Professional Documents

Culture Documents

Kirloskar Intern Ship Report

Uploaded by

Harshith Mn AcchuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kirloskar Intern Ship Report

Uploaded by

Harshith Mn AcchuCopyright:

Available Formats

KIRLOSKAR ELECTRICALS. LTD.

INTRODUCTION

FOUNDERS:

Was a successful industrialist, but his chief merit lay in the trail he blazed, for the principle in life

he depended upon were his vision and a spirit of pioneering.

His message stands as a very practical guidance to all of us even today.

"My faith is in the human intellect. It gives us our means to create wealth by directing our talents

towards productive work. And therefore, freedom for individual ability is the only way a society

can prosper. After all, you can't distribute wealth unless you first create it. And you can't create it

unless you know how."

His Childhood

Born on June 20, 1869 in the small town of Gurlhosur in Dharwar district, he was the fifth and

youngest child of a retired land surveyor by name Kashinath Vasudeo Kirloskar whose income

was twelve rupees a month.

At the age of three he lost his mother and his father had to look after him and was sent to Belgaum,

Karnataka to study. His hobby was drawing and toy making.

When he was still in fourth standard, at the age of sixteen, he quit school to go to Bombay. He

enrolled himself in the Sir J.J.School of Art and Crafts and gave up painting and confined himself

to drawing in black and white.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 1

KIRLOSKAR ELECTRICALS. LTD.

While he was still a student in the third year school at the Art School, he joined as a drawing

teacher in Victoria Jubilee Technical School at a very nominal monthly salary. At the Technical

School he acquired a working knowledge of handling lathes, drills and presses.

VISION AND MISSION

The power of now is the energy opportunities that comes to us disguised as challenges. That power

of now at Kirloskar Electric is the dynamic of making opportunities work as by meeting clients’

tough specifications of cost competitiveness, quality and reliability.

His Vision

"We cannot continue as slaves of foreign know-how indefinitely, we must intensify our R & D

efforts," he would repeatedly say.

He was a very observant man and he was able to use the past to analyze and interpret the future.

He had talent for absorbing information easily and had a very good grasp of fundamentals.

Long before small scale industries became popular, he encouraged his workers to branch out on

their own and also provided technical guidance, financial assistance and assured them a market for

their products.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 2

KIRLOSKAR ELECTRICALS. LTD.

HISTORY

India's first iron plough from the Kirloskar Group, not only became an instrument of wealth for

the entire society but also kick started an industrial revolution in India. Today building on its core

engineering strength, the group's scope of operations spans across a gamut of industrial equipment

ranging from pumps & valves, eco-friendly diesel engines & silent generating sets, air & gas

compressors, air-conditioning and refrigeration equipment, a wide range of anti-corrosion coatings

and castings for automotive sector.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 3

KIRLOSKAR ELECTRICALS. LTD.

GLOBAL PRESENCE:

IN INDIA KIRLOSKAR COMPANY LOCATIONS:

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 4

KIRLOSKAR ELECTRICALS. LTD.

INDIA

World's largest irrigation scheme brought Green Revolution in over 4,600 towns and villages in

drought-prone Saurashtra.

Rugged and dependable power packs, 100% reliable back-up power for radar grids, HVAC

solutions for fighter aircrafts and propulsion power for naval ships meets country's defense needs.

Millions of energies efficient Kirloskar engines and pump sets save energy worth billions.

Diesel engines power over 80 different applications. Gensets form the backbone of satellite,

cellular and telecommunications.

Gas compression solutions for natural gas filling stations ensure environment free transportation.

Critical castings that house one among four tractor engines in India.

AFRICA

A large number of Kirloskar pumps have transformed a million lives across the length and breadth

of Africa by providing water for agricultural irrigation and other necessities. With their unique

AAA (Adaptable, Appropriate and Affordable) technology, Kirloskar is committed to bringing

about a Green Revolution in Africa.

EGYPT

For the past thirty years, over 100,000 Kirloskar pump sets have been working along the river Nile,

for greening the desert lands in Egypt. A total of 40 pumping stations incorporating Kirloskar

pumps have been able to reclaim over 150,000 acres of desert land for agriculture, making the

brand name 'Kirloskar' synonymous with pumps in Egypt.

MIDDLE EAST

Reliable and energy efficient compressors help preserve seafood, also bringing prosperity to

fishermen in the Middle East.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 5

KIRLOSKAR ELECTRICALS. LTD.

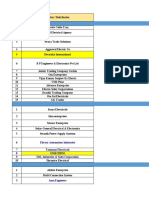

COMPANIES

KIRLOSKAR BROTHERS LTD

KIRLOSKAR OIL ENGINES LTD

KIRLOSKAR PNEUMATIC CO. LTD

KIRLOSKAR SYSTEMS LTD

KIRLOSKAR PROPRIETARY LTD

KIRLOSKAR KENYA LTD

KIRLOSKAR ELECTRIC PVT. LTD

KIRLOSKAR FERROUS IND. LTD

KIRLOSKAR CHILLERS PVT. LTD

KIRLOSKAR INSTITUTE OF ADVANCED MANAGEMENT STUDIES (SOCIETY)

KIRLOSKAR INTEGRATED TECHNOLOGIES PVT.LTD

KIRLOSKAR INDUSTRIES LTD

KIRLOSKAR DMCC

KIRLOSKAR ENERGEN PVT. LTD.

KIRLOSKAR SOUTH EAST ASIA COMPANY LTD.

KIRLOSKAR SOLAR TECHNOLOGIES PVT. LTD

KIRLOSKAR BROTHERS LTD

Company & HO Address "Yamuna", Survey No. 98 (3-7), Baner, Pune 411 045 Business Areas

Pumps & Fluid Handling Solutions

Major Products / Services with Range / Categories

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 6

KIRLOSKAR ELECTRICALS. LTD.

KIRLOSKAR PRODUCTS

Engines, Gensets and Power Solutions

Pumps and Fluid Handling Solutions Compressors, Refrigeration and Process Gas

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 7

KIRLOSKAR ELECTRICALS. LTD.

KIRLOSKAR ELECTRIC COMPANY PVT. LTD.

THE FACTORY PLANT OF KIRLOSKAR ELECTRIC COMPANY

LOCATED AT FIVE PLACES:

1. Bangalore rural (Govenhalli, Nelamangala)

2. Hubli

3. Tumkur

4. Mysore

5. Pune.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 8

KIRLOSKAR ELECTRICALS. LTD.

AC MOTORS

KIRLOSKAR ELECTRIC COMPANY PVT. LTD. HUBBALLI

Kirloskar Electric was the first company in India to manufacture AC motors way back in 1948.

Since then it has developed millions of motors for domestic and international market.

Alternating Current (AC) is what power companies transmit through the electric wires. AC travels

in both directions and is used so that transformers may raise and lower the voltage. Electric

generators produce low voltage electricity and transformers are used to raise the voltage for long

distance transmission.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 9

KIRLOSKAR ELECTRICALS. LTD.

INTRODUCTION

Electric motors defined as electromechanical devices that convert electrical energy to mechanical

energy; they are the interface between the electrical and mechanical systems of a facility.

Electric motors are an important part of any electrical system. They used throughout every

manufacturing plant, office, and home consuming about 64% of all electricity generated.

There are numerous ways to design a motor, thus there are many different types of motors and

each type possess different operating characteristics (that will be listed later). Based on these

characteristics the motor can be chosen for a specified application.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 10

KIRLOSKAR ELECTRICALS. LTD.

Principle of How Motors Work:

1. Electrical current flowing in a loop of wire will produce a magnetic field across the loop.

2. When this loop is surrounded by the field of another magnet, the loop will turn, producing a

force (called torque) that results in mechanical motion

Motor basic parts:

Electric machines are classified into two categories D.C. and A.C. motors, the basic parts for each

type will be different for each type as follows:

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 11

KIRLOSKAR ELECTRICALS. LTD.

1- AC Motor Basic Parts:

1. Enclosure.

2. Stator.

3. Rotor.

4. Bearings.

5. Conduit Box.

6. Eye Bolt

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 12

KIRLOSKAR ELECTRICALS. LTD.

1. Enclosure

The enclosure consists of a frame (or yoke) and two end brackets (or bearing housings).

A motor's enclosure not only holds the motor's components together, it also protects the

internal components from moisture and containments. The degree of protection depends

on the enclosure type. In addition, the type of enclosure affects the motor's cooling.

2. Stator

The motor stator consists of two main parts:

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 13

KIRLOSKAR ELECTRICALS. LTD.

A. Stator Core

The stator is the stationary part of the motor's electromagnetic circuit. The stator is

electrical circuit that performs as electromagnet. The stator core is made up of many thin

metal sheets, called laminations. Laminations are used to reduce energy losses that would

result if a solid core were used.

B. Stator (Windings)

Stator laminations are stacked together forming a hollow cylinder. Coils of insulated wire

are inserted into slots of the stator core.

When the assembled motor is in operation, the stator windings are connected directly to

the power source. Each grouping of coils, together with the steel core it surrounds, becomes

an electromagnet when current is applied. Electromagnetism is the basic principle behind

motor operation.

3. Rotor.

The rotor is the rotating part of the motor's electromagnetic circuit. Magnetic field from

the stator induces an opposing magnetic field onto the rotor causing the rotor to "push"

away from the stator field.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 14

KIRLOSKAR ELECTRICALS. LTD.

There are a lot of rotor types like Squirrel cage rotor and wound rotor, they will be

explained later.

Production Department:

This department is responsible for all the production activities carried out by the unit. The

whole running of unit depends on this department the proper and timely functioning of this

department helps in product reaching the customer at the time.

Objectives:

1. To follow up the production schedules as per the plan.

2. To maintain close and key relationship with other departments.

3. To upgrade the technical efficiency of the production.

Shop 1:

The manufacturing functions are carried out in this shop. In this shop all the raw materials

are pooled up then given a shape, which is semi ready. Various steps are carried out here

to give final shape of various parts of the products like shaft, base milling, machining i.e.

boring, drilling, tapping, covers are also done here.

To avoid the run out 360-degree balancing is done. Here additional balancing type is

adopted.

Pressure testing is carried out to know if any leakage, blowholes. If they are present it's

rejected.

Shop 2:

In this shop only die casting is done. i.e. shape of body and name plates are given in their

final shape. Here all three-body shape and name plates are done with aluminum, which is

heated up to 750 to 800 degrees centigrade. This molten aluminum itself takes the given

shape after cooling. Machine used is H660.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 15

KIRLOSKAR ELECTRICALS. LTD.

Pre-treatment shop:

It is also known as painting shop. Here the components used in the motors are pretreated

and painted. A unique innovation technology called UNIBAKES, installed in 1992 used

for drying the components to be used in export motors.

Shop 3:

This is assembly shop, where the products will get ready up to 9% here. Only final finishing

stages will be left at this stage. The frame size 63-180 motors are assembled here. The

assembling i.e. fixing covers, screws and nuts are done manually. The shaft is fixed through

hydraulic pressing machine. The product comes to connection wing where electrical

connections are given and then later on electrical parts are checked. The product is given

first coat of painting.

Shop 4:

This shop is known as INVOTECH CENTER i.e. R&D division of the firm in this shop,

the product development is the main function. This shop is closely related to the

engineering department and hence carries on its activities in accordance with the

engineering department. The activities of this shop include tests for future department,

vibrators testing reliability etc.

Shop 5:

This shop is for assembly. In this shop there are two sections. One deal with AC motors

and other one with AC generator. In this section of AC motors, the assembling of machine

up to 200-450 frames is done here. In this section of AC motors, the process begins with

the shaft being inserted into rotor through hydraulic press machine. This also has own

painting and dispatch section.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 16

KIRLOSKAR ELECTRICALS. LTD.

Material management department:

Material management department is one of the important departments for any industry or

manufacturing unit, raw materials are necessary. But only processing of raw material is not

sufficient. The quality, delivery time and price factor are all to be considered and this is

not as simple as it seems. It involves lot of inspection negotiation. Hence KSL has

established a separate department which takes care of all the above-mentioned factors.

Manufacturing and engineering department:

This department is responsible for capital equipment and their design and dies activity

using appropriate methods.

Functions:

1. Preparation of drawing jigs, fixtures, dies, tooling storage devices and gauges.

2. Providing guidelines for revision of drawing introducing design changes.

3. To explain the methods of conducting designs.

4. Finalizing the manufacturing process.

5. Verification of jigs and fixtures.

6. Finalizing the specification, procurement and machines for manufacturing.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 17

KIRLOSKAR ELECTRICALS. LTD.

Quality assurance:

The role of quality is so functional division in achieving and maintaining level of specified

quality requirements economically. Quality assurance department maintain quality systems as ISO

9001-1994

Functions:

1. Incoming raw material testing.

2. Re-inspection of product which are required to meet specified requirements.

3. Ensuring that calibrated instruments are used for measurements.

4. Final product inspection.

5. Assisting for customer inspection of products when required quality.

AC motors product range includes:

Open Type Cage Spectrum

KEC designs, manufacture and supply open type cage spectrum motors to suit the exact

requirements of the application resulting in satisfactory performance and operation.

Close Type Cage

KEC designs, manufacture and supply close type cage spectrum motors to suit the exact

requirements of the application resulting in satisfactory performance and operation.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 18

KIRLOSKAR ELECTRICALS. LTD.

Primo

KEC designs, manufacture and supply close type cage primo motors to suit the exact requirements

of the application resulting in satisfactory performance and operation.

Open Type Wound Rotor

Spectrum

KEC designs, manufacture and supply open type wound spectrum motors to suit the exact

requirements of the application resulting in satisfactory performance and operation.

Close Type Wound Rotor

Spectrum

KEC designs, manufacture and supply close type wound spectrum motors to suit the exact

requirements of the application resulting in satisfactory performance and operation

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 19

KIRLOSKAR ELECTRICALS. LTD.

AC Motors

High Voltage Motors: Megapack Closed Type Cage

Operating & Supply Conditions

FEATURES &

VALUES/STANDARDS

Ambient Temperature -10 to +50°C

Altitude

Not exceeding 1000 m above mean sea level

Atmosphere

Non corrosive & non hazardous

Relative Humidity

Up to 100%

Voltage

415V, 690V, 6.6kV, 3.3kV, 11kV +/- 10%

Frequency

50Hz +/-5%

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 20

KIRLOSKAR ELECTRICALS. LTD.

Low Voltage Motors: Open Type Series

Operating & Supply Conditions

FEATURES &

VALUES/STANDARDS

Ambient Temperature -10 to +50°C

Altitude

Not exceeding 1000mtrs above mean sea level.

Atmosphere

Non corrosive & non hazardous

Relative Humidity

Up to 100%

Voltage

415V±10%, 3 ph.

Frequency

50Hz ±5%

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 21

KIRLOSKAR ELECTRICALS. LTD.

Operating & Supply Conditions

FEATURES

VALUES/STANDARDS

Ambient Temperature -10 to +50°C

Altitude

Not exceeding 1000mtrs above mean sea level.

Atmosphere

Non-Corrosive & non-Hazardous

Relative Humidity

Up to 100%

Voltage

415V±10%, 3 pH.

Frequency

50Hz ±5%

Combined Variation 10%

Duty

S1 (continuous)

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 22

KIRLOSKAR ELECTRICALS. LTD.

Low Voltage Motors: Wound Close Type Series

Operating & Supply Conditions

FEATURES &

VALUES/STANDARDS

Ambient Temperature -10 to +50°C

Altitude

Not exceeding 1000mtrs above mean sea level.

Atmosphere

Non corrosive & non-Hazardous

Relative Humidity

Up to 100%

Voltage

415V ±10%, 3 Ph.

Frequency

50Hz ±5%

Combined Variation 10%

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 23

KIRLOSKAR ELECTRICALS. LTD.

LEARNING OUTCOMES:

1. Ability to analyze a given engineering problem, identify an appropriate problem-solving

methodology, implement the methodology and propose a meaningful solution.

2. This training helps to bridge the gap between the theoretical knowledge into practical.

3. Ability to apply prior acquired knowledge in problem solving.

4. Ability to identify sources of hazards and identify appropriate health and safety measures.

5. Ability to work in a team.

6. Ability to take initiatives.

7. Ability to effectively communicate solution to a problem.

8. Ability to adopt a factual approach to decision making.

9. Ability to take engineering action.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 24

KIRLOSKAR ELECTRICALS. LTD.

REFERENCE

1. www.google.com

2. www.kirloskar.in

3. Wikipedia

4. AC Motors Wikipedia

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING, VVIET, MYSURU Page | 25

You might also like

- InventoryDocument100 pagesInventoryadithisarmaNo ratings yet

- Business Explosure - Kirloskar Project.1Document29 pagesBusiness Explosure - Kirloskar Project.1mrunalNo ratings yet

- KPCL Final ProjectDocument66 pagesKPCL Final Projectravikumar198775% (8)

- Report On Industrial VisitDocument18 pagesReport On Industrial VisitSuman KunduNo ratings yet

- Training at Rana Pratap Sagar Hydro Power StationDocument55 pagesTraining at Rana Pratap Sagar Hydro Power StationJatin Pannu50% (2)

- Tranining ReportDocument33 pagesTranining ReportNaamshid Ameen DqNo ratings yet

- KEC Internship ReportDocument20 pagesKEC Internship ReportKartik SKNo ratings yet

- Work Experience at United Electrical Industries LTD PDFDocument68 pagesWork Experience at United Electrical Industries LTD PDFSruthy KrishnaNo ratings yet

- Prajwal Rao K.BDocument44 pagesPrajwal Rao K.BHaroon HaneefNo ratings yet

- TPPL Organizations StudyDocument59 pagesTPPL Organizations StudySatish PvNo ratings yet

- Cash ManagementDocument79 pagesCash ManagementVinayaka Mc100% (3)

- VIshal JavalgeDocument53 pagesVIshal JavalgeSuraj 1212No ratings yet

- 10.solar Based Mini Hybrid Vehicle-2016Document69 pages10.solar Based Mini Hybrid Vehicle-2016msathish_eeeNo ratings yet

- Final Report KECDocument40 pagesFinal Report KECshridhar chalvadiNo ratings yet

- PiezoelectreicityDocument21 pagesPiezoelectreicitykumarpunnu2004No ratings yet

- Kyocera SolarWaterPumps PDFDocument52 pagesKyocera SolarWaterPumps PDFjuly2nt6No ratings yet

- Abhishek Training ReportDocument59 pagesAbhishek Training ReportSudhesh srivastavaNo ratings yet

- Seminar Report SR1Document22 pagesSeminar Report SR1gokulNo ratings yet

- Industry ProfileDocument15 pagesIndustry ProfileUma DeviNo ratings yet

- Dealer of CompetitorsDocument30 pagesDealer of CompetitorsDIVYESH GUPTANo ratings yet

- Internship Training Report OnDocument17 pagesInternship Training Report Onabhisheks1222003No ratings yet

- Emerging Areas in The Field of Electrical EngineeringDocument10 pagesEmerging Areas in The Field of Electrical EngineeringAkiraNo ratings yet

- POWER GRID 400 by 220 Substation ReportDocument85 pagesPOWER GRID 400 by 220 Substation ReportAditya0% (1)

- Solar Generator ReportDocument26 pagesSolar Generator ReportHasan HemaniNo ratings yet

- Bharat Heavy Electrical Limited Training ReportDocument72 pagesBharat Heavy Electrical Limited Training ReportSuresh Sunny100% (1)

- KelDocument71 pagesKelJazmal JabbarNo ratings yet

- Internship Project of Kirloskar Electric Company LTDDocument103 pagesInternship Project of Kirloskar Electric Company LTDJyothi RameshNo ratings yet

- NVE Profile 2020Document12 pagesNVE Profile 2020Hussain ShaikhNo ratings yet

- Industry Visit Report RahulDocument25 pagesIndustry Visit Report RahulVaibhavNo ratings yet

- Industrial Visit ReportDocument24 pagesIndustrial Visit ReportParayatham ManasaNo ratings yet

- K Electric PresentationDocument15 pagesK Electric PresentationSyed SumamaNo ratings yet

- KPTCL ProjectDocument38 pagesKPTCL ProjectSalman Khan50% (2)

- Summer Internship Report OnDocument15 pagesSummer Internship Report OnmohantyomNo ratings yet

- 66 KV Substation Getco RanasanDocument7 pages66 KV Substation Getco RanasanDivyanshu Agarwal100% (1)

- Abhishek Rawat TRAINNG REORTDocument44 pagesAbhishek Rawat TRAINNG REORTrohitkhatrifitness720No ratings yet

- Future Investment Project by R Balakrishna: 15000 00 CR Estimate 1000 00 CR ESTIMATEDocument7 pagesFuture Investment Project by R Balakrishna: 15000 00 CR Estimate 1000 00 CR ESTIMATENirmala KarnatiNo ratings yet

- Report On Industrial Visit (1) - 2Document21 pagesReport On Industrial Visit (1) - 2Suman KunduNo ratings yet

- Manufacturing and Constructional Features of Electrical MachinesDocument46 pagesManufacturing and Constructional Features of Electrical Machines251 Mahitha Devi PatnalaNo ratings yet

- Final Rpeort (Jakson)Document82 pagesFinal Rpeort (Jakson)Vikas SolankiNo ratings yet

- Bhel EpdDocument80 pagesBhel EpdJayanth C VNo ratings yet

- Bhel EpdDocument80 pagesBhel EpdKrs HereNo ratings yet

- Project Report of Industrial Summer TrainingDocument40 pagesProject Report of Industrial Summer Trainingrahul_singh654492580% (15)

- ProjetcDocument22 pagesProjetcAryanNo ratings yet

- Training ReportDocument41 pagesTraining Report12 EC ATUL KUMAR SRIVASTAVANo ratings yet

- Smart Motor LimitedDocument18 pagesSmart Motor LimitedAravindha PrakashNo ratings yet

- Genetion of Power With Speed BreakersDocument19 pagesGenetion of Power With Speed BreakersShailendra Singh57% (7)

- Trabalho de InglêsDocument8 pagesTrabalho de InglêsJäfët Måtöndö MånzämbïNo ratings yet

- DPK EngineersDocument16 pagesDPK EngineersAvinash UppiNo ratings yet

- Indraprasth Power Generation Co LTDDocument76 pagesIndraprasth Power Generation Co LTDRajat Rawat100% (1)

- Vocational Training Report 2018Document38 pagesVocational Training Report 2018Sameer Bara50% (2)

- Hitesh Industrial Report On Employ AbsenteeismDocument18 pagesHitesh Industrial Report On Employ AbsenteeismHiteshpatel12No ratings yet

- Lab 2. No.5 and DiscussionDocument2 pagesLab 2. No.5 and DiscussionApril JulianoNo ratings yet

- Anshul BhelDocument96 pagesAnshul BhelMessieurs Avinash PurohitNo ratings yet

- Company Profile: Contact UsDocument20 pagesCompany Profile: Contact Usengnajeeb75No ratings yet

- Summer Training Project ReportDocument37 pagesSummer Training Project ReportSumit Bansal100% (1)

- Prajwal Rao K.BDocument44 pagesPrajwal Rao K.BanthonykulaiNo ratings yet

- The AI Energy Equation: Transforming Power Utilities with Artificial IntelligenceFrom EverandThe AI Energy Equation: Transforming Power Utilities with Artificial IntelligenceNo ratings yet

- Power Utility Job Blueprint: Strategies for Engineers in the Power SectorFrom EverandPower Utility Job Blueprint: Strategies for Engineers in the Power SectorNo ratings yet

- Final Internship Reports (Kaynes)Document47 pagesFinal Internship Reports (Kaynes)Harshith Mn AcchuNo ratings yet

- Final Internship Reports (Kaynes)Document47 pagesFinal Internship Reports (Kaynes)Harshith Mn AcchuNo ratings yet

- Harshith Coreection ContentsDocument1 pageHarshith Coreection ContentsHarshith Mn AcchuNo ratings yet

- Kirloskar Front Page 2Document4 pagesKirloskar Front Page 2Harshith Mn AcchuNo ratings yet

- Kirloskar Front Page 2Document4 pagesKirloskar Front Page 2Harshith Mn AcchuNo ratings yet

- Technology - Comparison of MEC MFL For Tank Floor Inspection-MinDocument7 pagesTechnology - Comparison of MEC MFL For Tank Floor Inspection-MinCepi Sindang KamulanNo ratings yet

- Subject Code: EE-221 Full Marks: 30 Time: 24 HRS.: End-Semester ExaminationDocument4 pagesSubject Code: EE-221 Full Marks: 30 Time: 24 HRS.: End-Semester Examinationhajarilal meenaNo ratings yet

- UL Appliances Motors For Motor Manuf Whitepaper 06292010 UL 1004Document5 pagesUL Appliances Motors For Motor Manuf Whitepaper 06292010 UL 1004Rip_BarNo ratings yet

- Magnetic Particle InspectionDocument36 pagesMagnetic Particle InspectionEthem GüngörNo ratings yet

- 3340902Document5 pages3340902Arjun SomaiyaNo ratings yet

- Diffraction Q. What Is Meant by Diffraction of Light? Distinguish Between Fresnal and Fraunhofer Classes of Diffraction. SolutionDocument17 pagesDiffraction Q. What Is Meant by Diffraction of Light? Distinguish Between Fresnal and Fraunhofer Classes of Diffraction. SolutionDr. Soni YadavNo ratings yet

- Classic G10 Vintage: General SpecificationsDocument1 pageClassic G10 Vintage: General SpecificationsDaniel MambuscayNo ratings yet

- Sloution To Que Paper - HVE (S-11 To S-22) PDFDocument13 pagesSloution To Que Paper - HVE (S-11 To S-22) PDFAmol0% (1)

- SlayyDocument16 pagesSlayyAsli GoncNo ratings yet

- Pee Unit 1 NotesDocument9 pagesPee Unit 1 NotesGopi chand GamerNo ratings yet

- Aperture-Shared Radiation Surface A Promising Technique For Multifunctional Antenna Array DevelopmentDocument20 pagesAperture-Shared Radiation Surface A Promising Technique For Multifunctional Antenna Array DevelopmentpikothemanNo ratings yet

- Electrical Partsof Wind TurbinesDocument62 pagesElectrical Partsof Wind TurbinessatishnamalaNo ratings yet

- E16355Document30 pagesE16355HOFFERNo ratings yet

- HWXX-6516DS1-VTM - HWXX-6516DS1-A2M: General SpecificationsDocument4 pagesHWXX-6516DS1-VTM - HWXX-6516DS1-A2M: General SpecificationsLuis Adolfo Mazini RodriguesNo ratings yet

- HD Boyser RBT-40Document4 pagesHD Boyser RBT-40MiguelNo ratings yet

- MV Viva QuestionsDocument12 pagesMV Viva QuestionsOMKAR KULKARNINo ratings yet

- H2 Physic 2007 A Level SolutionsDocument19 pagesH2 Physic 2007 A Level SolutionsonnoezNo ratings yet

- SCHLEICH - EN - Bedienungsanleitung SurgeWinDocument55 pagesSCHLEICH - EN - Bedienungsanleitung SurgeWinRolando LoayzaNo ratings yet

- EMV Multi Cable Transit Modular System (EMC-System) : PDFDocument7 pagesEMV Multi Cable Transit Modular System (EMC-System) : PDFbakien-canNo ratings yet

- Applied Optics: Lecture III-3 Reflection and Refraction of EM-waves at A Plane-Interface Between DielectricsDocument5 pagesApplied Optics: Lecture III-3 Reflection and Refraction of EM-waves at A Plane-Interface Between Dielectricstamania naeemNo ratings yet

- PWSUNP193420220927111318062sound Waves-2Document20 pagesPWSUNP193420220927111318062sound Waves-2rishit.yadav1102No ratings yet

- G6RNDocument3 pagesG6RNValeri Luht Eurocargo FinlandNo ratings yet

- NCERT Exemplar Solution Class 10 Science Chapter 10Document24 pagesNCERT Exemplar Solution Class 10 Science Chapter 10Hitesh Parakh X-ANo ratings yet

- 300 MW Variable Speed Drives For Pump-Storage Plant Application GoldisthalDocument24 pages300 MW Variable Speed Drives For Pump-Storage Plant Application GoldisthalMiguel Esteban MartinezNo ratings yet

- Topic 3 Alternating Current Circuits I PDFDocument20 pagesTopic 3 Alternating Current Circuits I PDFFeddy BlaizNo ratings yet

- 3774 Books Doubtnut Question BankDocument60 pages3774 Books Doubtnut Question BankNano SuyatnoNo ratings yet

- The Effect of Dielectric Inside An Inductance CoilDocument43 pagesThe Effect of Dielectric Inside An Inductance CoilAlamNo ratings yet

- Chapter 10Document21 pagesChapter 10StefanPerendijaNo ratings yet

- Teco s310 User ManualDocument10 pagesTeco s310 User ManualEhsan GhanbarzadehNo ratings yet

- Inductor - Vitec PN 53PR105-722 - 20121106Document2 pagesInductor - Vitec PN 53PR105-722 - 20121106senayan pltdNo ratings yet