Professional Documents

Culture Documents

F-HSE-01 Daily Inspection Checklist (AutoRecovered)

Uploaded by

gilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F-HSE-01 Daily Inspection Checklist (AutoRecovered)

Uploaded by

gilCopyright:

Available Formats

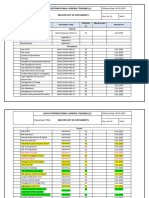

PPE YES NO CHEMICAL YES NO ELECTRICAL YE NO

S

Hard hat available as per task requirements store is available, organized, and tidy with no expired products. Are election Plugs in good condition

Staff footwear available as per task requirements Staff are trained in chemical handling Are cable in Good Condition

Worker wearing suitable T-shirt/pants MSDS is available, kept in a folder, and displayed. Are cable protected for damage

Gloves available as per task requirements Products are stored properly in designated areas, on shelves Are circuit board access restricted

orderly manner.

Harness available as per task requirements Eye wash station is available, along with an information poster. Are electric sockets overload

Goggles available as per task requirements Emergency contact information is posted and signs available. Competent technician available

3M Cartridge available as per task requirements Container information stickers are available. Are signs / Instruction available

Visitor safety vest and steel-toe shoe covers available MSDS and spill kit are available. Are there expose electrical connection

Chemical Cleaning gloves available Area is well-ventilated and adequate lighting Are election Plugs in good condition

Reflected vest available Spill kit is available. Are cable in Good Condition

Freezer and Chiller gloves available Chemical storage areas are segregated based on compatibility

RACKS /PALLET TROLLEY EMERGENCY SETUPS, FIRE & FIRST AID SITE LAYOUT

Rack proper label Emergency action plan, route poster fixed. Is the environment tidy, water/light switch off when not

Rack load capacity / dos and don’ts poster available Extinguisher, hose reel, update date/ signage available Are routes free from obstruction and assembly point

Item stack on racks as safe height ERT trained & Available on site and information posters Are materials Stack correctly

Pallet trolley good working Condition Fire extinguisher and MCP free from obstruction Are materials stored in safe area & not obstructing aisle

Material stack properly on pallet trolley Fire alarm systems audible & maintained Waste compactor & chemical leak free

Rack without damage and column guard available Escape route free from obstruction and proper signages Computers switch off when not use

Safe use of pallet trolley Emergencies procedure communicated to all the staff Are open floor covered

Trolley kept in safe location First Aid Box available and signage provided Noise free environment

Safe aligned/storage of items on racks Evacuation map available at strategic point Sufficient light in the factory

Aisle safe and free from obstruction Assembly points free from obstruction Waste bins provided

FORKLIFT / DRIVING Safety information board HEALTH &WELFARE/TOILET

Available trained operators Heigh risk area identified

Daily pre-use inspection conducted Manual handling poster identified Available drinking

Third-party inspection completed Information board fixed Dining, rest room & toilet available

Blind spots identified Hand Washing facilities available

Driving policy available Hygiene Poster Fixed in toilet

Accident report guidelines available Toilet facilities available and clean

Safety reflective vests used by operators Safe manual handling of crate & tray

Pre-checklist completed

Helmet uses by operator and VNA helper use harness

You might also like

- SLO County Citizens Homeless Commission ReportDocument16 pagesSLO County Citizens Homeless Commission ReportNick WilsonNo ratings yet

- Energy Efficiency in Motor Systems Proceedings of The 11th International ConferenceDocument748 pagesEnergy Efficiency in Motor Systems Proceedings of The 11th International Conferencedelta_scopeNo ratings yet

- 012-Practice Questions - Income TaxDocument106 pages012-Practice Questions - Income Taxalizaidkhan29% (7)

- # Monthly Inspection Check List-PDDocument7 pages# Monthly Inspection Check List-PDArjun KoiralaNo ratings yet

- Safety Industrial Safety Inspection ChecklistDocument2 pagesSafety Industrial Safety Inspection ChecklistAhmadi HasanNo ratings yet

- Workplace Inspection Checklist PDFDocument4 pagesWorkplace Inspection Checklist PDFFarah Izzati100% (2)

- Workplace Inspection Checklist PDFDocument4 pagesWorkplace Inspection Checklist PDFzaiazwaNo ratings yet

- Hazard Identification ChecklistDocument4 pagesHazard Identification Checklistmanishpandey1972No ratings yet

- Construction Safety Audit PDFDocument5 pagesConstruction Safety Audit PDFAnonymous Q1Y71rNo ratings yet

- FRM-9114-0144 Workplace Inspection ChecklistDocument2 pagesFRM-9114-0144 Workplace Inspection ChecklistdrakoniiNo ratings yet

- Office and Administration AreasDocument3 pagesOffice and Administration Arease cubeNo ratings yet

- Site Inspection ChecklistDocument2 pagesSite Inspection ChecklistDexter QuébecNo ratings yet

- Workplace Inspection ChecklistDocument4 pagesWorkplace Inspection ChecklistHaider Ali100% (1)

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesWaqasNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesOliver Reazon RueloNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesLakshmi BalaNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesDellendo FarquharsonNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No Notesveera reddy gogi reddyNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesSachin KumbharNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesHaider AliNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No Notesveera reddy gogi reddyNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesInigoNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesInigoNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesSachin KumbharNo ratings yet

- Site Inspection Checklist - Generic: LocationDocument2 pagesSite Inspection Checklist - Generic: Locationg5nbNo ratings yet

- EHS Officer Inspection-SAB, RosslynDocument6 pagesEHS Officer Inspection-SAB, RosslynAmukelaniNo ratings yet

- EHS Checklist-QCDocument7 pagesEHS Checklist-QCFarzana HossainNo ratings yet

- Daily Pre Start ChecklistDocument1 pageDaily Pre Start ChecklistAhmed El-sherpiniNo ratings yet

- Construction Safety Inspection ChecklistDocument5 pagesConstruction Safety Inspection ChecklistanamayitoNo ratings yet

- Daily Observation Form and ChecklistDocument2 pagesDaily Observation Form and ChecklistABDUL RISHAD KunduthodeNo ratings yet

- Safety Patrol Form CWE CCIEEDocument4 pagesSafety Patrol Form CWE CCIEECarlos G Pangilinan JrNo ratings yet

- Bishnupur AtRDocument5 pagesBishnupur AtRDayananda SalamNo ratings yet

- Hs3e Walk Through InspectionDocument1 pageHs3e Walk Through InspectionDaniel PradityaNo ratings yet

- Checklist BoilerDocument4 pagesChecklist BoilerJion MujionoNo ratings yet

- How To Use This Student Computer Lab Inspection Checklist: Safetyunit@gre - Ac.uk October 2010 Page 1 of 6Document6 pagesHow To Use This Student Computer Lab Inspection Checklist: Safetyunit@gre - Ac.uk October 2010 Page 1 of 6Timi0% (1)

- F805 - 003D FM Haz ID Checklists Cleaners Only 1 - 13Document4 pagesF805 - 003D FM Haz ID Checklists Cleaners Only 1 - 13Reyes PedroNo ratings yet

- Hotel Safety Checklist PDFDocument2 pagesHotel Safety Checklist PDFDarius Dsouza0% (1)

- Fairway Office Supplies LTD & Fairway Office InteriorsDocument5 pagesFairway Office Supplies LTD & Fairway Office Interiorsyahoo83No ratings yet

- Hazard Identification Checklist: Issues/Areas To ConsiderDocument3 pagesHazard Identification Checklist: Issues/Areas To ConsiderAaquil RaziNo ratings yet

- GN 1 WelfarefacilitiesatlabourcampDocument3 pagesGN 1 WelfarefacilitiesatlabourcampDeepu RavikumarNo ratings yet

- Appendix A SPA FormDocument2 pagesAppendix A SPA FormMohamed HadjkacemNo ratings yet

- HSEF - 023 Health, Safety 06Document2 pagesHSEF - 023 Health, Safety 06zxred284No ratings yet

- Checklist On Daily InspectionDocument2 pagesChecklist On Daily InspectionR Sahadeo ReddyNo ratings yet

- Drilling ChecklistDocument4 pagesDrilling ChecklistMurali PokkunuriNo ratings yet

- Construction Safety ChecklistDocument2 pagesConstruction Safety Checklistwirnos100% (1)

- CGS Weekly Safety & Health Inspection ReportDocument1 pageCGS Weekly Safety & Health Inspection Reportတိုး ေဝ ေအာင္No ratings yet

- FMS - EOC ChecklistDocument6 pagesFMS - EOC Checklisthany winihastutiNo ratings yet

- Short Term: Availability of Platforrm Scales in The DepotDocument6 pagesShort Term: Availability of Platforrm Scales in The DepotDayananda SalamNo ratings yet

- EHS Checklist-MBDocument3 pagesEHS Checklist-MBFarzana HossainNo ratings yet

- H&S InspectionDocument20 pagesH&S InspectionAllan ResmaNo ratings yet

- CanteenDocument4 pagesCanteenRydel CuachonNo ratings yet

- General Warehouse Safety Checklist: Prevention of Slips, Trips and FallDocument3 pagesGeneral Warehouse Safety Checklist: Prevention of Slips, Trips and FallFfttNo ratings yet

- H&S Assurance Monitoring Report On Behalf of Coventry UniversityDocument4 pagesH&S Assurance Monitoring Report On Behalf of Coventry UniversityDennis HaycoxNo ratings yet

- MTHL-PK1 - Health and Safety Inspection Report-70 - 4th Week January 2020 (Version 1) .XLSBDocument13 pagesMTHL-PK1 - Health and Safety Inspection Report-70 - 4th Week January 2020 (Version 1) .XLSBpradeepputta925No ratings yet

- 010 Pre-Job Safety Checklist (Rivision 2) - UPDATEDDocument1 page010 Pre-Job Safety Checklist (Rivision 2) - UPDATEDLijo John100% (1)

- HSE-F-NEOM-018 - Weekly Site Safety Inspection ChecklistDocument3 pagesHSE-F-NEOM-018 - Weekly Site Safety Inspection ChecklistAhmed MohamedNo ratings yet

- Check List: Managing Industrial Technology & Design WorkspacesDocument5 pagesCheck List: Managing Industrial Technology & Design Workspacesmohammed sameeullahNo ratings yet

- Demobilasation Plan: Should Be Done by A Third Party Approved Contractors. Isolate The Dismantling AreaDocument3 pagesDemobilasation Plan: Should Be Done by A Third Party Approved Contractors. Isolate The Dismantling ArearadeepNo ratings yet

- A-2.2-11-29-01 - Monitoring Checklist For Labour CampDocument3 pagesA-2.2-11-29-01 - Monitoring Checklist For Labour Camptivopa3612No ratings yet

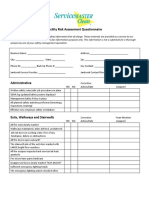

- Facility Risk Assessment QuestionnaireDocument5 pagesFacility Risk Assessment QuestionnaireGrayNo ratings yet

- forms (2)Document1 pageforms (2)gilNo ratings yet

- forms (1)Document1 pageforms (1)gilNo ratings yet

- Safety ContentDocument8 pagesSafety ContentgilNo ratings yet

- F-HSE-25 Emergency DrillDocument3 pagesF-HSE-25 Emergency DrillgilNo ratings yet

- Motivation LetterDocument2 pagesMotivation LettergilNo ratings yet

- F-HSE-28 Subcontractor HSE Pre-Qualification FormDocument3 pagesF-HSE-28 Subcontractor HSE Pre-Qualification FormgilNo ratings yet

- Forklift Maintenance Records: Document Owner Warehouse Operations Pre-Use Equipment Inspection Form Number REV Start DateDocument2 pagesForklift Maintenance Records: Document Owner Warehouse Operations Pre-Use Equipment Inspection Form Number REV Start DategilNo ratings yet

- Observation Report Al WeerDocument1 pageObservation Report Al WeergilNo ratings yet

- Master List of DocumentDocument3 pagesMaster List of DocumentgilNo ratings yet

- Scaffold TrainingDocument34 pagesScaffold TraininggilNo ratings yet

- A00F207e - Audit Report-2 V01 2022Document10 pagesA00F207e - Audit Report-2 V01 2022gilNo ratings yet

- Al Falak Middle East Hsse Site Induction: DIA SP551Document17 pagesAl Falak Middle East Hsse Site Induction: DIA SP551gilNo ratings yet

- Health, Safety & Environment: Refer NumberDocument2 pagesHealth, Safety & Environment: Refer NumbergilNo ratings yet

- Thermo Shaker Sh26: Instruction ManualDocument7 pagesThermo Shaker Sh26: Instruction ManualgilNo ratings yet

- Manual Viscometer PCE-RVI 3Document20 pagesManual Viscometer PCE-RVI 3gilNo ratings yet

- Thermo-Shaker: User ManualDocument9 pagesThermo-Shaker: User ManualgilNo ratings yet

- Fire Extinguisher ExplosionDocument6 pagesFire Extinguisher ExplosiongilNo ratings yet

- OETC-HSE-O-GUL-M-013 Waste ManagementDocument6 pagesOETC-HSE-O-GUL-M-013 Waste ManagementgilNo ratings yet

- R-HSE-02 Environmental Aspect Impact AssessmentDocument5 pagesR-HSE-02 Environmental Aspect Impact AssessmentgilNo ratings yet

- Loto Implementation Procedure Plan PDFDocument18 pagesLoto Implementation Procedure Plan PDFgilNo ratings yet

- SQL Server (Transact-SQL) - CREATE LOGIN StatementDocument4 pagesSQL Server (Transact-SQL) - CREATE LOGIN StatementEL Ghazouany MedNo ratings yet

- Research and Consideratio Ns For: Conor Timmons Juan Garelli Iris LichnovskáDocument23 pagesResearch and Consideratio Ns For: Conor Timmons Juan Garelli Iris LichnovskáAmal HameedNo ratings yet

- DGL SBLC 110 World BanksDocument3 pagesDGL SBLC 110 World BanksJavier E. Hernández F.No ratings yet

- Rateek OEL: Areer BjectiveDocument2 pagesRateek OEL: Areer BjectiveSapna SinghNo ratings yet

- CSE-SS Unit 3 QBDocument43 pagesCSE-SS Unit 3 QBJKNo ratings yet

- Av RemoveDocument616 pagesAv RemoveSlobodan VujnicNo ratings yet

- Professionalization of Pre-Service Teachers Through University-School PartnershipsDocument13 pagesProfessionalization of Pre-Service Teachers Through University-School Partnershipsurban7653No ratings yet

- QuestionaireDocument26 pagesQuestionaireMaqdoom MohiuddinNo ratings yet

- AWS Simple Icons PPT v15.10.2Document35 pagesAWS Simple Icons PPT v15.10.2narsingthakurNo ratings yet

- In Re Guarina, 24 Phil. 37Document1 pageIn Re Guarina, 24 Phil. 37WrenNo ratings yet

- ME 205 ThermodynamicsDocument3 pagesME 205 Thermodynamicsnandan144No ratings yet

- International Standard 2671: Environmental Tests For Aircraft Equipment - Part 3.4: Acoustic VibrationDocument12 pagesInternational Standard 2671: Environmental Tests For Aircraft Equipment - Part 3.4: Acoustic VibrationfgnestorNo ratings yet

- 1.2 Nationalized Banks in India: Axis BankDocument4 pages1.2 Nationalized Banks in India: Axis BankUsman KulkarniNo ratings yet

- Bento4 Users GuideDocument157 pagesBento4 Users GuidearmashulaNo ratings yet

- mt4 GuideDocument24 pagesmt4 GuideGeorge PruteanuNo ratings yet

- Mastering Listening and Non Verbal Communication Skills and Communicating in Teams Chp2Document32 pagesMastering Listening and Non Verbal Communication Skills and Communicating in Teams Chp2soldastersNo ratings yet

- TXP Advanced ExplanationDocument109 pagesTXP Advanced ExplanationDaniel OrdoñezNo ratings yet

- 100 Marks ProjectDocument89 pages100 Marks ProjectVijay Rane100% (1)

- Wicked Women - Women & Pre-Code HollywoodDocument6 pagesWicked Women - Women & Pre-Code HollywoodNickyNo ratings yet

- Cigre TB 498Document79 pagesCigre TB 498jchinchayNo ratings yet

- Zombie: Survival GuideDocument25 pagesZombie: Survival Guideapi-462582713No ratings yet

- Reverse LogisticsDocument21 pagesReverse LogisticsParth V. PurohitNo ratings yet

- Groovy Tutorial PDFDocument35 pagesGroovy Tutorial PDFPratishta TambeNo ratings yet

- Cable Construction & Cable Selection - Part - 1 - Electrical Notes & ArticlesDocument7 pagesCable Construction & Cable Selection - Part - 1 - Electrical Notes & Articlesscyper89100% (1)

- Certificate of InsuranceDocument1 pageCertificate of InsuranceElisson MoreiraNo ratings yet

- Blood Glucose Meter PDFDocument10 pagesBlood Glucose Meter PDFsneh1509No ratings yet

- Rural Marketing - Project ShaktiDocument12 pagesRural Marketing - Project ShaktiMonisha HenryNo ratings yet