Professional Documents

Culture Documents

ASTM E18 (2019) - Part5

ASTM E18 (2019) - Part5

Uploaded by

david4231993Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E18 (2019) - Part5

ASTM E18 (2019) - Part5

Uploaded by

david4231993Copyright:

Available Formats

E18 − 19

TABLE 2 Rockwell Superficial Hardness Scales

Scale Symbols

Total Test Force,

N Scale, Diamond T Scale, 1⁄16-in. W Scale, 1⁄8-in. X Scale, 1⁄4-in. Y Scale, 1⁄2-in.

kgf (N)

Indenter (1.588-mm) Ball (3.175-mm) Ball (6.350-mm) Ball (12.70-mm) Ball

15 (147) 15N 15T 15W 15X 15Y

30 (294) 30N 30T 30W 30X 30Y

45 (441) 45N 45T 45W 45X 45Y

5.4 Indenters—The standard Rockwell indenters are either 5.5.6 Special anvils or fixtures, including clamping fixtures,

diamond spheroconical indenters or tungsten carbide balls of may be required for testing pieces or parts that cannot be

1.588 mm (1⁄16 in.), 3.175 mm (1⁄8 in.), 6.350 mm (1⁄4 in.), or supported by standard anvils. Auxiliary support may be used

12.70 mm (1⁄2 in.) in diameter. Indenters shall meet the for testing long pieces with so much overhang that the piece is

requirements defined in Annex A3. Steel ball indenters may be not firmly seated by the preliminary force.

used in certain circumstances (see 5.1.2.1). 5.6 Verification—Rockwell testing machines shall be veri-

5.4.1 Dust, dirt, or other foreign materials shall not be fied periodically in accordance with Annex A1.

allowed to accumulate on the indenter, as this will affect the

test results. 5.7 Test Blocks—Test blocks meeting the requirements of

Annex A4 shall be used to verify the testing machine in

NOTE 3—Indenters certified to revision E18-07 or later meet the accordance with Annex A1.

requirements of this standard.

NOTE 4—Test blocks certified to revision E18-07 or later meet the

5.5 Specimen Support—A specimen support or “anvil” shall requirements of this standard.

be used that is suitable for supporting the specimen to be NOTE 5—It is recognized that appropriate standardized test blocks are

tested. The seating and supporting surfaces of all anvils shall be not available for all geometric shapes, or materials, or both.

clean and smooth and shall be free from pits, deep scratches, 5.8 Use of Portable Rockwell Hardness Testing Machines:

and foreign material. Damage to the anvil may occur from 5.8.1 A fixed-location Rockwell hardness testing machine

testing too thin material or accidental contact of the anvil by may not be capable of testing certain samples because of the

the indenter. If the anvil is damaged from any cause, it shall be sample size or weight, sample location, accessibility of the test

repaired or replaced. Anvils showing the least visibly percep- point or other requirements. In these circumstances, the use of

tible damage may give inaccurate results, particularly on thin a portable Rockwell hardness testing machine is an acceptable

material. method to test these samples. This method allows the use of a

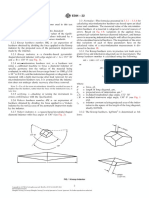

5.5.1 Common specimen support anvils should have a portable Rockwell hardness testing machine as follows.

minimum hardness of 58 HRC. Some specialty support anvils 5.8.1.1 The portable Rockwell hardness testing machine

require a lower material hardness. shall meet the requirements of this method, including the test

5.5.2 Flat pieces should be tested on a flat anvil that has a principle, apparatus, indenters, applied forces, test procedures

smooth, flat bearing surface whose plane is perpendicular to and the direct and indirect verifications of the testing machine

the axis of the indenter. (except as indicated in Table A1.1). Test Method E110 covers

5.5.3 Small diameter cylindrical pieces shall be tested with portable Rockwell hardness testing machines that cannot be

a hard V-grooved anvil with the axis of the V-groove directly directly verified or cannot pass direct verification but meet the

under the indenter, or on hard, parallel, twin cylinders properly other requirements of this method.

positioned and clamped in their base. These types of specimen 5.8.1.2 A portable Rockwell hardness testing machine shall

supports shall support the specimen with the apex of the be used only when testing circumstances make it impractical to

cylinder directly under the indenter. use a fixed-location Rockwell hardness testing machine. In

5.5.4 For thin materials or specimens that are not perfectly such cases, it is recommended that an agreement or under-

flat, an anvil having an elevated, flat “spot” 3 mm (1⁄8 in.) to standing be made between all parties involved (for example,

12.5 mm (1⁄2 in.) in diameter should be used. This spot shall be testing service and customer) that a portable Rockwell hard-

polished smooth and flat. Very soft material should not be ness testing machine will be used instead of a fixed-location

tested on the “spot” anvil because the applied force may cause Rockwell hardness testing machine (see 5.8.1.)

the penetration of the anvil into the under side of the specimen 5.8.1.3 The portable Rockwell hardness testing machine

regardless of its thickness. shall measure hardness by the Rockwell hardness test principle

5.5.5 When testing thin sheet metal with a ball indenter, it is (see 5.1). Portable hardness testing machines or instruments

recommended that a diamond spot anvil be used. The highly that measure hardness by other means or procedures different

polished diamond surface shall have a diameter between 4.0 than the Rockwell hardness test principle, such as those defined

mm (0.157 in.) and 7.0 mm (0.2875 in.) and be centered within in Test Methods A883, A956, A1038 or B647, produce

0.5 mm (0.02 in.) of the test point. converted Rockwell hardness values and do not comply with

5.5.5.1 CAUTION: A diamond spot anvil should only be this method.

used with a maximum total test force of 45 kgf (441 N) and a 5.8.2 Daily Verification of portable hardness testing

ball indenter. This recommendation should be followed except machines—Portable hardness testing machines are susceptible

when directed otherwise by material specification. to damage when they are transported or carried from one test

Copyright ASTM International

Provided by IHS Markit under license with ASTM

5

No reproduction or networking permitted without license from IHS

You might also like

- Des Plaines Centennial Celebration Booklet, 1935Document52 pagesDes Plaines Centennial Celebration Booklet, 1935Revitalize Des Plaines!100% (3)

- G 14 - 04 (2010) E1Document6 pagesG 14 - 04 (2010) E1jose floresNo ratings yet

- A327A327M-11 Standard Test Methods For Impact Testing of Cast IronsDocument4 pagesA327A327M-11 Standard Test Methods For Impact Testing of Cast IronsjuegyiNo ratings yet

- Linux Bash Cheat Sheet-1Document7 pagesLinux Bash Cheat Sheet-1Prajakta WahurwaghNo ratings yet

- The Road Cormac McCarthy PDFDocument3 pagesThe Road Cormac McCarthy PDFAvilioNo ratings yet

- Astm C947Document3 pagesAstm C947Faiz Sulthan100% (2)

- AAMA 906-05: Voluntary Specification For Sliding Glass Door Roller AssembliesDocument5 pagesAAMA 906-05: Voluntary Specification For Sliding Glass Door Roller AssembliesMarian Joyce Macadine100% (1)

- B294-10 Standard Test Method For Hardness Testing of Cemented Carbides PDFDocument8 pagesB294-10 Standard Test Method For Hardness Testing of Cemented Carbides PDFdiego rodriguezNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- PS Magazine - The Preventive Maintenance Monthly 575 (2000) (LOGSA)Document35 pagesPS Magazine - The Preventive Maintenance Monthly 575 (2000) (LOGSA)fierman3449No ratings yet

- Astm e 110 2014Document5 pagesAstm e 110 2014Carlos Enrique Calles Serrano100% (2)

- Monitoring, Evaluation and Learning (Mel) Guide: Using MEL To Strengthen Your Organisational EffectivenessDocument21 pagesMonitoring, Evaluation and Learning (Mel) Guide: Using MEL To Strengthen Your Organisational EffectivenessboubkerNo ratings yet

- ASTTM D 4435 - Rock Nail TestDocument5 pagesASTTM D 4435 - Rock Nail TestmetropodikasNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- ASTM A833-08aDocument3 pagesASTM A833-08aАртем ТитовNo ratings yet

- ASTM G14 - 04 (Reapproved 2010)Document6 pagesASTM G14 - 04 (Reapproved 2010)Sofia YuliNo ratings yet

- E303 93 (Reapproved 2013) Standard - Test - Method - For - MeasuDocument5 pagesE303 93 (Reapproved 2013) Standard - Test - Method - For - MeasuCrystal Douglas100% (1)

- Astm E110Document3 pagesAstm E110alouisNo ratings yet

- Analisis Ekonomi TeknikDocument61 pagesAnalisis Ekonomi Teknikfadel muhammadNo ratings yet

- 2-6-ASME Sect. IX-2013-Section of Pipe Welder Qual.-Qw 452.6Document1 page2-6-ASME Sect. IX-2013-Section of Pipe Welder Qual.-Qw 452.6Tina MartinezNo ratings yet

- ASTM E519 Standard Test Method For Diagonal Tension in Masonry AssemblagesDocument5 pagesASTM E519 Standard Test Method For Diagonal Tension in Masonry AssemblagesFélix LlamosasNo ratings yet

- The Design of Piled Foundations: Structures and Solid Body MechanicsFrom EverandThe Design of Piled Foundations: Structures and Solid Body MechanicsRating: 4 out of 5 stars4/5 (8)

- Astm C1006 PDFDocument3 pagesAstm C1006 PDFVíctor Molina100% (2)

- Astm C748.10372Document3 pagesAstm C748.10372Luis Felipe Cam ChiangNo ratings yet

- Rockwell Hardness of Graphite Materials: Standard Test Method ForDocument3 pagesRockwell Hardness of Graphite Materials: Standard Test Method ForMuhammad NaumanNo ratings yet

- Astm C748Document2 pagesAstm C748정호철No ratings yet

- Flexural Properties of Thin-Section Glass-Fiber-Reinforced Concrete (Using Simple Beam With Third-Point Loading)Document3 pagesFlexural Properties of Thin-Section Glass-Fiber-Reinforced Concrete (Using Simple Beam With Third-Point Loading)Ghazi Al ObaidiNo ratings yet

- Flexure Testing of Slate (Breaking Load, Modulus of Rupture, Modulus of Elasticity)Document3 pagesFlexure Testing of Slate (Breaking Load, Modulus of Rupture, Modulus of Elasticity)Waleed MedhatNo ratings yet

- Rockwell Hardness of Graphite Materials: Standard Test Method ForDocument3 pagesRockwell Hardness of Graphite Materials: Standard Test Method ForLabeed ShamilNo ratings yet

- 1 - Rockwel Hardness TestingDocument9 pages1 - Rockwel Hardness Testingmetallurgy mettexNo ratings yet

- Experiment # 4 - Hardness Testing of Materials Purpose:: BackgroundDocument5 pagesExperiment # 4 - Hardness Testing of Materials Purpose:: BackgroundTapas JenaNo ratings yet

- Hardness of RockDocument7 pagesHardness of RockPushpendra ChouhanNo ratings yet

- ASTM E18 (2019) - Part6Document1 pageASTM E18 (2019) - Part6david4231993No ratings yet

- ASTM D785-1965 Dureza en Plastico RockwellDocument8 pagesASTM D785-1965 Dureza en Plastico RockwellAngel Alvarez CarrilloNo ratings yet

- Wsdot Fop For C 805: 1. ScopeDocument6 pagesWsdot Fop For C 805: 1. ScopesadasNo ratings yet

- Astm G14Document6 pagesAstm G14kashif ehsanNo ratings yet

- Degradation of Fine Aggregate Due To Attrition: Standard Test Method ForDocument3 pagesDegradation of Fine Aggregate Due To Attrition: Standard Test Method ForRam Kumar JaiswalNo ratings yet

- Determining The High Stress Abrasion Resistance of Hard MaterialsDocument6 pagesDetermining The High Stress Abrasion Resistance of Hard MaterialsHadi HowaidaNo ratings yet

- ASTM E110 (2010) - Standard Test Method For Indentation Hardness of Metallic Materials by Portable Hardness TestersDocument3 pagesASTM E110 (2010) - Standard Test Method For Indentation Hardness of Metallic Materials by Portable Hardness TestersLalit PatelNo ratings yet

- Exp 11 and 12 Rockwell Hardness Testing and Universal Testing MachineDocument5 pagesExp 11 and 12 Rockwell Hardness Testing and Universal Testing MachineAhsan FarooqNo ratings yet

- Reconfirmation Notice: AS 1012.10-2000 (Reconfirmed) 2014-10-24Document9 pagesReconfirmation Notice: AS 1012.10-2000 (Reconfirmed) 2014-10-24heyh jdjNo ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- Astm e 110 2002 PDFDocument2 pagesAstm e 110 2002 PDFtehOnipisNo ratings yet

- ASTM E110 - 10 (Dureza Equipos Portátiles)Document3 pagesASTM E110 - 10 (Dureza Equipos Portátiles)torirojas14No ratings yet

- E435 Steel PlatesDocument4 pagesE435 Steel PlatesLeina Rosa Wilches AtencioNo ratings yet

- Hardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method ForDocument2 pagesHardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method ForMohammad YaseenNo ratings yet

- D 3967 - 95a R01 - (Ingles) PDFDocument3 pagesD 3967 - 95a R01 - (Ingles) PDFFrancisNo ratings yet

- Chain TestDocument18 pagesChain TestMinh TruongNo ratings yet

- Resistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusDocument7 pagesResistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusROHITNo ratings yet

- E190 1044228-1Document4 pagesE190 1044228-1mantra2010No ratings yet

- D451D451M-91 (2013) E1 Standard Test Method For Sieve Analysis of Granular Mineral Surfacing For Asphalt Roofing ProductsDocument2 pagesD451D451M-91 (2013) E1 Standard Test Method For Sieve Analysis of Granular Mineral Surfacing For Asphalt Roofing Productssonic8981No ratings yet

- G - Standards - TMP - Astm c880.880m 2009Document3 pagesG - Standards - TMP - Astm c880.880m 2009BALEN KAKLNo ratings yet

- Roundness of Glass Spheres: Standard Test Method ForDocument4 pagesRoundness of Glass Spheres: Standard Test Method ForCamilo GuardadoNo ratings yet

- Aashto T-97-10Document5 pagesAashto T-97-10Roberto VasquezNo ratings yet

- Splitting Tensile Strength of Masonry Units: Standard Test Method ForDocument3 pagesSplitting Tensile Strength of Masonry Units: Standard Test Method ForMaría Elena Novelo ArjonaNo ratings yet

- Direct Tensile Strength of Intact Rock Core Specimens: Standard Test Method ForDocument3 pagesDirect Tensile Strength of Intact Rock Core Specimens: Standard Test Method ForEdmundo Jaita Cuellar100% (1)

- Astm C 364Document3 pagesAstm C 364Amar JabarNo ratings yet

- Estandarizacion MosquetonesDocument6 pagesEstandarizacion Mosquetonescarlos francisco riveros davalosNo ratings yet

- FSEL Split Cylinder Testing Rev 00Document10 pagesFSEL Split Cylinder Testing Rev 00Clyde LabayNo ratings yet

- Astm C1716 C1716M 16Document6 pagesAstm C1716 C1716M 16RaquelNo ratings yet

- Rockwell and Brinell Hardness of Metallic Materials by Portable Hardness TestersDocument5 pagesRockwell and Brinell Hardness of Metallic Materials by Portable Hardness TestersJones Pereira NetoNo ratings yet

- Tumbler Test For CokeDocument5 pagesTumbler Test For Cokeruben castroNo ratings yet

- FSEL Concrete Compression Rev 00Document10 pagesFSEL Concrete Compression Rev 00Isaiah Paul SacramentoNo ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- ASTM E18 (2019) - Part11Document1 pageASTM E18 (2019) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part2Document1 pageASTM E18 (2019) - Part2david4231993No ratings yet

- Complete ST Francis Magazine, Feb 2011, Vol 7:1Document215 pagesComplete ST Francis Magazine, Feb 2011, Vol 7:1Abu DaoudNo ratings yet

- Cockshott Economic PlanningDocument24 pagesCockshott Economic Planningt1ckTMNo ratings yet

- Sri RahayuDocument10 pagesSri RahayuJumardin SNo ratings yet

- Lube Distributorship AgreementDocument15 pagesLube Distributorship AgreementAngelo Jose De RamosNo ratings yet

- 244ENG AC2speed UML51R Set PDFDocument6 pages244ENG AC2speed UML51R Set PDFSinuhe LopezNo ratings yet

- Tongue Taste Map Is WrongDocument2 pagesTongue Taste Map Is Wrongapi-260339450No ratings yet

- Asking Questions Part 2 British English StudentDocument9 pagesAsking Questions Part 2 British English Studentralvan WilliamsNo ratings yet

- Mil Week 5Document4 pagesMil Week 5DARRYN SIERRANo ratings yet

- The Latter RainDocument11 pagesThe Latter RainFelex FowardNo ratings yet

- Perfect Hair Forever (Seasons 1-2) - Episode GuideDocument4 pagesPerfect Hair Forever (Seasons 1-2) - Episode GuidekkikNo ratings yet

- Power of Supreme Court To Transfer The CaseDocument11 pagesPower of Supreme Court To Transfer The CaseAdv Aastha MakkarNo ratings yet

- Jquery - Introduction: Welcome To The Odyssey With Jquery!Document17 pagesJquery - Introduction: Welcome To The Odyssey With Jquery!Shubham Mittal100% (1)

- Ebf PSBHDocument14 pagesEbf PSBHDevashish MishraNo ratings yet

- Authorization LetterDocument4 pagesAuthorization LetterCherry Mae CarredoNo ratings yet

- Final Project Ren Zhaohui WordDocument4 pagesFinal Project Ren Zhaohui Wordapi-509069065No ratings yet

- ASYCUDA Tariff (22961) PDFDocument363 pagesASYCUDA Tariff (22961) PDFSeanClarenceSahibdeenNo ratings yet

- Econ 12 PaperDocument11 pagesEcon 12 PaperKKNo ratings yet

- Lecture 4 SRE-Social & Cultural Issues in Requirements EngineeringDocument22 pagesLecture 4 SRE-Social & Cultural Issues in Requirements EngineeringTalha JabbarNo ratings yet

- Definition of Authority:: Commissioner AppealDocument3 pagesDefinition of Authority:: Commissioner AppealJaveria Feroze MemonNo ratings yet

- Detailed Lesson Plan - MISE EN PLACEDocument8 pagesDetailed Lesson Plan - MISE EN PLACEmiijoy80No ratings yet

- BCP Week 9 Upper SecondaryDocument9 pagesBCP Week 9 Upper SecondaryGjieBaxNo ratings yet

- Advisory Re CELEBRATING THE 33RD LIBRARY AND INFORMATION SERVICES MONTH (LISM) IN NOVEMBER 2023Document2 pagesAdvisory Re CELEBRATING THE 33RD LIBRARY AND INFORMATION SERVICES MONTH (LISM) IN NOVEMBER 2023Bienvenido TamondongNo ratings yet

- Case Study AnalysisDocument9 pagesCase Study Analysisapi-607246034No ratings yet

- Activity Sheet AFA 10 M2Document4 pagesActivity Sheet AFA 10 M2Ganzon MarlynNo ratings yet