Professional Documents

Culture Documents

SB3 0 101

Uploaded by

jussmeeeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SB3 0 101

Uploaded by

jussmeeeCopyright:

Available Formats

SERVICE BULLETIN

NOTICE: The Type of Change and Recommended Compliance specified reflects Solar’s best judgment regarding the

Service Bulletin. All questions should be directed to your Solar Field Service Representative. Solar, Saturn,

Centaur, Taurus, Mercury, Mars, Titan, SoLoNOx, and Turbotronic are trademarks of Solar Turbines Incorporated.

Cat and Caterpillar are trademarks of Caterpillar Inc. Specifications subject to change without notice.

NUMBER: 3.0/101A

ISSUED: October 1999

REVISED: September 2001

PRODUCT: Mars

MODEL(S): All

Specifics:

SUBJECT: MARS ENGINES - IGNITION ISSUES

Type of Change: Product Improvement

Recommended

Compliance: Earliest Convenience

Purpose:

To provide information to improve Mars engine ignition.

Revision A

• Introduces a torch “pre-light” procedure.

The torch is lit a few seconds before the main gas supply is turned on to guarantee an

established pilot flame when the main gas supply is opened.

• Increases the turbine light-off speed and abandons the interrupted crank cycle to increase

the turbine air flow and make the light-off less sensitive to fuel pressure variations.

• Extends the validity of this Service Bulletin from SoLoNOx turbines to all Mars turbines.

• Gives examples of ladder-logic changes to allow the installation of above improvements

into the start sequence of Allen Bradley PLC’s.

SERVICE BULLETIN Page 1 of 13

NUMBER: 3.0/101A

GENERAL INFORMATION:

Several incidents of Mars engines have experienced inconsistent or rough engine ignition. In a few

cases exhaust duct damage occurred due to late engine light-off. Potential causes of hard light-offs

are: unreliable operation, extended ignition timer and a fuel schedule that supplies too much fuel

into the combustion system at light-off. This Service Bulletin provides information for improved

engine light-off with existing systems and lists the software modifications required to retrofit newer

Allen Bradley control systems.

To address the root cause of the light-off problems, Solar Turbines has altered the start sequence

on new Mars production packages in two important ways:

• Torch pre-light

The torch is lit a few seconds before the main gas supply is turned on. This modification

insures a fully established torch flame at the time the main gas supply is turned on. Main

combustor light-off will occur smoothly as the ideal air-gas mixture is reached.

• Increased light-off speed (light-and-go)

Marginal engine airflow during turbine light-off has been recognized as one of the main

reasons for the critical torch pressure adjustments and the sensitive fuel scheduling. To

correct this problem, the turbine light-off speed was increased, and the interrupted crank

cycle was abandoned. Engine light-off is now initiated directly at the end of the turbine

purge cycle without interrupting the starter motor. This increases the turbine airflow during

ignition and makes the fuel gas scheduling (torch and main gas supply pressures) less

critical.

As an added benefit, the engine start time is shortened, and the start sequence for Mars

turbines is similar to the sequence used in all other Solar product lines.

PROCEDURE:

During investigation of any reported ignition issues, the following areas should be addressed. Users

should contact the local Solar District Office for assistance with any of the following issues.

1. TORCH PRESSURE:

For a normal light-off, with the existing start sequence, the nominal gas supply pressure

to a Mars torch should be around 5 psi (35 kPa). Measure torch pressure near the torch

fuel inlet, downstream of the torch valve. The torch pressure regulator sets the torch fuel

pressure. The torch pressure for optimum light-off may vary from application to applica-

tion. If the engine is experiencing hard light-offs, the torch gas pressure settings should

be optimized. It is strongly recommended that users contact Solar Field Services for

assistance in this optimization.

Accurate torch gas pressure control is necessary to avoid ignition problems. Mars pack-

ages, produced since June, 1999, use two pressure regulators to better control the torch

pressure. Previous Mars units relied on one regulator to reduce the gas pressure from

Page 2 of 13 SERVICE BULLETIN

NUMBER: 3.0/101A

skid supply pressure to 5 psi (35 kPa) torch pressure. With the new dual regulator sys-

tem, the first regulator reduces the gas pressure to 35 psi (241 kPa), and the second: from

35 psi to 5 psi (241 kPa to 35 kPa). The torch regulator upgrade is available as a retrofit

kit Solar P/N 1038766-100 from Solar Service Parts. The kit contains all the necessary

hardware and installation instructions necessary for successful installation. If assistance

is required in installing the kit, contact your Solar District Service Office.

After installation of the “light-and-go” logic into any Mars turbine package, the light-off

speed and engine air-flow increase, require increased torch gas flow. For light-off at

nominal purge crank speeds (21 to 25% Ngp), the torch gas pressure should be reset to

about 8 psi (55 kPa). Due to the higher air and gas flows, the torch gas pressure is much

less sensitive, and the recommended value should be correct for most applications.

2. IGNITION TIMER SETTING:

UNDER NO CIRCUMSTANCES SHOULD THE IGNITION TIMER BE IN-

CREASED TO MORE THAN 10 SECONDS.

The as-shipped ignition timer setting in the Allen Bradley software is 10 seconds. How-

ever, for a normal ignition, the torch should light within 3 to 4 seconds after the ignition

is initiated. The ignition timer setting can be reduced to 5 seconds, provided ignition can

consistently be achieved within that time.

3. TORCH:

Mars SoLoNOx torches are difficult to engage into the combustor floating grommet due

to their offset non-radial design. If light-off problems persist after the torch gas pressure

has been checked, proper torch engagement should be verified. Remove a fuel injector

at the 5 o’clock to 7 o’clock position and insert a flexible Borescope tip between the

outer combustor shell and the outside housing. Guide the Borescope tip until you see

the side of the torch and the outside wall of the combustor. The torch should line up

and fully engage into the floating combustor grommet. A new extended length torch,

P/N 195005-102, that replaced the earlier -101 design has been incorporated in new and

overhauled engines since 1996 and is designed to eliminate the possibility of the torch

disengaging.

In addition, several cases have been reported where engine light-off problems were ex-

perienced due to an incorrect fuel-metering orifice installed during the torch assem-

bly. Mars SoLoNOx engine torches have a .040 inch (1.0 mm) diameter orifice P/N

951879C1. During engine light-off troubleshooting, the orifice in the torch should be

checked for proper size and for fouling and obstructions.

SERVICE BULLETIN Page 3 of 13

NUMBER: 3.0/101A

4. PRE-LIGHT:

Improvements in light-off reliability can be achieved by “pre-lighting” the torch. New

production engines light the torch four seconds before the main gas supply is switched

on. This delay insures that the pilot flame is fully established by the time the main fuel

gas is metered into the combustion chamber. Due to the fully established pilot flame, the

main fuel starts to burn as soon as a combustible mixture is present, insuring a reliable

and smooth light-off.

Attachment 1 lists the light-off sequence with “pre-light” for Mars dual fuel turbines and

newer Allen Bradley control systems. Single fuel control logic and other types of control

systems can be individually adapted based on the above example. Please contact Solar

Field Services for assistance.

5. LIGHT-AND-GO START SEQUENCE:

This start sequence omits the engine “roll-down” after the engine purge sequence and

initiates ignition directly after the purge cycle, keeping the starter engaged during the

entire start cycle. Due to the increased light-off speed, the turbine airflow is higher and

metering of the torch and main fuel gas is less critical.

New fuel pressure and pressure switch settings:

• If the fuel gas schedule is correct, the main gas fuel flow will adjust itself to the new

conditions.

• The torch gas pressure must be increased from the current value to 8 psi (55 kPa).

• Liquid fuel schedules for torch and main fuel flow will adjust themselves to the

higher combustion chamber pressure and should not require adjustment.

• The fuel pressure increase due to the elevated light-off speed is small. The shut

downs, “High gas fuel start pressure” (TP341-1 or S341-1; nominal 8 psig (55 kPa))

and/or “High liquid fuel start pressure” (TP341-2 or S341-2; nominal 12 psig (83

kPa)), do not require resetting. Check fuel schedules and timer settings if problems

with these switches arise after the increase in light-off speed.

Crank speed:

• The correct crank speed is obviously critical to make the new "light-and-go"

system work. Nominal crank speed is between 21 and 25% Ngp. This speed is

ideal for the new ignition sequence.

• All direct drive AC start motors crank within this speed range, and no changes

are required.

• On electro-hydraulic (hydrostatic) start systems, the pressure control valve for

partial stroke (PCV901, attached to the hydraulic motor) must be set to achieve

a crank speed within 21 and 25% Ngp.

Page 4 of 13 SERVICE BULLETIN

NUMBER: 3.0/101A

• Pneumatic start systems with 2-step pressure regulation must be adjusted to

crank between 21 and 25% Ngp (old expansion turbine or new Hilliard positive

displacement starter).

• Old pneumatic start systems with a single step pressure regulator (mainly

packages built in the 1980’s) crank much faster than desirable. Crank speeds well

above 30% Ngp can be experienced. Service Bulletin 3.0/105D recommends a

maximum crank speed of 25% Ngp for all Mars engines. Solar is developing

a retrofit kit to install the newer 2-step start system for customers wishing to

convert to the "light-and-go" ignition system.

• Hydrodynamic (Pelton wheel) starters cannot be economically adapted to a

reduced crank speed. A conversion to a modern AC direct drive system is

recommended in these cases.

Retrofit:

With the exception of older pneumatic and hydrodynamic start systems, software

changes-only are required, together with a few adjustments of pressure settings.

Attachment 2 lists the “light-and-go” logic for newer control systems and AC direct drive

start systems.

Attachment 3 lists the "light-and-go" logic for newer control systems and electro-hy-

draulic start systems.

6. LIQUIDS IN TORCH LINE:

The six-o’clock position of the torch and the torch fuel line provides the combustor with a

low collection point for water and other liquids. The torch line will condense water from

PCD air. During the engine light-off investigation, the torch and the torch line should

be drained of any liquids, which have accumulated in them. If liquid contamination is

observed in the gas fuel line, corrective action should be initiated to properly condition

the fuel gas per Solar Specification ES 9-98.

7. CHECK VALVE:

One other possible contributor to poor ignition is trapped PCD air in the fuel system. To

eliminate trapped PCD air, the check valve VCS933-2 could be moved downstream of

the torch solenoid L340-1. Verify proper operation of the check valve VCS933-2 at this

position. To improve torch light-off, this change has been incorporated on Mars packages

shipped from the factory after June, 1999.

SERVICE BULLETIN Page 5 of 13

NUMBER: 3.0/101A

8. FUEL SCHEDULE:

Most Mars packages are equipped with an electro-pneumatic servo controlled L344-6

fuel system. The fuel system can supply excessive fuel into the engine during light-off, if

the fuel schedule is set too high or the airflow is too low. With the fuel schedule K-values

set to factory setting, the fuel supply pressure of the throttle valve ranges from 6 to 8 psig

(41 to 55 kPa). The impact of a late light-off from the torch may be reduced if the fuel

schedule is lowered or the airflow is improved. Field experience has indicated that, if

a hard light off occurs, a lower fuel schedule may be required to get a more reliable

light-off. In some cases, a gas fuel supply pressure of 3 psig (21 kPa) to the throttle

valve is optimum for an ignition time of 3-4 seconds. It is strongly recommended that

users contact Solar Field Services for assistance in this optimization.

ACTION REQUIRED:

• Investigate your basic light-off parameters and compare with above recommendations.

Make sure, that critical values like torch gas pressure, main fuel pressure and maximum

ignition timer setting do not exceed the given limits.

• No changes in the basic light-off logic (e.g., adding torch ”pre-light” or “light-and-go”) are

required unless unreliable or hard engine light-offs are experienced.

Only qualified and experienced personnel should investigate the hard light-off problem. It is

strongly recommended that users contact Solar Field Services for assistance.

Page 6 of 13 SERVICE BULLETIN

NUMBER: 3.0/101A

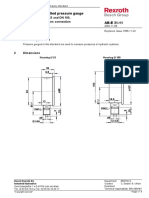

ATTACHMENT 1

MARS LIGHT-OFF LOGIC WITH TORCH "PRE-LIGHT" FOR NEWER DUAL FUEL PACKAGES

SERVICE BULLETIN Page 7 of 13

NUMBER: 3.0/101A

Page 8 of 13 SERVICE BULLETIN

NUMBER: 3.0/101A

ATTACHMENT 2

"LIGHT-AND-GO" START LOGIC FOR MARS PACKAGES WITH NEWER CONTROL

LOGIC AND DIRECT DRIVE AC START SYSTEMS

SERVICE BULLETIN Page 9 of 13

NUMBER: 3.0/101A

Page 10 of 13 SERVICE BULLETIN

NUMBER: 3.0/101A

ATTACHMENT 3

"LIGHT-AND-GO" START LOGIC FOR MARS PACKAGES WITH NEWER CONTROL

LOGIC AND ELECTRO-HYDRAULIC (HYDROSTATIC) START SYSTEMS

SERVICE BULLETIN Page 11 of 13

NUMBER: 3.0/101A

Page 12 of 13 SERVICE BULLETIN

NUMBER: 3.0/101A

SERVICE BULLETIN Page 13 of 13

NUMBER: 3.0/101A

You might also like

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- 3-0-105f EXHAUST SYSTEM PURGE CRANK TIMES TO PREVENT POTENTIALDocument11 pages3-0-105f EXHAUST SYSTEM PURGE CRANK TIMES TO PREVENT POTENTIALMohamed HussinNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Gas Turbine1Document13 pagesGas Turbine1Saurabh BarangeNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Tr7-8fi ManualDocument82 pagesTr7-8fi ManualClint CooperNo ratings yet

- 30 Naphtha Firing in Gas Turbines PDFDocument10 pages30 Naphtha Firing in Gas Turbines PDFcynaidu100% (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- GT Frame 9 ManualDocument102 pagesGT Frame 9 ManualSSC & GSC of LebanonNo ratings yet

- C20R Optimized Start Technique For C20 and C20RDocument4 pagesC20R Optimized Start Technique For C20 and C20REstevamNo ratings yet

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.From EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Rating: 3 out of 5 stars3/5 (4)

- Radial Inflow Turboexpander Redesign Steamboat Geothermal Power Plants I/IA - Reno, Nevada Brad Platt, Project ManagerDocument4 pagesRadial Inflow Turboexpander Redesign Steamboat Geothermal Power Plants I/IA - Reno, Nevada Brad Platt, Project ManagerrcarpiooNo ratings yet

- Latest Development in Turbochargers: Oil Mist Instead of Water CoolingDocument13 pagesLatest Development in Turbochargers: Oil Mist Instead of Water CoolingSachin SawantNo ratings yet

- 015Document10 pages015pf06No ratings yet

- 6 Testing and Qualification of Two-Stage Turbocharging SystemsDocument16 pages6 Testing and Qualification of Two-Stage Turbocharging SystemsMuzaffar Ali QuaziNo ratings yet

- Automobile Electric IgnitionDocument35 pagesAutomobile Electric IgnitionPM50% (2)

- Ch-5-W-10-11 - TurbochargingDocument71 pagesCh-5-W-10-11 - TurbochargingArkew Bogale100% (1)

- Advance and Ignition Timing For Better Fuel EconomyDocument9 pagesAdvance and Ignition Timing For Better Fuel EconomySebastian BryceNo ratings yet

- Gas Engines OSC9 G01 and OSC11 G03: en-GBDocument36 pagesGas Engines OSC9 G01 and OSC11 G03: en-GBRuanNo ratings yet

- Servico de CombustibleDocument19 pagesServico de CombustibleManuel IzquierdoNo ratings yet

- Fisher Steam Turbines Application Guide August 2013Document11 pagesFisher Steam Turbines Application Guide August 2013Juan Manuel Pardal100% (1)

- Service Bulletin Mercarb 97 - 08Document6 pagesService Bulletin Mercarb 97 - 08hormiganegra431No ratings yet

- Engine Management System SAAB TRIONIC T5.5, Rev 102Document9 pagesEngine Management System SAAB TRIONIC T5.5, Rev 102RxHughesNo ratings yet

- Function 4 OralsDocument24 pagesFunction 4 OralsSiva PrakasamNo ratings yet

- (REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 EnginesDocument16 pages(REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 Enginesvictor.cipriani100% (1)

- Weber 3236 AdjustDocument1 pageWeber 3236 AdjustNarendra WijayasuriyaNo ratings yet

- Αir / Fuel ratio - Lambda of LPG vs PetrolDocument4 pagesΑir / Fuel ratio - Lambda of LPG vs PetrolCostas GeorgatosNo ratings yet

- Thermal Power Plant Simulator TPP 200 Laboratory Exercise Tutorial N1: Rolling Up of Turbine Train and Connection of Generator To The GridDocument13 pagesThermal Power Plant Simulator TPP 200 Laboratory Exercise Tutorial N1: Rolling Up of Turbine Train and Connection of Generator To The GridPriyajit SahooNo ratings yet

- KZ Slide Carb Tuning-1Document6 pagesKZ Slide Carb Tuning-1pertonpcNo ratings yet

- Ignition Timing: Dead Center (BTDC) - Advancing The Spark BTDC Means That The Spark Is EnergizedDocument5 pagesIgnition Timing: Dead Center (BTDC) - Advancing The Spark BTDC Means That The Spark Is Energizedmiguel angelNo ratings yet

- Service Bulletin: Updated Titan™ 250 Maximum Purge Crank SpeedDocument12 pagesService Bulletin: Updated Titan™ 250 Maximum Purge Crank SpeedjussmeeeNo ratings yet

- Adjustable Nozzle RingDocument26 pagesAdjustable Nozzle RingThomas JoseNo ratings yet

- GT Acesssory, Torque ConverterDocument29 pagesGT Acesssory, Torque ConverterAnkur Sharma100% (2)

- Turbine MaintainanceDocument9 pagesTurbine Maintainanceer_sanjaypatel100% (2)

- TB 5000 Start UpDocument10 pagesTB 5000 Start UpVineeth VsNo ratings yet

- Fuel Oil System by P.KDocument28 pagesFuel Oil System by P.Kkr_abhijeet72356587100% (1)

- Doosan Gas TurbinesDocument20 pagesDoosan Gas TurbinesUhrin ImreNo ratings yet

- Solar 5.2MVADocument15 pagesSolar 5.2MVAsohaila7No ratings yet

- Megafire ManualDocument6 pagesMegafire ManualBehnam NoorizadehNo ratings yet

- Turbochargers, VTA Project GuideDocument44 pagesTurbochargers, VTA Project Guideaston_astonNo ratings yet

- Trinity & Matrix: Natural To LP Conversion InstructionsDocument4 pagesTrinity & Matrix: Natural To LP Conversion InstructionsFREDNo ratings yet

- Summer Training Report OdDocument60 pagesSummer Training Report OdTanya MishraNo ratings yet

- M Combustion Chamber and Cold Starting of CDocument45 pagesM Combustion Chamber and Cold Starting of CAnonymous LFgO4WbIDNo ratings yet

- Nett Manual Universal-Fit ProductsDocument2 pagesNett Manual Universal-Fit ProductsJesus Santana GalvezNo ratings yet

- Automotive Interview and ReviewerDocument20 pagesAutomotive Interview and ReviewerMichael Radan90% (10)

- Stromberg 175Document17 pagesStromberg 175vanapeer100% (10)

- GT Frame 9 ManualDocument98 pagesGT Frame 9 ManualSANJAY100% (2)

- GE Gas Turbine Frame 9E Course 1695532004Document156 pagesGE Gas Turbine Frame 9E Course 1695532004Achnafian Rafif Zufaryansyah100% (1)

- TURBINE TIP NO. 7 - Benefits Accrue From Observing Startup, Operational, Shutdown Sequences - Combined Cycle JournalDocument5 pagesTURBINE TIP NO. 7 - Benefits Accrue From Observing Startup, Operational, Shutdown Sequences - Combined Cycle JournalVenkata Madhav ModugaNo ratings yet

- Fuel System Pressure - Test: Testing and AdjustingDocument4 pagesFuel System Pressure - Test: Testing and AdjustingAbdoulaye Boua BERTHENo ratings yet

- Boiler Control From Power Magazines InputDocument11 pagesBoiler Control From Power Magazines InputUdhayakumar VenkataramanNo ratings yet

- SB3 0 115 - NCDocument4 pagesSB3 0 115 - NCjussmeeeNo ratings yet

- Bosch Mechanical Fuel InjectionDocument10 pagesBosch Mechanical Fuel InjectionmfiazzoNo ratings yet

- Paxman SpecsDocument9 pagesPaxman Specsbastech100% (2)

- VTA Project GuideDocument39 pagesVTA Project GuideTapas ChaudhuriNo ratings yet

- Service BulletinDocument9 pagesService BulletinjussmeeeNo ratings yet

- SB3 1 101Document3 pagesSB3 1 101jussmeeeNo ratings yet

- SB3 1 100Document10 pagesSB3 1 100jussmeeeNo ratings yet

- SB3 0 120Document2 pagesSB3 0 120jussmeeeNo ratings yet

- SB3 1 102Document6 pagesSB3 1 102jussmeeeNo ratings yet

- SB 7-4-102Document2 pagesSB 7-4-102jussmeeeNo ratings yet

- SB 7-4-101Document2 pagesSB 7-4-101jussmeeeNo ratings yet

- Solar SB 14-032Document6 pagesSolar SB 14-032jussmeeeNo ratings yet

- SB 7-1-106Document2 pagesSB 7-1-106jussmeeeNo ratings yet

- SB 7-1-107Document8 pagesSB 7-1-107jussmeeeNo ratings yet

- Solar SB 16-002Document3 pagesSolar SB 16-002jussmeeeNo ratings yet

- Solar SB 15-007Document3 pagesSolar SB 15-007jussmeeeNo ratings yet

- Air Flow Balancing ProcedureDocument3 pagesAir Flow Balancing ProcedureJONATHANNo ratings yet

- Solar SB 14-032Document6 pagesSolar SB 14-032jussmeeeNo ratings yet

- Service Bulletin: SubjectDocument5 pagesService Bulletin: SubjectjussmeeeNo ratings yet

- 22 0 100 - NCDocument7 pages22 0 100 - NCjussmeeeNo ratings yet

- Service Bulletin: Subject: Mars Overrunning (Sprag) ClutchDocument2 pagesService Bulletin: Subject: Mars Overrunning (Sprag) ClutchjussmeeeNo ratings yet

- Service BulletinDocument9 pagesService BulletinjussmeeeNo ratings yet

- Solar SB 21-0-109Document3 pagesSolar SB 21-0-109jussmeeeNo ratings yet

- Service Bulletin: Subject: Turbine Package Electrical System Test KitDocument4 pagesService Bulletin: Subject: Turbine Package Electrical System Test KitjussmeeeNo ratings yet

- Service BulletinDocument20 pagesService BulletinjussmeeeNo ratings yet

- Service Bulletin: Service Bulletin NUMBER: 22.0/101 Caterpillar: Confidential Green Page 1 of 3Document3 pagesService Bulletin: Service Bulletin NUMBER: 22.0/101 Caterpillar: Confidential Green Page 1 of 3jussmeeeNo ratings yet

- Service Bulletin: Number: 23.2/104 Issued: March 2012 Revised: Product: Mercury 50 MODEL (S) : Generator SpecificsDocument6 pagesService Bulletin: Number: 23.2/104 Issued: March 2012 Revised: Product: Mercury 50 MODEL (S) : Generator SpecificsjussmeeeNo ratings yet

- Service Bulletin: Number: 23.2/102 Issued: July 2011 Revised: Product: Mercury 50 MODEL (S) : Generator SpecificsDocument3 pagesService Bulletin: Number: 23.2/102 Issued: July 2011 Revised: Product: Mercury 50 MODEL (S) : Generator SpecificsjussmeeeNo ratings yet

- Service Bulletin: Subject: Engine and Exhaust Drain System On Recuperated UnitsDocument5 pagesService Bulletin: Subject: Engine and Exhaust Drain System On Recuperated UnitsjussmeeeNo ratings yet

- Service Bulletin: Subject: Retrofit of Combustor Bolts (P.A. REFERENCE NO. 20006)Document2 pagesService Bulletin: Subject: Retrofit of Combustor Bolts (P.A. REFERENCE NO. 20006)jussmeeeNo ratings yet

- Service Bulletin Page 1 of 4 NUMBER: 3.0/106Document4 pagesService Bulletin Page 1 of 4 NUMBER: 3.0/106jussmeeeNo ratings yet

- Service Bulletin: Subject: Hydraulic - Electric Servoactuator (P/N 919360C1 & P/N 914636C1) FAILURESDocument2 pagesService Bulletin: Subject: Hydraulic - Electric Servoactuator (P/N 919360C1 & P/N 914636C1) FAILURESjussmeeeNo ratings yet

- Service Bulletin: Updated Titan™ 250 Maximum Purge Crank SpeedDocument12 pagesService Bulletin: Updated Titan™ 250 Maximum Purge Crank SpeedjussmeeeNo ratings yet

- Service Bulletin: Subject: Replacement Torch Air Assist Solenoid VALVE P/N 120867-1Document3 pagesService Bulletin: Subject: Replacement Torch Air Assist Solenoid VALVE P/N 120867-1jussmeeeNo ratings yet

- MBBR Wastewater Treatment Basin Sizing and Aeration Calculations - S.I. UnitsDocument30 pagesMBBR Wastewater Treatment Basin Sizing and Aeration Calculations - S.I. Unitsdiego80% (5)

- Ohlson VFFS ManualDocument32 pagesOhlson VFFS ManualbjpNo ratings yet

- Cohesive Zone - Blast FurnaceDocument8 pagesCohesive Zone - Blast Furnacescribdaccount0No ratings yet

- Hydraulic Spring Stiffness Testing Machine: Nagre N.P., Bhosale M.S., Prof. Patil S.CDocument5 pagesHydraulic Spring Stiffness Testing Machine: Nagre N.P., Bhosale M.S., Prof. Patil S.CShivam MishraNo ratings yet

- 13 Noise-Prediction PDFDocument5 pages13 Noise-Prediction PDFsnamprogNo ratings yet

- 6379 Topper 21 129 510 2 2192 Gaseous State Up201612091655 1481282727 7964Document47 pages6379 Topper 21 129 510 2 2192 Gaseous State Up201612091655 1481282727 7964BhootNo ratings yet

- Syltherm XLT CatalogDocument27 pagesSyltherm XLT CatalogJose Angel MalumbresNo ratings yet

- Differential Pressure Sensor: FeaturesDocument3 pagesDifferential Pressure Sensor: Featuresdanieldaliquispe22No ratings yet

- Exercise Questions For Section VIII Div.Document13 pagesExercise Questions For Section VIII Div.Karthikeyan Nadarajan100% (1)

- Physics Exam Sem 2Document23 pagesPhysics Exam Sem 2aljazi aliNo ratings yet

- Thumb Rules - Xls For Chemical EngineerDocument46 pagesThumb Rules - Xls For Chemical EngineerAnuj KaliyerNo ratings yet

- Optical Leak Testing of Hermetic DevicesDocument9 pagesOptical Leak Testing of Hermetic DevicesTueNo ratings yet

- Cellular Respiration LabDocument7 pagesCellular Respiration LabShari HuntNo ratings yet

- Audco Valve Handbook PDFDocument39 pagesAudco Valve Handbook PDFPoojaashish TripathiNo ratings yet

- Day 3 Pumps & Heat ExchangerDocument48 pagesDay 3 Pumps & Heat ExchangerChristian Cañon GenterolaNo ratings yet

- Glycerine Filled Pressure Gauge AB-E 31-11: DN 63 and DN 100, Bottom ConnectionDocument4 pagesGlycerine Filled Pressure Gauge AB-E 31-11: DN 63 and DN 100, Bottom ConnectionhaggNo ratings yet

- C16 C18 AdbacDocument6 pagesC16 C18 AdbachopemarineNo ratings yet

- Beltranparedes 2010Document12 pagesBeltranparedes 2010Abdillah MuharramNo ratings yet

- Pascal's Principle and HydraulicsDocument3 pagesPascal's Principle and Hydraulicscovos labNo ratings yet

- Application of Integration - Fluid PressureDocument2 pagesApplication of Integration - Fluid PressureJumarie CoresesNo ratings yet

- Basics of Industrial Maintenance (Schoolcraft Publishing)Document7 pagesBasics of Industrial Maintenance (Schoolcraft Publishing)rfgerfgNo ratings yet

- Sonatrach Skikda New LNG Train Project Skikda, AlgeriaDocument59 pagesSonatrach Skikda New LNG Train Project Skikda, AlgeriabijayroyNo ratings yet

- Wu-Abuaf-1981Study of Nonequilibrium Flashing... v2Document170 pagesWu-Abuaf-1981Study of Nonequilibrium Flashing... v2hamed0% (1)

- Gas LawsDocument4 pagesGas LawsJanelyn GarinNo ratings yet

- 21 - MANUAL ORIGINAL DE USUARIO - Operación y Servicio BásicoDocument74 pages21 - MANUAL ORIGINAL DE USUARIO - Operación y Servicio BásicoNorbey Marin MorenoNo ratings yet

- 2008-01-2958 TOP FUEL Powertrian ModellingDocument10 pages2008-01-2958 TOP FUEL Powertrian ModellingT SmiNo ratings yet

- TesDocument6 pagesTesDanika PutriNo ratings yet

- Oxygen O-40 Filling: Gases, Refrigerants and CylindersDocument2 pagesOxygen O-40 Filling: Gases, Refrigerants and CylindersRani NoumanNo ratings yet

- Operation & Maintenance Manual PDFDocument60 pagesOperation & Maintenance Manual PDFArundhati BoseNo ratings yet

- Ventiladores SilosDocument20 pagesVentiladores SilosJOSE ACOSTA RODRIGUEZNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Grid-Scale Energy Storage Systems and ApplicationsFrom EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNo ratings yet

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersFrom EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersRating: 4.5 out of 5 stars4.5/5 (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerFrom EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo ratings yet

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)

- Global Landscape of Renewable Energy FinanceFrom EverandGlobal Landscape of Renewable Energy FinanceNo ratings yet

- DIY Free Home Energy Solutions: How to Design and Build Your own Domestic Free Energy SolutionFrom EverandDIY Free Home Energy Solutions: How to Design and Build Your own Domestic Free Energy SolutionRating: 5 out of 5 stars5/5 (1)

- Biogas Production: Pretreatment Methods in Anaerobic DigestionFrom EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNo ratings yet

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Practical Methods for Analysis and Design of HV Installation Grounding SystemsFrom EverandPractical Methods for Analysis and Design of HV Installation Grounding SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet