Professional Documents

Culture Documents

Condenser Inlet-Outlet Optimization

Uploaded by

Jonas PadillaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Condenser Inlet-Outlet Optimization

Uploaded by

Jonas PadillaCopyright:

Available Formats

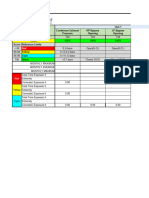

Condenser Inlet/Outlet Optimization Plan

Item Subject Issue Description

Clogged Filters due to barnacle

1 Secondary Filter

accumulation/Biofouling

2 Secondary Filter

Worn out/ Peeled off Rubber lining of

secondary filter cylinder body

Internal Corrosion and worn out coating

Condenser

3

Inlet/Outlet Pipes

Difficulty of water draining on condenser

inlet/outlet pipe due to passing inlet/outlet

valves

4 Ball Collector Worn out/ Peeled off Rubber lining of ball

collector cylinder body

5 Cathodic Protection Not functional

Implication/s Action Item

1. Change Operating strategy of secondary filters from

DP based trigger start to time based (once per shift) to

promote constant backwashing

2. Review Hypoclorite dosing procedure

3. Calibration of Secondary Filter Differential Pressure

transmitter for accurate monitoring

1. Decreased Condenser

Performance

2. System overpressure 4. Relocation of downstream sensing element from

current location to downstream pipe spool

5. Calibration and repair of condenser inlet/outlet

monitoring instruments.( Pressure Transmitter, Flow

Transmitter, Temp Transmitter) for condenser health

monitoring

6. Review/update PM frequency for Filter

cleaning/servcing

1. Reline or Coat with better coating agents during block

outage

1. Wall loss on cylinder body due to

corrosion leading to severe leakage 1. Purchase spares as reflected on critical spare list

including filter elements and pipe spool

1. UT inspection and Recoating during block outage

1. Pipe wall loss due to corrosion

leading to severe leakage

1. Rectify Inlet/Outlet Valve Passing

2. Increase diamter of inlet/outlet pipe drain line

1. Unable to perform required 3. Change drain line valve type from globe valve to ball

maintenance activities valve

4. Review Sump Pit Pump dischage capacity to cater

increase drain line diameter

1. Reline or Coat with better coating agents during block

1. Wall loss on cylinder body due to outage

corrosion leading to severe leakage

1. Include routine checks for cathodic Protection

functionality, local panel monitoring protection current

1. Acceleration of Corrosion on

inlet/outlet pipes and equipment

2. Review/update PM frequency for Cathodic Protection

Action Owner Action Due Date Remarks

OPS/TSD ME/DCIC March 15,2024

TSD ME/WTP OPS March 15,2024

SR reference:

1. 24-10030815

2. 24-10030813

I&C MTC/DCIC March 30,2024 3. 24-10030818

4. 24-10030814

DCIC/I&C April 30,2024

ECN to be initiated by TSD ME

For SR

I&C MTC/DCIC March 30,2024

TSD ME/MTC February 29,2024

MTC Outage Scheduled Block Outage

MTC August 30,2024

MTC Outage Scheduled Block Outage

MTC Scheduled Block Outage

MTC/TSD ME October 30,2024 MTC to initiate ECN

MTC/TSD ME October 30,2024

MTC to initiate ECN

TSD ME February 29,2024

MTC Outage Scheduled Block Outage

OPS March 15,2024

TSD Electrical/ MTC

March 15,2024

Electrical

You might also like

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlFrom EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNo ratings yet

- Somers Inlet Works Condition Assessment BriefDocument20 pagesSomers Inlet Works Condition Assessment BriefJames RoddNo ratings yet

- MNT 003-04 Multicolumn Distillation Plant OperationDocument3 pagesMNT 003-04 Multicolumn Distillation Plant OperationAniket kopateNo ratings yet

- 22 13 18 - Drainage Waste and Vent Piping - PlasticDocument2 pages22 13 18 - Drainage Waste and Vent Piping - PlasticLangzkie NalipaNo ratings yet

- MDC Water Treatment and Disinfection FR 07 EMCD MET 001 Rev.1 1Document2 pagesMDC Water Treatment and Disinfection FR 07 EMCD MET 001 Rev.1 1Jovani G. BallonNo ratings yet

- J910-DD02-P0GDF-125134 - A - Design Criteria For WTPDocument14 pagesJ910-DD02-P0GDF-125134 - A - Design Criteria For WTPAdrianus Hindradjaja100% (1)

- Simple File For ZaheerDocument6 pagesSimple File For ZaheerHaiDer J MarWatNo ratings yet

- MS TTP Filter Bed Penstock PassingDocument5 pagesMS TTP Filter Bed Penstock PassingAnsari TanveerNo ratings yet

- WP-004 ICCP InspectionDocument5 pagesWP-004 ICCP InspectionYusuf Maulana SaitNo ratings yet

- Read MeDocument13 pagesRead MeSameera LakmalNo ratings yet

- Final Mini Project Aluminium ProcessDocument6 pagesFinal Mini Project Aluminium ProcessAbdul QayyumNo ratings yet

- Mini Project Potassium ClorideDocument6 pagesMini Project Potassium ClorideAbdul QayyumNo ratings yet

- Mini Project Potassium ClorideDocument6 pagesMini Project Potassium ClorideAbdul QayyumNo ratings yet

- Hydrostatic Test ProcedureDocument11 pagesHydrostatic Test Procedurevena rizkyNo ratings yet

- CCB - Rev 04Document102 pagesCCB - Rev 04Alok SinghNo ratings yet

- 0294PF-N-WM-PW01-PL-TEN-1002 - A01 Technical Note-Pipeline Pigging PhilosophyDocument15 pages0294PF-N-WM-PW01-PL-TEN-1002 - A01 Technical Note-Pipeline Pigging PhilosophyfadhilNo ratings yet

- 2-Solar Water HeaterDocument124 pages2-Solar Water Heaterp4p7 projectsNo ratings yet

- CATO2 WP3.04 D18 v2014.10.15 Well Integrity Tests - Public PDFDocument23 pagesCATO2 WP3.04 D18 v2014.10.15 Well Integrity Tests - Public PDFtaufiq01No ratings yet

- Techno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteDocument9 pagesTechno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteTech MongerNo ratings yet

- BR 1701 PDFDocument7 pagesBR 1701 PDFdestiny2bnNo ratings yet

- MD1-0-T-060-05-00614-A Method Statement For Chemical Cleaning (Pre-Boiler Alkali Cleaning) PDFDocument60 pagesMD1-0-T-060-05-00614-A Method Statement For Chemical Cleaning (Pre-Boiler Alkali Cleaning) PDFNguyễn ĐứcNo ratings yet

- Hydrotest ProcedureDocument12 pagesHydrotest Procedurealex_feryando42100% (1)

- Syllabus Modul GeothermalDocument6 pagesSyllabus Modul GeothermalAgastyo WahyuNo ratings yet

- Hydrotest Procedure - UTCL Hirmi AQC & PHDocument12 pagesHydrotest Procedure - UTCL Hirmi AQC & PHJOHnNo ratings yet

- TS For Pipe-Duct DismantlingDocument10 pagesTS For Pipe-Duct DismantlingAmitava SilNo ratings yet

- Fiberstrong Installation Guide For Underground Pipe SystemDocument48 pagesFiberstrong Installation Guide For Underground Pipe System721917114 47No ratings yet

- Vacuum Pump ManualDocument29 pagesVacuum Pump ManualAnonymous Qy5TzR1fNo ratings yet

- MQ SP P 5028 PDFDocument10 pagesMQ SP P 5028 PDFjaseelNo ratings yet

- KHARAGPUR-721 302, INDIA: Indian Institute of TechnologyDocument3 pagesKHARAGPUR-721 302, INDIA: Indian Institute of TechnologyJabir AghadiNo ratings yet

- BR 170 1Document7 pagesBR 170 1Himanshu ChaturvediNo ratings yet

- Penyelenggaraan, Pemeriksaan Dan Pembaikan DandangDocument12 pagesPenyelenggaraan, Pemeriksaan Dan Pembaikan DandangMdnor RahimNo ratings yet

- 60-F8451S-H0101-01 RevD DBR of CPPDocument19 pages60-F8451S-H0101-01 RevD DBR of CPPK R Kumar RanjanNo ratings yet

- Inspection of Steel PenstocksDocument23 pagesInspection of Steel Penstocksbibeka_kalita9490No ratings yet

- Techno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteDocument9 pagesTechno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteTech MongerNo ratings yet

- Sid Su 5106 CDocument13 pagesSid Su 5106 ColalekanNo ratings yet

- QP-018, Quality Manual Procedure For Coupon and Probes MonitoringDocument12 pagesQP-018, Quality Manual Procedure For Coupon and Probes MonitoringIksan Adityo MulyoNo ratings yet

- Works Masterspec 221500Document9 pagesWorks Masterspec 221500Paolo BorlonganNo ratings yet

- Abbott DI Proposal PDFDocument17 pagesAbbott DI Proposal PDFFaiqMullaNo ratings yet

- Engineering Guide Double Contained SewersDocument12 pagesEngineering Guide Double Contained SewersAkram DriraNo ratings yet

- Fire Protection System: Testing & Commissioning Method StatementDocument14 pagesFire Protection System: Testing & Commissioning Method Statementselcuk peken50% (2)

- SMP - Condenser, Tube Cleaning & Debris FilterDocument3 pagesSMP - Condenser, Tube Cleaning & Debris Filtervivekpathak101100% (1)

- 08 Hydronic Systems App 2Document14 pages08 Hydronic Systems App 2scarpredator5No ratings yet

- Method Statement Pipe Handling and AssemblyDocument6 pagesMethod Statement Pipe Handling and AssemblyDanny NguNo ratings yet

- STP Design Report - IndiqubeDocument20 pagesSTP Design Report - IndiqubeRajkishore NayakNo ratings yet

- ANSYS CapabilitiesDocument5 pagesANSYS CapabilitiesAliyana ShresthaNo ratings yet

- SOP - Chill Water Chemistry Management Rev ADocument12 pagesSOP - Chill Water Chemistry Management Rev Abenjiy80No ratings yet

- Udupi Thermal Power Project UNITS-#1&2: Boiler Steam Purging ProcedureDocument41 pagesUdupi Thermal Power Project UNITS-#1&2: Boiler Steam Purging ProcedureravikirangeNo ratings yet

- Swimming Pool SystemDocument22 pagesSwimming Pool Systemanaseid977No ratings yet

- Ed Well ControlDocument18 pagesEd Well ControlAmeer BabylonianNo ratings yet

- Petroleum Development Oman L.L.C.: Unrestricted Document ID: SP-1032 October 1998 Filing KeyDocument17 pagesPetroleum Development Oman L.L.C.: Unrestricted Document ID: SP-1032 October 1998 Filing Keysalem AhmedNo ratings yet

- Prosedure HEX & HPWJDocument131 pagesProsedure HEX & HPWJNaniura CreationNo ratings yet

- Completion Report: Solar DWS System in Lower Kurram (FXKI 006)Document12 pagesCompletion Report: Solar DWS System in Lower Kurram (FXKI 006)JawadNo ratings yet

- Emp Appendix 6 - Deep Well SpecificationsDocument12 pagesEmp Appendix 6 - Deep Well SpecificationsMadhusudanan78No ratings yet

- Manual Experimental - Gas Diffusion CoefficientDocument13 pagesManual Experimental - Gas Diffusion CoefficientDAYANG NUR SYAZANA AG BUHTAMAMNo ratings yet

- FIXED Fire FightingDocument17 pagesFIXED Fire FightingvamsiarangiNo ratings yet

- Saep 1026Document18 pagesSaep 1026paul cafeNo ratings yet

- Long Shutdown Management Dr. Pothala Kotewswara Rao ILAMDocument8 pagesLong Shutdown Management Dr. Pothala Kotewswara Rao ILAMP Koteswara RaoNo ratings yet

- Abbott DI ProposalDocument17 pagesAbbott DI ProposalFaiqMullaNo ratings yet

- Techno-Commercial Offer 120KLD TM Based On SBR Technology, VrindavanDocument9 pagesTechno-Commercial Offer 120KLD TM Based On SBR Technology, VrindavanTech MongerNo ratings yet

- Kaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Document7 pagesKaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Jonas PadillaNo ratings yet

- Coal-Fired Thermal Power PlantDocument157 pagesCoal-Fired Thermal Power PlantJonas PadillaNo ratings yet

- Failure of Application Server 01 in Unit 4Document1 pageFailure of Application Server 01 in Unit 4Jonas PadillaNo ratings yet

- Control Valves Thermal ImagingDocument5 pagesControl Valves Thermal ImagingJonas PadillaNo ratings yet

- IST Sample Outage Report 1Document26 pagesIST Sample Outage Report 1Jonas PadillaNo ratings yet

- ReimbursementDocument1 pageReimbursementJonas PadillaNo ratings yet

- Critical Operating Parameter Monitoring Reference - BoilerDocument1 pageCritical Operating Parameter Monitoring Reference - BoilerJonas PadillaNo ratings yet

- Drawing ListDocument976 pagesDrawing ListJonas PadillaNo ratings yet

- Critical Operating ParametersDocument4 pagesCritical Operating ParametersJonas PadillaNo ratings yet

- Critical Operating Parameters - TURBINEDocument6 pagesCritical Operating Parameters - TURBINEJonas PadillaNo ratings yet

- Salehpresentation 131120012211 Phpapp01Document15 pagesSalehpresentation 131120012211 Phpapp01Jonas PadillaNo ratings yet

- Heatrate Pulserateofpowerplant 130306032305 Phpapp01Document9 pagesHeatrate Pulserateofpowerplant 130306032305 Phpapp01Kanwar P SinghNo ratings yet

- Strength BrochureDocument152 pagesStrength BrochureDavid ChanNo ratings yet

- TW Ebook Product Thinking Playbook Digital2pdfDocument172 pagesTW Ebook Product Thinking Playbook Digital2pdfgermtsNo ratings yet

- New 2010 York PerfectDocument9 pagesNew 2010 York Perfectbasl haymourNo ratings yet

- Electronic Instrumentation and Measurement Full PDFDocument143 pagesElectronic Instrumentation and Measurement Full PDFchildhoodtoons81No ratings yet

- Tara Housing-Case StudyDocument25 pagesTara Housing-Case StudyTonmoy kumar sarker100% (1)

- Income Tax Calulator With Functions and Robus Validation: PFC - Assignment - Part 1Document4 pagesIncome Tax Calulator With Functions and Robus Validation: PFC - Assignment - Part 1tran nguyenNo ratings yet

- EENG226 Lab1 PDFDocument5 pagesEENG226 Lab1 PDFSaif HassanNo ratings yet

- Experiences of Students On Online LearningDocument24 pagesExperiences of Students On Online LearningcharmaineNo ratings yet

- MECN5015A - Chapter 4 - Lecture Slides 6 AprilDocument61 pagesMECN5015A - Chapter 4 - Lecture Slides 6 AprilGulain MayomboNo ratings yet

- SBxx-1SP-US-40-IA-xx-16 Instruct ManDocument224 pagesSBxx-1SP-US-40-IA-xx-16 Instruct ManSmellyDog360No ratings yet

- LAB 7: Functions: Student Name: Nathaneal Anak Biat Student ID: EP01081100 Section:02ADocument9 pagesLAB 7: Functions: Student Name: Nathaneal Anak Biat Student ID: EP01081100 Section:02AWilfredNo ratings yet

- Polytec Vibrometer Controller OFV-5000Document121 pagesPolytec Vibrometer Controller OFV-5000vnetawzNo ratings yet

- Cat 320 Next Gen Excavator BrochureDocument16 pagesCat 320 Next Gen Excavator BrochureKeron TrotzNo ratings yet

- PesisirDocument1 pagePesisirMohammad Hafiz MahadzirNo ratings yet

- AN1009: Driving MOSFET and IGBT Switches Using The Si828x: Key FeaturesDocument22 pagesAN1009: Driving MOSFET and IGBT Switches Using The Si828x: Key FeaturesNikolas AugustoNo ratings yet

- Love Marriage Specialist PanditDocument3 pagesLove Marriage Specialist PanditLove marriage specialist panditNo ratings yet

- Cama BajaDocument32 pagesCama BajaCarlosSilvaYruretaNo ratings yet

- Discrete Mathematics - Propositional LogicDocument8 pagesDiscrete Mathematics - Propositional LogicAldrich PanioNo ratings yet

- Construction Planning and SchedulingDocument70 pagesConstruction Planning and SchedulingDessalegn AyenewNo ratings yet

- Bomag BF 300 C2Document4 pagesBomag BF 300 C2Vishwdeep VaidNo ratings yet

- Exercise A: Confine Space AssessmentDocument7 pagesExercise A: Confine Space AssessmentMohammad Sohel100% (1)

- Managerial Economics and Strategy: Third EditionDocument30 pagesManagerial Economics and Strategy: Third EditionRaeNo ratings yet

- BM3 PlusDocument2 pagesBM3 Pluscicik wijayantiNo ratings yet

- DL067AA - Delcos 1000 PDFDocument2 pagesDL067AA - Delcos 1000 PDFmak67% (3)

- 2023 It SbaDocument8 pages2023 It SbaCarl ThomasNo ratings yet

- ISO Accredited Training and Certification: VCAT I - Vibration AnalysisDocument3 pagesISO Accredited Training and Certification: VCAT I - Vibration AnalysisPraveenNo ratings yet

- Our Findings ShowDocument35 pagesOur Findings ShowNarimane BelamriNo ratings yet

- Construction Cost Estimation SystemDocument5 pagesConstruction Cost Estimation SystemURBANHIJAUNo ratings yet

- Guia de Usuario Sokkia LinkDocument81 pagesGuia de Usuario Sokkia LinkEdwin VelasquezNo ratings yet

- Information Policy - AssignmentDocument2 pagesInformation Policy - Assignmentzira jerryNo ratings yet