Professional Documents

Culture Documents

5.6 Steel Column

5.6 Steel Column

Uploaded by

Philip ChanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.6 Steel Column

5.6 Steel Column

Uploaded by

Philip ChanCopyright:

Available Formats

Page 1

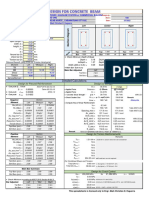

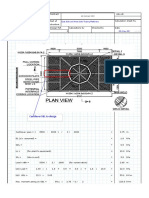

Design for 200x150x16 mm Rectangular Hollow Section

A) Design Data

Member Mark: MC1 (1/F) L = 2.90 m

Steel Grade: S355 py = 355 MPa Table 3.2

Member Size: 200x150x16 mm Rectangular Hollow Section

Sectional properties:

4 3

Wt = 79.88 kg/m Ix = 5337 cm Zx = 534 cm B

4 3

D = 200 mm Iy = 3325 cm Zy = 443 cm

3

B = 150 mm rx = 7.24 cm Sx = 667 cm

3

t = 16 mm ry = 5.72 cm Sy = 540 cm

4

b = 102 mm u = 0.9 J = 6117 cm

2 d D

d = 152 mm x = 13 A = 102 cm

-1

b/t = 6.38 Hp/A = 70 m

d/t = 9.5

b

B) Ultimate Design Load

Shear Force V = 10.00 kN

Bending Moment (Major Axis) Mx = 10.00 kNm

Bending Moment (Minor Axis) My = 5.00 kNm

Tension Force Ft = 0.00 kN

Compressive Force Fc = 1050.00 kN

C) Section Classification

ε = 275 / py = 0.88

b/t = 6.38 < 28 ε

d/t = 9.5 < 64 ε

< 70 ε

∴ Section is Class 1 plastic Table 7.1

∴ Not required to check for shear buckling Clause 8.4.6

D) Shear Capacity Clause 8.2.1

Shear area Av = 2td = 4864.00 mm²

py Av eq. 8.1

Shear capacity Vc = = 996.92 kN

3

> 10.00 kN O.K.

0.6 Vc = 598.15 kN

∴ Low shear condition

E) Moment Capacity Clause 8.2.2

Moment capacity Mcx = py x smaller of ( S ,1.2 x Z) = 227.37 kNm eq. 8.2

> 10.00 kNm O.K.

Mcy = py x smaller of ( S ,1.2 x Z) = 188.85 kNm eq. 8.2

> 5.00 kN O.K.

F) Moment resistance to later-torsional buckling Clause 8.3.5

mLT = 1.00 Table 8.4 a&b

Effective length for lateral-torsional buckling LE = 1.00 L = 2.9 m Clause 8.3.4

λ = LE / r y = 50.70 eq. 8.26

Slenderness factor v = 1 / (1+0.05( λ / x )2)0.25 = 0.861 eq. 8.27

βw = 1

Equivalent slenderness λLT = u v λ βw = 39.27 eq. 8.25

Limiting slenderness λL0 = 0.4 π2 E / py = 30.20 eq. A8.10

αLT = 7.0 eq. A8.11

Perry factor ηLT = αLT (λLT - λL0 ) / 1000 = 0.064 eq. A8.5

π2 E

Elastic Critical Bending Stress pE = = 1311.905 MPa eq. A8.3

λ2LT

py + (ηLT + 1)pE

Φ LT = = 875.1161 MPa eq. A8.4

2

pE p y

Bending Buckling Strength pb = = 327.30 MPa eq. A8.2

ΦLT + (Φ2LT - pEpy)

Buckling Resistance Moment Mb = pb x S = 218.44 kNm eq. 8.21

Laterial-torsional buckling need not to be checked, RHS with λ < 670ε² (Table 8.2) > 0.00 kNm O.K.

Page 2

G) Tension Capacity Clause 8.6.1

Effective area Ae = 10176 mm² Clause 9.3.4.4.

Tension capacity Pt = py Ae = 3612.48 kN

> 0.00 kN O.K.

H) Compressive resistance Clause 8.7.5

Effective length LE = 1.00 L = 2.9 m Table 8.6

λ = LE / r y = 50.70

For Hot - finished structural hollow section Buckling curves: a) Table 8.7

α = 2

Limiting slenderness λ0 = 0.2 π2 E / py = 15.10 eq. 8.35

Perry factor η = α (λ - λ0 ) / 1000 = 0.071 eq. A8.34

π2 E

Euler Strength pE = 2 = 787.1358 MPa eq. A8.32

λ

py + (η + 1)pE

Φc = = 599.0903 MPa eq. A8.33

2

pE p y

Compressive Buckling Strength pc = = 317.18 MPa eq. A8.31

Φc + (Φ2c - pEpy)

Compressive capacity Pc = Ag Pc = 3227.58 kN eq. 8.73

> 1050.00 kN O.K.

I) Cross-section capacity (Tension Members under combined axial Force and moments) Clause 8.8

Ft Mx My 0 10 5

+ + = + + = 0.07 eq. 8.77

Pt Mcx Mcy 3612 227 189

< 1 O.K.

J) Cross-section capacity (Compression Members under combined axial Force and moments) Clause 8.9.1

Fc Mx My 1050 10 5

+ + = + + = 0.36 eq. 8.78

Ag Py Mcx Mcy 3612 227 189

< 1 O.K.

K) Cross-section capacity (Member buckling resistance) Clause 8.9.2

Fc mLT Mx MLT My 1050 10 5

+ + = + + = 0.40 eq. 8.81

Pcy Mcx Mcy 3228 227 189

< 1 O.K.

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Discrete Cosine Transform: Algorithms, Advantages, ApplicationsFrom EverandDiscrete Cosine Transform: Algorithms, Advantages, ApplicationsNo ratings yet

- 1997 - Cone Penetration Testing in Geotechnical Practice - LunneDocument332 pages1997 - Cone Penetration Testing in Geotechnical Practice - LunneRenaud Martin-EnglishNo ratings yet

- 2.0 Part 2 Design Working Platform Type A - SHEET NO.2-50 - M4 Channel CheckDocument2 pages2.0 Part 2 Design Working Platform Type A - SHEET NO.2-50 - M4 Channel CheckBQ HeNo ratings yet

- 2.0 Part 2 Design Working Platform Type A - SHEET NO.2-50 - M7 Channel CheckDocument2 pages2.0 Part 2 Design Working Platform Type A - SHEET NO.2-50 - M7 Channel CheckBQ HeNo ratings yet

- 2.0 Part 2 Design Working Platform Type A - SHEET NO.2-50 - M7a Channel CheckDocument2 pages2.0 Part 2 Design Working Platform Type A - SHEET NO.2-50 - M7a Channel CheckBQ HeNo ratings yet

- Check BeamDocument3 pagesCheck BeamZULFIKAR AZANNo ratings yet

- ColumnsDocument1 pageColumnsyusuf_jtNo ratings yet

- Scaffold Tube CapacityDocument2 pagesScaffold Tube CapacityVignesh Ramalingam100% (1)

- Design of Member : Strut (Layer 1)Document8 pagesDesign of Member : Strut (Layer 1)freddyNo ratings yet

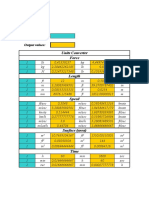

- Input Values: Output Values:: Units Converter ForceDocument5 pagesInput Values: Output Values:: Units Converter ForceJeyder GeorgeNo ratings yet

- ASD-Design of Steel BeamDocument5 pagesASD-Design of Steel BeamsivakumarNo ratings yet

- Connection Design: Given DataDocument2 pagesConnection Design: Given Datasyed muneeb haiderNo ratings yet

- 5 Verification On Loading: References CalculationsDocument1 page5 Verification On Loading: References CalculationsAzahar Bin HashimNo ratings yet

- Perencanaan Pondasi: Table: Joint Reactions Table: Joint Reactions Joint Outputcase Casetype U1 U2 U3 R1 R2 R3Document7 pagesPerencanaan Pondasi: Table: Joint Reactions Table: Joint Reactions Joint Outputcase Casetype U1 U2 U3 R1 R2 R3AgungNugrohoNo ratings yet

- 4 Skin Plate Form Work PDFDocument4 pages4 Skin Plate Form Work PDFraghuveer11No ratings yet

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Pier P7&8 PDFDocument94 pagesPier P7&8 PDFSanjeev VermaNo ratings yet

- Tension Member Double AngleDocument1 pageTension Member Double AnglechaNo ratings yet

- BracketDocument1 pageBracketmohammed nafethNo ratings yet

- Calc Leg Check of Cross BracingDocument4 pagesCalc Leg Check of Cross Bracingdinesh_akabariNo ratings yet

- AISC 13.0 Properties ViewerDocument10 pagesAISC 13.0 Properties ViewerFREDY LEDESMA QUISPENo ratings yet

- BOX Sec-Beam-Column-AiscDocument6 pagesBOX Sec-Beam-Column-AiscWintun73No ratings yet

- Monorail Hoist BeamDocument20 pagesMonorail Hoist Beamsam bchNo ratings yet

- Connection v1.3Document14 pagesConnection v1.3Trần Minh ChiếnNo ratings yet

- Diseño de Zapata Excentrica Entre 5-5 Y A-ADocument1 pageDiseño de Zapata Excentrica Entre 5-5 Y A-AMiguel Egoavil TaipeNo ratings yet

- This Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodDocument9 pagesThis Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodsopnanairNo ratings yet

- (Ac) Dimensiones de Elementos Y Propiedades Fisicas: W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single AnglesDocument41 pages(Ac) Dimensiones de Elementos Y Propiedades Fisicas: W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single AnglesrichardNo ratings yet

- 001 AutoCAD 2D and 3D Practice Drawing CourseDocument11 pages001 AutoCAD 2D and 3D Practice Drawing CoursemathuNo ratings yet

- Design of Tie Beam Design Of: Tb5 at AxisDocument7 pagesDesign of Tie Beam Design Of: Tb5 at AxisSuhail AhamedNo ratings yet

- Hot-Rolled Steel Beam Calculation To AISC 360-16Document2 pagesHot-Rolled Steel Beam Calculation To AISC 360-16vanda_686788867No ratings yet

- Design of Temporary Steel BridgeDocument7 pagesDesign of Temporary Steel BridgeMsh GuruNo ratings yet

- Datos Generales: Metrado de CargasDocument4 pagesDatos Generales: Metrado de CargasDavid Alexander RojasNo ratings yet

- Bearing Capacity Calculation Shallow Found - FinalDocument2 pagesBearing Capacity Calculation Shallow Found - Finalabcd efghNo ratings yet

- Doubly Reinforced Concrete Beam Design - DesignDocument3 pagesDoubly Reinforced Concrete Beam Design - DesignMark Brien Vincent YbañezNo ratings yet

- 15m RC TG Superstructure DesignDocument22 pages15m RC TG Superstructure DesignEngineeri TadiyosNo ratings yet

- PurlinsDocument17 pagesPurlinsSara RamliNo ratings yet

- Doubly Reinforced Concrete Beam Design - InvestigationDocument4 pagesDoubly Reinforced Concrete Beam Design - InvestigationMark Brien Vincent YbañezNo ratings yet

- B1 Beam DesignDocument7 pagesB1 Beam DesignakhilNo ratings yet

- Anexo Ii: Refuerzo Transversal de Columna T: Ø Øvc VsDocument1 pageAnexo Ii: Refuerzo Transversal de Columna T: Ø Øvc VsJoseph LaurenteNo ratings yet

- Moment Conn-FlDocument2 pagesMoment Conn-Flmahmoud Ibrahem100% (1)

- AISC Propiedades y Pesos - TOTALDocument41 pagesAISC Propiedades y Pesos - TOTALjuanchi1979scribdNo ratings yet

- Hot-Rolled Steel Beam Calculation To AISC 360-16Document2 pagesHot-Rolled Steel Beam Calculation To AISC 360-16vanda_686788867No ratings yet

- Mean Flange Thickness T Overall Depth DDocument3 pagesMean Flange Thickness T Overall Depth DAkhil BabuNo ratings yet

- Monorail 2 Tonne - 17M Length (Demag Project)Document9 pagesMonorail 2 Tonne - 17M Length (Demag Project)Bang OchimNo ratings yet

- Design of Slabs: Input DataDocument6 pagesDesign of Slabs: Input Datagewegw3gNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Presentation2 Design of RC - GirderDocument18 pagesPresentation2 Design of RC - Girderrekcah ehtNo ratings yet

- Calculo Techado CorpacanchaDocument4 pagesCalculo Techado CorpacanchaMyE SACNo ratings yet

- Bases de Diseño AiscDocument127 pagesBases de Diseño AiscZain AndabloNo ratings yet

- Zapata ExcentricaDocument2 pagesZapata ExcentricaYadira AspNo ratings yet

- Ion Beams for Materials AnalysisFrom EverandIon Beams for Materials AnalysisR. Curtis BirdNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Pre-Accepted Structural Program: Program Reference Program Last Valid Date RemarksDocument31 pagesPre-Accepted Structural Program: Program Reference Program Last Valid Date RemarksBQ HeNo ratings yet

- SE P5r1Document18 pagesSE P5r1BQ HeNo ratings yet

- 2.0 Part 2 Design Working Platform Type A - 20220802Document68 pages2.0 Part 2 Design Working Platform Type A - 20220802BQ HeNo ratings yet

- Pre-Accepted Structural Program: Program Reference Program Version Valid Till RemarksDocument30 pagesPre-Accepted Structural Program: Program Reference Program Version Valid Till RemarksBQ HeNo ratings yet

- Pre-Accepted Structural Program: Program Reference Program Valid Till RemarksDocument31 pagesPre-Accepted Structural Program: Program Reference Program Valid Till RemarksBQ HeNo ratings yet

- 4.3 Chequer Plate DesignDocument1 page4.3 Chequer Plate DesignBQ HeNo ratings yet

- 4.1a SB1 DesignDocument2 pages4.1a SB1 DesignBQ HeNo ratings yet

- LDBP Submission Report - by JackyDocument5 pagesLDBP Submission Report - by JackyBQ HeNo ratings yet

- 4.2b SB2 UC CheckDocument3 pages4.2b SB2 UC CheckBQ HeNo ratings yet

- NR13 4 Apa A Lo-03Document1 pageNR13 4 Apa A Lo-03BQ HeNo ratings yet

- AD (DP) All Project Teams and Contract Managers 22 August 2013Document11 pagesAD (DP) All Project Teams and Contract Managers 22 August 2013BQ HeNo ratings yet

- NR13 4 Apa A Lo-04Document1 pageNR13 4 Apa A Lo-04BQ HeNo ratings yet

- DS 1034 BDocument5 pagesDS 1034 BBQ HeNo ratings yet

- NR13 4 Apa A Lo-04-1Document1 pageNR13 4 Apa A Lo-04-1BQ HeNo ratings yet

- NR13 4 Apa A Lo-02Document1 pageNR13 4 Apa A Lo-02BQ HeNo ratings yet

- Structural Appraisal Methodology For Ageing Public Rental Housing (PRH) Buildings With Reinforcement Corrosion - Part 1Document4 pagesStructural Appraisal Methodology For Ageing Public Rental Housing (PRH) Buildings With Reinforcement Corrosion - Part 1BQ HeNo ratings yet

- NR13 4 Apa A Lo-03-1Document1 pageNR13 4 Apa A Lo-03-1BQ HeNo ratings yet

- APH From SL2018 - 022019 - 18022019Document83 pagesAPH From SL2018 - 022019 - 18022019BQ HeNo ratings yet

- NR13 4 Apa A Lo-01Document1 pageNR13 4 Apa A Lo-01BQ HeNo ratings yet

- Mathcad - PART II Ceiling (ICU) 20200602 (Update) - 2Document418 pagesMathcad - PART II Ceiling (ICU) 20200602 (Update) - 2BQ HeNo ratings yet

- DS 1081 BDocument3 pagesDS 1081 BBQ HeNo ratings yet

- C3009 Hydraulic I: Bernoulli's Eq. Example Ex.1Document4 pagesC3009 Hydraulic I: Bernoulli's Eq. Example Ex.1Obazie isiomaNo ratings yet

- Parts List - Service Manual 969430401 - MAT 500 - R534 - enDocument2 pagesParts List - Service Manual 969430401 - MAT 500 - R534 - enharrykgs7No ratings yet

- Physical Ageing in Amorphous Polymers and Other MaterialsDocument249 pagesPhysical Ageing in Amorphous Polymers and Other Materialswc_11111No ratings yet

- Calcite Microcrystals in The Pineal Gland of The Human BrainDocument8 pagesCalcite Microcrystals in The Pineal Gland of The Human Brainnidus14No ratings yet

- Bamboo Moso MechaDocument13 pagesBamboo Moso MechaYopNo ratings yet

- Landsat DN To ReflectanceDocument4 pagesLandsat DN To ReflectanceSesa WigunaNo ratings yet

- Electronic Structure of AtomsDocument29 pagesElectronic Structure of AtomsTiara MejicaNo ratings yet

- One Way and Two Way SlabDocument2 pagesOne Way and Two Way SlabQueenie Louise DasilioNo ratings yet

- Physics 11 Cheat SheetDocument2 pagesPhysics 11 Cheat SheetAnshul AhujaNo ratings yet

- Nano Silica Modified Carbon-Phenolic CompositesDocument4 pagesNano Silica Modified Carbon-Phenolic CompositesAbrizal HaryadiNo ratings yet

- Lzxfitness: Shandong Zhix NG Fitness Technology Co. LTDDocument90 pagesLzxfitness: Shandong Zhix NG Fitness Technology Co. LTDChristopher WoodbridgeNo ratings yet

- Astm E1621-21Document9 pagesAstm E1621-21Tamara Silvana CárcamoNo ratings yet

- 4100R Series - Thick Film Molded Dips: FeaturesDocument3 pages4100R Series - Thick Film Molded Dips: FeaturesCarlos IbaNo ratings yet

- Loss Fuction: by Fatema Khairunnasa Lecturer, Dept. of Statistics, BsmrstuDocument7 pagesLoss Fuction: by Fatema Khairunnasa Lecturer, Dept. of Statistics, BsmrstuSherena KhatunNo ratings yet

- An Investigation Into The Distinctive Properties of LiAuS A - 2023 - Results inDocument7 pagesAn Investigation Into The Distinctive Properties of LiAuS A - 2023 - Results inronaldquezada038No ratings yet

- Example 1.2: Several Springs Are Connected As Shown in Figure 1.2 Subjected To An Axial ForceDocument5 pagesExample 1.2: Several Springs Are Connected As Shown in Figure 1.2 Subjected To An Axial ForceVinaasha BalakrishnanNo ratings yet

- My NotesDocument6 pagesMy NotesSyed Rooh UllahNo ratings yet

- Design of Structures and Foundations For Vibrating MachinesDocument212 pagesDesign of Structures and Foundations For Vibrating MachinesDarlon OliveiraNo ratings yet

- Window Louver Structure Calculation SheetDocument67 pagesWindow Louver Structure Calculation SheetTONY HANNo ratings yet

- Conversion Factors: in FT U.S. Gal Liters MDocument8 pagesConversion Factors: in FT U.S. Gal Liters MSamuel MahendraNo ratings yet

- rk85 2-300 GB (85 C01e)Document2 pagesrk85 2-300 GB (85 C01e)Ali GameelNo ratings yet

- Materials Science & Engineering ADocument10 pagesMaterials Science & Engineering AArraafi FadhillahNo ratings yet

- Conxtech Conxl Moment Connection: 10.1. GENERALDocument24 pagesConxtech Conxl Moment Connection: 10.1. GENERALPaola DoradoNo ratings yet

- High-Quality Few Layer Graphene Produced by Electrochemical Intercalation and Microwave-Assisted Expansion of GraphiteDocument8 pagesHigh-Quality Few Layer Graphene Produced by Electrochemical Intercalation and Microwave-Assisted Expansion of Graphitemartha SevillaNo ratings yet

- Flow Characteristics Impeller Change of An Axial Turbo FanDocument4 pagesFlow Characteristics Impeller Change of An Axial Turbo FanFilippo Da Silva ZuccolottoNo ratings yet

- Title Marine Engineering MathematicsDocument10 pagesTitle Marine Engineering MathematicsgunapalshettyNo ratings yet

- Problem Set-02Document2 pagesProblem Set-02linn.pa.pa.khaing.2020.2021.fbNo ratings yet

- Experiment 6Document4 pagesExperiment 6Karthik PeddiNo ratings yet

- Lecture 5 Angular MomentumDocument47 pagesLecture 5 Angular MomentumdodifebrizalNo ratings yet