Professional Documents

Culture Documents

28GS3121AB Deionized Cartridge Replacement

28GS3121AB Deionized Cartridge Replacement

Uploaded by

ofon OML102Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

28GS3121AB Deionized Cartridge Replacement

28GS3121AB Deionized Cartridge Replacement

Uploaded by

ofon OML102Copyright:

Available Formats

28GS3121A/B

VSD de ionized cooling water

Resin cartridge replacement

GMC OFON – OML 102

Netco Dietsmann Date : 18 February 2016

Title Replacement of the resin cartridge on the de-ionized cooling water

Trade MECHANICAL

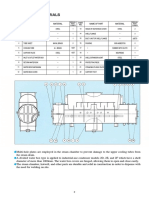

Cooling circuit hydraulic diagram

Resin cartridge Pressure /air release valve

P1 P2

Manual valve VG030 quick coupling manual valve VG031

Connection P1/P2

➢ Disconnecting Cartridge

1. Close the manual valves VG030&VG031, install rag on the top of the resin cartridge to avoid water

spillage

2. Use the pressure /Air release valve to reduce the pressure inside the cartridge. Open the valve slowly

for smooth pressure release and do not open fully, (using rag sponge the water released)

Note: If the valve opened fully under pressure the resin will spill out.

3. After the pressure release disconnect the flexible hose at the points P1 & P2 mark the both flexible

according resin cartridge inlet and outlet inlet and outlet to avoid mistake during reconnection.

Quick coupling P1/P2

28GS3121A/B

VSD de ionized cooling water

Resin cartridge replacement

4. Take the cartridge out from the cooling unit.

5. Test the solenoid to be sure the valve is open when the led is green

6. Disconnect the flexible metal hose from the old cartridge mark the both flexible according resin

cartridge inlet and outlet inlet and outlet

➢ Preparation and connecting new cartridge

1. Check the new cartridge is same kind.

2. Connect the flexible metal hose to the new cartridge.

3. By using De-ionized water flush the new cartridge. This will remove air in the cartridge.

Note: The water flow must be from IN – OUT all the times.

4. Fix the new cartridge in the cooling unit.

5. Fill the hose with de ionized water to minimize the quantity of air introduce into the circuit

6. Connect the flexible hoses at right places.

7. Open the manual valve VG030 & VG031

8. Check the pressure PG040 (the pressure should be between 1.5 and 2Bars)

9. Monitor for leakage (if any leakage as been detected need to fix it before to continue this procedure”

10. Run the cooling water pump (force active in the PLC need assistance of ICSS supervisor)

11. Monitor the de ionized water the value should be less than 1μS

You might also like

- Schermafbeelding 2021-09-18 Om 15.57.50Document386 pagesSchermafbeelding 2021-09-18 Om 15.57.50Esoteric Sensations100% (1)

- Gender Cartoons PrecisDocument12 pagesGender Cartoons Precisapi-561977850No ratings yet

- Smart GX ManualDocument83 pagesSmart GX ManualLuis MPNo ratings yet

- Flygt Pump 3153/3171/3203/3301/3315/5100/5150Document12 pagesFlygt Pump 3153/3171/3203/3301/3315/5100/5150Mohammad HazbehzadNo ratings yet

- Thermostatic Expansion Valves - DanfossDocument20 pagesThermostatic Expansion Valves - DanfossRay RavelNo ratings yet

- Operation - Manual Sondex A/S SFD 6: Customer: Newbuilding No: Order No.: Sondex Order No.: Encl.Document132 pagesOperation - Manual Sondex A/S SFD 6: Customer: Newbuilding No: Order No.: Sondex Order No.: Encl.AlexDor100% (1)

- Manual 2K25 11672 R1Document44 pagesManual 2K25 11672 R1Tarek MassimoNo ratings yet

- Assessment in Learning 1 Activity 1Document3 pagesAssessment in Learning 1 Activity 1Alaba Norvi AngeliNo ratings yet

- Nutrition Intervention TerminologyDocument2 pagesNutrition Intervention Terminologyfatih azzahra100% (1)

- 28GS3121AB Deionized Cartridge Replacement Pressure SwitchDocument3 pages28GS3121AB Deionized Cartridge Replacement Pressure Switchofon OML102No ratings yet

- RND50 Manual Eng 2015 V1.0Document24 pagesRND50 Manual Eng 2015 V1.0Ahmed HosniNo ratings yet

- Frigimat EZ Dry Ice Maker: Catalog No. H38878-0010Document1 pageFrigimat EZ Dry Ice Maker: Catalog No. H38878-0010Joaquin GonzaliasNo ratings yet

- KIKAWA Manual KQ enDocument6 pagesKIKAWA Manual KQ enkanokNo ratings yet

- Refrigerated Dryer: Installation Operation Debugging Maintain InstructionsDocument26 pagesRefrigerated Dryer: Installation Operation Debugging Maintain InstructionsHoàng LongNo ratings yet

- 2d - Guidance On Safe Use of TelehandlersDocument5 pages2d - Guidance On Safe Use of TelehandlersmohammudpNo ratings yet

- Re-Circulated Hot Water Bath Vaporizer: For Chlorine, Sulphur Dioxide and AmmoniaDocument3 pagesRe-Circulated Hot Water Bath Vaporizer: For Chlorine, Sulphur Dioxide and AmmoniaNyandoro E-max MaxmoreNo ratings yet

- T82520en PDFDocument8 pagesT82520en PDFpaulo cesar f machadoNo ratings yet

- Manual Plate-Type Condenser PKDocument3 pagesManual Plate-Type Condenser PKzhyhhNo ratings yet

- Sondex SFD6Document160 pagesSondex SFD6a.amangazinov1995No ratings yet

- Vacuum CondensersDocument12 pagesVacuum CondensersErick EspinosaNo ratings yet

- 6567 905A BK File InstallationGuidelines 151313 Ori 2016sep20132637Document1 page6567 905A BK File InstallationGuidelines 151313 Ori 2016sep20132637Suresh ChajjedNo ratings yet

- Water ChillerDocument74 pagesWater ChillerDimitri LyssiNo ratings yet

- Turbocharger Aftercooler: NoticeDocument5 pagesTurbocharger Aftercooler: NoticeLuwīsi Karikamo RomaniNo ratings yet

- Quick BoilerB3 ManualDocument5 pagesQuick BoilerB3 ManualartemNo ratings yet

- Technical Instructions: DescriptionDocument4 pagesTechnical Instructions: Description薛泽绵No ratings yet

- Series 1170, LF1170, L1170 and LFL1170 Installation InstructionsDocument4 pagesSeries 1170, LF1170, L1170 and LFL1170 Installation InstructionsWattsNo ratings yet

- A Sacca EngDocument43 pagesA Sacca EngCan Kutay TuçNo ratings yet

- Acumulatori PneumohidrauliciDocument43 pagesAcumulatori PneumohidrauliciSam HaNo ratings yet

- Pages From Vacuum - Condensers2Document2 pagesPages From Vacuum - Condensers2boeiniNo ratings yet

- 23G Illustrated Parts Manual 2010-04.pdf - GambroDocument88 pages23G Illustrated Parts Manual 2010-04.pdf - GambroTomNo ratings yet

- Operation Manual Refrigerant Compressed Air Dryers SharkDocument14 pagesOperation Manual Refrigerant Compressed Air Dryers SharkIlham Wisnu AjiNo ratings yet

- SFD 13 Samlet ManualDocument95 pagesSFD 13 Samlet ManualHüseyin TekinNo ratings yet

- R59770032 01 LiquidcoolingrefurbishmentDP100 DP90 XLMDocument22 pagesR59770032 01 LiquidcoolingrefurbishmentDP100 DP90 XLMRamon Bochaca SandiumengeNo ratings yet

- Service Manual 13-7832Document7 pagesService Manual 13-7832Pedro GarciaNo ratings yet

- 6bDocument6 pages6bJason WilliamNo ratings yet

- Pressure Operated Water Valve Type WVFX and WVS: Data SheetDocument14 pagesPressure Operated Water Valve Type WVFX and WVS: Data Sheettiếm nguyễnNo ratings yet

- Instruction Manual 12340Document10 pagesInstruction Manual 12340Oțeleanu BogdanNo ratings yet

- Lawler Series 66 Thermostatic Water Controller PDFDocument4 pagesLawler Series 66 Thermostatic Water Controller PDFStacy OneillNo ratings yet

- Antigel Motor ATDDocument2 pagesAntigel Motor ATDstiloooNo ratings yet

- Industrial Solenoid ValvesDocument36 pagesIndustrial Solenoid Valvesศตวรรษ ฉิมวัยNo ratings yet

- Watts63C Yerden Isitma Icin Termostatik Karisim VanasiDocument4 pagesWatts63C Yerden Isitma Icin Termostatik Karisim VanasiErdinc KlimaNo ratings yet

- Gejzir VazduhDocument9 pagesGejzir VazduhssteticNo ratings yet

- PureWaterCooler Service ManualDocument38 pagesPureWaterCooler Service ManualAzhar HassanNo ratings yet

- 62 enDocument6 pages62 enshaonaaNo ratings yet

- 2.3operator Manual of SDLF-80Document27 pages2.3operator Manual of SDLF-80pachara sarntiyakulNo ratings yet

- Watts 500800 User-Manual PDFDocument8 pagesWatts 500800 User-Manual PDFfogdartNo ratings yet

- Bar's Leaks Technical BulletinDocument2 pagesBar's Leaks Technical BulletinmazacotesNo ratings yet

- Evans HDC Install Procedure Mack E7 Rev 02feb12Document5 pagesEvans HDC Install Procedure Mack E7 Rev 02feb12juanNo ratings yet

- TB NitrogenBlanketDocument1 pageTB NitrogenBlanketMohamedHussein MohamedHusseinNo ratings yet

- Im BW1880Document192 pagesIm BW1880ORLNDONo ratings yet

- GEN 3018 HANDING OVER CENTRIFUGAL COMPRESSORS FOR MAINTENAàDocument3 pagesGEN 3018 HANDING OVER CENTRIFUGAL COMPRESSORS FOR MAINTENAàBikas SahaNo ratings yet

- AppBull Chlo2 08-11Document2 pagesAppBull Chlo2 08-11Darshan PatelNo ratings yet

- Liquid Withdrawal Device: For Liquid Nitrogen 25LD, 35LD, 35LD-T and 50LD DewarsDocument4 pagesLiquid Withdrawal Device: For Liquid Nitrogen 25LD, 35LD, 35LD-T and 50LD DewarsmarcelloairesNo ratings yet

- Curing: Rubber Lining Application Manual Revision Date: September 1, 2009 Section 11: Curing Page: 11 - 1Document17 pagesCuring: Rubber Lining Application Manual Revision Date: September 1, 2009 Section 11: Curing Page: 11 - 1malika_00No ratings yet

- DermalogicatuclavemanualDocument17 pagesDermalogicatuclavemanualyasminah hanitralalainaNo ratings yet

- 8-05 en Frese Safety Valves NOV 17Document1 page8-05 en Frese Safety Valves NOV 17anasm01No ratings yet

- Bluebox Zeta Rev HP 5.2Document7 pagesBluebox Zeta Rev HP 5.2NikolaNo ratings yet

- Quarius Typ 70 ENGLISHDocument10 pagesQuarius Typ 70 ENGLISH7777777777777-733005No ratings yet

- Control Valve Thumb Rule CalculationDocument82 pagesControl Valve Thumb Rule CalculationShubham AgarwalNo ratings yet

- Technical Instructions: Form TI410-5 v3Document8 pagesTechnical Instructions: Form TI410-5 v3薛泽绵No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Hydrostatic Test Lube Oil Bellow x2Document2 pagesHydrostatic Test Lube Oil Bellow x2ofon OML102No ratings yet

- Weekly Drainning Seal Gas Filters MPA-BDocument4 pagesWeekly Drainning Seal Gas Filters MPA-Bofon OML102No ratings yet

- Compress EursDocument11 pagesCompress Eursofon OML102No ratings yet

- Extract Page 2Document1 pageExtract Page 2ofon OML102No ratings yet

- Umfluxus f8vx Xen - BookDocument236 pagesUmfluxus f8vx Xen - Bookofon OML102No ratings yet

- SFT-109A - Hydraulic SpreadersDocument1 pageSFT-109A - Hydraulic Spreadersofon OML102No ratings yet

- Instr Procedure - 1y - PM - 28-K - 3112Document33 pagesInstr Procedure - 1y - PM - 28-K - 3112ofon OML102No ratings yet

- P462-Series Manual Pumps en-USDocument2 pagesP462-Series Manual Pumps en-USofon OML102No ratings yet

- Mini Project Separation TechnolgyDocument12 pagesMini Project Separation TechnolgyDaniel IsmailNo ratings yet

- (EngSub) The Legend of The Blue Sea - Ep2Document43 pages(EngSub) The Legend of The Blue Sea - Ep2Try SandiNo ratings yet

- Mechanism of Formation of Atoll Garnet During High-Pressure MetamorphismDocument16 pagesMechanism of Formation of Atoll Garnet During High-Pressure MetamorphismGhislainarrowNo ratings yet

- WLP FILIPINO 8 (1st To 2nd Quarter)Document12 pagesWLP FILIPINO 8 (1st To 2nd Quarter)REYNIEL BERNALES VILLANo ratings yet

- Experimental Research: Group 3Document12 pagesExperimental Research: Group 3Clarise HechanovaNo ratings yet

- Classroom Observation ReportDocument4 pagesClassroom Observation ReportSarwar AzizNo ratings yet

- Introduction To Agilent ADS MomentumDocument11 pagesIntroduction To Agilent ADS MomentumDawah Ilm IbadahNo ratings yet

- Final Test MathematicsDocument5 pagesFinal Test MathematicsChatarina WulandariNo ratings yet

- The Role of MuscleDocument5 pagesThe Role of MuscleMuhammad FaiqNo ratings yet

- Graham Holton - UFOs and Religious CultsDocument23 pagesGraham Holton - UFOs and Religious CultsJorsant EdNo ratings yet

- Problem-Solution Essay RubricDocument2 pagesProblem-Solution Essay Rubric白卡持有人No ratings yet

- Research Plan and Project Data LogbookDocument26 pagesResearch Plan and Project Data LogbookRome Tancioco TayerNo ratings yet

- Analysis of Silo Supporting Ring Beams Resting On Discrete Supports - O Zeybek, Et Al, 2019Document12 pagesAnalysis of Silo Supporting Ring Beams Resting On Discrete Supports - O Zeybek, Et Al, 2019Benjamin IndrawanNo ratings yet

- Thermal Conductivity of Composite Slab: Vishwakarma Institute Technology, Pune ofDocument7 pagesThermal Conductivity of Composite Slab: Vishwakarma Institute Technology, Pune ofHussain MagarNo ratings yet

- Adaptive Linear NeuronDocument4 pagesAdaptive Linear NeuronSelvamNo ratings yet

- MATH 210 Final Lecture NotesDocument13 pagesMATH 210 Final Lecture NotestoNo ratings yet

- Geotechnical Investigations and Studies: APRIL 1991Document35 pagesGeotechnical Investigations and Studies: APRIL 1991roshan_geo078896No ratings yet

- Diploma in Engineering and Technology: 1220 Department of Mechanical Engineering (Tool & Die)Document320 pagesDiploma in Engineering and Technology: 1220 Department of Mechanical Engineering (Tool & Die)anbarasuNo ratings yet

- Electrochemistry MCQDocument9 pagesElectrochemistry MCQSarah DevilNo ratings yet

- Saline and Alkali SoilDocument19 pagesSaline and Alkali Soilavinash SinghNo ratings yet

- Viva Questions - GraphicsDocument2 pagesViva Questions - GraphicsSALONIKA AHUJANo ratings yet

- CAPITAL Engineering Mathematics 1 AssignmentDocument3 pagesCAPITAL Engineering Mathematics 1 Assignmentshamil cmNo ratings yet

- Methanol Casalestartsupmore IMCConvertersDocument13 pagesMethanol Casalestartsupmore IMCConvertersGonzalo Aldair Carbajal FloresNo ratings yet

- MicroteachingDocument27 pagesMicroteachingLaveena AswaleNo ratings yet

- Instruction Manual: EM Series Multibeam Echo SoundersDocument136 pagesInstruction Manual: EM Series Multibeam Echo SoundersEvgeny YudinNo ratings yet

- Intellectual HealthDocument27 pagesIntellectual Healthapi-546569844No ratings yet