Professional Documents

Culture Documents

ProcSmMpFrm 715002173rB

Uploaded by

Riad ManamanniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ProcSmMpFrm 715002173rB

Uploaded by

Riad ManamanniCopyright:

Available Formats

Maintenance Procedure for the

PATROL UPLC Process Sample Manager

© 2009-2010 Waters Corporation

™ ®

Complete Form 11 to verify completion of the maintenance procedure for the PATROL UPLC process

sample manager. For information on how to perform any of the steps in this form, see the instrument’s

system guide on the Waters® SystemsQT™ Projects/Documentation DVD.

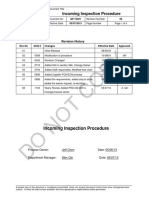

Form 11 Maintenance Procedure for the PATROL UPLC Process Sample Manager

PATROL UPLC Process Sample Manager Serial Number

Owner’s ID

Procedure Completed

1. Replace the diluent pump.

Initials

2. Replace the sample pump.

3. Replace the priming valve cartridge.

4. Replace the sample valve cartridge.

5. Replace the process valve cartridge.

6. Replace the inject valve cartridge.

7. Replace the sample loop.

8. Replace the process pump tubing.

9. Replace the inline filter/mixer.

10. Clean the air filters.

11. Replace the solvent bottle filters.

12. Clean the bar code reader window.

13. From the ACQUITY Console, run the applicable process sample manager diagnostics.

Comments

Certification

The undersigned performer attests that the maintenance procedure was performed according to the procedure

shown above.

Performer Date

Signature

The undersigned reviewer accepts that the maintenance procedure was performed according to the procedure

shown above.

Reviewer Date

Signature

© 2010 Waters Corporation

715002173 Revision B 1 of 1

You might also like

- Water Operator Certification Study GuideDocument417 pagesWater Operator Certification Study GuideM Jafar100% (4)

- Water System PQDocument46 pagesWater System PQVeChrist PharmacistoLshop100% (3)

- QP 74301 Rev 08 Incoming Inspection ProcedureDocument9 pagesQP 74301 Rev 08 Incoming Inspection ProcedureAngeline D'AlmaidaNo ratings yet

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- The Central Business District: New Administrative CapitalDocument18 pagesThe Central Business District: New Administrative CapitalAbanoub HakeemNo ratings yet

- SOP For PW Generation System, New - 25-11-10Document15 pagesSOP For PW Generation System, New - 25-11-10markandey gupta100% (3)

- GTEC Chemical Cleaning, Pressure Testing & Flushing ProcedureDocument12 pagesGTEC Chemical Cleaning, Pressure Testing & Flushing ProcedureS GoudaNo ratings yet

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhNo ratings yet

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhNo ratings yet

- DI IQ OQ ReportDocument11 pagesDI IQ OQ ReportVemulapalli SaibabuNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- A Guide To Validating Purified WaterDocument4 pagesA Guide To Validating Purified WaterDonig Fermanian100% (1)

- SOP For Operation of Effulent Treatment PlantDocument3 pagesSOP For Operation of Effulent Treatment PlantRakesh RauniyarNo ratings yet

- Water System PQDocument47 pagesWater System PQsainzb8389% (9)

- PQ For Water Treatment PlantDocument29 pagesPQ For Water Treatment PlantDilawar Bakht100% (2)

- Ahu Operation Qualification DocumentDocument21 pagesAhu Operation Qualification DocumentRamakrishna Agumbe100% (9)

- Testing & Commissioning of Chilled Water Pressurization UnitsDocument3 pagesTesting & Commissioning of Chilled Water Pressurization Unitsvin ssNo ratings yet

- Water System Validation ExampleDocument6 pagesWater System Validation ExampleBhuwan SNo ratings yet

- Apeks Flight 2ndt Stage Maintenance Issue 9 (28-11-2011)Document21 pagesApeks Flight 2ndt Stage Maintenance Issue 9 (28-11-2011)ReadnixNo ratings yet

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Procedure For Testing & Commissioning of Water Booster Jockey PumpsDocument3 pagesProcedure For Testing & Commissioning of Water Booster Jockey Pumpsvin ssNo ratings yet

- Aqualung - Core - 1er Étage - Service ManualDocument23 pagesAqualung - Core - 1er Étage - Service ManualLaurent LeclercqNo ratings yet

- Reverse Osmosis (RO) Preventive MaintenanceDocument5 pagesReverse Osmosis (RO) Preventive MaintenanceAmy FitzpatrickNo ratings yet

- Operation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreDocument17 pagesOperation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreSathishkumar DhamodaranNo ratings yet

- Acq SM FTNMP FRMDocument1 pageAcq SM FTNMP FRMRiad ManamanniNo ratings yet

- Acq QSM MP FRMDocument1 pageAcq QSM MP FRMRiad ManamanniNo ratings yet

- Acq SM MP FRMDocument1 pageAcq SM MP FRMRiad ManamanniNo ratings yet

- Acq BSM MP FRMDocument1 pageAcq BSM MP FRMRiad ManamanniNo ratings yet

- Acq So MP FRMDocument1 pageAcq So MP FRMRiad ManamanniNo ratings yet

- Acq Els MP FRMDocument1 pageAcq Els MP FRMRiad ManamanniNo ratings yet

- 1.0 Protocol Approval Sheet: Operation QualificationDocument21 pages1.0 Protocol Approval Sheet: Operation QualificationMohammadNo ratings yet

- AcqPDATUVMpFrm 715002849rBDocument1 pageAcqPDATUVMpFrm 715002849rBRiad ManamanniNo ratings yet

- FAT ProcedureDocument61 pagesFAT ProcedureBagus SigitNo ratings yet

- SQDMP FRMDocument5 pagesSQDMP FRMRiad ManamanniNo ratings yet

- 573 2012 - Appendix - C Process NarativeDocument14 pages573 2012 - Appendix - C Process NarativeamilasriNo ratings yet

- Philippine National Standard: PNS/PAES 154:2010 (PAES Published 2010) ICS 65.060.01Document22 pagesPhilippine National Standard: PNS/PAES 154:2010 (PAES Published 2010) ICS 65.060.01Jemina Jean Dorado SensanoNo ratings yet

- Method Statement For The Testing of Domestic PumpDocument11 pagesMethod Statement For The Testing of Domestic Pumpa100% (1)

- TSB 20190417 - Cuckoo WP Installation Check PointsDocument6 pagesTSB 20190417 - Cuckoo WP Installation Check PointsINSTA SERVICENo ratings yet

- Service Manual: Scope BuddyDocument20 pagesService Manual: Scope BuddyNacho LopezNo ratings yet

- Calibration of Bulk Density ApparatusDocument4 pagesCalibration of Bulk Density Apparatusashishchandan13No ratings yet

- NEOPRSP001WI017 - Rev. 01 - Pages 07 - Cleaning in Place of RO System Work InstructionsDocument7 pagesNEOPRSP001WI017 - Rev. 01 - Pages 07 - Cleaning in Place of RO System Work Instructionsalialharbi021No ratings yet

- E10-002 Dry Transformer InspectionDocument8 pagesE10-002 Dry Transformer InspectionAtika SekarNo ratings yet

- Ees - Preventive Maintenance ChecklistDocument3 pagesEes - Preventive Maintenance ChecklistEkdant Enviro Services ekdant labNo ratings yet

- API Review: PR0A028I Issue/Rev. 0.0 (7/07) - Slide 1Document33 pagesAPI Review: PR0A028I Issue/Rev. 0.0 (7/07) - Slide 1IChan ItuIchsanNo ratings yet

- Service - Program Crawler ExcavatorsDocument6 pagesService - Program Crawler ExcavatorsLucky OkoteNo ratings yet

- NEOPRSP001 - Rev. 01 - Pages 12 - Plant Operation Control ProcedureDocument11 pagesNEOPRSP001 - Rev. 01 - Pages 12 - Plant Operation Control Procedurealialharbi021No ratings yet

- Audit Checklist - Department Wise in Pharmaceuticals - Pharma BeginnersDocument32 pagesAudit Checklist - Department Wise in Pharmaceuticals - Pharma Beginnersisrael afolayan mayomiNo ratings yet

- ELx50 Operators Manual - 4071059 Rev CDocument164 pagesELx50 Operators Manual - 4071059 Rev CShylla NathalyNo ratings yet

- Water Operator Certification Study Guide PreviewDocument13 pagesWater Operator Certification Study Guide Previewarslansabir627No ratings yet

- Maintenance RecordDocument6 pagesMaintenance RecordCarlos GonçalvesNo ratings yet

- Sop For Air Preparation SystemDocument4 pagesSop For Air Preparation SystemKenny ObayomiNo ratings yet

- 04-SOP No. ENG-GEN-015-01 Internal Cleaning of Water ReservoirDocument6 pages04-SOP No. ENG-GEN-015-01 Internal Cleaning of Water ReservoirAjlan KhanNo ratings yet

- PQ Templet - Water Bath - NewDocument7 pagesPQ Templet - Water Bath - Newpuri_aravind2011199No ratings yet

- Manual Water Health-W10286Document449 pagesManual Water Health-W10286emilNo ratings yet

- Final SOP For Hydro TestDocument2 pagesFinal SOP For Hydro TestBhaskar KolichelimaNo ratings yet

- Annexe 6.2 FDA-3511g - 09-04-19 - Not-SecureDocument7 pagesAnnexe 6.2 FDA-3511g - 09-04-19 - Not-SecureMoulayEsmailTalibiNo ratings yet

- Sop Starting The Hydrant and Sprinkler Duty PumpDocument7 pagesSop Starting The Hydrant and Sprinkler Duty PumpSathya SeelanNo ratings yet

- 100RLCB03032 Valvula de CortadoDocument84 pages100RLCB03032 Valvula de CortadoOrlando MantillaNo ratings yet

- NEOPRSP001WI020 - Rev. 01 - Pages 05 - Lime Milk Preparation and Dosing Work InstructionsDocument5 pagesNEOPRSP001WI020 - Rev. 01 - Pages 05 - Lime Milk Preparation and Dosing Work Instructionsalialharbi021No ratings yet

- Design of Wastewater and Stormwater Pumping Stations MOP FD-4, 3rd EditionFrom EverandDesign of Wastewater and Stormwater Pumping Stations MOP FD-4, 3rd EditionNo ratings yet

- SQ Detector Operators GuideDocument220 pagesSQ Detector Operators GuideRiad ManamanniNo ratings yet

- ELS Detector Response ReportDocument5 pagesELS Detector Response ReportRiad ManamanniNo ratings yet

- Excitation Wavelength AccDocument2 pagesExcitation Wavelength AccRiad ManamanniNo ratings yet

- System PrecisionDocument3 pagesSystem PrecisionRiad ManamanniNo ratings yet

- System IQDocument3 pagesSystem IQRiad ManamanniNo ratings yet

- Sampler Temp AccDocument1 pageSampler Temp AccRiad ManamanniNo ratings yet

- Gradient RMDocument6 pagesGradient RMRiad ManamanniNo ratings yet

- Qualification Summary RMDocument2 pagesQualification Summary RMRiad ManamanniNo ratings yet

- System Precision ReportDocument5 pagesSystem Precision ReportRiad ManamanniNo ratings yet

- Wavelength Accuracy ReportDocument3 pagesWavelength Accuracy ReportRiad ManamanniNo ratings yet

- MS Detector Lin Sens RMDocument4 pagesMS Detector Lin Sens RMRiad ManamanniNo ratings yet

- Test Injections RMDocument3 pagesTest Injections RMRiad ManamanniNo ratings yet

- Carryover RMDocument4 pagesCarryover RMRiad ManamanniNo ratings yet

- Test Injections UV RMDocument3 pagesTest Injections UV RMRiad ManamanniNo ratings yet

- Acq Samp Org OQDocument3 pagesAcq Samp Org OQRiad ManamanniNo ratings yet

- UV Injection Lin Acc RMDocument3 pagesUV Injection Lin Acc RMRiad ManamanniNo ratings yet

- Amounts TUVPDA2996Document4 pagesAmounts TUVPDA2996Riad ManamanniNo ratings yet

- Wavelength Accuracy ReportDocument3 pagesWavelength Accuracy ReportRiad ManamanniNo ratings yet

- Acq Els MP FRMDocument1 pageAcq Els MP FRMRiad ManamanniNo ratings yet

- AcqQSM BSMOQDocument3 pagesAcqQSM BSMOQRiad ManamanniNo ratings yet

- Test Equip CalDocument2 pagesTest Equip CalRiad ManamanniNo ratings yet

- Gain Linearity ReportDocument3 pagesGain Linearity ReportRiad ManamanniNo ratings yet

- Compositional Accuracy ReportDocument2 pagesCompositional Accuracy ReportRiad ManamanniNo ratings yet

- System Precision ReportDocument5 pagesSystem Precision ReportRiad ManamanniNo ratings yet

- Detector Linearity & Sensitivity ReportDocument4 pagesDetector Linearity & Sensitivity ReportRiad ManamanniNo ratings yet

- Final ApprovalDocument1 pageFinal ApprovalRiad ManamanniNo ratings yet

- Detector Linearity and Sensitivity ReportDocument5 pagesDetector Linearity and Sensitivity ReportRiad ManamanniNo ratings yet