Professional Documents

Culture Documents

5-Star Safety Inspection Report for MODON Jeddah – 3 OHTL 110KV Project

Uploaded by

Sn AhsanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5-Star Safety Inspection Report for MODON Jeddah – 3 OHTL 110KV Project

Uploaded by

Sn AhsanCopyright:

Available Formats

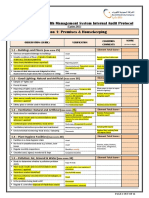

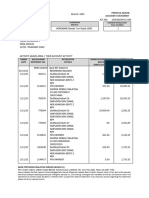

5-Star Safety and Health Management System

SEC-EHV (WOA-SOA) SAFETY REPRESENTATIVES’ INSPECTION REPORT (5.3.2)

LOCATION: MODON Jeddah – 3 OHTL 110KV CONTRACT NO: 4400005949

CONTRACTORS NAME: ASAMCO DATE: 28 February 2018

Contact Person: MODON Jeddah – 3 OHTL 110KV

Name Designation Mobile No E-Mail Address

Akram J. Abdulwahab SEC Project Manager 0565632099 AJAbdulwahab@ngrid.sa

Waseem Abro SEC Engineer 0544952485 waseem@gmail.com

Rommel.Acupan@dar-

Rommel Acupan QA/QC Engineer 0557117047

engineering.com

Shehrar Sheikh Project Manager 0580885918 shehryarsheikh@asamco.com.sa

Ali Aamir Site Manager 0559650434 aliaamir@asamco.com.sa

Ahsan Muntaz Safety Officer 0580078867 ahsanmumtaz@hotmail.com

STANDARD Y N Comments Major Threat

Structure, furniture, and

1.1 equipment in good and safe

condition

Floors - clean and free of dirt or

1.1

other dangers.

Good Lighting, natural or

1.2

artificial

1.3 Is ventilation adequate?

Rest room facilities - toilets,

1.4

wash basins, clean and hygienic

Kitchen, lunchroom clean. No

1.4

food in unauthorized areas.

1.5 Pollution of air, water, ground.

Hazardous waste disposal in

1.5

responsible manner.

1.6 Areas demarcated

1.7 Stacking - stable, neat and safe.

Areas inside and outside of

Maintained the Good Safety

1.8 buildings are neat and tidy. See good observation # 01

Practices. Means Good progress

General housekeeping.

Scrap and refuse bins enough

1.9

and correctly placed.

Color coding of pipes and plant

1.10

in order.

2.1 Machine guards in place.

All equipment / hazardous areas

can be isolated / locked out and

2.2

procedure displayed where

applicable.

Switches, isolators and valves

2.3

labeled, outlets marked.

Scaffolding structure no ladder

Ladders, scaffolds and hand

2.4 See Un-safe observation #02 resulting to serious injury,

rails in good condition fatality and damage property

2.5. Lifting gear in good condition

Gas cylinders and pressure

2.6.

vessels in order

1|Page As per Rev. Dated: 12/01/2016

5-Star Safety and Health Management System

Hazardous substances handled /

2.7 stored using correct

procedures.

Portable electric equipment in

2.10 good condition. No cords over

floors.

General electrical installations /

2.12

flameproof equipment are safe.

Hand tools in good condition

2.13

and properly stored.

Ergonomics: conditions safe

2.14

and comfortable

Appropriate protective clothing /

No helmet during termination on

2.18 equipment available, properly See unsafe observation #01

cable resulting to head Injury

utilized and in good condition.

Safety signs and notices in

2.24

place.

2.25 Working at Height

2.26 Confined Space

2.27 Excavation and trenching

3.1 Fire Extinguishers in position

Location of Fire Extinguishers

3.2 clearly visible, demarcated and

unobstructed.

Fire Extinguishing Equipment

3.3

maintained / inspected.

Flammable materials stored

3.4

correctly.

Alarm System working,

3.5

employees aware of system.

Emergency plan available and

3.8

understood by staff.

Injuries / Accidents which

4.2 occurred since previous

inspection.

5.6 Names of First Aiders displayed.

Safe Work Procedures available

5.19

and used

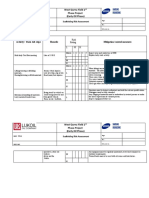

PROJECT SAFETY STATISTIC REPORT

Average No. of Manpower 28 Accumulated Man hours (From start of Project) 162,480

COORDINATION MEETING Jan Feb Mar Apr May Jun July Aug Sep Oct Nov Dec

CONDUCTED: 15

DRILL (Fire, Camp Etc.) 11

DATE ACCIDENT / INCIDENT HISTORY (Brief Description) Result of Accident

NIL

2|Page As per Rev. Dated: 12/01/2016

5-Star Safety and Health Management System

Site Visit Description:

Brief Summary of the conducted inspection.

Personnel Involved:

- Mr. Michael C. Data, SEC Safety Consultant

- Mr. Rommel B. Acupan, SEC QAQC Civil Engr./Consultant

- Mr. Ahsan Muntaz Contractor’s Safety Officer

On-Going Activities:

- Installation of Electrical Cable support in 110KV Basement Building

- Fabricated of Electrical Cable Tray Support in 110KV Basement Building

- Cable tray Installation in 110KV Basement Building

Good Observations Noted/Observed:

- Recognizable housekeeping was observed on 110kv Control Room Building.

Unsafe Observation Noted/Observed:

- Risk injury from head bump due to the worker not wearing helmet during termination of High voltage in OHTL

Gantry beside 380 KV

- Fall at height due to not providing a safe ladder on temporary scaffolding structure utilizing by high voltage

group

Near Miss Observation:

- No Near-miss Observation during my Inspection.

See attached photo and observations below

WEEKLY ACTIVITIES CONDUCTED

Installation of Electrical Cable support

Fabricated of Electrical Cable Tray Support in 110KV Basement Building

3|Page As per Rev. Dated: 12/01/2016

5-Star Safety and Health Management System

Cable tray Installation in 110KV Basement Building

SAFETY OBSERVATION AND RECOMMENDATIONS

GOOD OBSERVATIONS

Observation no. #1

As per SEC Safety and Health Management System (5-STAR) element 1.Premises and Housekeeping\1.9 Scrap and Refuse

Bins; 1.Premises and Housekeeping\1.8 Good Housekeeping

Recognizable housekeeping was observed on 110kv Control Room Building.

Recommendations:

1. Keep up the good work …Good Safety practices and provision should be maintained at site and office.

2. Cleaning can help to avoid injuries and improve the production.

3. Housekeeping should be a regular process, not a one-time execute.

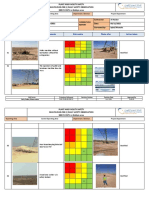

UNSAFE OBSERVATION

UNSAFE OBSERVATION no. 1 Observation no. #1: As per 5 Star Elements 2.15 Head Protection (Safety

Helmet), 2.18 Protective Clothing

Risk injury from head bump due to the worker not wearing helmet during

termination of High voltage in OHTL Gantry beside 380 KV

Recommendation:

1. Immediately called the attention of the Supervisor and Safety Officer from

ASAMCO to instruct the worker to wear the complete PPE during termination

of high voltage.

2. Safety Officer should be Conduct a risk assessment of their areas to carried-

out and checked properly the PPEs (head protectors) of the workers.

Unsafe Condition Action Taken

CORRECTIVE ACTION SHALL BE TAKEN ON OR

BEFORE (FEB. 28, 2018)

4|Page As per Rev. Dated: 12/01/2016

5-Star Safety and Health Management System

UNSAFE OBSERVATION no. 2 Observation no. #2 As per 5 Star Elements 2.4 ladders, stairs, walkways and

scaffolding

Fall at height due to not providing a safe ladder on temporary scaffolding

structure utilizing by high voltage group

Recommendation:

1. Temporary worked stopped Advised the Supervisor and Safety Engineer from

ASAMCO to dismantling the unsafe incomplete scaffold structure or rectified

to complete by competent scaffolder.

2. It must be rectified immediately to eliminate disabling injuries in the work

place.

3. It must be rectified immediately to eliminate disabling injuries in the work

place. Safety Officer should be Conduct a risk assessment of their areas and

responsibilities to carried-out and identify the risk prior to start the work

4. Working from an existing place of work, or using an existing means of access

and egress, Instruction and training and/or other means be implemented.

Unsafe Condition Action Taken

CORRECTIVE ACTION SHALL BE TAKEN ON OR BEFORE

(Mar. 01, 2018)

Report by Safety Representative:

Does the above report contain any major threat to the safety of any Employee?

YES NO

If yes, complete the following: The matter was reported as soon as practical.

In Writing Verbally

Prepared By: Checked By: Reviewed By:

Michael C. Data Charlie A. Borbon OMAR A. TAHER

Safety Consultant Safety Engineer Consultant Group Leader

Safety, Quality & Environmental Coordinator Safety, Quality & Environmental

Studies Group Safety, Quality & Environmental Studies Group

SEC Western Project Department Studies Group SEC Western Project Department

SEC Western Project Department

5|Page As per Rev. Dated: 12/01/2016

You might also like

- F 5.3 C Star-Safety-Inspection-JULYDocument4 pagesF 5.3 C Star-Safety-Inspection-JULYSn Ahsan100% (1)

- ErtyyuioluiolDocument16 pagesErtyyuioluiolVinoth Sudalai100% (1)

- HSE Inspection Report-06Document20 pagesHSE Inspection Report-06najihahNo ratings yet

- Assessment For CCTV System Testing & CommissioningDocument5 pagesAssessment For CCTV System Testing & CommissioningAnonymousNo ratings yet

- Site Inspection HSE Observations Report No.01 - 28.06.2022 N10Document2 pagesSite Inspection HSE Observations Report No.01 - 28.06.2022 N10MalabaNo ratings yet

- WRAL Weekly HSE Report 08-01-2024 To - 14-01-2024Document3 pagesWRAL Weekly HSE Report 08-01-2024 To - 14-01-2024sunday abachaNo ratings yet

- Jobsite Safety Checklist Long Ver 1Document5 pagesJobsite Safety Checklist Long Ver 1Usman ShahidNo ratings yet

- 2021 Year Ending HSE Performance ReviewDocument17 pages2021 Year Ending HSE Performance ReviewIfrekeNo ratings yet

- HSE Report Makhazen S/SDocument6 pagesHSE Report Makhazen S/SAnonymous kWfNFbNo ratings yet

- 45 Safety Observation Report. 380 KV OHTL - Qiddyia Area 07-11-2021Document4 pages45 Safety Observation Report. 380 KV OHTL - Qiddyia Area 07-11-2021Shafie ZubierNo ratings yet

- Heavy Lifting Safety ChecklistDocument1 pageHeavy Lifting Safety ChecklistMock ProjectNo ratings yet

- Visitors HSES InductionDocument30 pagesVisitors HSES InductionPradeep KunduNo ratings yet

- RB - HSE Daily Observation ReportDocument5 pagesRB - HSE Daily Observation ReportIdris AdeniranNo ratings yet

- Annual Tool Box Meeting Plan ScheduleDocument3 pagesAnnual Tool Box Meeting Plan Scheduletoxicity23No ratings yet

- Risk Assessment FOR: Over Head Crane ErectionDocument9 pagesRisk Assessment FOR: Over Head Crane ErectionZameer AhmedNo ratings yet

- SHE Committee Meeting Minutes ReviewDocument4 pagesSHE Committee Meeting Minutes ReviewCHETAN WANKHADE100% (2)

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

- Weekly Report Hsse OwjaDocument13 pagesWeekly Report Hsse OwjaSendi PTMNo ratings yet

- Lifting Operations Planning Risk Assessment PDFDocument1 pageLifting Operations Planning Risk Assessment PDFulisses costaNo ratings yet

- Construction Site Inspection Check List ALMCDocument2 pagesConstruction Site Inspection Check List ALMCAmeerHamzaWarraichNo ratings yet

- Risk Assessment For Stone WorkDocument17 pagesRisk Assessment For Stone WorkKhuda BukshNo ratings yet

- Safety Induction: Company-Ajyal Union Limited CompanyDocument53 pagesSafety Induction: Company-Ajyal Union Limited CompanyRajamanickam Subramanian0% (1)

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageDocument3 pagesEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanNo ratings yet

- HSE Close Out ReportDocument4 pagesHSE Close Out ReportVijayakumar KarunanidhiNo ratings yet

- W04 Safety Observations Report (8358 SS&L) MISK CITY PTS-20CN190 ABC, 22-01-2022Document5 pagesW04 Safety Observations Report (8358 SS&L) MISK CITY PTS-20CN190 ABC, 22-01-2022Shafie Zubier100% (1)

- Samsung Scaffold Risk Assesment 2Document7 pagesSamsung Scaffold Risk Assesment 2Saleem AkhtarNo ratings yet

- SRA-GEN Risk Assessment for Turbine MaintenanceDocument3 pagesSRA-GEN Risk Assessment for Turbine Maintenanceacanbasri1980No ratings yet

- Personal Protective Equipment Hazard AssessmentDocument5 pagesPersonal Protective Equipment Hazard AssessmentKrsnaPentayah100% (1)

- 03-F07 Job Safe Procedure Template - DAMMAM - NO. 01Document1 page03-F07 Job Safe Procedure Template - DAMMAM - NO. 01jawad khanNo ratings yet

- Health Safety Performance Report 2020Document20 pagesHealth Safety Performance Report 2020Okla OkiloaNo ratings yet

- HSE-FRM-40 Daily HSE Report (04-05-2020)Document2 pagesHSE-FRM-40 Daily HSE Report (04-05-2020)SHAH NAWAZ SAEEDNo ratings yet

- Contractor Safety Observation Report: Contac T PersonDocument3 pagesContractor Safety Observation Report: Contac T PersonAhsan MumtazNo ratings yet

- Safety Weekly Stats Report Upto 04-Sep - 2021Document1 pageSafety Weekly Stats Report Upto 04-Sep - 2021Sabre Alam100% (1)

- Health and Safety Induction Training SheetDocument2 pagesHealth and Safety Induction Training Sheetnil thaeuNo ratings yet

- Risk Assessment & Safe Working PracticeDocument4 pagesRisk Assessment & Safe Working Practicekamranshamoo1100% (1)

- Asm Risk Assesment fv2 PDFDocument3 pagesAsm Risk Assesment fv2 PDFshijadNo ratings yet

- Incidents By Root Causes Tools Equipment TrainingDocument5 pagesIncidents By Root Causes Tools Equipment TrainingvictorNo ratings yet

- Construction Site Safety Program REV-02Document95 pagesConstruction Site Safety Program REV-0201095902062ahmedNo ratings yet

- INDOKOMAS BUANA PERKASA PROJECT HSE MONTHLY REPORTDocument5 pagesINDOKOMAS BUANA PERKASA PROJECT HSE MONTHLY REPORTBiyan YogaNo ratings yet

- Templates Package 1 ContentDocument1 pageTemplates Package 1 ContentM IqbalNo ratings yet

- Risk Assessment For Installation of Enclosed Switches IsolatorsDocument7 pagesRisk Assessment For Installation of Enclosed Switches IsolatorsADIL AL-AQABYNo ratings yet

- Contractor Weekly Hse Report Blank With DefinitionsDocument4 pagesContractor Weekly Hse Report Blank With DefinitionsGonzalo Davila100% (2)

- Life Saving Rules Engagement Final Pack June - 2022Document40 pagesLife Saving Rules Engagement Final Pack June - 2022vinil radhakrishnaNo ratings yet

- Weekly HSE Report - 13-05-2023Document24 pagesWeekly HSE Report - 13-05-2023abhinav djNo ratings yet

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocument2 pagesRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- Task /activity: Installation of Abseil HooksDocument10 pagesTask /activity: Installation of Abseil HooksfrancisbautistaNo ratings yet

- EHS is Everyone’s ResponsibilityDocument88 pagesEHS is Everyone’s ResponsibilityMarthaNo ratings yet

- Site Environmental Control ReportDocument5 pagesSite Environmental Control ReportJasonTeeNo ratings yet

- HSE PlanDocument52 pagesHSE PlanSyahriadin SyamNo ratings yet

- HSE Inspection Report-07Document32 pagesHSE Inspection Report-07najihahNo ratings yet

- Class: Non Conformance ReportDocument4 pagesClass: Non Conformance ReportStephenNo ratings yet

- Monthly HSE Report - January 2022Document13 pagesMonthly HSE Report - January 2022adeniyi abiolaNo ratings yet

- 2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- ARA - For Emergency Diesel GeneratorDocument4 pagesARA - For Emergency Diesel GeneratorShaikh AftabNo ratings yet

- HSE Inspection Report-10Document14 pagesHSE Inspection Report-10najihahNo ratings yet

- Naseem & Son: Emergency Response PlanDocument6 pagesNaseem & Son: Emergency Response PlanSagar SharmaNo ratings yet

- ZFP Sor 2023-1-10Document7 pagesZFP Sor 2023-1-10irfan shafiqueNo ratings yet

- Schedule For Inspection Aug 19Document1 pageSchedule For Inspection Aug 19Siddharth RanaNo ratings yet

- Inv 2024 01845Document2 pagesInv 2024 01845Sn AhsanNo ratings yet

- 07-f05 Ohs Ms Document RegisterDocument3 pages07-f05 Ohs Ms Document RegisterSn AhsanNo ratings yet

- OHS Document Control MatrixDocument1 pageOHS Document Control MatrixSn AhsanNo ratings yet

- 07-f05 Ohs Ms Document RegisterDocument3 pages07-f05 Ohs Ms Document RegisterSn AhsanNo ratings yet

- Health and Safety Induction: Muhammad RazaDocument1 pageHealth and Safety Induction: Muhammad RazaSn AhsanNo ratings yet

- OHS Document Change RequestDocument1 pageOHS Document Change RequestSn AhsanNo ratings yet

- Master document listDocument12 pagesMaster document listSn AhsanNo ratings yet

- 07-f05 Ohs Ms Document RegisterDocument3 pages07-f05 Ohs Ms Document RegisterSn AhsanNo ratings yet

- 07-F03 Document Issue RegisterDocument1 page07-F03 Document Issue RegisterSn AhsanNo ratings yet

- OHS Document Change RequestDocument1 pageOHS Document Change RequestSn AhsanNo ratings yet

- 07-f05 Ohs Ms Document RegisterDocument3 pages07-f05 Ohs Ms Document RegisterSn AhsanNo ratings yet

- OHS Document Control MatrixDocument1 pageOHS Document Control MatrixSn AhsanNo ratings yet

- 07-F03 Document Issue RegisterDocument1 page07-F03 Document Issue RegisterSn AhsanNo ratings yet

- OHS-PR-02-07 Document ControlDocument14 pagesOHS-PR-02-07 Document ControlSn Ahsan100% (1)

- 13-F08 Self Contained Breathing Apparatus InspectionDocument2 pages13-F08 Self Contained Breathing Apparatus InspectionSn AhsanNo ratings yet

- 13-F05 Training Use of A Fire Extinguisher (Non Fire Team Members)Document1 page13-F05 Training Use of A Fire Extinguisher (Non Fire Team Members)Sn AhsanNo ratings yet

- Master document listDocument12 pagesMaster document listSn AhsanNo ratings yet

- 13-F07 Emergency Equipment RegisterDocument1 page13-F07 Emergency Equipment RegisterSn AhsanNo ratings yet

- Daily Forklift Inspection ChecklistDocument1 pageDaily Forklift Inspection ChecklistSn AhsanNo ratings yet

- 13-F06 EMERGENCY ALARM TESTING and INSPECTIONDocument1 page13-F06 EMERGENCY ALARM TESTING and INSPECTIONSn AhsanNo ratings yet

- 13-F04 Fire Fighting Equipment InspectionDocument1 page13-F04 Fire Fighting Equipment InspectionSn AhsanNo ratings yet

- 10-F20 Fuel Driven Equipment InspectionDocument3 pages10-F20 Fuel Driven Equipment InspectionSn AhsanNo ratings yet

- Machinery, Tools and Equipment Safety Ohs-Pr-02-10-F16 Fixed Ladder ChecklistDocument2 pagesMachinery, Tools and Equipment Safety Ohs-Pr-02-10-F16 Fixed Ladder ChecklistSn AhsanNo ratings yet

- 03-F09 Planned Job Observation ScheduleDocument1 page03-F09 Planned Job Observation ScheduleSn Ahsan0% (1)

- 03-F11 RA and JSP Briefing RecordDocument2 pages03-F11 RA and JSP Briefing RecordSn AhsanNo ratings yet

- 10-F17 Driver License RegisterDocument1 page10-F17 Driver License RegisterSn AhsanNo ratings yet

- 10-F18 Motor Vehicle Daily InspectionDocument2 pages10-F18 Motor Vehicle Daily InspectionSn AhsanNo ratings yet

- 03-F07 Job Safe Procedure TemplateDocument1 page03-F07 Job Safe Procedure TemplateSn AhsanNo ratings yet

- HIRA Report Job ObservationDocument1 pageHIRA Report Job ObservationSn Ahsan100% (1)

- 03-F08 HIRA Risk RegisterDocument1 page03-F08 HIRA Risk RegisterSn AhsanNo ratings yet

- Module 3 - ABC Lecture S23Document26 pagesModule 3 - ABC Lecture S23Prachi YadavNo ratings yet

- Emergency Preparedness ReportDocument44 pagesEmergency Preparedness ReportMatt OSullivanNo ratings yet

- Project Study Report On Employees RetentionDocument61 pagesProject Study Report On Employees RetentionMuskan KothariNo ratings yet

- Advance Chapter 1Document16 pagesAdvance Chapter 1abel habtamuNo ratings yet

- Pass SlipDocument1 pagePass SlipVobbin Jay CariasNo ratings yet

- Supplier FebruaryDocument2 pagesSupplier FebruaryRaiyanNo ratings yet

- Breach of ContractDocument26 pagesBreach of ContractSandeep100% (1)

- 2018 (4) KHC 409Document6 pages2018 (4) KHC 409atulsohan6453No ratings yet

- The Engineer'S Presentation Regarding Dispute # 2: Contract No. NKB/ICB-01 Presented By: KHANKI ConsultantsDocument25 pagesThe Engineer'S Presentation Regarding Dispute # 2: Contract No. NKB/ICB-01 Presented By: KHANKI ConsultantsArshad MahmoodNo ratings yet

- Model For IMC Planning PDFDocument6 pagesModel For IMC Planning PDFApurva SharmaNo ratings yet

- Honey Lemon Sugaring Wax StudyDocument35 pagesHoney Lemon Sugaring Wax Studychester VelasquezNo ratings yet

- Cbse Question Bank Admission of PartnersDocument6 pagesCbse Question Bank Admission of Partnersvsy9926No ratings yet

- Sri Trang Gloves Company Profile and Focus on InnovationDocument20 pagesSri Trang Gloves Company Profile and Focus on InnovationRudy NASUHANo ratings yet

- Project Handover TemplateDocument3 pagesProject Handover TemplateDeviPrasadNathNo ratings yet

- Successful Career DevelopmentDocument7 pagesSuccessful Career DevelopmentAynurNo ratings yet

- Pressure GroupDocument5 pagesPressure GroupasthaNo ratings yet

- Gist of FIEO ServicesDocument1 pageGist of FIEO Servicessanjay patraNo ratings yet

- Karnataka Land Grant Rules, 1969Document20 pagesKarnataka Land Grant Rules, 1969Ramanan SelvamNo ratings yet

- L2M1 Tutor NotesDocument28 pagesL2M1 Tutor Notesdalia.diab.86No ratings yet

- List of Attorneys March 2018Document21 pagesList of Attorneys March 2018LOVETH KONNIANo ratings yet

- Second Activity in Allied - TOEICDocument2 pagesSecond Activity in Allied - TOEICRia Joy SanchezNo ratings yet

- E-Marketing in Hospitality Industry Prospect'S and ChallengesDocument17 pagesE-Marketing in Hospitality Industry Prospect'S and Challengesprakash rajuNo ratings yet

- Uts - Akm3 - Suci Purnama Devi - F0318108 - E17.9 & P21.13 PDFDocument4 pagesUts - Akm3 - Suci Purnama Devi - F0318108 - E17.9 & P21.13 PDFSuci Purnama Devi100% (1)

- Burger King Presentation FinalDocument22 pagesBurger King Presentation FinalYogesh Gupta50% (2)

- Financial Ratios Analysis: Dialog Axiata PLCDocument34 pagesFinancial Ratios Analysis: Dialog Axiata PLCjey456No ratings yet

- Nov 2023Document7 pagesNov 2023applybizzNo ratings yet

- Best Practices S4HANA 2022Document153 pagesBest Practices S4HANA 2022venkataravin100% (1)

- Coca-Cola Vs PepsicoDocument38 pagesCoca-Cola Vs PepsicoJenishNo ratings yet

- Custom AWE Process ExampleDocument19 pagesCustom AWE Process ExampleSiji Surendran100% (2)

- Polaroid - Process and Quality Control Case Study: Preparation by Presentation byDocument6 pagesPolaroid - Process and Quality Control Case Study: Preparation by Presentation byVinit Vijay SankheNo ratings yet