Professional Documents

Culture Documents

OMM-Unit 5 Sess 2 - Modern Concepts-S

Uploaded by

Onkar Shinde0 ratings0% found this document useful (0 votes)

6 views10 pagesOriginal Title

OMM-Unit 5 Sess 2- Modern Concepts-s

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views10 pagesOMM-Unit 5 Sess 2 - Modern Concepts-S

Uploaded by

Onkar ShindeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

UNIT 5

Modern Concepts in Operations Management

POKA YOKE

(MISTAKE-PROOFING / ERROR-PROOFING)

• Tool or mechanism that keeps a person from being able to perform

an action in an incorrect manner

• Decreases the opportunities for a failure to occur

• Developed as a key component of the Toyota Production System

(TPS)

• Avoid waste by eliminating or minimizing quality mistakes that lead

to rework as well as eliminating potential safety issues

POKA YOKE PROCEDURE

• Obtain or create a flowchart of the process. Review each step, thinking

about where and when human errors are likely to occur.

• For each error, think of potential ways to make it impossible for the error

to occur

• Choose the best mistake-proofing method or device for each error.

• Test it, then implement it.

• Three kinds of inspection methods provide rapid feedback:

• Successive inspection is done at the next step of the process by the next

worker

• Self-inspection means workers check their own work immediately after

doing it

• Source inspection checks, before the process step takes place, that

conditions are correct. Often it’s automatic and keeps the process from

proceeding until conditions are right

5S

• Methodology that results in a workplace that is clean, uncluttered, safe,

and well organized to help reduce waste and optimize productivity

• 5S

• Seiri - To separate needed tools, parts, and instructions from

unneeded materials and to remove the unneeded ones

• Seiton - To neatly arrange and identify parts and tools for ease of

use

• Seiso - To conduct a cleanup campaign

• Seiketsu - To conduct seiri, seiton, and seiso daily to maintain a

workplace in perfect condition

• Shitsuke - To form the habit of always following the first four S’s

5S

Japanes Translated English Definition

e

Seiri organize sort Eliminate whatever is not needed by separating

needed tools, parts, and instructions from

unneeded materials

Seiton orderliness set in order Organize whatever remains by neatly arranging

and identifying parts and tools for ease of use

Seiso cleanliness shine Clean the work area by conducting a cleanup

campaign

Seiketsu standardiz standardize Schedule regular cleaning and maintenance

e by conducting seiri, seiton, and seiso daily

Shitsuke discipline sustain Make 5S a way of life by forming the habit of

always following the first four S’s

3M’S

• Waste (Muda)- an activity which does not add value

to the product

• Three main types of waste

• Mura (unevenness in production volume)

• Muri (overburden ie. overloading equipment,

facility or people resources beyond its capacity)

• Muda (waste)

TOYOTA WASTES (TAIICHI OHNO)

MUDA

KAIZEN

• Change to become good or better

• Small improvements can yield big results

• Father of Kaizen, Masaaki Imai globally introduced kaizen as a systematic

management methodology in Kaizen: The Key to Japan’s Competitive

Success (1986)

• Continuous Improvement

• Kaizen is process of continuous improvements in small increments that make

process more efficient, effective and adaptable

You might also like

- 5S - Good HousekeepingDocument39 pages5S - Good Housekeepingrslapena100% (10)

- The 5s of Ideal HousekeepingDocument16 pagesThe 5s of Ideal HousekeepingKarenSantiago-VillanuevaNo ratings yet

- 5S and Productivity: An Organized Approach To Increase ProductivityDocument34 pages5S and Productivity: An Organized Approach To Increase ProductivityJove RevocalNo ratings yet

- PapelDocument8 pagesPapelignacio galindoNo ratings yet

- Productivity Improvement Tools 7TH MECH RAJDocument34 pagesProductivity Improvement Tools 7TH MECH RAJRaj VadhavanaNo ratings yet

- 5S Good HousekeepingDocument27 pages5S Good HousekeepingWilbur Grageda100% (1)

- 5S Workplace ManagementDocument9 pages5S Workplace Managementnsk79in@gmail.comNo ratings yet

- Apply 5s ProcedureDocument35 pagesApply 5s ProcedureBiniam Hunegnaw BitewNo ratings yet

- 5S Training and ImplementationDocument66 pages5S Training and ImplementationLlehk FranciscoNo ratings yet

- rh436 PDF 141215000247 Conversion Gate01 PDFDocument357 pagesrh436 PDF 141215000247 Conversion Gate01 PDFStephane FlotatNo ratings yet

- Hand Outs For 5SDocument34 pagesHand Outs For 5ShithaniNo ratings yet

- Wacker SilconeDocument16 pagesWacker SilconeWangYunNo ratings yet

- 5S PPT by ShaileshDocument42 pages5S PPT by ShaileshschrongdigerNo ratings yet

- 01 LC Vibratory Sifter 01Document2 pages01 LC Vibratory Sifter 01Ravi YadavNo ratings yet

- 5S Poka Yoke KaizenDocument20 pages5S Poka Yoke Kaizenprateekbapna90No ratings yet

- 5S Training and Its Implementation PDFDocument66 pages5S Training and Its Implementation PDFdlishNo ratings yet

- 5S Is A Defined Visual Simple Method For Maintaining The Workplace in The Optimum Condition and Eliminate WasteDocument1 page5S Is A Defined Visual Simple Method For Maintaining The Workplace in The Optimum Condition and Eliminate Wastejplarazi100% (1)

- 5S - House KeepingDocument20 pages5S - House KeepingRawinder100% (2)

- Grade 10 12 Revision Notes Kitwe District Education Board Civic Education 2030Document119 pagesGrade 10 12 Revision Notes Kitwe District Education Board Civic Education 2030Betsheba Mwila67% (3)

- 6 S PresentationDocument16 pages6 S PresentationVeeramuthu Sundararaju100% (1)

- 5 SDocument34 pages5 SRashmi ChoudharyNo ratings yet

- 5S From DOLE BookDocument34 pages5S From DOLE BookGene RodriguezNo ratings yet

- Dunning Objects ListsDocument1 pageDunning Objects ListsSachin SinghNo ratings yet

- 5S MethodologyDocument15 pages5S MethodologyNishank PandeyNo ratings yet

- 5 SDocument22 pages5 SAnkita RajNo ratings yet

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsFrom Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Housekeeping: Covered Topics: Housekeeping 7 Types of Waste 5S System ProcedureDocument31 pagesHousekeeping: Covered Topics: Housekeeping 7 Types of Waste 5S System ProcedureMaykaMidreliDeandraLigutomNo ratings yet

- 5S (Methodology)Document9 pages5S (Methodology)HARSHAVISALI DNo ratings yet

- BSP 5 SpokayokekaizenDocument20 pagesBSP 5 SpokayokekaizenSBNo ratings yet

- 5S - Workplace Management ToolDocument23 pages5S - Workplace Management ToolShiv PandyaNo ratings yet

- 5S Concepts & Quality Control: Presented By: K Arun Kumar K Raj Kamal V ThiyagarajanDocument18 pages5S Concepts & Quality Control: Presented By: K Arun Kumar K Raj Kamal V ThiyagarajanraazsayzNo ratings yet

- The 5S Philosophy / The Art of Good HousekeepingDocument16 pagesThe 5S Philosophy / The Art of Good HousekeepingLoreen Kaye GaboNo ratings yet

- 5'S Model: - Prepared By: Sumeet K.CDocument24 pages5'S Model: - Prepared By: Sumeet K.Csumeet kcNo ratings yet

- 5S Is A Basic Fundamental, Systematic Approach For Productivity, Quality and Safety Improvement in All Types of BusinessDocument16 pages5S Is A Basic Fundamental, Systematic Approach For Productivity, Quality and Safety Improvement in All Types of Businesscute_angel_10No ratings yet

- 5S: Japanese Methodology: Presented By: Aguila, Edelyn A. Banastas, Daniel Mark M. Belo, Veronica BDocument36 pages5S: Japanese Methodology: Presented By: Aguila, Edelyn A. Banastas, Daniel Mark M. Belo, Veronica BNakanakanaknakNo ratings yet

- What Is 5Document4 pagesWhat Is 5louieoren berondoNo ratings yet

- Introduction To 5SDocument16 pagesIntroduction To 5SJyruss RegaladoNo ratings yet

- Asq What Are The Five SDocument4 pagesAsq What Are The Five SCloud RedfieldNo ratings yet

- Chapter 4 TQMDocument72 pagesChapter 4 TQMCarlo Gojo Cruz HalasanNo ratings yet

- 5'SDocument13 pages5'SSharny Lee BasarteNo ratings yet

- A Work Place Organization Method: Deepak Singh Manager Quality AssuranceDocument21 pagesA Work Place Organization Method: Deepak Singh Manager Quality AssuranceDEEPAK SINGH SANGWAN100% (1)

- LESSON 2-Occupational Health and SafetyDocument6 pagesLESSON 2-Occupational Health and Safetymelanielampera17No ratings yet

- Unit II TQM PRINCIPLES - 7.1.15Document68 pagesUnit II TQM PRINCIPLES - 7.1.15p ganeshNo ratings yet

- What Is 5S PDFDocument0 pagesWhat Is 5S PDFSURJIT SINGHNo ratings yet

- 5S Kaizen Pokayoke: Business Structures and Processes PresentationDocument20 pages5S Kaizen Pokayoke: Business Structures and Processes PresentationSatya KumarNo ratings yet

- KAIZENDocument8 pagesKAIZENurbsafeNo ratings yet

- Pinakin Puranik Pg-11-102: Presented byDocument24 pagesPinakin Puranik Pg-11-102: Presented byPinakin PuranikNo ratings yet

- Om 3rd UnitDocument5 pagesOm 3rd Unit01fe20mam004No ratings yet

- 5 S Standard1Document5 pages5 S Standard1shukladevendrakumar8No ratings yet

- Om2 5Document22 pagesOm2 5achal sahareNo ratings yet

- 5'S of Philosophy: Sort (seiri 整理)Document4 pages5'S of Philosophy: Sort (seiri 整理)DonNo ratings yet

- 5 S May 2023Document46 pages5 S May 2023VICKY KUMARNo ratings yet

- Lean ManufacturingDocument22 pagesLean ManufacturingMd Hafizullah SabbirNo ratings yet

- 5s Lean ToolDocument11 pages5s Lean ToolRitu RajNo ratings yet

- Continuousprocessimprovement 150928231546 Lva1 App6892Document33 pagesContinuousprocessimprovement 150928231546 Lva1 App6892Eunize Escalona MagsinoNo ratings yet

- Team Spirit.: 5S Gives You A Workplace Which Is Clean,, Safe, AndorganizedDocument6 pagesTeam Spirit.: 5S Gives You A Workplace Which Is Clean,, Safe, AndorganizedPuja PrasadNo ratings yet

- Application of 5sDocument4 pagesApplication of 5sPerez Mark JoshuaNo ratings yet

- Good HousekeepingDocument12 pagesGood HousekeepingShane Anne Parcarey NambongNo ratings yet

- Maintenance Methods and SystemsDocument6 pagesMaintenance Methods and Systemsrocelin padonNo ratings yet

- Housekeeping Group 1Document38 pagesHousekeeping Group 1aspillagaarnelNo ratings yet

- What Is 5S?: 5S Implementation in Welding WorkshopDocument1 pageWhat Is 5S?: 5S Implementation in Welding WorkshopNell Sabas AdolfoNo ratings yet

- What Are The Five S'S (5S)Document2 pagesWhat Are The Five S'S (5S)NEERAJNo ratings yet

- 5S DetailsDocument10 pages5S DetailsHemalakshmiNo ratings yet

- Team Spirit.: 5S Gives You A Workplace Which Is Clean,, Safe, AndorganizedDocument6 pagesTeam Spirit.: 5S Gives You A Workplace Which Is Clean,, Safe, AndorganizedPuja PrasadNo ratings yet

- (A) Production Management Introduction: History, EvolutionDocument15 pages(A) Production Management Introduction: History, EvolutionOnkar ShindeNo ratings yet

- Script 29 June 2023Document6 pagesScript 29 June 2023Onkar ShindeNo ratings yet

- Social Research Methods: Mr. Onkar ShindeDocument24 pagesSocial Research Methods: Mr. Onkar ShindeOnkar ShindeNo ratings yet

- Eligibility - AffidavitDocument1 pageEligibility - AffidavitOnkar ShindeNo ratings yet

- Blank Political Map of IndiaDocument1 pageBlank Political Map of IndiaOnkar ShindeNo ratings yet

- Research PeparDocument104 pagesResearch PeparOnkar ShindeNo ratings yet

- Labour Law MCQDocument42 pagesLabour Law MCQOnkar ShindeNo ratings yet

- MM2325366Document3 pagesMM2325366Onkar ShindeNo ratings yet

- Second Semester Term End Examination Schedule Batch (2023-25)Document1 pageSecond Semester Term End Examination Schedule Batch (2023-25)Onkar ShindeNo ratings yet

- Script 29 June 2023Document6 pagesScript 29 June 2023Onkar ShindeNo ratings yet

- PM & HRDDocument1 pagePM & HRDOnkar ShindeNo ratings yet

- FAA Byju MCQDocument19 pagesFAA Byju MCQOnkar ShindeNo ratings yet

- Balaji Institute of Modern ManagementDocument3 pagesBalaji Institute of Modern ManagementOnkar ShindeNo ratings yet

- Unit 1 - Topic 1st Introduction To Business EconomicsDocument16 pagesUnit 1 - Topic 1st Introduction To Business EconomicsOnkar ShindeNo ratings yet

- Business Research Methods MCQDocument9 pagesBusiness Research Methods MCQOnkar ShindeNo ratings yet

- Mising Tile SyndromDocument2 pagesMising Tile SyndromOnkar ShindeNo ratings yet

- VedantaDocument2 pagesVedantaOnkar ShindeNo ratings yet

- Trade Union OverviewDocument45 pagesTrade Union OverviewOnkar ShindeNo ratings yet

- NumericalsDocument6 pagesNumericalsOnkar ShindeNo ratings yet

- 3 - Employer AssociationsDocument6 pages3 - Employer AssociationsOnkar ShindeNo ratings yet

- Presentation1 5Document11 pagesPresentation1 5Onkar ShindeNo ratings yet

- 2 Way ANOVA (With Replication)Document1 page2 Way ANOVA (With Replication)Onkar ShindeNo ratings yet

- Human Computer Interaction Cognitive ModelsDocument12 pagesHuman Computer Interaction Cognitive Modelsvicky arooraNo ratings yet

- Electromagnetic and Electrostatic Transmission-Line Parameters by Digital ComputerDocument10 pagesElectromagnetic and Electrostatic Transmission-Line Parameters by Digital Computermrjack1No ratings yet

- Bill Presentment Architecture in Oracle ReceivablesDocument42 pagesBill Presentment Architecture in Oracle Receivablessrees_15No ratings yet

- K-Means in Python - SolutionDocument6 pagesK-Means in Python - SolutionRodrigo ViolanteNo ratings yet

- AniscalMA - Learning Activity 4.1 4.3Document7 pagesAniscalMA - Learning Activity 4.1 4.3HeliNo ratings yet

- MVDKerala - RT Office PH No.sDocument2 pagesMVDKerala - RT Office PH No.sVidyaVasudevanNo ratings yet

- ASSESSMENT IN LEARNING 2 MODULE (Finals) With POSTTESTDocument63 pagesASSESSMENT IN LEARNING 2 MODULE (Finals) With POSTTESTcreqyaqaNo ratings yet

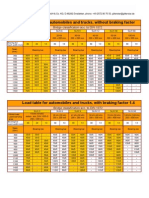

- 9 Gitterstar LoadTable Autom TrucksDocument1 page9 Gitterstar LoadTable Autom TrucksSnaz_nedainNo ratings yet

- Multimedia Project Team RolesDocument16 pagesMultimedia Project Team RolesrinaNo ratings yet

- LM123/LM223 LM323: Three-Terminal 3A-5V Positive Voltage RegulatorsDocument8 pagesLM123/LM223 LM323: Three-Terminal 3A-5V Positive Voltage Regulatorscarrasquel0No ratings yet

- RMC No. 124-2020Document6 pagesRMC No. 124-2020Raine Buenaventura-Eleazar100% (2)

- Paper IndustryDocument24 pagesPaper IndustryJonas ParagasNo ratings yet

- Lab Report of Data Structure Lab Course Code: CSE-206: U N I V E R S I T YDocument7 pagesLab Report of Data Structure Lab Course Code: CSE-206: U N I V E R S I T Yabdul mannanNo ratings yet

- Class 12 Business Studies Chapter 12 MCQ'sDocument41 pagesClass 12 Business Studies Chapter 12 MCQ'sPUTTU GURU PRASAD SENGUNTHA MUDALIARNo ratings yet

- Kushagra Sharma Resume 1Document1 pageKushagra Sharma Resume 1sehaj BabraNo ratings yet

- Campus Security AwarenessDocument19 pagesCampus Security AwarenessMiyangNo ratings yet

- PACER US Vs Adam Hageman Complaint - Nov 12 2020Document5 pagesPACER US Vs Adam Hageman Complaint - Nov 12 2020jpeppardNo ratings yet

- Biofuels Industry ReportDocument2 pagesBiofuels Industry ReportNiravNo ratings yet

- Bevco Everlast Chair Installation GuideDocument1 pageBevco Everlast Chair Installation GuideLuis OntiverosNo ratings yet

- 17CS754 San Notes Svit Module 3Document30 pages17CS754 San Notes Svit Module 3Jacob DragonetteNo ratings yet

- App 1238 PDFDocument3 pagesApp 1238 PDFIBRNo ratings yet

- Diliman, Quezon City 1101 Philippines: College of Home EconomicsDocument2 pagesDiliman, Quezon City 1101 Philippines: College of Home EconomicsAmina Rose AlghamdiNo ratings yet

- SECTION 2.5:: Special Services For Construction ProjectsDocument7 pagesSECTION 2.5:: Special Services For Construction ProjectsHeart DaclitanNo ratings yet

- CWTSDocument2 pagesCWTSShakira Isabel ArtuzNo ratings yet