Professional Documents

Culture Documents

SWMS 049 (A) Install Ductwork Shaft &or Peno

SWMS 049 (A) Install Ductwork Shaft &or Peno

Uploaded by

sumontp2022Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWMS 049 (A) Install Ductwork Shaft &or Peno

SWMS 049 (A) Install Ductwork Shaft &or Peno

Uploaded by

sumontp2022Copyright:

Available Formats

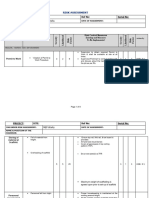

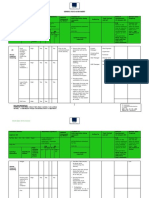

Cliff Goulding Associates trading as AC Goulding SWMS 049(A)

ABN: 57 007 347 515

65 Grange Rd Cheltenham 3192 Ph: (03) 9585 7577 SAFE WORK METHOD STATEMENT

Email: service@acgoulding.com.au

Installing ductwork to shaft/penetrations

Activity Hazards Risk Ranking Controls Risk Ranking Person

Break the job into steps what What can Harm you or others before controls are What are you going to do to carry out the work safely? After controls are implemented Responsible for

are you doing? list Hazards individually, do not group implemented H,M, or L (Apply the risk Hierarchy of control) H, M or L

implementation of the controls

MUST be inducted to site.

Falls, crushing, explosions, Site Supervisor/

H MUST attend Pre-Start meetings prior to commencing L

slips and trips Workers

Induction work

NO MOBILE PHONES TO BE USE whilst carrying out

Distractions M L Worker

work

Review work area conditions each day to ensure no

building materials or trip hazards in your working zone

or pathway to your working zone i.e. protruding pipe

work through ground slab. Site Supervisor/

Tripping hazards H L

Workers

Also check weather conditions – ie not to work in high

winds whilst working on a elevated platform. If this is

Take 5 review

so prepare another SWMS to deal with the conditions.

working area

for hazards

Co-ordinate at Pre Start meetings as to what is “live”

on site / what other trades are doing within the area.

Other services in the area –

Site Supervisor/

Tripping, dangers from their H L

Ensure penetration is secure upon arrival and the Workers

unfinished works

appropriate safety rails are in place. DO NOT start

works until penetration is secure and safety protections

are in place.

Review #1 09/1/18 1 Installing ductwork to shaft penos

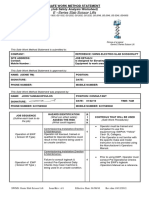

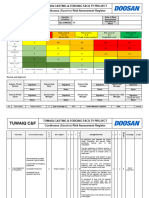

Cliff Goulding Associates trading as AC Goulding SWMS 049(A)

ABN: 57 007 347 515

65 Grange Rd Cheltenham 3192 Ph: (03) 9585 7577 SAFE WORK METHOD STATEMENT

Email: service@acgoulding.com.au

Activity Hazards Risk Ranking Controls Risk Ranking Person

Break the job into steps what What can Harm you or others before controls are What are you going to do to carry out the work safely? After controls are implemented Responsible for

are you doing? list Hazards individually, do not group implemented H,M, or L (Apply the risk Hierarchy of control) H, M or L

implementation of the controls

Mechanical devices (supplied by Site Manager) –ensure

all safety requirements are followed as per the Site

Co-ordinate Managers Mechanical Device SWMS. Loading Master/

with Site Musculoskeletal Disorders

H L Site Supervisor/

Manager/Load (MSD) Workers

Prior to lifting materials from transport - plan where

Master for

the materials are to be located.

Unloading

materials from

transport Ensure pathway to the final location is clear of all Site Supervisor/

Tripping H L

hazards i.e. holes, unstable ground, obstacles etc. Workers

Preparing

Minimise quantity/length of ductwork for

materials for MSD H L

lifting/lowering (if awkward use 2 people)

installing Site Supervisor/

ductwork Workers

If using 2 or people ensure lifting/lowering commands

are clear and precise.

Ensure pathway is clear of all hazards i.e. holes,

unstable ground, obstacles etc.

Ensure carrying out the correct manual handling

procedures for lifting/lowering

Refer to SWMS for Manual Handling

Ensure you are wearing PPE for the task – Gloves

should be worn when handling ductwork at all times

and making sure you are wearing the appropriate PPE

for the weather conditions.

(refer to SWMS for PPE)

Review #1 09/1/18 2 Installing ductwork to shaft penos

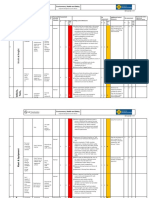

Cliff Goulding Associates trading as AC Goulding SWMS 049(A)

ABN: 57 007 347 515

65 Grange Rd Cheltenham 3192 Ph: (03) 9585 7577 SAFE WORK METHOD STATEMENT

Email: service@acgoulding.com.au

Activity Hazards Risk Ranking Controls Risk Ranking Person

Break the job into steps what What can Harm you or others before controls are What are you going to do to carry out the work safely? After controls are implemented Responsible for

are you doing? list Hazards individually, do not group implemented H,M, or L (Apply the risk Hierarchy of control) H, M or L

implementation of the controls

Preparing job

location with H Limit timing of repetitive work (swapping of employees L

equipment to break up the job).

Site Supervisor/

Use tools correctly i.e. using the appropriate safety Workers

Hand Tools – components i.e. double handle grips for hammer drills

battery etc).

operated

Always carry out works as per Manual Handling SWMS

Hand Tools – MSD from repetitive &/ high Ensure tools are in good working order.

Site Supervisor/

Power operated force H Limit timing of repetitive work (swapping of employees L

Workers

Hand Tools – to break up the job).

Power operated Severe cuts M Ensure the power tools are tested & tagged. L

Hand Tools –

Electrocution

Power operated Site Supervisor/

Safe Guards are kept on at all times and in good Workers

condition. (should they not be in good condition do not

use – report immediately to your Site Supervisor)

Ensure all safety components remain on the tools (such

as double handle grips for hammer drills etc.)

Hand tools MSD from repetitive &/ high Limit timing of repetitive work (swapping of employees

force M L

to break up the job).

Site Supervisor/

Use tools correctly i.e. using the appropriate safety Workers

components i.e. double handle grips for hammer drills

etc).

Always carry out works as per Manual Handling SWMS

Review #1 09/1/18 3 Installing ductwork to shaft penos

Cliff Goulding Associates trading as AC Goulding SWMS 049(A)

ABN: 57 007 347 515

65 Grange Rd Cheltenham 3192 Ph: (03) 9585 7577 SAFE WORK METHOD STATEMENT

Email: service@acgoulding.com.au

Activity Hazards Risk Ranking Controls Risk Ranking Person

Break the job into steps what What can Harm you or others before controls are What are you going to do to carry out the work safely? After controls are implemented Responsible for

are you doing? list Hazards individually, do not group implemented H,M, or L (Apply the risk Hierarchy of control) H, M or L

implementation of the controls

PPE Cuts, bruises Ensure your PPE is in good working order

Scissor Lift Falls from lift Ensure Worker is trained and licensed. Site Supervisor/

M L

Lift tilting/falling Carry out pre-start checklist. (as per Scissor SWMS Workers

refer)

Platform Falls from platform, Ladders Ensure trained correctly for climbing on/off the ladder

Ladders slipping M L

i.e. 3 points of contact. Site Supervisor/

Ensure feet of platforms, trends, rungs, handles, hinges Workers

are in good condition.

Duct Lifter Fingers jammed Ensure all safe guards are in good condition and in

H place – follow ductlifter check list L Site Supervisor/

Workers

Lifter tilting/falling Ensure stable ground.

Installing Falling from Elevated Working Ensure hand and safety rails are in place before

ductwork to Platforms (EWP) H penetration is un-covered L

Site Supervisor/

shaft/ Apparatus tilting and falling Replace and secure duct and penetration coverings at Workers

penetrations with person on or onto anytime work has STOPPED.

persons below Check prior to lowering duct that shaft is clar of

obstructions, the shaft is the correct size, there is not

one standing directly below the duct.

Head injuries from services Check ground is clear & stable to give installers stabel

above. base to lower duct.

Eye/Ear/Breathing/Skin Ensure wearing the appropriate PPE being your hard Site Supervisor/

M hat, glasses, ear muffs, gloves & dust mask L

Workers

Review #1 09/1/18 4 Installing ductwork to shaft penos

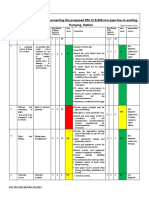

Cliff Goulding Associates trading as AC Goulding SWMS 049(A)

ABN: 57 007 347 515

65 Grange Rd Cheltenham 3192 Ph: (03) 9585 7577 SAFE WORK METHOD STATEMENT

Email: service@acgoulding.com.au

Activity Hazards Risk Ranking Controls Risk Ranking Person

Break the job into steps what What can Harm you or others before controls are What are you going to do to carry out the work safely? After controls are implemented Responsible for

are you doing? list Hazards individually, do not group implemented H,M, or L (Apply the risk Hierarchy of control) H, M or L

implementation of the controls

Limit timing of repetitive work (swapping of employees

H to break up the job).

Use tools correctly i.e. using the appropriate safety

Using battery components i.e. double handle grips for hammer drills

MSD from force and repetitive etc). Site Supervisor/

op hand L

drilling above shoulder height Workers

hammer drill Ensure lifting or lowering tool is carried out safety by

the 3 points of contact principal for EWP.

Always carry out works as per Manual Handling SWMS

Ensure wearing the appropriate PPE being your hard

hat, glasses, ear muffs, gloves & dust mask

Eye/Ear/ MSD from repetitive screwing Limit timing of repetitive work (swapping of employees Site Supervisor/

H L

Breathing/Skin above shoulder height to break up the job). Workers

Use tools correctly .

Housekeeping Tripping hazards All material is cleaned up at the end of each day and

Site Supervisor/

M stored/removed in the appropriate locations agreed L

Workers

upon by the Site Manager/Site Supervisor

Review #1 09/1/18 5 Installing ductwork to shaft penos

You might also like

- Risk Assessment For Kerb Stones, Wheel Stopper and Paving InterlocksDocument4 pagesRisk Assessment For Kerb Stones, Wheel Stopper and Paving Interlockspete chiz91% (23)

- Women's Prints & Graphics Forecast A/W 24/25: Future TerrainsDocument15 pagesWomen's Prints & Graphics Forecast A/W 24/25: Future TerrainsPari Sajnani100% (1)

- Yellowjackets 101 Pilot 2021Document82 pagesYellowjackets 101 Pilot 2021Javier MendozaNo ratings yet

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument7 pagesRisk Assessment For Installation of Automatic Revolving Door InstallationTECHCOM100% (1)

- Jsa For Lifting Activities With Mechanical EquipmentDocument4 pagesJsa For Lifting Activities With Mechanical EquipmentMuhammad Umar GondalNo ratings yet

- Retail Permit To Work System - Job Hazard AnalysisDocument7 pagesRetail Permit To Work System - Job Hazard AnalysisSanthosh Kumar100% (1)

- Safe Work Procedure On DuctingDocument5 pagesSafe Work Procedure On Ductingroland mago100% (1)

- SWMS 073 Install Exhaust FanDocument1 pageSWMS 073 Install Exhaust Fancraigfutcher2000No ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Naf 2020 Ra 012 00Document12 pagesNaf 2020 Ra 012 00vinayNo ratings yet

- Amb RaDocument4 pagesAmb RavivekanandhanNo ratings yet

- Night Work Risk Assessment1Document1 pageNight Work Risk Assessment1Muhammad ShafiqNo ratings yet

- Risk Assessment: Unilever ProjectDocument2 pagesRisk Assessment: Unilever ProjectmuradNo ratings yet

- Risk Assessment For Electrical ConduitDocument6 pagesRisk Assessment For Electrical ConduitMustafa RazaNo ratings yet

- Risk Assessment For Installation of A New Air Conditioning SystemDocument5 pagesRisk Assessment For Installation of A New Air Conditioning SystemErich BuenoNo ratings yet

- 3 - RA-mepDocument9 pages3 - RA-mephsem Al EimaraNo ratings yet

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- Risk Assessment For Installation of A New AC UnitDocument9 pagesRisk Assessment For Installation of A New AC Unitservice.amepNo ratings yet

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Shade Sail Installation Safe Work Method Statement-SAMPLEDocument3 pagesShade Sail Installation Safe Work Method Statement-SAMPLEMohammed MustafaNo ratings yet

- SWMS Traffic ManagementDocument5 pagesSWMS Traffic ManagementadminNo ratings yet

- Risk Assessment ForkliftDocument2 pagesRisk Assessment Forkliftmohamed ghaly100% (2)

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor50% (4)

- Risk Assessment-1 PDFDocument17 pagesRisk Assessment-1 PDFDayanandaNo ratings yet

- Fencing Safe Work Method Statement-SAMPLEDocument3 pagesFencing Safe Work Method Statement-SAMPLErohantparrNo ratings yet

- Task Sheet - S5 Risers - 10-06-22Document7 pagesTask Sheet - S5 Risers - 10-06-22LeeJB09No ratings yet

- RA Underground Fire Pipe Installation Work R02Document15 pagesRA Underground Fire Pipe Installation Work R02vinayNo ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- Genie E Series Slab Scissor Lift OperationDocument11 pagesGenie E Series Slab Scissor Lift OperationSanket Arun MoreNo ratings yet

- 10147-9 SampleDocument3 pages10147-9 SampleSun ShadeNo ratings yet

- CONFINED SPACE - Entry (Roof Space)Document6 pagesCONFINED SPACE - Entry (Roof Space)Tony ZhangNo ratings yet

- TRA - CW-A04 - Tighting With HammerDocument7 pagesTRA - CW-A04 - Tighting With HammervalveworkshseNo ratings yet

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- 5.19 JSP ScaffoldDocument4 pages5.19 JSP Scaffoldpoorm879No ratings yet

- Risk Assessment Steel Structure Spray TowerDocument5 pagesRisk Assessment Steel Structure Spray Towermohamed ghalyNo ratings yet

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 pagesCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNo ratings yet

- Overhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Document5 pagesOverhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Javid AaqibNo ratings yet

- Jsa Panel SullayilDocument6 pagesJsa Panel SullayilthennarasuNo ratings yet

- RAMS Air Conditioning Unit InstallDocument10 pagesRAMS Air Conditioning Unit InstallMohammad SaleemNo ratings yet

- Risk Assesmennt For OutfallDocument9 pagesRisk Assesmennt For Outfallchinmay jagdeepNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document4 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- Risk Assessment For .Testing and Commissioning of Fire DamperDocument9 pagesRisk Assessment For .Testing and Commissioning of Fire Damperarun kurlanNo ratings yet

- JRA 1Y-Centrifugal Pump Maintenance (Flowserve) - P-320CDocument5 pagesJRA 1Y-Centrifugal Pump Maintenance (Flowserve) - P-320CIlyasNo ratings yet

- Control Valves and Relief Valves Removal and InstallationDocument9 pagesControl Valves and Relief Valves Removal and InstallationELDIABLO 24KNo ratings yet

- 32 GRC WorksDocument2 pages32 GRC Workssamer alrawashdehNo ratings yet

- Roofing Safe Work Method StatementDocument14 pagesRoofing Safe Work Method Statementnextleve.test1No ratings yet

- JSA ELETRICAL MaintenanceDocument17 pagesJSA ELETRICAL MaintenanceWeru MorrisNo ratings yet

- Cutting DrillingDocument4 pagesCutting DrillingKoneti JanardhanaraoNo ratings yet

- Risk Assesment For Connecting The Existing Pipe To Pump StationDocument4 pagesRisk Assesment For Connecting The Existing Pipe To Pump StationSasi Kumar100% (2)

- 29 Housekeeping and CleaningDocument3 pages29 Housekeeping and CleaningMohammed Ali QaziNo ratings yet

- Safe Work Method StatementDocument4 pagesSafe Work Method StatementShahed Facebook100% (1)

- ZMDEI-AB-24-03-2022-Genral LIFTDocument15 pagesZMDEI-AB-24-03-2022-Genral LIFThussein aliNo ratings yet

- JSA 02-03 Vertical Borehole and Anode Bed InstallationDocument5 pagesJSA 02-03 Vertical Borehole and Anode Bed InstallationHaleemUrRashidBangash50% (2)

- Risk Assessment For Concrete Repair WorkDocument11 pagesRisk Assessment For Concrete Repair WorkSaeed AhmadNo ratings yet

- SK Vin Builders: Hazard Identification Risk Assessment & Determining Control (Hiradc)Document9 pagesSK Vin Builders: Hazard Identification Risk Assessment & Determining Control (Hiradc)Sanket0% (1)

- JHA - DU ReplacementDocument9 pagesJHA - DU ReplacementSanthosh KumarNo ratings yet

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document3 pagesRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo RajanNo ratings yet

- RA 014 (De-Watering by Pumps) 2Document9 pagesRA 014 (De-Watering by Pumps) 2abdulthahseen007No ratings yet

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- Installation of FormworkDocument3 pagesInstallation of FormworkJhundel Factor PajarillagaNo ratings yet

- Choreography 2Document12 pagesChoreography 2Pramendra AryaNo ratings yet

- The FireboltDocument10 pagesThe FireboltIsa Maria100% (1)

- Aocs Manual Gentlemen Poise and PresenceDocument18 pagesAocs Manual Gentlemen Poise and PresenceSanthoshNo ratings yet

- The Wizard World - CompleteDocument8,581 pagesThe Wizard World - Completedow oqdmqNo ratings yet

- Amigurumi ReindeerDocument15 pagesAmigurumi Reindeertaniareis100% (1)

- The Woman Who Lied - Claire DouglasDocument275 pagesThe Woman Who Lied - Claire DouglasMariaNo ratings yet

- Hooks & Eyes, Snaps, and Tape Fasteners: CT - MMB.029Document7 pagesHooks & Eyes, Snaps, and Tape Fasteners: CT - MMB.029lhenNo ratings yet

- Beauty and The BeastDocument11 pagesBeauty and The BeastAbdullmalik 7No ratings yet

- Tle7 Q1 W1 BCNC PDFDocument30 pagesTle7 Q1 W1 BCNC PDFMaricar Cornico YturriagaNo ratings yet

- Test 3 Am Nhan Doan VanDocument11 pagesTest 3 Am Nhan Doan Vankiet lyNo ratings yet

- Traditional Clothes of The Countryjoint BulletinDocument18 pagesTraditional Clothes of The Countryjoint BulletinSonali SasteNo ratings yet

- Untitled DocumentDocument4 pagesUntitled DocumentAishwaryaNo ratings yet

- Pemerintah Kabupaten Bogor Dinas Pendidikan Kecamatan ParungDocument3 pagesPemerintah Kabupaten Bogor Dinas Pendidikan Kecamatan ParungSDN PamagarsariNo ratings yet

- Final RMDocument34 pagesFinal RMGourav SahaNo ratings yet

- WM1060YTDDocument96 pagesWM1060YTDSasa GloginjicNo ratings yet

- Housekeeping Procedures, SOPsDocument5 pagesHousekeeping Procedures, SOPsMALOU ELEVERANo ratings yet

- Lista Parfum 09-2010Document114 pagesLista Parfum 09-2010geluciubotaruNo ratings yet

- Women's Designer Pumps Pumps & High Heels JIMMY CHOODocument1 pageWomen's Designer Pumps Pumps & High Heels JIMMY CHOOlgarity13No ratings yet

- Rubi Catalogue Update 0724.1595560920284 PDFDocument57 pagesRubi Catalogue Update 0724.1595560920284 PDFAnastasia LilikNo ratings yet

- Circle.: Unit 8 Test ADocument6 pagesCircle.: Unit 8 Test AHope HamNo ratings yet

- Uphill From Here.: Gabriel RobinsonDocument9 pagesUphill From Here.: Gabriel RobinsonGabriel RobinsonNo ratings yet

- Les 1Document13 pagesLes 1Meo MeoNo ratings yet

- Marina ObookoDocument85 pagesMarina ObookoCristina GribNo ratings yet

- VOGUEDocument47 pagesVOGUEArianne DiosoNo ratings yet

- Cô Ngoc-Bai Tap Về So Sanh Và TT Tinh TừDocument17 pagesCô Ngoc-Bai Tap Về So Sanh Và TT Tinh TừKimm NgọccNo ratings yet

- Everest Base CampDocument8 pagesEverest Base CampIsaac AlemanNo ratings yet

- Q3e LS3 U05 EverestDocument11 pagesQ3e LS3 U05 EverestmojganNo ratings yet

- Her Silent ScreamsDocument222 pagesHer Silent ScreamstyrometigerNo ratings yet