Professional Documents

Culture Documents

No21 A3 Sheet 01 PDF

Uploaded by

Eduardo NallarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No21 A3 Sheet 01 PDF

Uploaded by

Eduardo NallarCopyright:

Available Formats

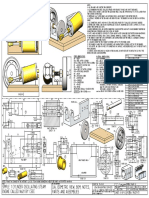

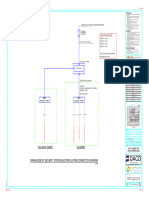

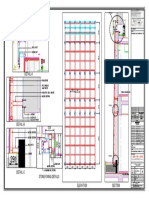

NOTES:

0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE AND SHAFT TOLERANCES.

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE APPROXIMATELY 5% TO 8% LARGER THAN

THE MATCHING TAPPED HOLE.

3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR BOLTS TO BE METRIC FINE (MF)

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE BUILDER CAN MAKE HIS/HER OWN MATERIAL

CHOICE.

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT SHALL BE SILVER/HARD SOLDERED.

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP), UNCOMPRESSED STATE IS APPROX 40% TO 60%

149.5 5.89

LONGER THEN COMPRESSED STATE.

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED AND PARTS CAN BE BONDED TOGETHER BY

USING EITHER HIGH STRENGTH GLUE, EPOXY RESIN, OR SOLDER.

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER SHOULD BE CONSTRUCTED USING NON-FERROUS

OR NON CORROSIVE MATERIAL SUCH AS BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR MONEL.

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED AND THE MODEL IS ASSEMBLED IS ENTIRELY

LEFT TO THE BUILDER/MODEL MAKER.

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE MODEL MAKER.

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED IS ENTIRELY LEFT UP TO THE BUILDER.

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES, WERE DEEMED NECESSARY TO PREVENT PARTS

FROM LOOSENING.

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT HESITATE TO CONTACT ME SO THAT THE

ERRORS/OMISSIONS CAN BE RECTIFIED.

OTHER ABBREVIATIONS MATERIAL ABBREVIATIONS: QTY. PART NUMBER

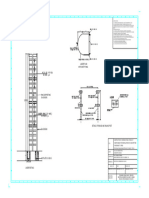

DP = DEEP ALU = ALUMINIUM 1 NO21-01-BASE FRAME

DAA= DRILL AFTER ASSEMBLY BRS = BRASS 2 NO21-02-CRANKSHAFT BEARING BUSH

D&TAA= DRILL AND TAP AFTER ASSEMBLY BRZ = BRONZE OR GUNMETAL (BRZ/GM) 1 NO21-03-CYLINDER PIVOT BUSH

CF = CLOSE FIT (SIZE FOR SIZE) CI = CAST IRON 1 NO21-04-CRANKSHAFT

PF = PRESS FIT CU = COPPER 1 NO21-05-CRANK DISC

PFAA= PRESS FIT AFTER ASSEMBLY GRA = GRAPHITE 1 NO21-06-FLYWHEEL

104.5 4.11

PCD = PITCH CIRCLE DIAMETER MS = MILD STEEL/BRIGHT MILD STEEL 1 NO21-07-CYLINDER

RM = REAM S/S = SILVER STEEL OR STAINLESS STEEL 1 NO21-08-CYLINDER FRONT LID

HEX = HEXACON, 6SIDED SPS = SPRING STEEL 1 NO21-09-CYLINDER REAR LID

CP = COMPRESSED PEEK= POLYETHER ETHER KETONE

KNL = KNURLED SYN = SYNTHETIC MATERIAL SUCH AS VETON, NYLON, 1 NO21-10-CYLINDER PIVOT SHAFT

CSK = COUNTERSINK TEFLON OR RUBBER 1 NO21-11-PIVOT SHAFT SPRING

PL = PLACES IN GENERAL SYNTHETIC MATERIALS SOULD BE 1 NO21-12-PISTON ROD GLAND

DWL= DOWEL ABLE TO WITHSTAND THE HEAT AND 1 NO21-13-PISTON ROD

HESOP=HOLES EQUALLY SPACED ON PCD PRESSURE(S) APPLIED TO THEM. 1 NO21-14-PISTON

SA-n-xxx = SUB ASSEMBL-n-xxx nnn/nnn MEANS THAT EITHER MATERIAL CAN BE USED 1 NO21-15-PISTON ROD BIG END

203.5 8.01 2 NO21-16-INLET-OUTLET PIPE

1 NO21-17-WOOD BASE

47 10 1 NO21-18-CYLINDER LAGGING

3 105 16 1 NO21-M4x9 PAN HEAD SCREW

8CF

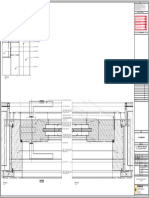

HARD ALU 9 9 13 MS

PF 8 NO21-M4x25 PAN HEAD SCREW

BRS

6

13

2 NO21-M6 NUT

12

6.5

M8

4 2 NO21-M6x25-WOOD SCREW

25

28

DAA

22

OPPOSITE

15

M4 16 45°

1

11PF

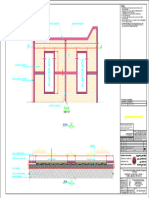

01 04

R1

57

20

4

6.5

6

M8 11CF FACE

32

EQUAL

8

36PCD

19

6

28RM

20

3 4.5

DAA

01 13.5 99

MS

12

12

26

05 SCALE 1:2 SCALE 1:2

6

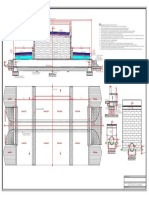

PART SECTION A-A WOOD

66 SCALE 1 : 1.5 55

MS 5 16

39PCD

25 55 C

8PF A 2.5 6 9

5

5.5 7

16

22.5 10 10 22.5

16PF 3 DAA 17

R1 2

.5

20.5

19.5

35 105 35 9

11RM

80

16PF

20

M6

8.6

06 1

43

25

26.5

19.5

10 5 10

21

37.5

5.5 7

R1 B

90° R11 1 32

34.5

34.5

5.5

16

BRS °

02 30

5

5.5 C

52.5PCD

9mm DEEP PILOT HOLES ONLY SCALE 1:2 SECTION C-C

20 20 07

100

25

11

SCALE 1 : 2

HARD ALU

88.5

A

BRS 100.5 33

12 SCALE 1:1.5 30

BRS 16 11

6RM

8PF

CHAMFER

5

B

M8

SECTION B-B

6

03 SCALE 1:2.5 SCALE 1:3 SCALE 1 : 3

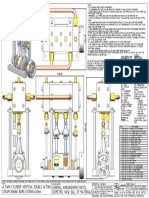

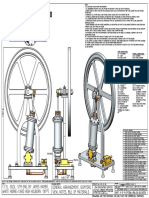

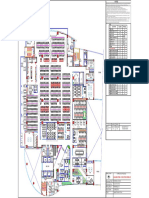

NOTES: FOUND THIS ENGINE ON THE INTERNET. CLASSIC STEAM ENGINE ENGINEERING WEBSITE.DESIGNER AND DRAFTER UNKNOWN.

TITLE DRAWING CONTENTS PROJECT No 09A-20-00 PROJECTION

MODEL SCALE: 1:1

SIMPLE 1 CYLINDER OSCILLATING STEAM G.A, ISOMETRIC VIEW, BOM, NOTES, JDW DRAUGHTING SERVICES DATE

JDWDS DWG SCALE: 1:1 @A3 OR AS SHOWN

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110. JULY-2016 J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

ENGINE CALLED No21 BY CSEE PARTS AND ASSEMBLIES NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 01 OF 02 A3 No: No21-01

You might also like

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- Engine Called No21 by Csee Simple 1 Cylinder Oscillating Steam Parts and Assemblies G.A, Isometric View, Bom, NotesDocument2 pagesEngine Called No21 by Csee Simple 1 Cylinder Oscillating Steam Parts and Assemblies G.A, Isometric View, Bom, NotesBryan OlayaNo ratings yet

- Isometric View: Dymac GlobalDocument2 pagesIsometric View: Dymac GlobalMaarij AnjumNo ratings yet

- Concrete LatheDocument41 pagesConcrete Latherandom55No ratings yet

- Steel For Mechanical Work at High Velocity With Removal of ChipsDocument6 pagesSteel For Mechanical Work at High Velocity With Removal of ChipsSuresh ShindeNo ratings yet

- Simlpe Oscillating Steam MachineDocument2 pagesSimlpe Oscillating Steam Machinehamzah40No ratings yet

- Simple 1 Cylinder OscillatingDocument2 pagesSimple 1 Cylinder OscillatingFaiq ZulfiarNo ratings yet

- 09C 38 00 A3 Sheet 01Document1 page09C 38 00 A3 Sheet 01udataashutoshNo ratings yet

- General Arrangement, Isomteric White Horne-Yard High Holburn (18??) View, Notes, Bill of Materials 1 Cyl. Oscil. STM Eng. by James HamerDocument4 pagesGeneral Arrangement, Isomteric White Horne-Yard High Holburn (18??) View, Notes, Bill of Materials 1 Cyl. Oscil. STM Eng. by James Hamertươi nguyễnNo ratings yet

- Crankless SteamDocument3 pagesCrankless Steamhamzahumo45No ratings yet

- Engine With Spool Valve Oiler and Reverser General Arrangement and Notes 2 Cylinder Vertical Marine Type SteamDocument4 pagesEngine With Spool Valve Oiler and Reverser General Arrangement and Notes 2 Cylinder Vertical Marine Type SteamGiuliana Elizabeth CáceresNo ratings yet

- Simple Vertical Engine 1Document4 pagesSimple Vertical Engine 1Orlando Rojas PintoNo ratings yet

- Grab Handholds: Sectional Plan Top PlanDocument1 pageGrab Handholds: Sectional Plan Top PlanAbdelmoneimNo ratings yet

- تغذية الدور العلويDocument1 pageتغذية الدور العلويAnonymous qOBFvINo ratings yet

- Typical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionDocument1 pageTypical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionCedrixe MadridNo ratings yet

- Parents Bath Room Door D9 SectionsDocument1 pageParents Bath Room Door D9 Sectionskumaarcivil97No ratings yet

- Salebuild: Team Architects (I) Pvt. LTDDocument1 pageSalebuild: Team Architects (I) Pvt. LTDNavdeep GopamwarNo ratings yet

- 4a405 Bathroom Detail-2Document1 page4a405 Bathroom Detail-2Bismo AnggoroNo ratings yet

- Lighting & Convenience Outlet Layout: General NotesDocument1 pageLighting & Convenience Outlet Layout: General NotesJayvee Latosa Dividina100% (1)

- Wh07-Cctv-Ups-Xx0001 - 001001 Rev-00Document1 pageWh07-Cctv-Ups-Xx0001 - 001001 Rev-00engrabbas75No ratings yet

- SERVICE GATE Detail - 23-03-2023Document1 pageSERVICE GATE Detail - 23-03-2023AmulyaRajbharNo ratings yet

- Parents Bath Room Door D9 DetailsDocument1 pageParents Bath Room Door D9 Detailskumaarcivil97No ratings yet

- 4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesDocument2 pages4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesOrlando Rojas PintoNo ratings yet

- Beam Layout & Schedule of ReinforcementDocument1 pageBeam Layout & Schedule of ReinforcementChetan B ArkasaliNo ratings yet

- Distribution - SS Rev.7A AP-2023.07.06Document12 pagesDistribution - SS Rev.7A AP-2023.07.06sundareee96No ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- IN00-CCTV-NC-XX0002-001001 REV-00-Layout2Document1 pageIN00-CCTV-NC-XX0002-001001 REV-00-Layout2engrabbas75No ratings yet

- DRG - SECTION OF CABLE TRENCHDocument1 pageDRG - SECTION OF CABLE TRENCHAmarjit KulkarniNo ratings yet

- HPC VupDocument1 pageHPC VupShivam SharmaNo ratings yet

- General Notes:: Footing PlanDocument1 pageGeneral Notes:: Footing PlanBetinol RachelNo ratings yet

- Page 16Document1 pagePage 16barcoma.mylene.nNo ratings yet

- CondenserDocument1 pageCondenserKrizza Joyce AblolaNo ratings yet

- ElectricalDocument1 pageElectricalMrs XNo ratings yet

- Plumbing Notes:: Prepared By: P-03Document1 pagePlumbing Notes:: Prepared By: P-03Francess Leanne RamosNo ratings yet

- PDW-TB-487 Paved Area Detail For A-Type Store at Kotri-Pdw-Tv-487 Iso A3Document1 pagePDW-TB-487 Paved Area Detail For A-Type Store at Kotri-Pdw-Tv-487 Iso A3ihsan ul haqNo ratings yet

- 1002016-0100-DRG-CC-0003 Typical Details Pipe Marker DetailDocument1 page1002016-0100-DRG-CC-0003 Typical Details Pipe Marker Detailhexiaogang167No ratings yet

- 85 Welwyn Ave Schematic 01052022Document2 pages85 Welwyn Ave Schematic 01052022Joseph MunawarNo ratings yet

- Preliminary: Lineshop LineshopDocument1 pagePreliminary: Lineshop LineshopDarren LaiNo ratings yet

- 85 Welwyn Ave Concept 26022022Document1 page85 Welwyn Ave Concept 26022022Joseph MunawarNo ratings yet

- Gis 2315000007 Civil 1Document1 pageGis 2315000007 Civil 1aelsheikh834No ratings yet

- Water Feature DrawingDocument1 pageWater Feature DrawingSiva RajanNo ratings yet

- Shop Drawing: Band Stamped Concrete Pedestrian PrecintDocument1 pageShop Drawing: Band Stamped Concrete Pedestrian Precinta.shwekhNo ratings yet

- KPC Medical College & Hospital: 1F, Raja Subodh Chandra Mullick Road, Jadavpur, Kolkata, West Bengal 700 032Document1 pageKPC Medical College & Hospital: 1F, Raja Subodh Chandra Mullick Road, Jadavpur, Kolkata, West Bengal 700 032Kausik DewanNo ratings yet

- Schedule of Loads: To Service Entrance 2WIRE, 1 PHASE, 230V, 60 HZ FrequencyDocument1 pageSchedule of Loads: To Service Entrance 2WIRE, 1 PHASE, 230V, 60 HZ FrequencyVincent FilomenaNo ratings yet

- Pdd-101786-203722-Lay-206-Rev - 2Document3 pagesPdd-101786-203722-Lay-206-Rev - 2A ZamanNo ratings yet

- Mace Ar 10 B1 02Document1 pageMace Ar 10 B1 02Syead OwaisNo ratings yet

- Drawing Sheet 4Document1 pageDrawing Sheet 4Kunal SharmaNo ratings yet

- General Notes: Single Line Diagram EDocument1 pageGeneral Notes: Single Line Diagram EJeanelyn DioNo ratings yet

- CIRCULAR WATER TANK DESIGN-Layout1 AkhilDocument1 pageCIRCULAR WATER TANK DESIGN-Layout1 AkhilVENKAT KALYANNo ratings yet

- First Floor Plan: Ms Pergola Covered With 12Mm THK Poly Carbonate SheetDocument1 pageFirst Floor Plan: Ms Pergola Covered With 12Mm THK Poly Carbonate SheetradhapunnaNo ratings yet

- VKG Akhnoor Project DrawingDocument1 pageVKG Akhnoor Project DrawingNikhil Dwivedi Seismoflex Private LimitedNo ratings yet

- Gate ElevationDocument1 pageGate Elevationno oneNo ratings yet

- WH07 NVR GN XX0001 00001 Layout1Document1 pageWH07 NVR GN XX0001 00001 Layout1engrabbas75No ratings yet

- QP10-U-703 Rev0 Typical Line MarkerDocument1 pageQP10-U-703 Rev0 Typical Line MarkernawajhaNo ratings yet

- Plumbing1 ModelDocument1 pagePlumbing1 ModelMarvin VinaraoNo ratings yet

- Plumbing1 ModelDocument1 pagePlumbing1 ModelMarvin VinaraoNo ratings yet

- C200-Roadworks Notes and Details-C240Document1 pageC200-Roadworks Notes and Details-C240Don WangNo ratings yet

- P3Document1 pageP3CUBE ProjectsNo ratings yet

- Specifications: LegendsDocument1 pageSpecifications: LegendsMary Joy AzonNo ratings yet

- 2023-07-18 B159 STR 102 GFC R0Document1 page2023-07-18 B159 STR 102 GFC R0arjunNo ratings yet

- Structural IfpDocument4 pagesStructural IfpDanny NguyenNo ratings yet

- 1473a-Ir-A0-0001 - General Notes and Legends Irrigation LayoutDocument1 page1473a-Ir-A0-0001 - General Notes and Legends Irrigation LayoutMohsin ShaikhNo ratings yet

- No 21 Oscillator Rev 08 PDFDocument16 pagesNo 21 Oscillator Rev 08 PDFEduardo NallarNo ratings yet

- Fmrij 04 00058Document6 pagesFmrij 04 00058Eduardo NallarNo ratings yet

- High-Performance Airfoil With Low Reynolds-Number Dependence On Aerodynamic CharacteristicsDocument5 pagesHigh-Performance Airfoil With Low Reynolds-Number Dependence On Aerodynamic CharacteristicsEduardo NallarNo ratings yet

- Fmrij 04 00056Document5 pagesFmrij 04 00056Eduardo NallarNo ratings yet

- AIRBUS A320/A321: Normal ChecklistDocument3 pagesAIRBUS A320/A321: Normal ChecklistEduardo NallarNo ratings yet

- Metallurgy - Question BankDocument12 pagesMetallurgy - Question BankSayantan Chatterjee100% (1)

- Broggi Flatware and HollowwareDocument342 pagesBroggi Flatware and HollowwareTabletopJournalNo ratings yet

- Ch.2 HWDocument5 pagesCh.2 HWNewshaSajadiNo ratings yet

- Trisoxalatoaluminato PDFDocument1 pageTrisoxalatoaluminato PDFFelipe VilchesNo ratings yet

- Astm 666Document7 pagesAstm 666JOSEPH REFUERZONo ratings yet

- SAGA System Quick ReferenceDocument14 pagesSAGA System Quick ReferenceMichael Soucy100% (1)

- b205g - MS Plus - 201601Document44 pagesb205g - MS Plus - 201601Alexandre SouzaNo ratings yet

- Ar002Document28 pagesAr002Pedro Tiago Batista CoelhoNo ratings yet

- TolyltriazoleDocument4 pagesTolyltriazolemnasiroleslamiNo ratings yet

- Induction CookingDocument9 pagesInduction Cookingtechzones100% (1)

- Lorch, MX350 EU, Operation ManualDocument31 pagesLorch, MX350 EU, Operation ManualdinescNo ratings yet

- Technical Training Guide LinconDocument48 pagesTechnical Training Guide LinconiwantfreeNo ratings yet

- 75KW Continuous Mesh Belt Quenching Furnace - Huarui, Sally WuDocument3 pages75KW Continuous Mesh Belt Quenching Furnace - Huarui, Sally WuMohsin Ul Amin KhanNo ratings yet

- Bombas Goulds 4NS Aguas ResidualesDocument6 pagesBombas Goulds 4NS Aguas ResidualescamatuteNo ratings yet

- Astm B 367 - 09Document6 pagesAstm B 367 - 09taker6No ratings yet

- IanDickie Euroflo EU Series 2 2013 PDFDocument11 pagesIanDickie Euroflo EU Series 2 2013 PDFduongpnNo ratings yet

- Copper Alloy Spec SheetsDocument1 pageCopper Alloy Spec SheetsvinodmysoreNo ratings yet

- EIL A6 Piping Vendor ListDocument16 pagesEIL A6 Piping Vendor Listdhan210100% (2)

- Astm A747 Standard Specification For Steel Castings, Stainless, Precipitation HardeningDocument4 pagesAstm A747 Standard Specification For Steel Castings, Stainless, Precipitation HardeningLuiz Henrique V Souza50% (2)

- Igcse Chemistry SolutionsDocument6 pagesIgcse Chemistry Solutionspreeti.2405No ratings yet

- Partially Melted Zone in Aluminum Welds - Liquation Mechanism and Directional SolidificationDocument8 pagesPartially Melted Zone in Aluminum Welds - Liquation Mechanism and Directional SolidificationtazzorroNo ratings yet

- BridgesDocument64 pagesBridgesrivergodNo ratings yet

- Logging Masts - Lightweight AluminumDocument2 pagesLogging Masts - Lightweight AluminumRio de MarioNo ratings yet

- Unit 5 Organic Chemistry ReactionsDocument9 pagesUnit 5 Organic Chemistry ReactionsRobbing_Hood100% (1)

- Ec 1110-2-288 Standard Designs For Lock Dam and Waterway SignsDocument50 pagesEc 1110-2-288 Standard Designs For Lock Dam and Waterway Signssonjo_suaNo ratings yet

- Galvanizing High Strength Bolts - Portland BoltDocument18 pagesGalvanizing High Strength Bolts - Portland BoltLavanyan SatchithananthanNo ratings yet