Professional Documents

Culture Documents

Tank GA

Uploaded by

leeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tank GA

Uploaded by

leeCopyright:

Available Formats

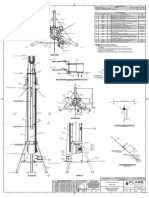

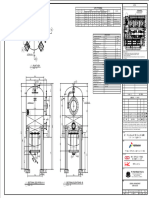

16500 GENERAL NOTES

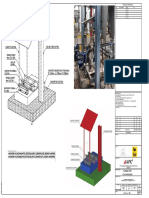

LIGHTNING ROD 15600

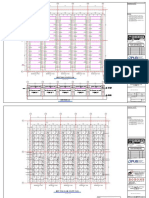

TYPICAL FOR ROOF HAND RAIL

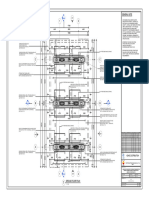

ROOF PLATFORM AND STAIRS 1. ALL DIMENSIONS & ELEVATIONS ARE IN MM, UNLESS MATERIAL OF CONSTRUCTION DESIGN DATA

1250 SHALL BE WITH HANDRAIL OTHERWISE STATED. SHELL PLATES ASTM A 516 GR. 70 NACE+HIC TESTED

N36

N35 2. ALL WELDS CONTINUOUS EXCEPT AS NOTED. ROOF PLATES ASTM A 516 GR. 70 NACE+HIC TESTED TANK TAG NO. 371-00-TK-001A

1100

N34 T.O.G. EL. +22700 3. ALL BUTT WELDS SHALL BE FULL PENETRATION WELD. ANNULAR BOTTOM PLATES ASTM A 516 GR. 70 NACE+HIC TESTED NUMBER REQUIRED 1 EACH

N33 4. ALL NOZZLE FLANGE GASKET SEATING SURFACE SHALL HAVE

BOTTOM PLATES ASTM A 516 GR. 70 NACE+HIC TESTED SERVICE NAME TREATED WATER STORAGE TANK

N3 N16

125 TO 250 AARH FINISH.

ROOF PLATE / 7mm SHELL MANHOLE NECKS ASTM A 516 GR. 70 NACE+HIC TESTED DESIGN CODE API 650 13TH. EDITION ANNEX E, F, P, T, V

5. UP TO 20" DIAMETER, FLANGE DIMENSIONS SHALL BE IN

TOP WIND GIRDER / NPL 150 N47AN47B SHELL MANHOLE FLANGES/COVERS S235 JR (EN 10025) PRODUCT HANDLED TREATED WATER DISSOLVED O2 (20ppb)

ACCORDANCE TO ASME B 16.5. FOR 20" AND BIGGER SIZE

1 T.O.G. EL. +20100 NOZZLE PIPES ASTM A106 Gr B / A283 Gr. C AS PER NACE MR-0175

15

N1D N1E FLANGE DIMENSIONS SHALL BE IN ACCORDANCE TO ASME B DESIGN SP. GRAVITY 0.985

1110

INTERMEDIATE 6 16.47 SERIES A. NOZZLE FLANGES & BLINDS (EXT./INT.) ASTM A105 AS PER NACE MR-0175 OPERATING PRESSURE [barg] 0,020

451,03

GIRDER ROOF SLOPE +EL.19000

10. COURSE / 8 mm 6. ALL STUD BOLTS SHALL BE FULLY THREADED, UNLESS REINFORCEMENT PLATES S235 JR (EN 10025) OPERATING TEMPERATURE [°C] +75

1980

N11 N20A

EL. +18480 OTHERWISE SPECIFIED. GASKETS S.W. SS316+FLEXIBLE GRAPHITE FILLER TP 316 I.R./C.S. O.R. DESIGN PRESSURE/VACUUM [barg] 0,12 + FULL OF WATER LOAD /-0,005

EL. +18480 EL. +18130 N13A

7. AFTER ERECTION AND INSPECTION, THE TANK SHALL BE

2800

EXTERNAL STUD BOLTS/NUTS ASTM A 193 Gr.B7 / ASTM A 194 Gr.2H +90

400

N15 DESIGN TEMPERATURE [°C]

N13B TESTED BY WATER FILLING FOR TIGHTNESS & DEFORMATION. INTERNAL STUD BOLTS/NUTS DUPLEX STAINLESS STEEL

N19AN19B 9. COURSE / 8 mm MDMT [°C] -4,7

1250

1565

CLEAN WATER SHALL BE USED FOR HYDROTEST. TEST WATER

EXTERNAL GUSSETS S235JR (EN 10025) NET WORKING CAPACITY [m^3] 15362

pH FACTOR OF BETWEEN 6 AND 8,3 IS ACCEPTABLE.

STRUCTURALS (CURB ANGLE) S 235 (EN 10025) GROSS CAPACITY [m^3] 17615

INTERMEDIATE 8. WPS, PQR & WELDERS QUALIFICATION SHALL BE APPROVED

INTERNAL PIPES (UP TO 14" PIPE) DUPLEX STAINLESS STEEL AS PER NACE MR-0175 RADIOGRAPHY YES (AS PER API STD. 650)

1980

GIRDER/NPL 150 8. COURSE / 8 mm BY SICIM AND/OR LUKOIL.

+EL.13800 9. UNLESS OTHERWISE INDICATED, ALL FLANGE HOLES SHALL INTERNAL PIPES (14" AND BIGGER PIPE) DUPLEX STAINLESS STEEL AS PER NACE MR-0175 HYDROSTATIC TESTING YES (0,12 barg AIR+FULL OF WATER )

∅406x9 COLUMN BE STRADDLE TO MAIN AXIS. STRUCTURALS (SUPPORINT MAIN STEEL) S275 JR (EN 10025) AS PER NACE MR-0175 (SEE NOTE 27) HYDROTESTING HOLDING TIME 24 HOURS

1x CENTER COLUMN 10. ALL NOZZLE PIPE SIZES ARE TO ANSI B36.10 STRUCTURALS (ROOF COLUMNS) S235 JR (EN 10025) AS PER NACE MR-0175 (SEE NOTE 27) TEST FLUID POTABLE WATER

1980

7. COURSE / 10 mm

11. AIR LEAKAGE TEST SHOULD BE PROVIDED FOR ALL STRUCTURALS (STAIRWAY/PLATFORMS/GRATING) S235 JR (EN 10025) AS PER NACE MR-0175 (SEE NOTE 27)

N/A INSULATION (EXT.)

REINFORCED NOZZLES AND MANHOLES. AFTER THE LEAKAGE STRUCTURALS (INTERNAL PIPE SUPPORTS) S235 JR (EPOXY LINED) AS PER NACE MR-0175 (SEE NOTE 27)

YES (AS PER 8015-0151-LM20-00-000-CP-SP-00002)

INTERNAL COATING

TEST, 1/4" NPT TEST HOLE WILL BE CLOSED WITH CORROSION

9000 EARTHING LUGS AISI 304 YES (AS PER 8015-0151-SC03-00-000-ME-SP-00003)

EXTERNAL COATING

1980

6. COURSE / 12 mm INHIBITING GREASE. (LEAKAGE TEST PRESSURE IS 1.0 Kg/cm2g)

STRUCTURALS (HANDRAIL) S235 JR (EN 10025) BOTTOM 3

12. WELDER QUALIFICATION HAS TO BE PROVED ACCORDING

19385

TO API 650. INTERNAL PIPE FITTINGS S 235 JR SHELL 3

+EL.9200 CORROSION

∅355x9 COLUMN ANCHORE BOLTS ASTM A 307 Gr A ROOF 3

13. ALL SHARP CORNERS SHALL BE ROUNDED OFF.

1980

EVENLY DISTRIBUTED 5. COURSE / 14 mm ALLOWANCE [mm]

14. SHELL NOZZLE PROJECTIONS ARE MEASURED FROM STRUCTURAL BOLTING ASTM A 307 Gr B INTERNALS 3

12x COLUMN

OUTSIDE OF SHELL TO FACE OF FLANGE. BRACKET FOR NAME PLATE S235 JR (EN 10025) STRUCTURE 3

15. ALL WELD JOINTS ON TANK BOTTOM SHALL BE TESTED EXTERNAL CLIPS WITH PAD ASTM A 36 & S235 JR EN 10025 MAX. WIND SPEED [m/s] 40

1980

4. COURSE / 16 mm USING VACUUM BOX METHOD. NAME PLATE AISI 304 MAX. SNOW LOAD N/A

16. ALL ELEVATIONS ARE MEASURED FROM REF. LEVEL EL +0.00 TOP WIND GIRDER S235 JR / EN 10025 FIRE PROOFING N/A

(TOP SIDE OF ANNULAR PLATE)

COUPLINGS ASTM A105 FIRE FIGHTING N/A

1980

+EL.4600 3. COURSE / 18 mm 17. ALL LAP WELD SHALL HAVE A MINIMUM OF TWO PASSES

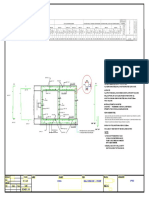

TANK NOMINAL DIAMETER [mm] 34000

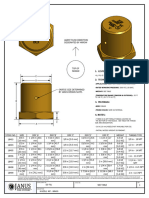

1950 48" SUCTION WITH 1950 DEPOSIT. NOZZLE & ACCESSORIES SCHEDULE HEIGHT OF TANK [mm] 19400

VORTEX BREAKER 18. ALL WELDING SYMBOLS SHOWN IN THIS DWG. ARE ACC. TO PROJ. NOZZLE NOZZLE

30" SUCTION WITH FLANGE MAX. OPERATING LIQUID LEVEL [mm]18120

AWS. MARK NB THK QTY (FROM EL. ANGLE

SERVICE REMARKS CENTER)

1980

2400x2400 ANTI VORTEX BREAKER

N18A EL. +3000 EL. +3000 N18B 2. COURSE / 20 mm RTG TYPE STD (mm) (Degree)

SHELL NOZZLE AND ACCESSORIES

VORTEX PL./20mm 19. ALL GIVEN FILLET WELD SIZES ARE LEG HEIGHT. (mm) THERMAL STRESS RELIEF AS PER API650

N1A N1B N1C

SHELL MANHOLE W/DAVIT ARM W/ DAVIT-HINGE 17403 1020 3°, 105°, 219° SURFACE PREPARATION

1020

1500x1500 ANTI 20. MT OR PT EXAMINE SHALL BE PROVIDED ALL SHELL N1A/B/C 36" SCH. STD 3 AS PER API650 Sa-2 1/2 (ACC. TO SWEDISH NORM)

600

∅700 REINFORCEMENT VORTEX PL. /15mm FITTINGS PER API STD. 650 ASME SEISMIC RISC ZONE

N40 EL. +1400 2500 N11 30" SCH. STD 1 150# SO,RF B16.47A SPARE W/BLIND W/ ELBOW 17403 18480 287,5° 1

1980

PLATE / 20mm 1. COURSE / 22 mm 21. STUD BOLTS AND NUTS SHALL BE RUST PROTECTED. ASME IMPACT FACTOR 1

N13A 30" SCH. STD 1 150# SO,RF B16.47A TREATED WATER INLET W/ DIP PIPE 17403 18130 270°

SEISMIC

N31B N31A EL. +290

22. ALL ELBOWS SHALL BE LONG RADIUS TYPE AS PER ASME PEAK ACCELERATION 0,075g

ASME

B16.9 N13B 34" SCH. STD 1 150# SO,RF B16.47A TREATED WATER INLET W/BLIND W/ DIP PIPE 17403 18130 SEE DETAIL CONDITIONS

1 SCALING FACTOR (Q) 1

4803 BOTTOM PLATE / 9mm 23. THE CONNECTIONS BETWEEN DUBLEX STAINLESS STEEL ASME

N15 30" SCH. STD 1 150# SO,RF B16.47A FEED INLET (FUTURE) W/BLIND W/ ELBOW 17403 18480 292,5°

SOIL TYPE

400

120 My

AND CS COMPONENTS SHALL BE ELECTRICALLY INSULATED TO W/ ELBOW

Se (UBC 1997)

ANNULAR PLATE / 11mm ASME

N18A 48" SCH. STD 1 150# SO,RF B16.47A OUTLET 17403 3000 180°

BOTTOM SLOPE W/ VORTEX PL. MATERIAL CERTIFICATE YES (EN 10204/3.1)

∅34000 PREVENT GALVANIC CORROSION (PTFE, HNBR OR EQUIVALENT W/ ELBOW

ASME

(INSIDE DIA. AT BOTTOM COURSE) MAXIMUM ALLOWABLE

MATERIAL. N18B 30" SCH. STD 1 150# SO,RF B16.47A OUTLET (FUTURE) W/BLIND W/ VORTEX PL. 17403 3000 SEE DETAIL STAIRWAY / PLATFORM YES / YES

NOZZLE LOADS ASME

∅34144 24. TANK FOUNDATION SHALL BE A SLAB W/ RINGWALL AND N19A/B 30" SCH. STD 2 150# SO,RF B16.47A OVERFLOW W/ DIP PIPE 17403 18480 65°, 252° STAMP NO

(TANK BOTTOM PLATE) Mz SAND PAD. ASME FLOATING SUCTION (SWING LINE) NO

Mx N20A 30" SCH. STD 1 300# WN,RF B16.47A MINIMUM FLOW RETURN W/ DIP PIPE 17403 18480 190°

6° NP 25. PERSONAL PROTECTION SHIELDING SHALL BE PROVIDED IN ASME MAX. INLET FLOW RATE [m^3/h] 1104

Mx My Mz N31A/B 6" SCH. STD 2 150# WN,RF B16.5 DRAIN W/ DRAIN SUMP 17403 290 130°, 230°

TYP. 0° N1B NOZZLE Fx [N] Fy [N] Fz [N] ALL AREAS REACHABLE BY OPERATORS (ROOF AND WALLS). MAX. OUTLET FLOW RATE [m^3/h] 1104

EL [Nm] [Nm] [Nm] ASME

SEE DOC. NO. 8015-0151-36-ME-POSC03ME0002-D03-00025 N40 2" SCH. XS 1 300# SO,RF B16.5 TEMPERATURE GAUGE NOZZLE 17403 1400 75°

3° 8° N11 25000 60000 13750 40000 5500 24000 TYPE OF ROOF COLUMN SUPPORTED RAFTERS

FOR DETAILS. EL - - 5 - - - EARTING LUG - 200 8°+72° APART

N13A 25000 60000 13750 40000 5500 24000 JOINT EFFICIENCY 1.0 ON SHEEL

26. PLATFORM/HANDRAIL SHOWN AS INDICATIVE ONLY. REFER

N13B 30000 57252 15257 45000 8000 30000 NP - - 1 - - - NAMEPLATE W/BRACKET - 1500 3° INTERNAL CATODIC PROTECTION YES

TO DETAIL DRAWINGS FOR PLATFORM AND PIPE CLIP.

33°

ROOF NOZZLE AND ACCESSORIES

N15 25000 60000 13750 40000 5500 24000 N1D/E 36" SCH. STD 2 AS PER API650 ROOF MANHOLE W/ HINGE 20500 33°, 213° EXTERNAL CATODIC PROTECTION BY OTHERS

27. STRUCTURAL MATERIAL FOR TANK INTERNALS SHALL BE AS

N1E N18A 40000 125000 25000 85000 10000 50000 ASME

PER NACE MR-0175 AND EXTERNALLY PAINTED IN N3 8" SCH. STD 1 150# WN,RF B16.5 GAUGE HATCH 20500 61° EARTHING LUGS YES / 1 FOR EACH 25m

3° N18B 35000 46225 9245 65000 6000 30000

ACCORDANCE WITH THE JOB SPECIFICATION FOR IN SOUR N16 8" SCH. STD 1 150# WN,RF

ASME

SPARE NOZZLE W/BLIND 20500 80° DESING RAINFALL [mm/h] 60

N19 25000 75000 13750 40000 5500 30000 B16.5

SERVICE DOC. NO. 8015-0151-SECL-00-000-PI-SP-00028. ASME BREATHER 10-110

N20A 25000 75000 13750 40000 5500 30000 N33 24" SCH. STD 1 150# SO,RF B16.47A THIEF HATCH 20500 70° VALVE SETTINGS EMERGENCY

46° 28. REFERENCE DOCUMENTS 120

N31 2900 2750 1225 3200 490 1100 N34 12" SCH. STD 1 150# WN,RF ASME

PV VENT NOZZLE 20500 92° [mbarg]

- 8015-0151-SECL-00-000-PI-SP-00003 - Engineering Design B16.5

4

N47B PV VENT 115 mbarg / -2 mbarg

12,8°

434

ASME

50° Specification For Painting N35 14" SCH. STD 1 150# WN,RF NITROGEN INLET NOZZLE 23100 CENTER

R15

B16.5

N47A

Ø3

- 8015-0151-SC03-00-000-PI-ST-00001 - Pipe Support Standard 1 300# WN,RF

ASME

PRESSURE TRANSMITTER NOZZLE 20500 55°

N36 2" SCH. STD

0

600

B16.5

00

55° And Details

D.

ASME

2 300# WN,RF

34

N47A/B 4" SCH. STD LEVEL TRANSMITTER NOZZLE 20500 46°, 50°

BC

N36 - 8015-0151-SECL-50-000-SB-SP-00001 - General Design B16.5

.Ø

Specification For Steel Structures LR - - 1 - - - LIGHTNING ROD SEE DRG. 152°

ID

33° 8015-0151-SECL-00-

000-PI-SP-00003

ENGINEERING DESIGN SPECIFICATION FOR PAINTING

61° - COMPANY STD. DETAILS: A2.901, A2.210, A2.302, A2.933,

N3 A2.102, A2.101 BASE LOADS 8015-0151-SC03-00-

000-PI-ST-00001

PIPE SUPPORT STANDARD AND DETAILS

296° EL 13 - 8015-0151-SC03-36-371-PC-PD-10001 - P&ID Water Storage 8015-0151-SECL-50-

GENERAL DESIGN SPECIFICATION FOR STEEL STRUCTURES

° N19A 65° RINGWALL SLAB 000-SB-SP-00001

And Distribution System / LP Water Storage And Distribution SHEAR FORCE AXIAL FORCE

OVERTURNING OVERTURNING

4°

292,5° N15 System - Tank [kN] [kN] 8015-0151-TOYO-00- GENERAL SUPPLY RULES FOR FIXED AND FLOATING ROOF TANK

MOMENT [kNm] MOMENT [kNm] 000-ME-SP-00004

5°

N33 70° - 8015-0151-LM20-00-000-CP-SP-00002 - Specification For 8015-0151-EN07-00- MATERIAL SELECTION REPORT

000-MT-RP-00001

Internal Lining

6°

287,5° N11 WIND 753 -939 7847 7847 8015-0151-SECL-00- VESSEL STANDARD DRAWINGS

- 8015-0151-TOYO-00-000-ME-SP-00004 - General Supply Rules 000-MS-ST-00001

N40 75° For Fixed And Floating Roof Tank EARTHQUAKE 11670 - 86591 158490 8015-0151-SC03-36-

9°

DAVIT ARM TO LOCATE ON TOP P&ID - WATER STORAGE AND DISTRIBUTION SYSTEM/ LP WATER STORAGE

RING NEAR ROOF ACCESS (250 kg)

17403 371-PC-PD-10001 AND DISTRIBUTION SYSTEM - TANK

- 8015-0151-SECL-00-000-PI-SP-00004 - Engineering Design

Specification For Hot Insulation INTERNAL 8015-0151-LM20-00- SPECIFICATION FOR INTERNAL LINING

26,0°

DAVIT ARM ALONG WITH CHAIN - 10895 - -

23,9°

000-CP-SP-00002

N16 EL 80° PRESSURE

10°

PULLEY BLOCK - 8015-0151-SECL-00-000-MS-ST-00001 - Vessel Standard 8015-0151-SC03-22-

SPECIFICATION FOR TREATED WATER TANK

484-ME-SP-00008

Drawings EXTERNAL

25°

N13B - 1577 - - 8015-0151-SC03-22- MECHANICAL DATA SHEET FOR TREATED WATER TANK 371-00-TK-001A

- 8015-0151-EN07-00-000-MT-RP-00001 - Material Selection PRESSURE 371-ME-DS-00004

2150

Report

10°

EMPTY COMPANY STANDARD DETAILS: A2.901, A2.210, A2.302, A2.933, A2.102, A2.101

- 8015-0151-SC03-22-484-ME-SP-00008 - Specification For - 3993 - -

270° N13A 90° Treated Water Tank

WEIGHT 08

N34 92° - 8015-0151-SC03-22-371-ME-DS-00004 - Mechanical Datasheet HYDROTEST

- 176557 - -

For Trearted Water Tank WEIGHT

15°

2°

N35

- 8015-0151-36-CP-POSC03ME0002-D02-00004 - INTERNAL OPERATING

CATHODIC PROTECTION ASSEMBLY DRAWINGS

- 162695 - -

WEIGHT

40°

0° SCALE: 1/300 SCALE: 1/15

105°

N1A

252°

N19B

72

° 11 1100

17 0

525

° 0

273,9° 3350

17403

R1 1250

54

00

33° 300

1100

R165 R14

50

00

23,9°

39°

10500

230° 130° 270° 90°

N31B N31A 2200

525

R16

224°

5°

500

1000

210

EL 0

10° 65

0 4600

219° R1

N1C

00

3000

00

1100 15342m3

43

22

210

213° 8 750 8 150

152°

R1

N1D WIDTH OF STAIR TREAD

EL SHELL PLATE

LR

190°

26°

N20A

N18A N18B 35°

180° GENERAL DIMENSION OF INTERMEDIATE PLATFORM

180°

SCALE: 1/15 (3 SETS INTERMEDIATE PLATFORM REQUIRED)

STAIR TREAD SECTION VIEW TANK ROOF WALKWAY PLATFORM PLAN

You might also like

- 1 Million Email Subscriber PlaybookDocument29 pages1 Million Email Subscriber PlaybookGabriel Ramos100% (4)

- Project Quality PlanDocument35 pagesProject Quality Planlee100% (19)

- P92-4998 Harness Aftertreatment PDFDocument4 pagesP92-4998 Harness Aftertreatment PDFDiego LiraNo ratings yet

- PQPDocument60 pagesPQPlee100% (4)

- Flipkart vs Amazon comparison studyDocument6 pagesFlipkart vs Amazon comparison studysunnyNo ratings yet

- Itinerary For 3days and 2nights in Pangasinan, PhilippinesDocument5 pagesItinerary For 3days and 2nights in Pangasinan, PhilippinesKathleen Gail Arguelles ArcegaNo ratings yet

- Nokia Help PDFDocument101 pagesNokia Help PDFTim GargNo ratings yet

- Chemical Storage Tank GADocument1 pageChemical Storage Tank GAdgmprabhakarNo ratings yet

- Structural column and foundation detailingDocument1 pageStructural column and foundation detailingHarbhajan SinghNo ratings yet

- 3D PV 2017 BrochureDocument6 pages3D PV 2017 BrochurehabilNo ratings yet

- ArielDocument1 pageArielWilsonLópezNo ratings yet

- Electrical Site Setting Layout Plan: Prop. Ground Floor VillaDocument1 pageElectrical Site Setting Layout Plan: Prop. Ground Floor VillathaenNo ratings yet

- J21-04-Astron - Energy-01 SHT 1 OF 9-REV.01Document1 pageJ21-04-Astron - Energy-01 SHT 1 OF 9-REV.01Jadon TheophilusNo ratings yet

- 111-GA-MGF-101 G.A. FOR MULTI GRADE FILTER-ModelDocument1 page111-GA-MGF-101 G.A. FOR MULTI GRADE FILTER-ModelShanmuganathan ShanNo ratings yet

- Crude Oil 200 BBL - Ga - RCDocument1 pageCrude Oil 200 BBL - Ga - RCApichart ChoksawadNo ratings yet

- 01.STD DrawingDocument82 pages01.STD Drawingjplaza3074No ratings yet

- Dish End Dimension ListDocument1 pageDish End Dimension ListShanmuganathan ShanNo ratings yet

- Orientation Plan (Hold) : TOP BottomDocument1 pageOrientation Plan (Hold) : TOP BottomSuneel MalpaniNo ratings yet

- Sppss-rmaeg-Ist-dia-003 Rev - A Vendor Submission For Wiring Diagram For Gas Chromatography SystemDocument7 pagesSppss-rmaeg-Ist-dia-003 Rev - A Vendor Submission For Wiring Diagram For Gas Chromatography SystemFershaalNo ratings yet

- KS-304 Kiosk Substation Plinth Details Enclosure Type 4-15Document1 pageKS-304 Kiosk Substation Plinth Details Enclosure Type 4-15RickNo ratings yet

- BBQ Chicken M-01Document1 pageBBQ Chicken M-01agflamesengineering.salesNo ratings yet

- CC Wall Reinforcement DetailsDocument8 pagesCC Wall Reinforcement DetailsDushyant JadaunNo ratings yet

- Harn - Allison 4th Gen, Dash P92-3018 - 01: VAR Option Omit Connectors Omit WiresDocument3 pagesHarn - Allison 4th Gen, Dash P92-3018 - 01: VAR Option Omit Connectors Omit WiresMohanad MHPSNo ratings yet

- Drawing2 Layout1Document1 pageDrawing2 Layout1Chuck Henry CarlosNo ratings yet

- Wiring PDFDocument1 pageWiring PDFBenny OquinNo ratings yet

- 1 Tablas Bolinter, Fittings & Valves-FinalDocument21 pages1 Tablas Bolinter, Fittings & Valves-FinalTIPAZONo ratings yet

- Service Installation Pole Mount (Shown) : Notes: Grounding SystemDocument1 pageService Installation Pole Mount (Shown) : Notes: Grounding SystemEnrique Hdez. E.No ratings yet

- As Aigc Ga TCTV 001 7Document1 pageAs Aigc Ga TCTV 001 7engrabbas75No ratings yet

- As Aigc Ga TCTV 001 3Document1 pageAs Aigc Ga TCTV 001 3engrabbas75No ratings yet

- Tender Drawing For StructuralDocument12 pagesTender Drawing For StructuralSaif MohammadNo ratings yet

- Technical Data Sheet: SL. NODocument1 pageTechnical Data Sheet: SL. NOVirendra RaiNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract Pagesnauman faiziNo ratings yet

- Spot Detail: (Media Agua)Document10 pagesSpot Detail: (Media Agua)john gabriel zapantaNo ratings yet

- As Aigc Ga TCTV 001 5Document1 pageAs Aigc Ga TCTV 001 5engrabbas75No ratings yet

- Nozzle Schedule: General NotesDocument1 pageNozzle Schedule: General NotesArielNo ratings yet

- Pre Cast SignedDocument1 pagePre Cast SignedcivilceejiNo ratings yet

- 33KV SPSC pole designDocument1 page33KV SPSC pole designRubanNo ratings yet

- 5500DBD LOBBY Site PreparationDocument8 pages5500DBD LOBBY Site PreparationJose MarcosNo ratings yet

- ARV-HII-ELECT-038 - XA - 28VDC Aux PWRDocument2 pagesARV-HII-ELECT-038 - XA - 28VDC Aux PWRArmando CastellanosNo ratings yet

- Sand Filter-rwtp (1)Document6 pagesSand Filter-rwtp (1)Abu SuraisyNo ratings yet

- Specification: App. Leng Mark Size Service Rat Ing Remark Design Data For VesselDocument1 pageSpecification: App. Leng Mark Size Service Rat Ing Remark Design Data For VesselcayovinNo ratings yet

- Construction Notes: CASE-1Document1 pageConstruction Notes: CASE-1Cyril AleaNo ratings yet

- Design Calculations: Usf Project 7 & 8 Non Hub TowersDocument11 pagesDesign Calculations: Usf Project 7 & 8 Non Hub TowersasirprakashNo ratings yet

- ALL IN ONE FILE DOORSDocument17 pagesALL IN ONE FILE DOORSamr.elsaeid53No ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-5.GF ROOF SLAB PLANDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-5.GF ROOF SLAB PLANMr. SinghNo ratings yet

- Nfef 60 44 Ci DR TD 009 - d1 - 000Document1 pageNfef 60 44 Ci DR TD 009 - d1 - 000Abid AyubNo ratings yet

- WS 005Document1 pageWS 005Er Navneet JassiNo ratings yet

- DS-701 - 90 Degree Brass Nozzle - Rev 3Document1 pageDS-701 - 90 Degree Brass Nozzle - Rev 3miguelsanguinettiNo ratings yet

- S5-00A_ WOOD WALL SCHEDULE AND DETAILS Rev.2 markupDocument1 pageS5-00A_ WOOD WALL SCHEDULE AND DETAILS Rev.2 markupjhamiralexNo ratings yet

- S-3.0 3723 Noah ST - Lot 1 - Windstorm Ties & NotesDocument1 pageS-3.0 3723 Noah ST - Lot 1 - Windstorm Ties & NotesTAIQ MASROORNo ratings yet

- Site Preparation para Dispensador Lobby DIEBOLD 522Document4 pagesSite Preparation para Dispensador Lobby DIEBOLD 522Jose MarcosNo ratings yet

- Berri-Nsh2023-Cvl-159 Relocation of Cable Tray 1Document2 pagesBerri-Nsh2023-Cvl-159 Relocation of Cable Tray 1Ramil LazaroNo ratings yet

- MBR Tank Cover - 02 - r1Document5 pagesMBR Tank Cover - 02 - r1Nirvekala BalakrishnanNo ratings yet

- Ga Pondasi Pompa P701 RevoDocument3 pagesGa Pondasi Pompa P701 RevoMaria OsawaNo ratings yet

- FINALISED SET1-merged PDFDocument5 pagesFINALISED SET1-merged PDFSuren NathanNo ratings yet

- Spot Detail Spot Detail Spot DetailDocument1 pageSpot Detail Spot Detail Spot DetailLyricsNo ratings yet

- 2012 KW Oem Engine HarnessDocument4 pages2012 KW Oem Engine HarnessSergio HernandezNo ratings yet

- Truss Detail Gutter Detail: Ft1 Detail Rr1 DetailDocument1 pageTruss Detail Gutter Detail: Ft1 Detail Rr1 DetailMaxine GarcesNo ratings yet

- Schedule of Beams: Typical Beam DetailsDocument1 pageSchedule of Beams: Typical Beam Detailsjohn dale ibaleNo ratings yet

- MBBR FabricationDocument1 pageMBBR Fabricationvikraman_sNo ratings yet

- BC2-Double 2m X 2mDocument1 pageBC2-Double 2m X 2moseni momoduNo ratings yet

- PW-CH-CRX19001-GAD-001 - 5 - GENERAL ARRANGEMENT DRAWING - Pig Launcher Receiv..Document1 pagePW-CH-CRX19001-GAD-001 - 5 - GENERAL ARRANGEMENT DRAWING - Pig Launcher Receiv..DarshAwadNo ratings yet

- General Note: Adnoc DistributionDocument1 pageGeneral Note: Adnoc DistributionShaheer.saNo ratings yet

- ABSto BrakeDocument3 pagesABSto BrakeManuel MoralesNo ratings yet

- S-106 Concrete LayoutDocument1 pageS-106 Concrete Layoutarno assassinNo ratings yet

- Overall Project Quality Management PlanDocument62 pagesOverall Project Quality Management Planlee100% (9)

- Conversation Survival Guide HindiDocument2 pagesConversation Survival Guide HindiDanial ChakkaravarthyNo ratings yet

- Verbs 20090914Document14 pagesVerbs 20090914Kapil100% (1)

- HostsDocument4 pagesHostsakoe.hendryanaNo ratings yet

- Math 11 ABM Org - MGT Q2-Week 2Document16 pagesMath 11 ABM Org - MGT Q2-Week 2Gina Calling Danao100% (1)

- Python specializationFAQDocument2 pagesPython specializationFAQGenerowiczNo ratings yet

- Maslows TheoryDocument9 pagesMaslows TheoryPratik ThakkarNo ratings yet

- Digitech's s100 ManualDocument24 pagesDigitech's s100 ManualRudy Pizzuti50% (2)

- LinhNg BSBXCM301 ProjectPortfolio Task2Document11 pagesLinhNg BSBXCM301 ProjectPortfolio Task2Trần Thái Bảo HânNo ratings yet

- Combined Orders (SAP Library - Production Planning and Control)Document3 pagesCombined Orders (SAP Library - Production Planning and Control)Rashid KhanNo ratings yet

- Cuprinol - Wood - Preserver - Clear - (BP) Safety Data SheetDocument13 pagesCuprinol - Wood - Preserver - Clear - (BP) Safety Data SheetEdgar ArdinazoNo ratings yet

- Carbon Cycle SEDocument7 pagesCarbon Cycle SEAlex0% (3)

- Managing People and OrganisationsDocument50 pagesManaging People and OrganisationsOmkar DesaiNo ratings yet

- Example of Maritime Thesis TitleDocument7 pagesExample of Maritime Thesis Titleafcnahwvk100% (2)

- Essay On Causes of Corruption and Its RemediesDocument30 pagesEssay On Causes of Corruption and Its Remediesanoos04100% (2)

- Sample ProposalDocument22 pagesSample Proposalbrynzky100% (1)

- Philips Gemini TF 64 Preferred Room LayoutDocument3 pagesPhilips Gemini TF 64 Preferred Room Layoutahmed_galal_waly1056No ratings yet

- CBM4Document11 pagesCBM4Nathalie CapaNo ratings yet

- Communication Skills: Condition of Slums in IndiaDocument17 pagesCommunication Skills: Condition of Slums in Indiahappyskd1993No ratings yet

- Quick Refer Ence Guide Collection:: ST Armorstart and Armorstart ST ConnectivityDocument12 pagesQuick Refer Ence Guide Collection:: ST Armorstart and Armorstart ST ConnectivityYeltsin MuniveNo ratings yet

- History of US Medical Device RegulationDocument7 pagesHistory of US Medical Device RegulationHector Tinoco GarciaNo ratings yet

- New Position Performance Evaluation FormDocument4 pagesNew Position Performance Evaluation FormRomero SanvisionairNo ratings yet

- How To Knit SocksDocument10 pagesHow To Knit SocksHolly Robles100% (1)

- Dangerous Goods Hazmat Material Training Cat-10Document24 pagesDangerous Goods Hazmat Material Training Cat-10Claudio GonzalezNo ratings yet

- LPU/HRD/IC/200905/001/672/164 Dated: 05 Sep 2020: OutstandingDocument1 pageLPU/HRD/IC/200905/001/672/164 Dated: 05 Sep 2020: OutstandingadityamduttaNo ratings yet

- 809kW Marine Propulsion Engine SpecificationsDocument2 pages809kW Marine Propulsion Engine SpecificationsRoberto StepankowskyNo ratings yet

- Sanel Core HMODocument13 pagesSanel Core HMOAutomotive Wholesalers Association of New EnglandNo ratings yet

- Final Project at NucsoftDocument97 pagesFinal Project at NucsoftmainasshettyNo ratings yet

- Case Study:: Barangay HallDocument13 pagesCase Study:: Barangay HallReiner Gatdula50% (2)