Professional Documents

Culture Documents

42.SPC Format

Uploaded by

RS MANIKANDANCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

42.SPC Format

Uploaded by

RS MANIKANDANCopyright:

Available Formats

DATE :- 10.29.

2022

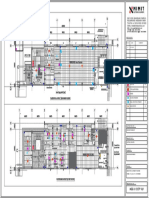

STATISTICAL PROCESS CONTROL STUDY APPROVED CHECKED PREPARED

NAVODIT

INSTRUMENT SUPPLIER NAME OR MACHINING

PART NAME: Rubber Fork Bolt QUALITY CHARACTERISTICS Dimension PP MACHINE NAME M/S HMSI

NAME: SECTION NAME

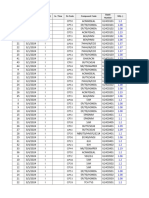

PART NO. : 1100492 SPECIFICATION 3.8 ± 0.20 OPERATION: COMPRESSION MOLDING LEAST COUNT 0.001 DOCUMENT CONTROL NO. :

DATA COLLECTION: -

DATE OF MEASUREMENT 12-Dec-22 12-Dec-22 12-Dec-22 12-Dec-22 12-Dec-22 12-Dec-22 12-Dec-22 12-Dec-22 12-Dec-22 12-Dec-22 SAMPLING RATIO

MEASUREMENT TIME 11.00 AM 11.30 AM 12.00 AM 12.30 PM 01.00 PM 01.30 PM 02.00 PM 02.30 PM 03.00 PM 03.30 PM 04.00 PM 04.30 PM 05.00 PM 05.30 PM 06.00 PM 06.30 PM 07.00 PM 07.30 PM 08.00 PM 08.30 PM ALL DIMENSIONS ARE IN MM UP TO 5 SAMPLES ' D3' VALUE = 0

GROUP NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 SAMPLE d2 A2 D4

X1 5.10 5.11 5.11 5.10 5.12 5.11 5.10 5.10 5.09 5.11 5.11 5.12 5.11 5.10 5.11 5.10 5.12 5.11 5.11 5.10 5.11 5.12 5.11 5.09 5.11 USL 5.50 1 1.123 2.560 3.270

MEASURED VALUE

X2 5.11 5.12 5.11 5.12 5.11 5.11 5.12 5.11 5.12 5.11 5.10 5.11 5.12 5.11 5.11 5.10 5.11 5.11 5.10 5.11 5.12 5.11 5.10 5.11 5.12 2 1.128 1.880 3.270

X3 5.15 5.10 5.08 5.04 5.05 5.11 5.03 5.05 5.11 5.09 5.09 5.11 5.09 5.15 5.11 5.12 5.11 5.12 5.11 5.10 5.15 5.10 5.08 5.15 5.15 3 1.693 1.020 2.570

X4 5.10 5.16 5.09 5.10 5.10 5.11 5.09 5.14 5.10 5.11 5.10 5.10 5.12 5.11 5.10 5.12 5.11 5.09 5.10 5.11 5.12 5.11 5.11 5.12 5.11 LSL 5.00 4 2.059 0.800 2.280

X5 5.15 5.11 5.11 5.10 5.10 5.11 5.12 5.11 5.09 5.11 5.11 5.12 5.10 5.12 5.11 5.11 5.12 5.11 5.10 5.10 5.10 5.11 5.11 5.10 5.11 5 2.326 0.590 2.110

CALCULATIONS: -

FOR HISTOGRAM :-

XLARGE 5.15 5.16 5.11 5.12 5.12 5.11 5.12 5.14 5.12 5.11 5.11 5.12 5.12 5.15 5.11 5.12 5.12 5.12 5.11 5.11 5.15 5.12 5.11 5.15 5.15 Xmax.= 2.200

NO.OF NON CONFORMING PART = 0 NOS.

XSMALL 5.10 5.10 5.08 5.04 5.05 5.11 5.03 5.05 5.09 5.09 5.09 5.10 5.09 5.10 5.10 5.10 5.11 5.09 5.10 5.10 5.10 5.10 5.08 5.09 5.11 Xmin.= 1.800

RANGE 0.05 0.06 0.03 0.08 0.07 0.00 0.09 0.09 0.03 0.02 0.02 0.02 0.03 0.05 0.01 0.02 0.01 0.03 0.01 0.01 0.05 0.02 0.03 0.06 0.04 R 0.03720 NO. OF PARTS ABOVE U.C.L. = 8 NOS.

AVG. 5.12 5.12 5.10 5.09 5.10 5.11 5.09 5.10 5.10 5.11 5.10 5.11 5.11 5.12 5.11 5.11 5.11 5.11 5.10 5.10 5.12 5.11 5.10 5.11 5.12 X 5.1078 NO. OF PARTS BELOW L.C.L. = 6 NOS.

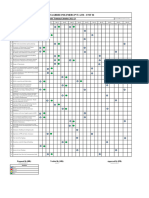

Process Width ( R ) = 0.4000 Specification Width ( S ) = 0.5000 No. of Class Intervals = 1 + 3.222 × log10 N = 7.756 Shift Of ' X ' from ' D ' = -0.1422 INTERVAL FREQ. CU. FREQ.

Design Centre ( D ) = 5.2500 Interval ( C ) = ( R + L.C.) / k = 0.0000 Selecting no. of classes (k) = 0 5.0295 0.0000 125 125

Lower Class Limit = 5.0295

Starting Point = 5.0300 No. of readings ( N ) = 125 Index ( K ) = R x ( D-R ) / S = 3.880 0.0000 0.0000 0 125

0.0000 0.0000 0 125

5.140 X-bar CHART

U.C.L. 5.1305.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 5.1298 0.0000 0.0000 0 125

5.120

5.110

VALUE

L.C.L. 5.1005.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 5.0859 0.0000 0.0000 0 125

5.090 AVG. U.C.L.

U.C.L.5.0800.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0785 0.0000 0.0000 0 125

5.070 L.C.L. X-BAR

5.060

L.C.L. 0.0000

1

0.0000

2 3

0.0000

4

0.0000

5

0.0000

6 7

0.0000

8

0.0000

9

0.00000.0000

10

0.0000

11

0.0000

0.0000

12

0.0000

13

0.0000

14

0.0000

15

0.0000

16

0.0000

17

0.0000

18

0.0000

19 20 21 22 23 24

0.0000

25

0.0000 0.0000 0 125

SAMPLE

X-BAR 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 5.1078 U.C.L.X = X + A2×R 5.129788

R CHART

0.10

R-BAR 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 0.0372 L.C.L.X = X - A2×R 5.085892

0.08

0.0785

VALUE

0.06 U.C.L.R = R x D4

0.04

R AN GE U .C .L.

L.C.L.R = R x D3 0.0000

0.02 L.C .L. R -BAR

0.00 Std.Dev.'σ'= R / d2 0.0160

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

SAMPLE Cp = (S/6σ) 5.21

Cpk U=(USL-X)/3σ 8.17

REMARKS: Cp&Cpk value will be greater than 1.67, if Cp&Cpk value is greater than 1.67 ,So that our process is good condition Cpk L=(X-LSL)/3σ 2.25

ACTUAL Cpk 2.25

Format Number: JPPL/H/QAD/F/42

Rev No: / Date: 01/05.01.2023

You might also like

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Larsen & Toubro Limited: Distribution Transformer Sizing CalculationDocument33 pagesLarsen & Toubro Limited: Distribution Transformer Sizing CalculationEngr. Nabid Rayhan KhalequeNo ratings yet

- Bracket, Maz67723101Document1 pageBracket, Maz67723101แต่ก่อน เสี่ยหำ เดี๋ยวนี้ ป๋าหำNo ratings yet

- 4 Oil Discharge Monitoring Equipment-Final DrawingDocument92 pages4 Oil Discharge Monitoring Equipment-Final DrawingAung SquNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument13 pagesLarsen & Toubro Limited: ECC Division - EDRCEngr. Nabid Rayhan KhalequeNo ratings yet

- Tampak Dan PotonganDocument1 pageTampak Dan Potonganmorning loverNo ratings yet

- D and T-Series-masterDocument12 pagesD and T-Series-masterJavier PerezNo ratings yet

- Design of Leaf Canopy Using SAP2000Document51 pagesDesign of Leaf Canopy Using SAP2000John Paul ApostolNo ratings yet

- ModelDocument1 pageModelYash BhattNo ratings yet

- Rawabi Project: Design CriteriaDocument1 pageRawabi Project: Design CriteriaaliiiiiiiiiiNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument12 pagesLarsen & Toubro Limited: ECC Division - EDRCEngr. Nabid Rayhan KhalequeNo ratings yet

- Tok 0002 e Ga 0002 - 2Document1 pageTok 0002 e Ga 0002 - 2BUDI HARIANTONo ratings yet

- DE-119889 - Rev 14 Procedure For Painting of Offshore Platforms PDFDocument40 pagesDE-119889 - Rev 14 Procedure For Painting of Offshore Platforms PDFgorakhnathgosaviNo ratings yet

- 545 7489 (Eag349) - PfmeaDocument3 pages545 7489 (Eag349) - PfmeaDurai NaiduNo ratings yet

- Off Gas Drum 115-HPU1-D-007 Psa Off Gas Silencer 115-HPU1-X-003Document1 pageOff Gas Drum 115-HPU1-D-007 Psa Off Gas Silencer 115-HPU1-X-003victor rojasNo ratings yet

- D EHP: Nidec Sankyo Project P-200-2 3P3W-200VACDocument1 pageD EHP: Nidec Sankyo Project P-200-2 3P3W-200VACHoang TungNo ratings yet

- D EHP: Nidec Sankyo Project M-FAN-1 3P4W-380/220VACDocument1 pageD EHP: Nidec Sankyo Project M-FAN-1 3P4W-380/220VACHoang TungNo ratings yet

- Cost Estimation BundDocument81 pagesCost Estimation Bundmohan890No ratings yet

- Utility Check Sheet New 2022Document12 pagesUtility Check Sheet New 2022Yuva kalattaNo ratings yet

- Schedule Penyelesaian CabinDocument1 pageSchedule Penyelesaian CabinHeri RudiNo ratings yet

- Prototype Print: 1 AT516772 1 Raw Weldment Painted Weldment, Lap Bar 2 T449786 1 Handlebar Lapbar OvermoldDocument1 pagePrototype Print: 1 AT516772 1 Raw Weldment Painted Weldment, Lap Bar 2 T449786 1 Handlebar Lapbar OvermoldLilian ChangNo ratings yet

- Laporan Semesteran InventarisDocument26 pagesLaporan Semesteran Inventarisusep yulianaNo ratings yet

- 15-501-EP-LI-001 - REV.1 (Line List)Document3 pages15-501-EP-LI-001 - REV.1 (Line List)Umair A. KhanNo ratings yet

- Line 1 WJDocument1 pageLine 1 WJMahmoud A. HafeezNo ratings yet

- Line 2 WJDocument1 pageLine 2 WJMahmoud A. HafeezNo ratings yet

- Process Equipment ListDocument85 pagesProcess Equipment Listganesh kumarNo ratings yet

- Shelter PreparationDocument7 pagesShelter PreparationsukendarNo ratings yet

- Stormwater Drainage System Design Worksheet: Page 1 of 5Document5 pagesStormwater Drainage System Design Worksheet: Page 1 of 5khoohuikiangNo ratings yet

- Friction Slab and PARAPETDocument1 pageFriction Slab and PARAPETsaloman.vasuprada28No ratings yet

- Generator Control Panel Factory Test Procedure: Diffusion: Confidentielle Restreinte Controlee LibreDocument87 pagesGenerator Control Panel Factory Test Procedure: Diffusion: Confidentielle Restreinte Controlee LibreVenkateswarlu KolluruNo ratings yet

- PP23100001P PDFDocument37 pagesPP23100001P PDFRashmi AgarwalNo ratings yet

- Sheet Contents Revision Info RevisionDocument5 pagesSheet Contents Revision Info RevisionatelierNo ratings yet

- Electrical Wiring Diagram Asphalt Mixing Plant Console Desk: AMP-1000-FADocument60 pagesElectrical Wiring Diagram Asphalt Mixing Plant Console Desk: AMP-1000-FAwasco plantNo ratings yet

- 201.60 - 500mm Reference OnlyDocument1 page201.60 - 500mm Reference OnlyAbdalrahem Bin Tareef TareefNo ratings yet

- Combinepdf 6Document7 pagesCombinepdf 6priya giriNo ratings yet

- Revision Rev. Description Date Edited by Eco #: Section A-A SCALE 1: 12Document1 pageRevision Rev. Description Date Edited by Eco #: Section A-A SCALE 1: 12Ger DclNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesmohamedNo ratings yet

- Toaz - Info Sistema Hidraulico Perforadora DX 800 Sandvik PRDocument100 pagesToaz - Info Sistema Hidraulico Perforadora DX 800 Sandvik PRLuis Ayala Meza100% (1)

- Dus Packaging Rangka Kaki Dan Meja Utama: Revision REV Description Date Approved Assy No Sub Assy QTY RemarkDocument10 pagesDus Packaging Rangka Kaki Dan Meja Utama: Revision REV Description Date Approved Assy No Sub Assy QTY RemarkAhmad FalahNo ratings yet

- Daily Sales Progress: Ovh & Dynotest Cat3512 1 Sumatera & Kalimantan V Irawan/Yani V 100921 SQ000240 Fu PoDocument1 pageDaily Sales Progress: Ovh & Dynotest Cat3512 1 Sumatera & Kalimantan V Irawan/Yani V 100921 SQ000240 Fu PoSarohman RohmanNo ratings yet

- For Information: Foundation Design ManualDocument80 pagesFor Information: Foundation Design ManualabdulnasirNo ratings yet

- Piping List, Line Sizing and Tie-In Point...Document2 pagesPiping List, Line Sizing and Tie-In Point...Hiếu Nguyên100% (2)

- 13 Reservoir & Detail PondasiDocument8 pages13 Reservoir & Detail PondasiChua MilanoNo ratings yet

- Plantegning A3 PDFDocument1 pagePlantegning A3 PDFLavern P. SipinNo ratings yet

- D EHP: Nidec Sankyo Project M-AC-3 3P4W-380/220VACDocument1 pageD EHP: Nidec Sankyo Project M-AC-3 3P4W-380/220VACHoang TungNo ratings yet

- FM-200 Indicador de Descarga PDFDocument1 pageFM-200 Indicador de Descarga PDFruizNo ratings yet

- FM-200 Indicador de Descarga PDFDocument1 pageFM-200 Indicador de Descarga PDFxochitlNo ratings yet

- Client: Drawing Number Scale Dimensions 'MM' NTS SES 1062/16 Sheet Title 100A Ats Panel Project DetailsDocument7 pagesClient: Drawing Number Scale Dimensions 'MM' NTS SES 1062/16 Sheet Title 100A Ats Panel Project DetailsDinesh GowdNo ratings yet

- Modification Line Glucose-PervettiDocument1 pageModification Line Glucose-PervettiPaiz Ilham MauludiNo ratings yet

- Window & Door Schedule: StudioDocument1 pageWindow & Door Schedule: StudioBatWing ZNo ratings yet

- Basis of Design - Structural Support BuildingDocument16 pagesBasis of Design - Structural Support BuildingVic ValdezNo ratings yet

- Listado de Instrumentos - DescripciónDocument33 pagesListado de Instrumentos - DescripciónDaniel Camargo Perez100% (1)

- Apd Percepatan - 1276931003 - Cililin - Pasar - CililinDocument5 pagesApd Percepatan - 1276931003 - Cililin - Pasar - CililinDevit RatrianaNo ratings yet

- Me-Ff-02 - Standard Details-1 Fire Fighting SystemDocument1 pageMe-Ff-02 - Standard Details-1 Fire Fighting SystemEng Qais ShamikhNo ratings yet

- Toll Collection System Reflected Ceiling Plan (S2-001) : Metro Manila SkywayDocument1 pageToll Collection System Reflected Ceiling Plan (S2-001) : Metro Manila SkywayRhowelle TibayNo ratings yet

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- CNOOC Zhejiang LNG Plant, Ningbo China: Ga DrawingDocument7 pagesCNOOC Zhejiang LNG Plant, Ningbo China: Ga Drawing李军No ratings yet

- Cable M12-Picospox 0.5MDocument1 pageCable M12-Picospox 0.5MBoxerpower GasNo ratings yet

- J95 P DOC VE 027824 000 - 1 Protection Calculation Settings Report - 13!05!2020Document75 pagesJ95 P DOC VE 027824 000 - 1 Protection Calculation Settings Report - 13!05!2020Geetha BirudalaNo ratings yet

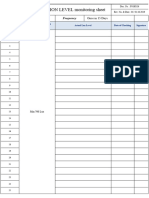

- Luxlevel Monitering SheetDocument1 pageLuxlevel Monitering SheetRS MANIKANDANNo ratings yet

- 10.checking AidsDocument1 page10.checking AidsRS MANIKANDANNo ratings yet

- Illumination Level Checksheet - QualityDocument4 pagesIllumination Level Checksheet - QualityRS MANIKANDANNo ratings yet

- Customer Complaints Tracker 2023-2024Document3 pagesCustomer Complaints Tracker 2023-2024RS MANIKANDANNo ratings yet

- Pfmea KVTDocument3 pagesPfmea KVTRS MANIKANDANNo ratings yet

- Touch Base TrackerDocument4 pagesTouch Base TrackerRS MANIKANDANNo ratings yet

- Routcar 3Document2 pagesRoutcar 3RS MANIKANDANNo ratings yet

- Trial Details April 2024Document45 pagesTrial Details April 2024RS MANIKANDANNo ratings yet

- Mold Drop Check SheetDocument1 pageMold Drop Check SheetRS MANIKANDANNo ratings yet

- 2.PFD & PQCS-18293-KVT-9000Document3 pages2.PFD & PQCS-18293-KVT-9000RS MANIKANDANNo ratings yet

- Customer Visit Plan Vs Actual - Apr-24Document3 pagesCustomer Visit Plan Vs Actual - Apr-24RS MANIKANDANNo ratings yet

- Trial Details March 2024Document48 pagesTrial Details March 2024RS MANIKANDANNo ratings yet

- Compound & Chemical Change Trial ReportDocument2 pagesCompound & Chemical Change Trial ReportRS MANIKANDANNo ratings yet

- 17 Mould Pick Up Check SheetDocument2 pages17 Mould Pick Up Check SheetRS MANIKANDANNo ratings yet

- BackupDocument8 pagesBackupRS MANIKANDANNo ratings yet

- Problem BatchesDocument12 pagesProblem BatchesRS MANIKANDANNo ratings yet

- Q DashboardDocument17 pagesQ DashboardRS MANIKANDANNo ratings yet

- Project 1 - TypoholicDocument2 pagesProject 1 - TypoholicRS MANIKANDANNo ratings yet

- 5EHG1U24C0101Document2 pages5EHG1U24C0101RS MANIKANDANNo ratings yet

- 18 4M Change Request Cum Approval FormDocument1 page18 4M Change Request Cum Approval FormRS MANIKANDANNo ratings yet

- Mould Parameter ChangeDocument3 pagesMould Parameter ChangeRS MANIKANDANNo ratings yet

- Life Cycle AnalysisDocument1 pageLife Cycle AnalysisRS MANIKANDANNo ratings yet

- Production - Needs and ExpectationsDocument1 pageProduction - Needs and ExpectationsRS MANIKANDANNo ratings yet

- TRG Calendar - 2022-23Document39 pagesTRG Calendar - 2022-23RS MANIKANDANNo ratings yet

- Material Inward RegisterDocument2 pagesMaterial Inward RegisterRS MANIKANDANNo ratings yet

- Critical: Closed Closed Closed Closed Closed Closed Closed Closed Closed ClosedDocument47 pagesCritical: Closed Closed Closed Closed Closed Closed Closed Closed Closed ClosedRS MANIKANDANNo ratings yet

- Compound Return NoteDocument1 pageCompound Return NoteRS MANIKANDANNo ratings yet

- TRG Calendar - 2021-22Document43 pagesTRG Calendar - 2021-22RS MANIKANDANNo ratings yet

- 29.QAV 2-4 Report - 08030-PQ3F-F1-029 FormatDocument8 pages29.QAV 2-4 Report - 08030-PQ3F-F1-029 FormatRS MANIKANDANNo ratings yet

- SPC SpreadsheetDocument8 pagesSPC SpreadsheetRS MANIKANDANNo ratings yet

- TQM in JAPANDocument15 pagesTQM in JAPANAman SallanNo ratings yet

- TCW Review TestDocument4 pagesTCW Review Testbeamari22.dimaandalNo ratings yet

- 3-06 - Presentation - The Future of Quality-FinalDocument40 pages3-06 - Presentation - The Future of Quality-FinalIlie Din VoiniceniNo ratings yet

- Quality Control: Mcgraw-Hill/IrwinDocument68 pagesQuality Control: Mcgraw-Hill/IrwinArjun A WarrierNo ratings yet

- BA 105 Problem SetDocument3 pagesBA 105 Problem SetJesús Martín Hilario RamosNo ratings yet

- Process Validation StatisticsDocument62 pagesProcess Validation StatisticsSangram KendreNo ratings yet

- Seminar Report2Document19 pagesSeminar Report2Parth MehtaNo ratings yet

- DBB2102 Unit-01Document21 pagesDBB2102 Unit-01Silent KillerNo ratings yet

- APQP Process Capability and Control Webinar 7JAN2020 PPDocument78 pagesAPQP Process Capability and Control Webinar 7JAN2020 PPMoti Ben-ZurNo ratings yet

- 2017 Quality 4.0 - Final-1Document28 pages2017 Quality 4.0 - Final-1m_ulilalbab100% (1)

- Construct Control Attribute Charts P and NP Chart On MinitabDocument4 pagesConstruct Control Attribute Charts P and NP Chart On MinitabMuhammad KhalilNo ratings yet

- Control Chart: Looking For More Quality Tools?Document3 pagesControl Chart: Looking For More Quality Tools?Cloud Redfield100% (1)

- Statistical Quality Control PDFDocument82 pagesStatistical Quality Control PDFInshal KhanNo ratings yet

- Chapter 2-Statistical Tools-1Document57 pagesChapter 2-Statistical Tools-1Computer Maintainance Hardware and softwareNo ratings yet

- Dissertacao Corrigida Laura Barroso 73943Document87 pagesDissertacao Corrigida Laura Barroso 73943Yulizar WidiatamaNo ratings yet

- Statistical Quality ControlDocument6 pagesStatistical Quality ControlAtish JitekarNo ratings yet

- Guru Guide Six Thought Leaders Who Changed The Quality World ForeverDocument8 pagesGuru Guide Six Thought Leaders Who Changed The Quality World ForeverJose Luis Moncada100% (4)

- MP T1 Report - 2Document25 pagesMP T1 Report - 2Vinay PanditNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- SQCDocument11 pagesSQCdinesh LoharNo ratings yet

- Process Capability & Performance (PP, PPK, CP, CPK)Document20 pagesProcess Capability & Performance (PP, PPK, CP, CPK)Rohit Soni100% (1)

- Quality Management SystemDocument36 pagesQuality Management Systemapi-3852528No ratings yet

- Operations Management (OPM530) - C12 QualityDocument54 pagesOperations Management (OPM530) - C12 Qualityazwan ayop100% (1)

- Operations MGMT - AIMADocument549 pagesOperations MGMT - AIMATata SatishkumarNo ratings yet

- AS052 Appendix ADocument2 pagesAS052 Appendix Akrishna kumarNo ratings yet

- Magna Electronics (MEI) - 4 Phases of APQP For Supplier Development EngineeringDocument20 pagesMagna Electronics (MEI) - 4 Phases of APQP For Supplier Development EngineeringBob Zepfel100% (4)

- Quality ControlDocument9 pagesQuality ControlAbdAllah KhodaryNo ratings yet

- TQM Tools & TechniquesDocument106 pagesTQM Tools & Techniquesvinay tripathiNo ratings yet

- RAID LevelsDocument2 pagesRAID LevelsVamsi BonamNo ratings yet

- Quality Function Deployment: More Than A Design ToolDocument26 pagesQuality Function Deployment: More Than A Design ToolSHASHANK ROHITNo ratings yet