Professional Documents

Culture Documents

SeraGalN-ER 02

Uploaded by

UtpalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SeraGalN-ER 02

Uploaded by

UtpalCopyright:

Available Formats

Product Information Process Auxiliaries

®

Sera Gal N-ER

Levelling agent with fibre affinity for dyeing polyamide

Function Levelling agent to minimise barré in dyeing polyamide with acid and

pre-metallised dyestuffs

Properties - dyeing polyamide with acid dyes and 1:2 pre-metallised dyes

- reduction of streaky dyeing polyamide articles produced from fibres with

different structures, used as pretreatment before dyeing or in the dyebath

- controlled differential effect if using defined product amounts in dyeing

differential polyamide materials

- reserving of polyamide fibres in dyeing polyamide/wool blends

- does not impair light fastness of dyed fabrics

- free of APEO and phosphates

Chemical Characteristics Preparation of aryl sulphonates

Technical Data Appearance: yellow, clear, liquid

pH: 7 - 9 (substance)

Density: 1.05 g/cm³

Ionicity: anionic

Dilution procedure: easily soluble in water

Shelf life: 24 month in closed original containers

Sera Gal N-ER - 2008/11 Page 1 of 3

Application

Because of the product's affinity to the fibre, the amount required must be

calculated on the basis of the fibre saturation value of the polyamide and the

structure of the substrate.

Due to the foaming nature of Sera Gal N-ER it might be necessary on jet dyeing

machines to use antifoamer, e.g. Sera Foam M-58 K or Sera Foam M-HTS.

General recommendation

General recommendations for dyeing of Pa with acid and 1:2 metal

complex dyes

Application in the dyebath

Pale Medium Heavy

shades shades shades

Sera Gal N-ER 5 - 4% 4 - 3% 3 - 1.5%

It is advantagous to use, beside the purely fibre affine leveller Sera Gal N-ER

additionally a leveller with affinity to dyestuff, e.g. 0.5 - 1% Sera Gal N-FS or

1 - 2% Sera Gal N-LP. Thus the indicated amounts of Sera Gal N-ER may be

reduced by up to 50%.

For covering severe barriness we recommend to apply a preboiling method.

The material is pretreated with

3 - 5% Sera Gal N-ER

at pH 5, 20 min at 100 °C.

Afterwards the liquor is cooled down to 80 °C, pH ist adjusted respectively and

after addition of dyes and heating till the boil the process is proceeded as usual.

Particularly in this case we recommend the combination with a dyestuff affine

leveller, e.g. 0.5 - 1% Sera Gal N-FS or 1 - 2% Sera Gal N-LP.

Differential dyeing of PA

Sera Gal N-ER is recommended for differential dyeing, if control (reduction) of

differentiation resp. contrast is aimed at.

In case of cross dyeing materials there is the necessity for a separate

antiprecipitant, which again increases the contrast slightly: Sera Gal W-MKS

and/or Sera Gal M-IW

Normal differentiation: 0.5 - 1 % Sera Gal N-ER

Low differentiation: 1 - 3 % Sera Gal N-ER

Resist agent for use in the dyeing of wool/polyamide blends

The amounts required depend on the blend ratio, dyes and depth of shade.

Wool/polyamide blends

When dyeing wool/polyamide blends, Sera Gal N-ER ensures excellent reserving

of polyamide fibres from sulfonated dyes. Its reserving effect is dye-specific. This

should be borne in mind when selecting dye combinations.

It can be used to dye wool/polyamide blends in all make-up forms.

Sera Gal N-ER - 2008/11 Page 2 of 3

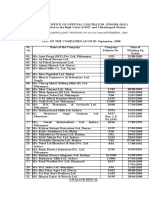

Amounts required

The amount of Sera Gal N-ER needed depends on depth of shade, dyes used and

the type of polyamide. When using acid dyes, the dye/reserving agent diagram

below can be used as a guide to calculate the amount required.

For metal complex dyeings and in some cases for acid dyeings as well the pure

resisting agent Sera Fast N-HW might be the better alternative. However there

must be considered its lack of levelling effect.

Therefore in terms of optimization of effect and recipe costs the might be quite

useful to combine the stronger levelling Sera Gal N-ER with the stronger

resisting Sera Gal N-HW without negative interferences.

In some recipes, particularly in case of deep shades, the shade of PA considerably

differs from that of wool. This effect can be hardly prevented neither by Sera Gal

N-ER nor by other resisting agents. Dye resist agent diagram for acid dyes e.g.

Telon® S-WP

The amounts of Sera Gal N-ER shown in the chart should be taken as a guide.

They can be reduced by up to 25% in some cases. If Sera Gal N-ER is used in

combination with Sera Fast N-HW, the indicated application amounts may be

reduced by up to 70%. The application amounts of Sera Fast N-HW are

described in respective technical info sheet.

8,0

7,6

7,2

6,8

6,4

Agent de réserve de teinture [%]

6,0

5,6

5,2

4,8

4,4 Perlon

4,0 (PA 6)

3,6

3,2

2,8

Nylon

2,4

2,0 (PA 6.6)

1,6

1,2

0,8

0,4

0,0

0,0 0,4 0,8 1,2 1,6 2,0 2,4 2,8 3,2 3,6 4,0

Profondeur de ton [%]

DyStar Textilfarben GmbH & Co. Deutschland KG This information and our technical advice - whether verbal, in

Industriepark Höchst, Building B 598 writing or by way of trials - are given in good faith but without

warranty, and this also applies where proprietary rights of third

65926 Frankfurt am Main, Germany parties are involved. Our advice does not release you from the

Phone: ++49 (0) 69 - 21 09 - 26 86 obligation to check its validity and to test our products as to their

Fax Marketing: ++49 (0) 69 - 21 09 - 76 86 suitability for the intended processes and uses. The application, use

and processing of our products and the products manufactured by

Fax Sales: ++49 (0) 69 - 21 09 - 26 20

you on the basis of our technical advice are beyond our control and,

DyStar.Auxiliaries@DyStar.com therefore, entirely your own responsibility. Our products are sold in

www.DyStar.com accordance with our General Conditions of Sale and Delivery.

Sera Gal N-ER - 2008/11 Page 3 of 3

You might also like

- SeraGalN-LP 01Document3 pagesSeraGalN-LP 01UtpalNo ratings yet

- SeraGalN LPDocument3 pagesSeraGalN LPUtpalNo ratings yet

- SeraGalN ESDocument3 pagesSeraGalN ESUtpalNo ratings yet

- Sera Gal P-LP - EDocument3 pagesSera Gal P-LP - ECarolina PereiraNo ratings yet

- SeraFastN HWDocument5 pagesSeraFastN HWArbab SkunderNo ratings yet

- SeraGalN-FS 01Document2 pagesSeraGalN-FS 01UtpalNo ratings yet

- SeraGalC RFXDocument3 pagesSeraGalC RFXUtpalNo ratings yet

- Input Industries Industrial DownloadDocument6 pagesInput Industries Industrial DownloadBoonyarit LurdgrienggraiyingNo ratings yet

- SeraConP ARDocument5 pagesSeraConP ARArbab SkunderNo ratings yet

- SeraFastN BSDocument10 pagesSeraFastN BSArbab SkunderNo ratings yet

- Laropal A81: Industrial CoatingsDocument3 pagesLaropal A81: Industrial CoatingsMOEEN KHAN ASLAM KHAN RISALDARNo ratings yet

- Chemplasa Ebs L-205F-TdsDocument1 pageChemplasa Ebs L-205F-TdsÁnh Nguyễn100% (1)

- EXM Powder Paint Coatings Color Chart EngDocument1 pageEXM Powder Paint Coatings Color Chart EngHomero BasalduaNo ratings yet

- Dis Persant EsDocument5 pagesDis Persant Esdargil66No ratings yet

- Nearchel Bad Sales Aid1Document5 pagesNearchel Bad Sales Aid1Jayant Subhash UdakheNo ratings yet

- Manómetros Con Sifón y Válvula-Instrucciones de Instalación y MantenimientoDocument1 pageManómetros Con Sifón y Válvula-Instrucciones de Instalación y MantenimientoHugh MantaNo ratings yet

- Laropal A 81 June 2014 R2 ICDocument3 pagesLaropal A 81 June 2014 R2 ICOswaldo Manuel Ramirez MarinNo ratings yet

- Laropal Grades: Technical InformationDocument6 pagesLaropal Grades: Technical InformationTOPS SYNERGIST CO.,LTDNo ratings yet

- EfkaIO6785 TI 30629447 ENDocument2 pagesEfkaIO6785 TI 30629447 ENEraNo ratings yet

- Latapoxy SP 100 TDSDocument3 pagesLatapoxy SP 100 TDSBithika DattaNo ratings yet

- Kraton Adhesive BrochureDocument14 pagesKraton Adhesive BrochureTélémaqueNo ratings yet

- Sudacolor Yellow G TdsDocument1 pageSudacolor Yellow G TdsRajiv DubeyNo ratings yet

- Fichas Tecnicas Ar3Document1 pageFichas Tecnicas Ar3german.canutiNo ratings yet

- Novacron FN Pocket Card1Document24 pagesNovacron FN Pocket Card1textile1to35No ratings yet

- Hostaphat OPS 100: Industrial & Consumer SpecialtiesDocument2 pagesHostaphat OPS 100: Industrial & Consumer Specialtiesm daneshpourNo ratings yet

- Albatex Sa-200 NewDocument5 pagesAlbatex Sa-200 NewruestchivaNo ratings yet

- Flooring - Product BookDocument9 pagesFlooring - Product BookvaducNo ratings yet

- Heliogen Blue L6905F-TDSDocument2 pagesHeliogen Blue L6905F-TDSOmer KaramustafaogluNo ratings yet

- Albigen A NewDocument7 pagesAlbigen A Newyadi haryadiNo ratings yet

- Dyeing Co-Pa Blends - enDocument4 pagesDyeing Co-Pa Blends - en宋德欽No ratings yet

- Textile Product Brochure 31-5-2018Document1 pageTextile Product Brochure 31-5-2018anon_159986285No ratings yet

- Norma S-572 Asabe Tamaños de Gotas PDFDocument1 pageNorma S-572 Asabe Tamaños de Gotas PDFRafael Antonio Sanchez DíazNo ratings yet

- Clariant Brochure Colorants For The Paint Industry 201703 enDocument36 pagesClariant Brochure Colorants For The Paint Industry 201703 enYohanes DitoNo ratings yet

- SeraFix SeraPadDocument3 pagesSeraFix SeraPadArbab SkunderNo ratings yet

- 54 C 838287 B 847Document5 pages54 C 838287 B 8478612106535No ratings yet

- Agro EmulsifiersDocument3 pagesAgro EmulsifiersFarizal HammiNo ratings yet

- Agaroses Manual: D1 Low EEODocument14 pagesAgaroses Manual: D1 Low EEONey SLimaNo ratings yet

- Chemical Resistance Guide Feb 2019Document28 pagesChemical Resistance Guide Feb 2019Henry AguileraNo ratings yet

- Clariant AdditivesDocument3 pagesClariant AdditivesZelal Harputlu OzbunarNo ratings yet

- Crude Fingerprinting and Predictive Analytics - GE Water & Process TechnologiesDocument12 pagesCrude Fingerprinting and Predictive Analytics - GE Water & Process TechnologiesAlejandro PedezertNo ratings yet

- Section VIII: Separation of RNA in Agarose GelsDocument18 pagesSection VIII: Separation of RNA in Agarose GelsVictorNo ratings yet

- Section VIII: Separation of RNA in Agarose GelsDocument18 pagesSection VIII: Separation of RNA in Agarose GelsVictorNo ratings yet

- 1 - Ink Shade CardDocument5 pages1 - Ink Shade Cardbh99988822No ratings yet

- Corrosion Resistance GuideDocument26 pagesCorrosion Resistance GuideFrancisco Javier Villegas AndersonNo ratings yet

- URI513 Catalog06Document25 pagesURI513 Catalog06INLAB SERVICENo ratings yet

- Shade Card BEZATHRENDocument9 pagesShade Card BEZATHRENFatih SezenNo ratings yet

- Clariant Brochure Shade Card Organic Pigments For Plastics Coloration 201710 EN DEDocument13 pagesClariant Brochure Shade Card Organic Pigments For Plastics Coloration 201710 EN DEᎽᎯ ᎡᎯ ᎯᏞᎯᎿᎿᎯᎡNo ratings yet

- FAQ - GelRed Nucleic Acid Gel StainDocument3 pagesFAQ - GelRed Nucleic Acid Gel StainGlennadi R. RualoNo ratings yet

- Carpet Brochure 7 CDP Single PagesBDocument8 pagesCarpet Brochure 7 CDP Single PagesBNguyễn Huy CườngNo ratings yet

- Flyer PES DRUCK EnglishDocument4 pagesFlyer PES DRUCK EnglishSajjad AhmedNo ratings yet

- Lanasyn Negro M-DLN 120Document1 pageLanasyn Negro M-DLN 120Emilio Rabanal100% (1)

- Shade CardDocument15 pagesShade CardmayurkkhatriNo ratings yet

- Ready-Mixed White and Yellow Traffic Paints: Standard Specification ForDocument3 pagesReady-Mixed White and Yellow Traffic Paints: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Protocolo Gelred BiotiumDocument4 pagesProtocolo Gelred BiotiummaryNo ratings yet

- Violet RL SPEC PDFDocument2 pagesViolet RL SPEC PDFمحمد مقلدNo ratings yet

- Zs Dyeset RFTDocument2 pagesZs Dyeset RFTRezoanul HaqueNo ratings yet

- Investigation of Effect of Pour Point Depressant On Wax DepositionDocument3 pagesInvestigation of Effect of Pour Point Depressant On Wax DepositionAfzal AktharNo ratings yet

- CHT Tubicoat A 71 I TDSDocument2 pagesCHT Tubicoat A 71 I TDSUtpalNo ratings yet

- Adhesivo 642 TDSDocument1 pageAdhesivo 642 TDSUtpalNo ratings yet

- Igsurf 33 Ci TDSDocument2 pagesIgsurf 33 Ci TDSUtpalNo ratings yet

- Acrolube MSDSDocument5 pagesAcrolube MSDSUtpalNo ratings yet

- Evo Stat QHT EnglishDocument2 pagesEvo Stat QHT EnglishUtpalNo ratings yet

- Argabuffer 65 TDSDocument2 pagesArgabuffer 65 TDSUtpalNo ratings yet

- Addilink LP - TDSDocument2 pagesAddilink LP - TDSUtpalNo ratings yet

- Evo Lan Shine EnglishDocument2 pagesEvo Lan Shine EnglishUtpalNo ratings yet

- Addiflam Booster Pes 80 New TDSDocument1 pageAddiflam Booster Pes 80 New TDSUtpalNo ratings yet

- Evo Lan GWA EnglishDocument2 pagesEvo Lan GWA EnglishUtpalNo ratings yet

- Evo Top A75 EnglishDocument2 pagesEvo Top A75 EnglishUtpalNo ratings yet

- Evo Lan WAF English 01Document4 pagesEvo Lan WAF English 01UtpalNo ratings yet

- LavaCellPower 01Document2 pagesLavaCellPower 01UtpalNo ratings yet

- Checklist For CoatingDocument2 pagesChecklist For CoatingUtpalNo ratings yet

- Evo Wax For Knitting YarnsDocument2 pagesEvo Wax For Knitting YarnsUtpalNo ratings yet

- 1119HCDS205v2 Zinador 35LDocument6 pages1119HCDS205v2 Zinador 35LUtpalNo ratings yet

- Evo Top A30 EnglishDocument2 pagesEvo Top A30 EnglishUtpalNo ratings yet

- WETSOFT NE 820 en 2020.07.01Document2 pagesWETSOFT NE 820 en 2020.07.01UtpalNo ratings yet

- Evo Wax GSDocument3 pagesEvo Wax GSUtpalNo ratings yet

- Evo Gard FSUDocument3 pagesEvo Gard FSUUtpalNo ratings yet

- Evo Lube 8358Document2 pagesEvo Lube 8358UtpalNo ratings yet

- ABIL B 9950 Technical InformationDocument3 pagesABIL B 9950 Technical InformationUtpalNo ratings yet

- Evo Sil HWADocument3 pagesEvo Sil HWAUtpalNo ratings yet

- Evo Gard FCCDocument3 pagesEvo Gard FCCUtpalNo ratings yet

- Biotex Productrange 202006Document32 pagesBiotex Productrange 202006UtpalNo ratings yet

- 08 - 080667e - Luwax OA TypesDocument4 pages08 - 080667e - Luwax OA TypesUtpalNo ratings yet

- Evo Fin HPUDocument2 pagesEvo Fin HPUUtpalNo ratings yet

- LavaSperseBase 01Document2 pagesLavaSperseBase 01UtpalNo ratings yet

- Deepchand Chemicals Pvt. LTD.: Ethylene Oxide CondensatesDocument3 pagesDeepchand Chemicals Pvt. LTD.: Ethylene Oxide CondensatesUtpalNo ratings yet

- Sonotube® Commercial Concrete Forms PDFDocument3 pagesSonotube® Commercial Concrete Forms PDFAnubhav MukherjeeNo ratings yet

- G Ga Arrllo Oc CK K: Seals and Sealing SystemsDocument32 pagesG Ga Arrllo Oc CK K: Seals and Sealing SystemsCristian DehnNo ratings yet

- Question Bank Subject: Materials Science and EngineeringDocument4 pagesQuestion Bank Subject: Materials Science and Engineeringsharma05031989No ratings yet

- How Does A Fan Work?Document2 pagesHow Does A Fan Work?HadiNo ratings yet

- Analisis de Gas de Aceite de Transformador Utilizando Una Columna de Separacion Astm d3612 KasalabDocument2 pagesAnalisis de Gas de Aceite de Transformador Utilizando Una Columna de Separacion Astm d3612 KasalabJohnatan HernándezNo ratings yet

- Statement of Compulsory Winding Up As On 30 SEPTEMBER, 2008Document4 pagesStatement of Compulsory Winding Up As On 30 SEPTEMBER, 2008abchavhan20No ratings yet

- Category L T P Credit Year ofDocument10 pagesCategory L T P Credit Year ofSAKHI U 20MLCE11No ratings yet

- Comparison of Gas Dehydration Methods Based On Energy Consumption PDFDocument6 pagesComparison of Gas Dehydration Methods Based On Energy Consumption PDFABULARA2K6No ratings yet

- Meadow Burke Innovating Tilt-Up Construction 2013 PDFDocument122 pagesMeadow Burke Innovating Tilt-Up Construction 2013 PDFFeliciano Leiva EstradaNo ratings yet

- ACI Shrinkage CalculationDocument15 pagesACI Shrinkage CalculationHussein BeqaiNo ratings yet

- Method For The Determination of CarotenesDocument2 pagesMethod For The Determination of CarotenesNakibuuka Magdalein50% (2)

- Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet: Section I - IdentificationMohamed AdelNo ratings yet

- Absorption Coefficient TableDocument1 pageAbsorption Coefficient TableMark bellie TeranteNo ratings yet

- Resistance AWSDocument82 pagesResistance AWSaravindan100% (1)

- Devulcanization of Recycled Tire Rubber Using Supercritical Carbon DioxideDocument11 pagesDevulcanization of Recycled Tire Rubber Using Supercritical Carbon DioxideJose Perez100% (1)

- 3DT128 - PBDocument1 page3DT128 - PBfarrah.taNo ratings yet

- Wittke, W, Pierau, B and Erichsen, C - New Austrian Tunneling Method (NATM) Stability PDFDocument419 pagesWittke, W, Pierau, B and Erichsen, C - New Austrian Tunneling Method (NATM) Stability PDFCalin MateiNo ratings yet

- Types of SpecificationDocument36 pagesTypes of SpecificationShann Hortaleza100% (2)

- Manufactured Substances in Industry FORM 4 SPMDocument7 pagesManufactured Substances in Industry FORM 4 SPMChristopher Lau Huat KhingNo ratings yet

- Building DefectDocument9 pagesBuilding DefectMohd Adib Abd TalibNo ratings yet

- A Review On Use of FRP Mesh and Bamboo Fiber Composite Material For AAC Block Masonry Wall Strengthening and WaterDocument5 pagesA Review On Use of FRP Mesh and Bamboo Fiber Composite Material For AAC Block Masonry Wall Strengthening and WaterIJRASETPublicationsNo ratings yet

- How To Calculate Quantities of Cement, Sand and Aggregate For Nominal Concrete Mix (1 - 2 - 4) - HapphoDocument20 pagesHow To Calculate Quantities of Cement, Sand and Aggregate For Nominal Concrete Mix (1 - 2 - 4) - HapphoJamohl Supremo AlexanderNo ratings yet

- Summative Test TleDocument18 pagesSummative Test TleGillyn Ruiz - AntonioNo ratings yet

- Science Form 1 Exam QuestionDocument7 pagesScience Form 1 Exam QuestionNorliyana Ali50% (8)

- Article WJPR 1490956558Document11 pagesArticle WJPR 1490956558Rudra RoyNo ratings yet

- Mahalakshmi: Engineering CollegeDocument16 pagesMahalakshmi: Engineering CollegeVijeesh VijayalayamNo ratings yet

- Flotation of MineralsDocument3 pagesFlotation of MineralsgabrielNo ratings yet

- CE 380 Lecture 1Document11 pagesCE 380 Lecture 1Srdan BoskovicNo ratings yet

- Tesco: Biodegradable Hydraulic Oil BIO 68Document2 pagesTesco: Biodegradable Hydraulic Oil BIO 68lucas ronaldo coronel mendozaNo ratings yet

- PSOW2 - MS For Waterproofing Dated 04.11.2023Document5 pagesPSOW2 - MS For Waterproofing Dated 04.11.2023projectsNo ratings yet