Professional Documents

Culture Documents

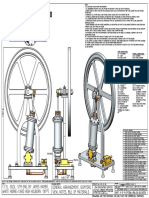

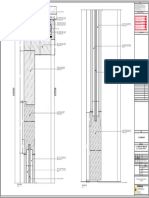

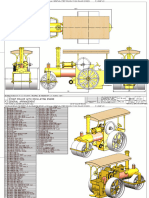

09C 38 00 A3 Sheet 01

Uploaded by

udataashutoshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

09C 38 00 A3 Sheet 01

Uploaded by

udataashutoshCopyright:

Available Formats

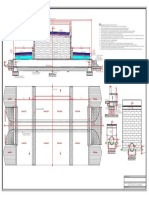

NOTES:

0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE AND SHAFT TOLERANCES.

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE APPROXIMATELY 5% TO 8% LARGER THAN

THE MATCHING TAPPED HOLE.

3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR BOLTS TO BE METRIC FINE (MF)

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE BUILDER CAN MAKE HIS/HER OWN MATERIAL

CHOICE.

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT SHALL BE SILVER/HARD SOLDERED.

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP), UNCOMPRESSED STATE IS APPROX 40% TO 60%

LONGER THEN COMPRESSED STATE.

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED AND PARTS CAN BE BONDED TOGETHER BY

USING EITHER HIGH STRENGTH GLUE, EPOXY RESIN, OR SOLDER.

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER SHOULD BE CONSTRUCTED USING NON-FERROUS

OR NON CORROSIVE MATERIAL SUCH AS BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR MONEL.

92 3.622

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED AND THE MODEL IS ASSEMBLED IS ENTIRELY

LEFT TO THE BUILDER/MODEL MAKER.

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE MODEL MAKER.

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED IS ENTIRELY LEFT UP TO THE BUILDER.

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES, WERE DEEMED NECESSARY TO PREVENT

PARTS FROM LOOSENING.

13. WASHERS AND/OR SPRINGWASHERS SHALL BE USED WHERE DEEMED NECESSARY.

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT HESITATE TO CONTACT ME SO THAT THE

ERRORS/OMISSIONS CAN BE RECTIFIED. MATERIAL

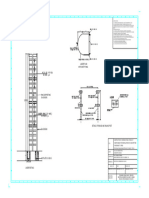

OTHER ABBREVIATIONS ABBREVIATIONS:

CRANK DP = DEEP ALU = ALUMINIUM

THE OFF SET ANGLE OF THE ECCENTRIC IN PIN DAA= DRILL AFTER HALU= HARD ALUMINIUM

RELATION TO THE CRANK AXIS TO BE CRANK ASSEMBLY BRS = BRASS

EXPERIMENTALLY DETERMINED FOR THE DISC D&TAA= DRILL AND BRZ = BRONZE OR

SMOOTH RUNNING OF THE ENGINE AND TAP AFTER ASSEMBLY GUNMETAL (BRZ/GM)

SATISFACTION OF THE BUILDER CF = CLOSE FIT (SIZE CI = CAST IRON

FOR SIZE) CU = COPPER

135 5.315 ECCENTRIC PF = PRESS FIT GRA = GRAPHITE

X PFAA= PRESS FIT MS = MILD STEEL/BRIGHT

AFTER ASSEMBLY MILD STEEL

PCD = PITCH CIRCLE SS = SILVER STEEL OR

DIAMETER STAINLESS STEEL

RM = REAM SPS = SPRING STEEL

HEX = HEXACON, PEEK= POLYETHER ETHER

6SIDED KETONE

CP = COMPRESSED SYN = SYNTHETIC

KNL = KNURLED MATERIAL SUCH AS

CSK = COUNTERSINK VETON, NYLON, TEFLON

PL = PLACES OR RUBBER

DWL= DOWEL IN GENERAL

SPF= SPOTFACE SYNTHETIC

(T)HESOP=(TAPPED)HOL MATERIALS SOULD

ES EQUALLY SPACED BE ABLE TO

ON PCD WITHSTAND THE

(T)HESOC=(TAPPED)HOL HEAT AND

ES EQUALLY SPACED PRESSURE(S)

ON CIRCUMFERENCE APPLIED TO THEM.

SA-xxx = SUB nnn/nnn MEANS THAT

ASSEMBLY-xxx EITHER MATERIAL CAN BE

USED

152 5.984

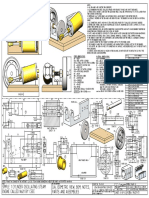

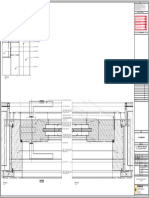

QTY. PART NUMBER

1 09C-38-00-1-01-BASE + CYL. PLATFORM

1 09C-38-00-1-02-CYLNDER BLOCK+VALVE CHEST

1 09C-38-00-1-03-CYLINDER BLOCK TOP COVER

4 09C-38-00-1-04-CYLINDER PIPE NIPPLE

1 09C-38-00-1-05-STEAM INLET PIPE

1 09C-38-00-1-06-STEAM OUTLET PIPE

2 09C-38-00-1-07-CROSS HEAD GUIDE

1 09C-38-00-2-01-CRANK SHAFT

2 09C-38-00-2-02-ECCENTRIC SHEAVE

2 09C-38-00-2-03-PISTON+CROSSHEAD

2 09C-38-00-2-04-CON-ROD

2 09C-38-00-2-05-SLIDE VALVE+SPINDLE

2 09C-38-00-2-06-ECCENTRIC STRAP

12 09C-38-00-M3 DOME NUT

2 09C-38-00-M3 NUT-BRASS

4 09C-38-00-M3 WASHER

4 09C-38-00-M3x18 A-K CYL HEAD SCREW

4 09C-38-00-M3x5 A-K CYL HEAD SCREW

6 09C-38-00-M3x5 A-K GRUB SCREW

12 09C-38-00-M4x10 A-K CYL HEAD SCREW

4 09C-38-00-M4x20 A-K CYL HEAD SCREW

8 09C-38-00-M4x26 A-K CYL HEAD SCREW

2 09C-38-00-M5 NUT

NOTES: THIS DESIGN IS BASED ON DRAWINGS WHICH WERE GIVEN TO ME. THE ORIGINAL DESIGN AND DRAWINGS WERE BY MALCOLM BEAK. DATED 1985. ENGINE CODE M.B.22

TITLE DRAWING CONTENTS PROJECT No 09C-38-00 PROJECTION

MODEL SCALE: 1:1

A TWIN CYLINDER VERTICAL DOUBLE ACTING GENERAL ARRANGEMENT,NOTES, JDW DRAUGHTING SERVICES DATE

JDWDS DWG SCALE: 1:1 @A3 OR AS SHOWN

AUGUST 2019 J.A.M. DE WAAL PAPAKURA NZ

STEAM ENGINE BORE/STROKE=20mm

Copyright ©

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA

ISOMETRIC VIEW, BILL OF MATERIALS SHEET: 01 OF 03 A3 No: 09C-38-00-SHT01

2110. NEW ZEALAND. PHONE: OO64 09 2988815. MOB:

0211791000 E-MAIL: dewaal@xtra.co.nz.

DRAWINGS ARE FOR PERSONAL USE ONLY NOT FOR COMMERCIAL PURPOSES

You might also like

- General Arrangement, Isomteric White Horne-Yard High Holburn (18??) View, Notes, Bill of Materials 1 Cyl. Oscil. STM Eng. by James HamerDocument4 pagesGeneral Arrangement, Isomteric White Horne-Yard High Holburn (18??) View, Notes, Bill of Materials 1 Cyl. Oscil. STM Eng. by James Hamertươi nguyễnNo ratings yet

- Crankless SteamDocument3 pagesCrankless Steamhamzahumo45No ratings yet

- Simlpe Oscillating Steam MachineDocument2 pagesSimlpe Oscillating Steam Machinehamzah40No ratings yet

- Simple 1 Cylinder OscillatingDocument2 pagesSimple 1 Cylinder OscillatingFaiq ZulfiarNo ratings yet

- No21 A3 Sheet 01 PDFDocument1 pageNo21 A3 Sheet 01 PDFEduardo NallarNo ratings yet

- Engine Called No21 by Csee Simple 1 Cylinder Oscillating Steam Parts and Assemblies G.A, Isometric View, Bom, NotesDocument2 pagesEngine Called No21 by Csee Simple 1 Cylinder Oscillating Steam Parts and Assemblies G.A, Isometric View, Bom, NotesBryan OlayaNo ratings yet

- Engine With Spool Valve Oiler and Reverser General Arrangement and Notes 2 Cylinder Vertical Marine Type SteamDocument4 pagesEngine With Spool Valve Oiler and Reverser General Arrangement and Notes 2 Cylinder Vertical Marine Type SteamGiuliana Elizabeth CáceresNo ratings yet

- Simple Vertical Engine 1Document4 pagesSimple Vertical Engine 1Orlando Rojas PintoNo ratings yet

- 4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesDocument2 pages4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesOrlando Rojas PintoNo ratings yet

- Typical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionDocument1 pageTypical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionCedrixe MadridNo ratings yet

- Page 16Document1 pagePage 16barcoma.mylene.nNo ratings yet

- Salebuild: Team Architects (I) Pvt. LTDDocument1 pageSalebuild: Team Architects (I) Pvt. LTDNavdeep GopamwarNo ratings yet

- Grab Handholds: Sectional Plan Top PlanDocument1 pageGrab Handholds: Sectional Plan Top PlanAbdelmoneimNo ratings yet

- Gis 2315000007 Civil 1Document1 pageGis 2315000007 Civil 1aelsheikh834No ratings yet

- 85 Welwyn Ave Concept 26022022Document1 page85 Welwyn Ave Concept 26022022Joseph MunawarNo ratings yet

- SERVICE GATE Detail - 23-03-2023Document1 pageSERVICE GATE Detail - 23-03-2023AmulyaRajbharNo ratings yet

- Distribution - SS Rev.7A AP-2023.07.06Document12 pagesDistribution - SS Rev.7A AP-2023.07.06sundareee96No ratings yet

- Lighting & Convenience Outlet Layout: General NotesDocument1 pageLighting & Convenience Outlet Layout: General NotesJayvee Latosa Dividina100% (1)

- M-01 Mechanical Plans and DetailsDocument1 pageM-01 Mechanical Plans and DetailsMario Franco Severo100% (1)

- تغذية الدور العلويDocument1 pageتغذية الدور العلويAnonymous qOBFvINo ratings yet

- Mace Ar 10 B1 02Document1 pageMace Ar 10 B1 02Syead OwaisNo ratings yet

- Beam Layout & Schedule of ReinforcementDocument1 pageBeam Layout & Schedule of ReinforcementChetan B ArkasaliNo ratings yet

- PDW-TB-487 Paved Area Detail For A-Type Store at Kotri-Pdw-Tv-487 Iso A3Document1 pagePDW-TB-487 Paved Area Detail For A-Type Store at Kotri-Pdw-Tv-487 Iso A3ihsan ul haqNo ratings yet

- 2023-07-18 B159 STR 102 GFC R0Document1 page2023-07-18 B159 STR 102 GFC R0arjunNo ratings yet

- Parents Bath Room Door D9 SectionsDocument1 pageParents Bath Room Door D9 Sectionskumaarcivil97No ratings yet

- 1473a-Ir-A0-0001 - General Notes and Legends Irrigation LayoutDocument1 page1473a-Ir-A0-0001 - General Notes and Legends Irrigation LayoutMohsin ShaikhNo ratings yet

- 1473a-Ir-A0-0001 - General Notes and Legends Irrigation LayoutDocument1 page1473a-Ir-A0-0001 - General Notes and Legends Irrigation LayoutMohsin ShaikhNo ratings yet

- 4a405 Bathroom Detail-2Document1 page4a405 Bathroom Detail-2Bismo AnggoroNo ratings yet

- Symbology Legend: Ministry of Transport & CommunicationsDocument1 pageSymbology Legend: Ministry of Transport & CommunicationsAbid AyubNo ratings yet

- DRG - SECTION OF CABLE TRENCHDocument1 pageDRG - SECTION OF CABLE TRENCHAmarjit KulkarniNo ratings yet

- J1273-S001-General NotesDocument1 pageJ1273-S001-General Notesroy jackNo ratings yet

- General Notes: Notes For Electrical: Notes For Etisalat & Eitc (Du) : NOTES FOR ETISALAT & EITC (Du) : (Continuation)Document1 pageGeneral Notes: Notes For Electrical: Notes For Etisalat & Eitc (Du) : NOTES FOR ETISALAT & EITC (Du) : (Continuation)togireeshNo ratings yet

- IN00-CCTV-NC-XX0002-001001 REV-00-Layout2Document1 pageIN00-CCTV-NC-XX0002-001001 REV-00-Layout2engrabbas75No ratings yet

- Structural IfpDocument4 pagesStructural IfpDanny NguyenNo ratings yet

- Specifications: LegendsDocument1 pageSpecifications: LegendsMary Joy AzonNo ratings yet

- Lot Information: Golden Bear Loop WestDocument1 pageLot Information: Golden Bear Loop WestGodino ChristianNo ratings yet

- D Eugp1 TPT G 000 Gen FWG 001 R01Document1 pageD Eugp1 TPT G 000 Gen FWG 001 R01debapriyoNo ratings yet

- CHB Connection Details: 1.0 General NotesDocument1 pageCHB Connection Details: 1.0 General NotesSabling DritzcNo ratings yet

- Concrete GradeDocument1 pageConcrete GradeAniket InarkarNo ratings yet

- I - General NotesDocument1 pageI - General NotesReadian FedelinNo ratings yet

- General: Workmanship/Construction Specification: ConcreteDocument1 pageGeneral: Workmanship/Construction Specification: ConcreteNabendu KARMAKARNo ratings yet

- CIRCULAR WATER TANK DESIGN-Layout1 AkhilDocument1 pageCIRCULAR WATER TANK DESIGN-Layout1 AkhilVENKAT KALYANNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- Parents Bath Room Door D9 DetailsDocument1 pageParents Bath Room Door D9 Detailskumaarcivil97No ratings yet

- 20171003-Beam & Slab Schedule-01Document1 page20171003-Beam & Slab Schedule-01Atul ShrivastavaNo ratings yet

- FF To Roof: Storey MarkingDocument1 pageFF To Roof: Storey MarkingHong Jin YaoNo ratings yet

- Train - C - DG10 - PIT Reinforcement DetailsDocument1 pageTrain - C - DG10 - PIT Reinforcement Detailsحسن صالح حسن المياحيNo ratings yet

- HPC VupDocument1 pageHPC VupShivam SharmaNo ratings yet

- Department of Transportation and Communications: Joint Venture WithDocument4 pagesDepartment of Transportation and Communications: Joint Venture WithDordas SingNo ratings yet

- Isometric View: Dymac GlobalDocument2 pagesIsometric View: Dymac GlobalMaarij AnjumNo ratings yet

- General Notes and Specification: 3-LegendDocument1 pageGeneral Notes and Specification: 3-LegendReadian FedelinNo ratings yet

- Drawing Sheet 4Document1 pageDrawing Sheet 4Kunal SharmaNo ratings yet

- First Floor Plan: Ms Pergola Covered With 12Mm THK Poly Carbonate SheetDocument1 pageFirst Floor Plan: Ms Pergola Covered With 12Mm THK Poly Carbonate SheetradhapunnaNo ratings yet

- Pineda, Khian, M. - Comed PlumbingDocument6 pagesPineda, Khian, M. - Comed PlumbingKhian PinedaNo ratings yet

- ElectricalDocument1 pageElectricalMrs XNo ratings yet

- A1 PDFDocument1 pageA1 PDFSketch UpNo ratings yet

- Chicken Coop Detailed Drawings (Issued For Approval)Document31 pagesChicken Coop Detailed Drawings (Issued For Approval)orode franklynNo ratings yet

- General Notes For Slab & StairDocument1 pageGeneral Notes For Slab & StairBibek BasnetNo ratings yet

- D-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021Document1 pageD-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021debapriyoNo ratings yet

- Optimization of Process Parameters in TuDocument10 pagesOptimization of Process Parameters in TuudataashutoshNo ratings yet

- Corr. RFP For EMA - Odisha Skills Competition 2020 - FINALDocument53 pagesCorr. RFP For EMA - Odisha Skills Competition 2020 - FINALudataashutoshNo ratings yet

- 09e 39 00 A3 Sheet 01Document1 page09e 39 00 A3 Sheet 01udataashutoshNo ratings yet

- Steam Roller de WaalDocument9 pagesSteam Roller de WaaludataashutoshNo ratings yet

- Bta502 B501 45 Sheet 02Document1 pageBta502 B501 45 Sheet 02udataashutoshNo ratings yet

- Bta502 B501 45 Sheet 09Document1 pageBta502 B501 45 Sheet 09udataashutoshNo ratings yet

- Magnetic Particle Testing (MPT) (8) : Magnetism Magnetic Field LinesDocument21 pagesMagnetic Particle Testing (MPT) (8) : Magnetism Magnetic Field Linesஅன்புடன் அஸ்வின்No ratings yet

- 34 Samss 711Document25 pages34 Samss 711naruto256No ratings yet

- 11-Winches.50 2002 200603Document16 pages11-Winches.50 2002 200603Mohamed SalemNo ratings yet

- H-E Parts Data Sheet PT-80 Chromium CarbideDocument1 pageH-E Parts Data Sheet PT-80 Chromium CarbideJorge VillalobosNo ratings yet

- Asme Sa-836 Specification For Forgings, Titaniumstabilized Carbon Steel, For Glass-Lined Piping and Pressure Vessel ServiceDocument5 pagesAsme Sa-836 Specification For Forgings, Titaniumstabilized Carbon Steel, For Glass-Lined Piping and Pressure Vessel Servicelucecita1902No ratings yet

- Specialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Document3 pagesSpecialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Jarbas MoraesNo ratings yet

- Ceramic Arts Buyers GuideDocument34 pagesCeramic Arts Buyers GuideStefan Van CleemputNo ratings yet

- Melting FurnacesDocument11 pagesMelting Furnacesabhishek_m_more0% (1)

- CRA Weld Overlay - Influence of Welding Process and Parameters On Dilution and Corrosion ResistanceDocument6 pagesCRA Weld Overlay - Influence of Welding Process and Parameters On Dilution and Corrosion ResistanceMichael TayactacNo ratings yet

- B16 Case 3 13 CR Stainless Steel ASME B16.34 Valves ASTM A182 F6a Class 1, A182 F6a Class 2, and A217 CA15 MaterialDocument8 pagesB16 Case 3 13 CR Stainless Steel ASME B16.34 Valves ASTM A182 F6a Class 1, A182 F6a Class 2, and A217 CA15 MaterialInaamNo ratings yet

- Activity 6Document4 pagesActivity 6api-299811796No ratings yet

- Bhel ReportDocument44 pagesBhel ReportRoyalAryansNo ratings yet

- ValvesDocument108 pagesValvesGautam Wayse100% (1)

- Metric Tube - ParkerDocument6 pagesMetric Tube - ParkerJenny Cecilia Ureña ZuriNo ratings yet

- Thyssenkrupp Materials (UK) LTD Aluminium Alloy 6063: Material Data SheetDocument2 pagesThyssenkrupp Materials (UK) LTD Aluminium Alloy 6063: Material Data Sheetdinesh choudharyNo ratings yet

- Astm A351 CF8MDocument1 pageAstm A351 CF8MnadeemNo ratings yet

- Astm D5600Document4 pagesAstm D5600Abu WildanNo ratings yet

- Astm A320-A320m-99Document8 pagesAstm A320-A320m-99NadhiraNo ratings yet

- GI Pipe Service PolesDocument12 pagesGI Pipe Service PolesaselabollegalaNo ratings yet

- Agoco Welding Procedure Specification: Smaw Manual JOINTS (QW-402)Document3 pagesAgoco Welding Procedure Specification: Smaw Manual JOINTS (QW-402)Anonymous 7vljJzH100% (1)

- Statically Indeterminate Members & Thermal StressesDocument24 pagesStatically Indeterminate Members & Thermal StressesBuddy SinghNo ratings yet

- 2836 Soft SolderingDocument1 page2836 Soft SolderingIvan Nugali ChocolatesNo ratings yet

- Campbell Chain PDFDocument46 pagesCampbell Chain PDFrisiana_limuriaNo ratings yet

- Otimo Tem Tudo PDFDocument978 pagesOtimo Tem Tudo PDFCicero Gomes de Souza100% (1)

- Final Standerization of All Committee 02062016Document6 pagesFinal Standerization of All Committee 02062016pramod_jvNo ratings yet

- Esab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)Document1 pageEsab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNo ratings yet

- BombaDocument2 pagesBombaMilena Lemus FonsecaNo ratings yet

- Basic Mechanical EngineeringDocument70 pagesBasic Mechanical EngineeringHemachandran100% (6)

- V2100 System Aerosol RO01 GDH682Document3 pagesV2100 System Aerosol RO01 GDH682Juan SantosNo ratings yet

- Sub-Zero Treatment of Steels - Technology, Processes, Equipment (Final Artwork) PDFDocument20 pagesSub-Zero Treatment of Steels - Technology, Processes, Equipment (Final Artwork) PDFBinh Thanh LeNo ratings yet