUser Manual: Opening Using The Opening Code Generally StructurePetre LeahNo ratings yet

- AOU - MEP Preferable Vendors' list-RevA PDFDocument55 pagesAOU - MEP Preferable Vendors' list-RevA PDFahmedNo ratings yet

- IQSK Issue 29 3Document27 pagesIQSK Issue 29 3Rustono R100% (3)

- In-Situ Gas AnalyzrDocument4 pagesIn-Situ Gas AnalyzrMuhammad AwaisNo ratings yet

- Access TipsDocument42 pagesAccess Tipshooverr5426No ratings yet

- Significance of Micro-Level Planning/design - : Case Study Mantri Square Mall, MalleshwaramDocument22 pagesSignificance of Micro-Level Planning/design - : Case Study Mantri Square Mall, Malleshwaramsrinivas kj100% (1)

- L4 MRASeightDocument11 pagesL4 MRASeightJens RydNo ratings yet