Professional Documents

Culture Documents

Ir562 Hmi 28.02.23

Uploaded by

Pinki Mitra DasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ir562 Hmi 28.02.23

Uploaded by

Pinki Mitra DasCopyright:

Available Formats

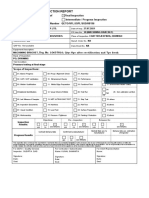

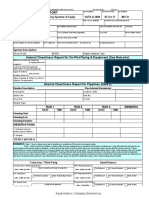

INSPECTION REPORT

Report of Final Inspection

Intermediate / Progress Inspection

QETO

QUALITY SERVICES Report Number QETO/VFL/QETO/SUD/00562

Client: M/s QETO QUALITY SERVICES Date of Insp.: 28.02.2023

Purchase Order No. PO/QETO/22-23/002 Dtd.

PO Line No: 01, 02, 03

28.11.2022

Contractor M/s HOWRAH MILLING INDUSTRIES Place of Inspection CHATTERJEEPARA, HOWRAH

Subcontractor NA Manuf. Order No. NA

QAP No : NA Data Sheet No. NA

Equipment Description:

HAMMER HEAD BOLT, Drawing. No. C-100-897, R02, M110-4nos., M80-12 nos., M56-18nos.

Basis of Inspection:

PO, Drawing

Test Condition:

M56 BOLTS, NUT & WASHER- FINAL MACHINED, OTHERS UNDER FINAL MACHINING OF HEAD

Scope of Inspections:

01. Manuf. Progress 09. Fit-up / Alignment Check 17. Assembly 25. Completeness

02. QAP / QCP Verification 10. Dimensional Checks 18. Performance 26. Marking

03. Welder Qualification 11. Welds Edge Preparation 19. Functional Test 27. Environment-Health-Safety

OK

04.Material Identification 12. Visual Check of Welds 20. Test Run 28. Inst. calibration verified.

Not OK

05. Lab Witness of Samples 13. NDT ULTRASONIC TEST 21. Strip Test 29. others

06. Inspection Documents 14. Hardness 22. PMI Test 30.others

07. Visual Condition 15. Load Test 23. Surface Preparation 31.others

08. Workmanship 16. Pressure / Tightness 24. Painting / Protection 32.others

Objections: Re – Inspection: Released for

Inspection

Results:

yes no see remarks yes no see remarks yes no see remarks

Earliest Date acc. to Delivery date acc. estimation

Contract Delivery Date Confirmed by Manufacturer

manufacturer of inspector

Progress Results

yes no see remarks

This inspection does not release the manufacturer / contractor from any contractual obligations to the purchaser also in case of discrepancies occurring after delivery or within the

period of guaranty. Any defects / deviations observed on receipt of materials at Client’s works / sites shall be intimated to the manufacturer. It is the responsibility of the manufacturer to

rectify / replace the defective material in time and free of cost. Anti-rust must be applied on all the machined surface before dispatch.

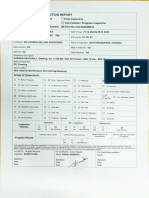

For QETO – Quality Services For Contractor / Subcontractor For Client Representative

Inspector: SUDIPTA DAS Name: KUNAL SAMANTA Name:

Signature: Signature: Signature:

Date: Date: Date:

Seal: Seal: Seal:

presented

required

Test Documents

discussed not discussed

Material Certificates acc. to specification -

Welding Filler Material Certificates

Dimensions Records / Drawings containing nominal and actual dimensions

Heat Treatment Certificates

Inspection Reports prepared by manufacturers Quality Control Department

Official Certificates of Inspection Authority

Pressure / Tightness Test Certificates

Records of NDT Testing

Welders Qualification Certificates

Works Certificates

Painting Certificate

Hardness Test Report

Others

Others

Inspection documents handed over during inspection

Inspection documents will be handed over by

Observations / Details of Inspection carried out:

M56 BOLT, NUT, WASHER:

1. The materials are offered in lacquered condition. Visually checked and found all

manufacturing operations are complete. Forging surface found on shank portion

(approx. 400mm long) in one bolt. No other abnormality observed.

2. Dimensions checked and found in order except in square head portion of three bolts

a) thickness C (35mm) found 38mm and b) thickness E (17.5mm) found 15mm.

3. Nut and washer was fitted on each bolt and found acceptable except in 2nos. bolts. To be

rectified.

M110 BOLT, NUT, WASHER: Shank and tread portion are ready. Square head machining of

one bolt is complete, another is under processing and not started for rest 2nos. Nut and

washers are ready.

M80 BOLT, NUT, WASHER: Shank and tread portion are ready. Square head machining of

7nos. bolt is ready, chamfer machining balance. For rest 5nos. bolt Square head machining is

yet to start. Nut and washers are ready.

Conclusion: M56 bolts are acceptable except deviation mentioned in point no. 1 & 2.

For QETO – Quality Services For Contractor / Subcontractor For Client Representative

Inspector: SUDIPTA DAS Name: KUNAL SAMANTA Name:

Signature: Signature: Signature:

Date: Date: Date:

Seal: Seal: Seal:

You might also like

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194Document2 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194sudipta dasNo ratings yet

- IR204 - Siddheswari Evaluation - SUD 06.08.21Document2 pagesIR204 - Siddheswari Evaluation - SUD 06.08.21sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00196Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00196sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00197Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00197sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report NumberDocument6 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Numbersudipta dasNo ratings yet

- Qeto Report - 00531Document2 pagesQeto Report - 00531Pinki Mitra DasNo ratings yet

- Hydro Test ProcedureDocument5 pagesHydro Test ProcedureBharat BhoirNo ratings yet

- ELECT-TIC-2.8 (Torque Testing and Final Inspection)Document4 pagesELECT-TIC-2.8 (Torque Testing and Final Inspection)Muhammad IrfanNo ratings yet

- Inspection and Test PlanDocument2 pagesInspection and Test PlantayyabNo ratings yet

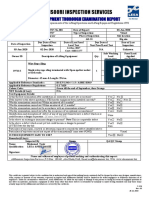

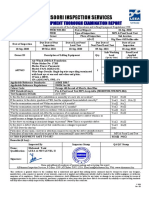

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- Manufacturin Quality Plan: Sheet No.: Page 1 of 23Document23 pagesManufacturin Quality Plan: Sheet No.: Page 1 of 23ashiihsaNo ratings yet

- Pneumatic Test ProcedureDocument5 pagesPneumatic Test ProcedureBharat BhoirNo ratings yet

- ITR-CNI (Instrument)Document21 pagesITR-CNI (Instrument)mahmoudNo ratings yet

- Sample ChecklistDocument3 pagesSample ChecklistrkssNo ratings yet

- Deckblatt - : First Sample Test Report VDADocument9 pagesDeckblatt - : First Sample Test Report VDAJuliaNo ratings yet

- NDT Request Form: Project Quality Assurance & ControlDocument1 pageNDT Request Form: Project Quality Assurance & ControlIzar Irhamni, ST100% (1)

- Saudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEDocument2 pagesSaudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEWaleed MedhatNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Check List For Installation of Cooling TowersDocument2 pagesCheck List For Installation of Cooling TowersGirithar M Sundaram67% (3)

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- QC Inspection CV UpdatedDocument7 pagesQC Inspection CV UpdatedEr AkhlaqueNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunNo ratings yet

- Pressure Test ReportDocument9 pagesPressure Test Reportjaysonquitelgonzales06No ratings yet

- SAIC-RT-2001 Revw of RT ProcedureDocument1 pageSAIC-RT-2001 Revw of RT ProcedureKirubhakarPooranamNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/115Document2 pagesInspection Report: IR No.: QETO/IR/SUD/115sudipta dasNo ratings yet

- Qap - LR BendDocument1 pageQap - LR BendSachin KumarNo ratings yet

- SATR-A-2001 Pressure Test ReportDocument8 pagesSATR-A-2001 Pressure Test Reportjohn ajitNo ratings yet

- Project Eagle: Quality Management Inspection ReportDocument2 pagesProject Eagle: Quality Management Inspection ReportrcpretoriusNo ratings yet

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationDocument16 pagesQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportnadeemNo ratings yet

- Bearing Plate Report TemplateDocument6 pagesBearing Plate Report TemplateFrans ManurungNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 Mechnadeem0% (1)

- Inspection and Test Plan: Tile WorksDocument2 pagesInspection and Test Plan: Tile WorksAlvene Tagoc100% (2)

- Inspection Report: IR No.: QETO/IR/SUD/114Document2 pagesInspection Report: IR No.: QETO/IR/SUD/114sudipta dasNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument9 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- BOP Plate Load Test Cert. DILJITH 1 NOV-20Document2 pagesBOP Plate Load Test Cert. DILJITH 1 NOV-20RanjithNo ratings yet

- Hydrostatico D2321186Document1 pageHydrostatico D2321186Iandeyara CarvalhoNo ratings yet

- Satr A 2006Document8 pagesSatr A 2006Shahzad HussainNo ratings yet

- Sample Template Itp For Piping Fabrication and InstallationDocument10 pagesSample Template Itp For Piping Fabrication and Installationmohd as shahiddin jafri100% (1)

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNo ratings yet

- By Akhilesh CHECKLIST - For AllDocument15 pagesBy Akhilesh CHECKLIST - For AllankurNo ratings yet

- Mechanical Testing Laboratory: Technical Services DivisionDocument2 pagesMechanical Testing Laboratory: Technical Services Divisionm.aliNo ratings yet

- 02-Singl Joint 1Document8 pages02-Singl Joint 1Abdou BoucheritNo ratings yet

- Form 02 Crane Inspection FormDocument2 pagesForm 02 Crane Inspection FormDenny SyafwalufiNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/116Document1 pageInspection Report: IR No.: QETO/IR/SUD/116sudipta dasNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/119Document2 pagesInspection Report: IR No.: QETO/IR/SUD/119sudipta dasNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument5 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Liquid Penetrant Inspection Report: Industrial Proforma FormDocument1 pageLiquid Penetrant Inspection Report: Industrial Proforma FormJohn DolanNo ratings yet

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaNo ratings yet

- SAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalDocument1 pageSAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalGOSP3 QC MechanicalNo ratings yet

- Precommissioning Checklist of Pa SystemDocument1 pagePrecommissioning Checklist of Pa SystemTamer EidNo ratings yet

- 05-Manual Tang 1Document1 page05-Manual Tang 1Abdou BoucheritNo ratings yet

- Uma PO Copy 8000024961Document11 pagesUma PO Copy 8000024961Pinki Mitra DasNo ratings yet

- Qap M030128-00Document19 pagesQap M030128-00Pinki Mitra DasNo ratings yet

- T (/TSP) : Echnical SpecificationDocument19 pagesT (/TSP) : Echnical SpecificationPinki Mitra DasNo ratings yet

- Communicatin-41 - ReplyDocument4 pagesCommunicatin-41 - ReplyPinki Mitra DasNo ratings yet

- Payslip Apr2020Document1 pagePayslip Apr2020Pinki Mitra DasNo ratings yet

- Payslip Apr2020Document1 pagePayslip Apr2020Pinki Mitra DasNo ratings yet

- CV - Gouranga GhoshDocument2 pagesCV - Gouranga GhoshPinki Mitra DasNo ratings yet

- PractiseDocument1 pagePractisePinki Mitra DasNo ratings yet

- ProjectDocument2 pagesProjectPinki Mitra DasNo ratings yet

- Bengali ProjectDocument5 pagesBengali ProjectPinki Mitra DasNo ratings yet

- Electro Copper - 01-12-.2022Document2 pagesElectro Copper - 01-12-.2022Pinki Mitra DasNo ratings yet

- Qeto Report - 00531Document2 pagesQeto Report - 00531Pinki Mitra DasNo ratings yet

- Gour New - 1548086409Document2 pagesGour New - 1548086409Pinki Mitra DasNo ratings yet

- CV - Gouranga GhoshDocument2 pagesCV - Gouranga GhoshPinki Mitra DasNo ratings yet

- Marketing Management Question Paper 2Document1 pageMarketing Management Question Paper 2Jeevan PradeepNo ratings yet

- Persona Based Identity and Access ManagementDocument39 pagesPersona Based Identity and Access Managementsneha sureshbabuNo ratings yet

- Customer SQ - Satisfaction - LoyaltyDocument15 pagesCustomer SQ - Satisfaction - LoyaltyjessiephamNo ratings yet

- International Trade TheoriesDocument41 pagesInternational Trade TheoriesShruti VadherNo ratings yet

- Rightnow Service Descriptions 1885273 PDFDocument179 pagesRightnow Service Descriptions 1885273 PDFamoussaaNo ratings yet

- Planning & Managing Inventory in Supply Chain: Cycle Inventory, Safety Inventory, ABC Inventory & Product AvailabilityDocument24 pagesPlanning & Managing Inventory in Supply Chain: Cycle Inventory, Safety Inventory, ABC Inventory & Product AvailabilityAsma ShoaibNo ratings yet

- Cash ReceiptDocument1 pageCash ReceiptShellinaNo ratings yet

- SynopsisDocument12 pagesSynopsisNikhil JainNo ratings yet

- One Point LessonsDocument27 pagesOne Point LessonsgcldesignNo ratings yet

- Chocolate Industry Final Case AnalysisDocument10 pagesChocolate Industry Final Case AnalysisSadia SaeedNo ratings yet

- Sources of Finance: Ib Business & Management A Course Companion (2009) P146-157 (Clark Edition)Document54 pagesSources of Finance: Ib Business & Management A Course Companion (2009) P146-157 (Clark Edition)sshyamsunder100% (1)

- Tomas Claudio CollegesDocument16 pagesTomas Claudio CollegesGemmillyn DigmaNo ratings yet

- Leadership & Innovation BrochureDocument10 pagesLeadership & Innovation BrochureFiona LiemNo ratings yet

- Ready To Eat Food DM20204Document18 pagesReady To Eat Food DM20204Akai GargNo ratings yet

- Unit 1 Evolution of Management ThoughtDocument4 pagesUnit 1 Evolution of Management ThoughtParvez SaifNo ratings yet

- Real Options and Other Topics in Capital BudgetingDocument24 pagesReal Options and Other Topics in Capital BudgetingAJ100% (1)

- Aileron Market Balance: Issue 19Document6 pagesAileron Market Balance: Issue 19Dan ShyNo ratings yet

- Enhancing Analytical & Creative Thinking Skills PDFDocument2 pagesEnhancing Analytical & Creative Thinking Skills PDFsonypall3339No ratings yet

- Group 13 Excel AssignmentDocument6 pagesGroup 13 Excel AssignmentNimmy MathewNo ratings yet

- The East Pacific Merchandising Corporation vs. The Director of Patents and Luis P. PellicerDocument31 pagesThe East Pacific Merchandising Corporation vs. The Director of Patents and Luis P. PellicerRalph HonoricoNo ratings yet

- GCC Placement List in MumbaiDocument14 pagesGCC Placement List in MumbaifaradayzzzNo ratings yet

- Case Study 1Document6 pagesCase Study 1Narendra VaidyaNo ratings yet

- How To Use Oracle Account Generator For Project Related TransactionsDocument40 pagesHow To Use Oracle Account Generator For Project Related Transactionsapnambiar88No ratings yet

- Timesheets and Laytime CalculationDocument14 pagesTimesheets and Laytime CalculationJuan Alfaro100% (1)

- SAP InvoiceDocument86 pagesSAP InvoicefatherNo ratings yet

- Cab - BLR Airport To Schneider PDFDocument3 pagesCab - BLR Airport To Schneider PDFVinil KumarNo ratings yet

- Hospital Equipments PrecurmentDocument10 pagesHospital Equipments PrecurmentRashid UmerNo ratings yet

- Slides CBDocument30 pagesSlides CBhasan_usman1234No ratings yet

- GeM Bidding 2401209Document4 pagesGeM Bidding 2401209SRARNo ratings yet