Professional Documents

Culture Documents

PRO Construction Method Statement

Uploaded by

ahmad muzakkir mohamadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PRO Construction Method Statement

Uploaded by

ahmad muzakkir mohamadCopyright:

Available Formats

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

Note: All Method Statement’s MUST be reviewed & signed off by a Temporary Work Coordinator. All Method Statement that

are in Temporary Work Category A or B, MUST be signed off by Temporary Work Coordinator and Head of Engineering Dept.

1. PREPARATION - SIGN OFF (Suitable Trained/Experienced Person.)

Preparation

Position Name Date Signature

Safety Officer Ahmad Muzakkir Bin Mohamad 31/12/2023

Lifting Supervisor Muhammad Zubair 31/12/2023

2. CHECK – SIGN OFF (Site Agent and Sub-Contractor prior to review sign off.)

Position Name Review Date Signature

Operation Director Nicholas Boey 31/12/2023

Engineer Bakri Bin Yusof 31/12/2023

3. PROJECT TEAM SOFT CONTROL APPROVAL REQUIRED Yes No

APPROVED BY

Signed by Project Team Signed by Project Team

Name: Date Name: Date

Note:

This document is controlled in soft copy. Any hard copies

seen are uncontrolled unless chopped with Red Control

Stamp.

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 1 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

SCOPE

This method statement covers the Unloading (Lift) Operations using 600t mobile crane

for Genset (PTU) equipment site proposed work area.

1.1 Limitations:

A. Working Hours: 7am to 5am. (Remark: Unable to conduct any lifting activities during

night shift)

Any works carried out after office hours (7pm onwards) are required to follow the

Standard operation procedure as follows:

o Monitor traffic flow (in and out movement) around the construction area to

avoid any excessive noise and road accidents;

o Ensure cleanliness on the construction site;

o Ensure no damages in common areas such as road verge, turfing, flood issue

during heavy rain etc;

o Ensure no damages on the road kerb, drainage, landscape, etc. in common

areas during construction.

B. Environmental Concern

Noise pollution control – to place noise barriers at site where required

Dust control – to regularly sprinkle water on haul roads and excavations to

mitigate dust

Oil leakage / spillage from the plant and the machineries used – to refuel the

machineries off-site

Water pumps will be used if there is heavy rainfall. The water in the trenches

done previously will be pumped out.

Notification on access main route for transportation to OSE vendor require for

their verification and acceptance.

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 2 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

1. REFERENCES

Drawing List

No Drawing Title Status Drawing Number

1. 220 Ton Crane Parking Logistics Plan

2. Equipment Hoisting Lifting Plan

1.2 Responsibility Matrix

Ref Facilities / Services PRO HUAWEI

1 Safety / Environmental / Quality

(a) General overhead protection ✓

(b) To common access areas ✓

(c) Perimeter handrails, Subcontract specific ✓

(d) Safety, Subcontract specific ✓

(e) Safety clothing / PPE ✓

(f) Project Uniform (Cost Borne By Subcontractor) ✓

(g) Safety signs – general, exit routes etc. ✓

(h) Safety signs – Subcontract specific ✓

(i) Fire Extinguishers – General ✓

(j) Fire Extinguishers – Subcontract Works specific ✓

(k) Noise mitigation measure/control/protection ✓

(l) Safety Induction Training ✓

(m) Strive for LIFE safety leadership training ✓

Appreciation courses, including crane, electrical

(n) ✓

and scaffold

Compliance with the Contractor’s health & safety

(o) ✓

policy, rules and standards

Compliance with the Contractor’s environmental

(p) ✓

policy, rules and standards

Compliance with the Contractor’s quality control

(q) ✓

policy, rules and standards

1 Hoisting Facilities & Loading

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 3 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

Ref Facilities / Services PRO HUAWEI

(a) Off -loading of materials supplied by the Contractor ✓

(b) Distribution of materials supplied by the Contractor ✓

Banksmen & Signalmen for off- loading and

(c) ✓

distribution materials

(d) Horizontal movement of materials ✓

(e) Unloading from trucks/containers ✓

(f) Special hoists and craneage ✓

(g) Movement of materials from stock or store ✓

Working platforms / Scissors lift / Access

(h) ✓

equipment

(i) Safe custody ✓

2 Insurance

Contractor All Risk Insurance / Employee's

(a) ✓

Compensation Insurance

(b) EC Insurance for labour and staff ✓

(c) Plant and equipment insurance ✓

(d) Third Party Liability ✓

(e) Deductibles ✓

3 General Responsibilities

Site supervision plan, method statements, daily

(a) ✓

reports, records and as-built submission

(b) Transport of materials & resources ✓

(c) Small tools, cutting benches, etc... ✓

(d) Addressing ground/surface/storm water ingress ✓

(e) Testing & certification ✓

Mosquito & pest control within Subcontractor's site

(f) ✓

area

(g) Temporary traffic management ✓

(h) Make good defects ✓

Permits and approvals from authorities & utility

(i) ✓

companies

(j) Permits and approvals from utility companies ✓

(k) Co-ordination with other subcontractors ✓

2. SUBCONTRACTOR DETAILS

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 4 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

Site Agent/Sub Agent Superintendent

Coordinating subcontractor direct Coordinate subcontractor direct labour

labour and suppliers; and suppliers;

Progressively check the work for Progressively checks performed

compliance with the approved works, and

specification and drawing; Ensure the works are carried out in

Monitor and record progress and accordance with the approved safety

safety of works, and standards.

Ensure works comply with statutory

regulations and coordinate with

relevant authorities.

Safety Officer Supervisor/Foreman

Ensure the control measures detailed Supervise the construction activities;

in the CRA are implemented by Progressively checks performed

supervisors and foremen. works, and

Ensure all project safety rules and Ensure all safety control measures

company safety standards are identified in the CRA have been

observed and followed by Pro and implemented and are being

subcontractor workers. maintained throughout the period of

Conduct regular safety inspections on the method statement activity by

work site and report safety completing the Job Hazard Analysis

deficiencies and findings at a timely (JHA) at designated intervals.

manner.

1.1 Responsibility and Contact Detail

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 5 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

Personnel Responsibilities

No Division Type of Manpower Job Function

Manage Overall Lift & Shift

Project Manager

Activities

1 Management

Project Coordinator Manage Individual Task Activities

Safety, Health & Ensuring Safety Procedures of Work

2 Safety Coordinator

Environmental Operations.

Monitor and Supervision of All Kind of

Site Engineer

Site Works

Site Supervisor Supervision of Site Works

General Workers Involved in General Works

3 Banksmen Direct the movement of Mobile Crane

& Lorries

Work Operation Lifting Supervisor Lead the Lifting Activities & Manage

all the Lifting Gears

Crane Mechanic Equipment Maintenance

Crane Operator Operation of Mobile Crane for Lifting

Rigger Aligning and anchoring the lifting

item

Personnel Responsibility and Contact Details

Name Company Responsibility Contact

Nicholas Boey PRO Project Manager 012-2907243

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 6 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

Muhammad Zubair PRO Lifting Supervisor 017-7659004

M.Yusuf PRO Boomlift/Skylift Operator 011-3960 6118

Ahmad Muzakkir PRO Safety Officer 011-6567 3637

Bakri PRO Operations Supervisor 012-580 4868

Ab Rasad PRO Assistant Supervisor 013-706 2672

Mohd Zarefin PRO Lead Forklift Operator 013-761 6967

Zakariah PRO Transport Supervisor 012-731 4868

Muhammad Zaid PRO Lead Signalman 019-713 9645

Welker PRO Lead Rigger 011-2762 0316

Tsze Hock Leong PRO Lead Mechanic 010-661 6388

Desmond Boey PRO Managing Director 019-779 4796

Abdul Disa PRO Rigger 016-7049730

Saipul PRO Rigger 011-35025664

Mohd Shahril PRO Rigger 013-9813482

1.2 Subcontractor Organization Chart

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 7 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 8 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

3. CONSTRUCTION METHOD AND SEQUENCE OF WORKS

This section describes how the project team is planning to construct the works by

detailing the relevant sequence of key steps and stages to complete the works and the

persons involved.

1. Pre-Operation Works (Step 1)

ACTIVITY ILLUSTRATIONS NOTES

1.1 Preliminary 1. Prepare Construction Method Statement,

Planning Construction Risk Assessment, Job Hazards

Procedures Assessment, Inspection Test Plan and other

related documents.

Related Safety

2. Coordinate interfacing work activities so there is

Standards:

no overlap of works in an unsafe manner.

Refer to PSS 3. Coordinate interfacing work activities so there is

All standard no overlap of works in an unsafe manner.

item.

COP 007

1.2 Adverse 1. Protect workers during heavy rain. Working

Weather during heavy rain is extremely prohibited in open

space construction site. It is applied to all kind of

works.

2. Adverse weather will be constantly monitored,

and safety team will keep the workforce

constantly updated.

3. Follow Project Inclement Weather Working

procedure. Workers to be briefed on Inclement

Working Procedure on regular basis.

4. All lifting operations are to be suspended if the

wind speed exceeds 10m/s or as advised by the

works supervisor.

5. Contractor to provide safe shelter at the job site

that can safely accommodate all employees.

6. Workers should stop all activities as soon as

they hear thunder and seek shelter. Upon

instruction from site supervisor or safety

personnel.

7. Workers should remain in the shelter until

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 9 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

further notice from Safety personnel.

8. During lighting or raining all activities will stop

and will stay at shelter

HOLD POINT – Obtain Approval on PTW,JHA,ITP

& LIFTING Permit

1.3 Personnel 1. Conduct induction for ALL personnel entering

Documents site.

check and

HOLD POINT – REVIEW Personnel Documents

Machinery /

Vehicle check

2. Mobilization of machinery (Mobile Crane)

3. Conduct pre-use check on Machinery / vehicles.

4. Machinery on-site shall not exceed 8 Years from

manufacturing date.

5. Machineries must be free of any leaks of

hydraulic oils & any moving parts to be properly

sealed in accordance to manufacturing spec.

HOLD POINT: Fill up pre-use checklist for

machinery / vehicles

1. All site personnel shall wear Personal Protective

Equipment (PPE) at construction site as per

LCM Standards & Requirements.

2. High Cut Safety Boots are essential at

construction sites and can prevent foot injuries

and accidents, making them highly

recommended for construction sites.

3. Workers required to wear safety goggles or a

face shield and impact gloves when performing

rigging tasks.

1.4 Briefing on 1. Toolbox Meeting before commencement to daily

CMS, CRA, job activity, Site Superintendent & Supervisors

JHA will brief the team and operators on CMS, CRA

and JHA.

HOLD POINT – Pre-Inspection of machinery

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 10 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

& equipments, Obtain PTW & PUC

1.5 Mobilization of 1. Constant supervision by site supervisor.

Heavy 2. Competent and licensed crane operator & Lorry

Machineries & driver.

Lifting 3. Experience banksman & flagman to control the

Equipment’s machinery movement.

into Sunway 4. Only trained operator and helper to unload the

Site. counterweights & lifting equipment’s to storage

position and unload by the same crane

5. Place signage and barricade the storage area

Related Safety 6. Placing outrigger pads to ensure the stability of

Standard : the mobile crane during crane inspection.

7. Wear full body harness if necessary while

working at height.

Refer to PSS 8. Mobilization work area to have barricaded to

1,3, 4, 26, 57, prevent entry by unauthorized personnel

63, COP 005 9. To undergo Machinery on-site inspection and

get approval and display the PUC information

board.

Heavy Machinery Entering Site:

a) 400 Ton Mobile Crane

b) 220 Ton Mobile Crane

c) 1 x 47ft x 4 Axle Low Loader

2. Set-up of Mobile Crane & Lifting Equipment’s at Hoisting Position (Step 2)

2.1 Checking of

ground HOLD POINT: To obtain PTW prior to

conditions & start work & PUC

Mobile Crane

Set Up at 1. Checking of ground condition, foundation or

Hoisting existing supporting structure. Making sure the

Position No. ground supporting structure can sustain the

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 11 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

10 PPMSB/GPJ23/1 crane designed GBP load provided.

2. Monitoring of ground conditions at all times,

- 600 Ton

stationery & during operation of mobile crane.

Mobile

3. Flagman, Banksman & certified riggers to assist

Crane

in crane entry to lifting position & counterweight

installation, ensuring load is controlled at all

times, using 2 x taglines and certified lifting

equipments.

4. All lifting equipments to be physically re-

inspected in accordance to Leighton standards.

5. Hard Barricade (Water filled Barriers) of crane

fatal zones minimum 600mm from crane body &

counterweight swing radius.

6. Placement of warning signage on barricades.

2.2 Set up of 1. Webbing Sling (1 Ton x 4meters) hooked onto

Lifeline on Mobile Crane auxiliary hook & attached to

Mobile crane certified fall prevention device = YOYO (10

auxiliary Hook meter line) on the other end of the webbing

sling.

2. Riggers to have work at height certification.

3. Regular supervision of fall protection set,

harness and lanyard attachment practices to

check for back hooking and other incorrect

methods of lanyard attachment

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 12 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

2.4 Set Up of 1. Refer to manufacturer spec on proper safe

Spreader Bar usage. Refer to Appendix D: Equipment

Certification

(3m – 5m x 50

2. Spreader Bar by third party before entering into

Tons SWL)

the site.

3. Install the shackle at spreader bar from the

ground floor

4. Lift spreader bar by crane , Lift in middle of item

and items that are lifted with height 1meter-

2meter from top item surface

1.

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 13 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

2.5 Set up of 600 1. Once Crane has been parked in designated

Ton position for hoisting, mobile crane counterweight &

Counterweight superlift system will be set up according to crane

& Super lift manufacturer spec with compliance to Sunway

System requirements.

1. Traffic Management Plan: Explain the traffic flow

inside construction site prior to delivery.

2. Banksmen: Banksmen to manage and ensure

the movement of the low-loader & trailer during

transportation into site and hoisting position

safely and smoothly through traffic with the

usage of light batons & traffic flags.

Transport Safety Measures:

3. The transport must be equipped with

appropriate safety measures, such as reflective

tape, warning lights, and signs indicating the

oversized load (applicable for low loader).

4. Once low loader carrying counter weight &

superlift system has reached hoisting point,

mobile crane will be used to unload the

accessories.

5. Communication: ALL communication will be

done using UHF walkie talkie dedicated

channels to avoid distraction miscommunication.

6. Riggers to used certified platform ladder to

access counterweight & SuperLift Lifting points

that are at height, safety harness attached to

lifeline to be secured at all time for any activities

involving WAH.

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 14 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

2.6 Set-Up of steel 10. Steel plates 20ft x 5ft x 24mm x 8 pieces will

plates with be placed on timber blocks to ensure

timber block levelled & smooth skidding process onto

base concrete plinth

11. Steel Plates will be unloaded from low

loader.

12. Ground condition to be checked & ensure its

compaction is able to withstand a min. of 15

Tons per sq/m.

2.7 Arrival of HOLD POINT: To obtain PTW prior to start

transport work and WAH

carrying

equipments

into final

hoisting

position

Related Safety

Standard:

2.7 Arrival of 7. Traffic Management Plan: Explain the traffic flow

transport inside construction site prior to delivery.

carrying 8. Banksmen: Banksmen to manage and ensure

equipments the movement of the low-loader & trailer during

into final transportation into site and hoisting position

hoisting safely and smoothly through traffic with the

position usage of light batons & traffic flags.

Related Safety

Transport Safety Measures:

Standard:

9. The transport must be equipped with

appropriate safety measures, such as reflective

tape, warning lights, and signs indicating the

oversized load (applicable for low loader).

10. Once low loader has reached hoisting point,

mobile crane will be used to unload the

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 15 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

equipments.

11. Communication: ALL communication will be

done using UHF walkie talkie dedicated

channels to avoid distraction miscommunication.

12. Riggers to used certified mobile scaffold to

access lifting points that are at height, safety

harness attached to lifeline to be secured at all

time for any activities involving WAH.

3.2 Lifting &

1. The truck mounted crane & mobile crane will be

Positioning of

Genset/PTU. positioned within the required working radius

and lifting capacity at the dedicated location

based on planned layout.

2. To ensure the stability of the mobile crane,

outrigger pads must be placed on the ground.

3. The lifting supervisor is responsible for ensuring

that the crane is parked securely before

commencing any lifting operations.

4. Steel landing Platform to be erected infront of

genset area.

Logistics Plan:

5. Transport carrying Genset/PTU section will

enter from west side of access road.

Rigging Method:

1) Top Section of Genset to be rigged using

webbing sling using container hook.

2) Top Section, Install 2 x Spreader bar with

eyelets before rigging with webbing sling to

crane main hook. As per Vertiv Assembly

& Installation Manual Provided.

Genset Hoist:

1) Top Section to be hoisted from transport

to the point and it will be position into the

position by skidding method.

2) Bottom section to be placed on revolving

skates, with stopper in place to ensure no

movement from skates during section

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 16 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

landing.

Skidding Method A:

JUNG Revolving Skates (4 x 4

Tons) 3) Fully Assembled genset will be skidded

into final position using 4 x 4 Tons JUNG

Revolving Skates with remote control to

position into the positioning area.

COP & PSS Safety Measures:

1. Only authorized personnel are permitted to

enter the working area at ALL times

2. The lifting area will be barricaded by Water

Barrier with safety signage for lifting operation.

3. Platform Ladder to be used to access rigging &

de-rigging points.

4. Ensure that the shackles are properly tightened

before lifting.

5. Tagline will be hooked onto the equipment

before lifting commence.

6. The monitoring of the unloading of the OSE

Equipment’s will be carried out by the

signalman who also instructs the crane

operator to hoist it.

7. During the hoisting period, 2 riggers of will be

controlling load using 2 taglines.

8. As the equipments approaches the designated

area, the signalman will slowly lower the

equipment & guide it into a soft landing.

9. Always Use walkie talkie as medium for

communication.

10. The rigging slings and shackles must be

greater than equipment dead weight with a ratio

of 1.2 safety factor.

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 17 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

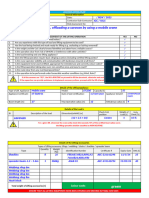

4. CONSTRUCTION RISK ASSESSMENT

The Construction Risk Assessment (CRA) describes sequentially the operational tasks

along with the associated risks and their corresponding mitigating control measures to be

implemented for the works.

5. STORAGE AND HANDLING

Non-Hazardous Substances/Materials

All non-hazardous materials like lifting equipments will be stored within laydown

boundary and barricaded properly with signages. IF ANY, the Disposal will be dispose at

Sunway’s designated waste disposal area.

Hazardous Substances/Materials

Hazardous materials on site should be identified / labelled and kept in Chemical Storage

temporarily. Hazardous material shall then be disposed with records by authorized

agent.

6 QUALITY ASSURANCE AND CONTROL

Key quality control and assurance issues for lifting activity are:

FWT/ FAT Report

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 18 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

Vendor Manual and Handling Instruction

Bill of Lading/ Packing List/ Delivery Order

Acceptance form upon site visit from Vendor

72 hrs Notification from Vendor

Any transportation prior to move into site or move out from site shall fill in Materials,

Tools & Equipment Declaration Form. This form shall sign off from related personnel

prior to approval.

a. Quality records

Material Receiving Inspection form shall be use as a checklist to ensure the

equipment receive is on good condition before any lifting activity. Once the

equipment is complete with the lifting activity, the same inspection form is been used

to ensure there is no damage occurs during hoisting activity.

7 ENVIRONMENTAL PROTECTION

During this activity (lifting operations), the regular environmental control measures will

be carried out as usual, such as:

General Waste Management Cleanliness and Protection of the environment /

ecosystem to be part of “our” work activities, in which case we will do several things:

- Provide trash bins in the work area according to its purpose.

- Disposing of waste according to the type of rubbish. (Consumable Waste)

- Perform clean-up work before and after the work is completed.

- Machinery well maintained to prevent oil leaks

- Oil spill kit, spill tray and proper fuel oil storage in place.

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 19 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

- Waste removal by authorized agent and disposed at authorised location.

- Machinery fuel refill is done by using refilling truck.

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 20 of 34

Management System – Uncontrolled Documents when Printed

PROFEESIONAL PACKERS AND MOVERS SDN BHD

Construction Method Statement

Contract Name: K2/ HUAWEI– Data Centre Project Contract No.:

Method Statement Title: Lifting and Hoisting for Genset Installation

Method Statement No. : SC/K2JHR01-03/WMS/PRO/001

ENVIRONMENTAL ASPECTS, IMPACTS AND MITIGATIONS

Reference should be made to the Environmental Control Plans for each environmental

aspect contained in the Environmental Management Plan.

Key: Level of Significance: Level 1 An impact that could cause pollution or degradation that may have irreversible detrimental

(High Severity) effects on the environment and/or community.

Level 2 An impact that could cause pollution or degradation that may have persistent but reversible

(Medium Severity) detrimental effects on the environment and/or community.

Level 3 An impact that could cause pollution or degradation that may have short term and reversible

(Low Severity) detrimental effects on the environment and/or community.

Aspects Sources Level of Significance Mitigation Plan Responsible By

Noise and Vibrations Use of Machinery 3 - Works would be undertaken Subcontractor / Superintendent/

within normal hours (0700- Supervisor/ Foreman

1900) General Day

- No such works shall be carried

out during restricted hours

(7pm to 7am and anytime of

General Holiday)

- Proper maintenance of

equipment / plant.

- Frequently maintain the plant /

machineries to reduce the

noise generation due to

machine components / parts

fatigue.

- all vessel and PMEs must

applied with Euro 5 diesel

Air Quality Use of Machinery 3 - Minimize idling time with engine Subcontractor / Superintendent/

off Supervisor/ Foreman

- Proper maintenance of

equipment / plant.

- all vessel and PMEs must

applied with Euro 5 diesel

Waste Management Inert / Non-inert waste 3 - Maintain good housekeeping Subcontractor / Superintendent/

generated practice including the waste Supervisor/ Foreman

sorting & segregation within

working area

- Remove generated waste from

works before off-duty daily

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2023 Page 21 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

Action(s) Complete /

Control Measures

# Task Class 1 Risks Responsible Control in Place

Person Checked by/

Image/Photo Description Pre-Work During

Signature

1 Mobilization of Machinery Traffic accident 1. Conduct Field Control Briefing – Take 5 Site Supervisor

& Equipments. during machine 2. Place banksman to control traffic

delivery 3. Pedestrian to use dedicated walkway

Minor injury 1. Conduct Field Control Briefing

when doing 2. Use proper working platform to unload the

equipment materials from truck

transfer 3. Work in buddy system

4. Wear specific PPE for specific work

2 Survey Work Fell from 1. Conduct Field Control Briefing Lifting Supervisor

height/ Slip, 2. Always check on ground condition

Trip, Fall before walking on slope

3. Work in buddy system

4. Workers to use proper PPE, safety boots,

long sleeve shirt, goggle, helmet, Impact

gloves

5. Always watch out for fall hazards when

working at installation area

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 22 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

3 Equipment Delivery Fall from height 1. Provide safeguarding system for all Operator

(Transport) moving, rotating and hazardous

machinery parts. Site Supervisor

Loose Material 2. Locate storage and loading areas

on/in transport away from areas of frequent

pedestrian activity

3. One way in, one way out and separate

IN/OUT entry

4. Assigned trained, competent and appointed

banksman to the designated areas.

5. Appointed banksman shall stay in the sight

of the operators/drivers and maintain

continuous signaling/ communicating until

the works done.

6. Provide a safe and even surface for the

machinery moves & mobilization of

mobile scaffold

7. Machinery operator shall check the

machinery’s condition before start work.

Ensure the machinery are all equipped with

Safety Devices for Plant and Equipment.

8. Comply to Class One Practice– 005-

Vehicle and Mobile Plant Movement

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 23 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

4 Movement of 1. Provide safeguarding system for all Site Safety

machinery moving, rotating and hazardous Supervisor

machinery parts.

2. Assigned trained, competent and appointed Site Supervisor

banksman to the designated areas. Operator

3. Appointed banksman shall stay in the sight Banksman

of the operators/drivers and maintain

continuous signaling/communicating until

the works done.

4. No entry warning signs, and red flashing

lights shall be positioned at the corner of

“Fatal Zones”.

5. All site personnel including worker work from

behind designated separation barriers in

order to maintain full clearance from potential

tipping and overturning zones of dump trucks

or other plant.

6. No person shall enter the Fatal Zone unless

accompanied by a banksman who has

positively communicated and confirmed all

operating plant have stopped.

7. Check validity of their driving license and

give them a short safety briefing on key

traffic rules before allowing them to enter

the site.

8. All the related permit to be obtained

before starting the work.

9. Only trained and authorized persons are

permitted to operate MEWPs.

10. Comply to Class One Practice– 005- Vehicle

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 24 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

5 Lifting area preparation Crane 1. Outrigger must be positioned on a flat Site Supervisor

Overturning due surface

Operator

to ground 2. Using plate or suitable materials for pads

condition to evenly distribute the load on the

ground

3. Crane to be located within radius for the

load being lifted where space, the

outrigger shall always be fully extended

4. Fully barricade around the crane with the

road barrier

5. Install the crane camera behind the

crane Ensure to prevent body injury

6. the workers and vehicle stay on the

designated access roads and do not

take shortcut road

6 Prepare rigging equipment Irregular 1. Wire rope shall be provide properly Foreman

inspection on all identified for SWL and manufacture Site Supervisor

lifting equipment 2. Inspections shall be done by authorized

personnel and by the safety department

3. Safe workload (SWL) tag shall provide

by the manufacture

4. Use only component with a known or

labeled working load limit.

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 25 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

7 Lifting and repositioning Ergonomic 1. The equipment for handling heavy Site supervisor

Equipment material should be check and inspect for Foremen

Manual handling safe to use. Site Safety

2. Proper wear correct PPE, including Supervisor

Caught in safety gloves (Impact Gloves) and steel- Operator

between parts of toed shoes. Banksman

body and load 3. Equipment should be handled in proper Site Supervisor

way use of safety device such as (safety

pin, safety lock)

4. Buddy system to ensure independent

workers are operating the hydraulic jack

and timber packs respectively with good

communication

5. Only trained or experience worker to

handle the jacking equipment (Hydraulic

Jacks and timber)

6. Cribbing timber block should have holder

to prevent any finger caught in between

heavy load

7. Ensure the process safely done without

placing or holding it with hand and

fingers directly under the loads. The

timber pack need to have marking (red &

white) to indicate pinch point area.

8. Equipment for handling heavy material

should have a safe working Load (SWL)

for each equipment and sufficient to

handle the load preventing mechanical

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 26 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

failure.

9. Only trained person will be allowed to

operate the hydraulic jack.

10. Close communication in between

supervisors, trained person and general

worker

8 Working at height Fallen object 1. Tools should be lift by the rope Scaffold

(Mobile Scaffold) Fall from height 2. Scaffold must be erect by competent inspector

Improper scaffold Site Safety

scaffolding 3. Use safety harness 100% tie during Supervisor

erection working at height above 1.8 meter Site Supervisor

4. Scaffold must be inspected by scaffold

inspector and with green tag

9 Unloading of Equipment Expose to the 1. Provide a safeguarding system for all Site supervisor

hanging moving, rotating and hazardous Foremen

overhead heavy machinery parts. Site Safety

equipment. 2. “No Entry” warning signs positioned at Supervisor

Crane topples the working premises. Operator

Fallen object 3. No one allowed to enter the working Banksman

Overload area, unless accompanied by a

Heat stress banksman who has positively

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 27 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

communicated and confirmed all the

operating machineries have stopped.

4. Assigned trained, competent and

appointed banksman to the working

areas

5. Appointed banksman must stay in the

sight of the operators/drivers and

maintain continuous

signaling/communicating until the works

done.

6. All personnel need to comply with 5

mandatory PPE

7. Conduct a pre-task talk

8. Ensure all the loading machineries

fitted with ‘performance lifting’ devices,

(refer to the Safety Devices for Plant &

Equipment checklist).

9. Ensure the counterweight of

the machineries fitted with finger warning

probes.

10. Loading zones have a fixed barrier

11. “No Entry” and “Crush Hazards” warning

signs positioned at the working

premises.

12. No one allowed to enter the working

area, unless accompanied by a

banksman who has positively

communicated and confirmed all the

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 28 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

operating machineries have stopped.

13. Comply to Class One Practice– 005-

Vehicle and Mobile Plant Movement

14. Comply to Class One Practice– 002-

Lifting Operation

15. Never allow anybody cross under

suspend load

16. Minimum 2 tagline shall be used to

control the load

17. Provide cold drinking water at site at all

times

10 Crushed by 1. Conduct Pre-Task Briefing Site supervisor

slewing point of 2. Provide a safeguarding system for all Foremen

machinery moving, rotating and hazardous Site Safety

machinery parts Supervisor

3. “No Entry” warning signs positioned at Operator

the working premises Banksman

4. No one allowed to enter the working

area, unless accompanied by a

banksman who has positively

communicated and confirmed all the

operating machineries have stopped.

5. Assigned trained, competent and

appointed banksman to the working

areas.

6. Appointed banksman must stay in the

sight of the operators/drivers and

maintain continuous

signaling/communicating until the works

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 29 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

done.

1. All personnel need to comply with 5

mandatory PPE.

2. Conduct a pre-task talk.

3. Ensure all the lifting machineries and

lifting gears fitted with ‘performance

lifting’ devices, (refer to the Safety

Devices for Plant & Equipment checklist).

4. Ensure the counterweight of the

machineries fitted with finger warning

probes.

5. “No Entry” and “Slewing Area” warning

signs positioned at the working premises.

6. Comply to Class One Practice– 005-

Vehicle and Mobile Plant Movement

11 Housekeeping Minor injury 1. Conduct pre-task briefing Site Supervisor

when doing 2. Worker to use hand glove while doing Workers

housekeeping housekeeping work

Slip and trip on 1. Conduct pre-task Site Supervisor

same level 2. Site supervisor to monitor worker doing Workers

housekeeping

Remarks/Comments

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 30 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

Field Control Inspection Check – Submission / Verification and Closeout

Field Control Inspector: I confirm that all CL 1 Risk control measures as stated within this JHA have been established, and are being maintained and controlled

at the working area. I also confirm that these controls, and others where necessary are in compliance with LA Class One Practices & Project Safety Standards.

Comments on rectifications can be seen in the above Remarks/Comments box.

JHA Submitted By Name: Signature: Date:

Position:

Verified By Name: Signature: Date:

Position:

Approve By Name: Signature: Date:

Position:

Note: Please issue the completed copies to Safety Department for filing

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 31 of 34

Management System – Uncontrolled Documents when Printed

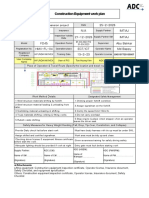

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

1) 50 Ton SWL Modular Spreader Bar x 2 pieces

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 32 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 33 of 34

Management System – Uncontrolled Documents when Printed

PROFESSIONAL PACKERS AND MOVERS SDN BHD

Construction Risk Assessment

ACCESS MAIN ROUTE

Title: Construction Method Statement

Version: 3.0 Date Published: 03/01/2022 Page 34 of 34

Management System – Uncontrolled Documents when Printed

You might also like

- Construction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideFrom EverandConstruction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideRating: 5 out of 5 stars5/5 (2)

- TGH-HSE-F0018 Lifting Plan Template LOCKEDDocument5 pagesTGH-HSE-F0018 Lifting Plan Template LOCKEDthana rajNo ratings yet

- Construction Lifting PlanDocument5 pagesConstruction Lifting PlanJuma KavesuNo ratings yet

- MOS Piping WorksDocument14 pagesMOS Piping Worksmuiqbal.workNo ratings yet

- MSRA - DemolitionDocument30 pagesMSRA - DemolitionCharmie Del CampoNo ratings yet

- Construction Safety Policy 022020Document20 pagesConstruction Safety Policy 022020leo100% (2)

- CMS-830-03-CK-72001 Rev 0Document5 pagesCMS-830-03-CK-72001 Rev 0Rajesh DodejaNo ratings yet

- TL - Powergrid Safety Checklist - Rev-2Document10 pagesTL - Powergrid Safety Checklist - Rev-2Raj Kiran GunduNo ratings yet

- MOS Structure Lifting PlanDocument15 pagesMOS Structure Lifting Planmuiqbal.workNo ratings yet

- CE MSTC 2023 Definition of TermsDocument18 pagesCE MSTC 2023 Definition of TermsRichard ParedesNo ratings yet

- CE Board 2010 2023 Definition of TermsDocument37 pagesCE Board 2010 2023 Definition of TermsRichard ParedesNo ratings yet

- Method Statement For Cranage & LiftingDocument6 pagesMethod Statement For Cranage & Liftingadeniyi abiolaNo ratings yet

- Method Statement For Construction of Gabion ProtectionDocument18 pagesMethod Statement For Construction of Gabion Protectiondanilo m.sampaga95% (38)

- Toaz - Info 005 Ms Manhole Construction Sew Risk Assessment From Javeed 1 PRDocument12 pagesToaz - Info 005 Ms Manhole Construction Sew Risk Assessment From Javeed 1 PRShah MuzzamilNo ratings yet

- Plant & Guide Wall ConstructionDocument10 pagesPlant & Guide Wall ConstructionAnonymous S7Cq7ZDgPNo ratings yet

- Method of Statement For Installation of Refrigeration System (Cold Store)Document2 pagesMethod of Statement For Installation of Refrigeration System (Cold Store)Salman SaifuddinNo ratings yet

- Neom Occupational Safety and Health Governance FrameworkDocument29 pagesNeom Occupational Safety and Health Governance Frameworkmohamed.elsawafNo ratings yet

- TDM Acp WSP Com Stat B Msra Sas Na 002Document31 pagesTDM Acp WSP Com Stat B Msra Sas Na 002jithu surendranNo ratings yet

- Comments Sheet - Method Statement & Risk Assessment For Installation of HoardingDocument1 pageComments Sheet - Method Statement & Risk Assessment For Installation of HoardingMohammed FasilNo ratings yet

- 02 Method of Statment - DX High Wall Split Unit - PSDocument12 pages02 Method of Statment - DX High Wall Split Unit - PSUnique PlanningNo ratings yet

- Contractor Hse Plan Guideline - EditedDocument11 pagesContractor Hse Plan Guideline - EditedMohd Azro Mohd NorNo ratings yet

- Method Statements For Construction of Masonry Lined Drains Rev 0Document13 pagesMethod Statements For Construction of Masonry Lined Drains Rev 0McDonald WesleyNo ratings yet

- Construction Equipment Work Plan Lifting EquipmentDocument2 pagesConstruction Equipment Work Plan Lifting EquipmentHMN YDVNo ratings yet

- SOP - ForkliftDocument4 pagesSOP - ForkliftGyanendra Narayan Nayak100% (1)

- Method Statement Construction & Casting of Concrete Manholes P-2Document17 pagesMethod Statement Construction & Casting of Concrete Manholes P-2a.nunezNo ratings yet

- Lift Plan FormDocument6 pagesLift Plan FormBibin JohnNo ratings yet

- Method Statement For GeotextileDocument17 pagesMethod Statement For GeotextileGökhan Gökçe0% (1)

- LiftingDocument6 pagesLiftinghsem Al EimaraNo ratings yet

- Monthly Work Permit-4.5tDocument1 pageMonthly Work Permit-4.5tHeaven BiswasNo ratings yet

- Working at HeightsDocument36 pagesWorking at Heightskelvinalphonce97No ratings yet

- Lifting Operations 2.034Document10 pagesLifting Operations 2.034svdnolen0% (1)

- Provisions For The Safe Use of Cranes On Construction SitesDocument2 pagesProvisions For The Safe Use of Cranes On Construction Siteskla_alkNo ratings yet

- AAH-P001-QC-CV-DOC-00003-00 Comments Response Sheet For MST (Shoring)Document2 pagesAAH-P001-QC-CV-DOC-00003-00 Comments Response Sheet For MST (Shoring)mahmoodNo ratings yet

- D1D2-MAR-A-0348 Rev.00Document54 pagesD1D2-MAR-A-0348 Rev.00francisbautistaNo ratings yet

- Imb SH Hse 0024 01Document19 pagesImb SH Hse 0024 0101095902062ahmedNo ratings yet

- Material Approval & Specification Comparison SheetDocument3 pagesMaterial Approval & Specification Comparison Sheetfrancisbautista100% (1)

- Excavation Method StatementDocument6 pagesExcavation Method StatementWaleed SalihNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument20 pagesNational Oil Corporation: Rev Date Description Checked ApprovedALI BEN AMORNo ratings yet

- MIR Camera Part 1 (MIR GH 001)Document1 pageMIR Camera Part 1 (MIR GH 001)a.m.ghazali.88No ratings yet

- PVC Pile Spacer (Turkish) For UAE MarketDocument67 pagesPVC Pile Spacer (Turkish) For UAE MarketGhayas JawedNo ratings yet

- 1 - Method Statement For Sika WaterproofingDocument6 pages1 - Method Statement For Sika WaterproofingAyda JohariNo ratings yet

- Conduiting Works - Ms - Rev 2 (Final)Document12 pagesConduiting Works - Ms - Rev 2 (Final)Adnan AbdulNo ratings yet

- Construction Methods TermsDocument7 pagesConstruction Methods TermsMingjaw MingmingNo ratings yet

- Deployment of Personnel FDR ContractDocument5 pagesDeployment of Personnel FDR ContractashutoshpathakcivilNo ratings yet

- 08 185000 4200000030 Sac Civ MST 000008 - 01Document19 pages08 185000 4200000030 Sac Civ MST 000008 - 01Mirza RahamanNo ratings yet

- CDM ChecklistDocument7 pagesCDM ChecklistJohn TangNo ratings yet

- PJ 2329 Shoring Msra Rev 01 (RCV TSC Mss S 010 Rev 01)Document33 pagesPJ 2329 Shoring Msra Rev 01 (RCV TSC Mss S 010 Rev 01)MANAS K. DUTTANo ratings yet

- PCC Method StatementDocument10 pagesPCC Method StatementChirag SharmaNo ratings yet

- Chapter 1Document14 pagesChapter 1Amir ahmedNo ratings yet

- 30) Method Statement For Loading & Unloading PlatformDocument3 pages30) Method Statement For Loading & Unloading Platformmanoj50% (2)

- Petrofac - Lifting Rigging ProcedureDocument12 pagesPetrofac - Lifting Rigging ProcedureNorakhmal HidayahNo ratings yet

- OTC19073 Float-Overs Offshore West AfricaDocument10 pagesOTC19073 Float-Overs Offshore West AfricaCees van ZandvlietNo ratings yet

- Method Statement For Installation of Kerbstone and Pavers in UAEDocument18 pagesMethod Statement For Installation of Kerbstone and Pavers in UAEGhayas JawedNo ratings yet

- Method Statement - Relocate Street LightingDocument6 pagesMethod Statement - Relocate Street Lightingahmad.nazareeNo ratings yet

- Work Procedure For CCB Installation of Raised Floor 2Document13 pagesWork Procedure For CCB Installation of Raised Floor 2ResearcherNo ratings yet

- 004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFDocument9 pages004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFKöksal Patan100% (1)

- SWC-CIMC-SWMS-0007 Edge Lifeline Barricade & Staircase BarricadeDocument42 pagesSWC-CIMC-SWMS-0007 Edge Lifeline Barricade & Staircase BarricadeHanitha (Digital & Technology)No ratings yet

- KBMS03 Method of Working For Surface Dressing JAN 2019Document33 pagesKBMS03 Method of Working For Surface Dressing JAN 2019Amit BhattNo ratings yet

- 009 Lifting PlanDocument2 pages009 Lifting Planromedic36No ratings yet

- Security Plan-ABS00-S0-GS-000014Document14 pagesSecurity Plan-ABS00-S0-GS-000014Jeffrey LumbaNo ratings yet

- OSHJ-CoP-01 Risk Management and Control Version 1 EnglishDocument15 pagesOSHJ-CoP-01 Risk Management and Control Version 1 EnglishsajinNo ratings yet

- HSE QuestionnaireDocument3 pagesHSE QuestionnaireAref El HusseinyNo ratings yet

- Manual ASDA B2Document337 pagesManual ASDA B2Ronaldo Kanasiro BasilioNo ratings yet

- Code of Conduct: Third PartyDocument3 pagesCode of Conduct: Third Partysamwel kariukiNo ratings yet

- Work at Height ChecklistDocument3 pagesWork at Height ChecklistThillai8975No ratings yet

- Ecelaws PPT Group 1Document28 pagesEcelaws PPT Group 1Jomeljames Campaner PanganibanNo ratings yet

- Seably - Training For The Maritime Professional-1Document6 pagesSeably - Training For The Maritime Professional-1Era ErmerraNo ratings yet

- BPA Report Into Structural Safety and Maintenance of Car Parks in The UK - 060712Document26 pagesBPA Report Into Structural Safety and Maintenance of Car Parks in The UK - 060712Roy HobbsNo ratings yet

- S 70 000 1139 001Document25 pagesS 70 000 1139 001Adnan RafiqNo ratings yet

- 9859 4th Edition enDocument170 pages9859 4th Edition enJoe Kronfli50% (2)

- Road Rules Quiz Keys 4 Life Module 1Document5 pagesRoad Rules Quiz Keys 4 Life Module 1Chitransh SrivastavaNo ratings yet

- 186.404.001 SCHOTTEL - MANUAL DE USUARIO STT 1FP + CD STERN ORDER 14379179-ComprimidoDocument290 pages186.404.001 SCHOTTEL - MANUAL DE USUARIO STT 1FP + CD STERN ORDER 14379179-ComprimidoJosé Verdejo QuirozNo ratings yet

- 1.2 History of ICS.: Four Essental RequirementsDocument3 pages1.2 History of ICS.: Four Essental Requirementszalmie0905No ratings yet

- 1973 TPS Handbook - Chapter 1 - A4Document50 pages1973 TPS Handbook - Chapter 1 - A4jdpardoNo ratings yet

- Patient Monitor - Dash3000 Service ManualDocument236 pagesPatient Monitor - Dash3000 Service ManualMohammed NahelNo ratings yet

- Käyttöohje Geda 500 Z ZP EngDocument114 pagesKäyttöohje Geda 500 Z ZP EngjillianixNo ratings yet

- Lsis Miniature Circuit BreakersDocument5 pagesLsis Miniature Circuit BreakersECATOnlineNo ratings yet

- Code Requirements For Determining Fire Resistance of Concrete and Masonry Construction AssembliesDocument5 pagesCode Requirements For Determining Fire Resistance of Concrete and Masonry Construction AssembliesPedro OscarNo ratings yet

- Ig 55 Material Safety Data SheetDocument4 pagesIg 55 Material Safety Data SheetJason BartramNo ratings yet

- 37.2 Agreement Between Employer and MandatoryDocument15 pages37.2 Agreement Between Employer and MandatorykkNo ratings yet

- Kodak QC V 2.5.0 PoC 120-140 Troubleshooting Guide June 2008Document58 pagesKodak QC V 2.5.0 PoC 120-140 Troubleshooting Guide June 2008Bartosz OgibowskiNo ratings yet

- Mock Business Plan Gemma LakinDocument9 pagesMock Business Plan Gemma LakinSam VeeversNo ratings yet

- Carpenter Interview QuestionsDocument2 pagesCarpenter Interview Questionsmico alilayaNo ratings yet

- Product Recall-18.6.23Document24 pagesProduct Recall-18.6.23Fatema Binte LatifNo ratings yet

- What If-Checklist ExampleDocument3 pagesWhat If-Checklist ExampleltroncosNo ratings yet

- 5-Star Safety and Health Management SystemDocument5 pages5-Star Safety and Health Management SystemSn Ahsan100% (1)

- Grinding: Thermax Engineering Construction Co. LTD Operational Control ProcedureDocument2 pagesGrinding: Thermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghNo ratings yet

- Fundamental of AIMSDocument5 pagesFundamental of AIMSTissa1969No ratings yet

- Operation & Maintenance Manual: (MGS 7310 GCP)Document47 pagesOperation & Maintenance Manual: (MGS 7310 GCP)Falgon IslamNo ratings yet