Professional Documents

Culture Documents

Glass Fin Analysis

Uploaded by

ruaconpsnrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glass Fin Analysis

Uploaded by

ruaconpsnrCopyright:

Available Formats

3.

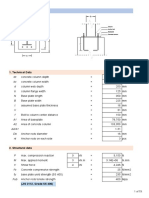

4 Analysis of Glass Fin

ASTM E1300-12a: Standard Practice for Determining Load Resistance of Glass in Buildings

Sa’adiyat Island Resort

Abu Dhabi, UAE

Dimensions and Material Properties of Glass

Glass type for external pane:

Glass_Fin_Type := "FT" AN(annealed), HS(heat strengthened), FT(fully tempered)

Glass_Fin_Thickness_Type := "L" Glass pane thickness type:

M(monolithic), L(laminated)

Load_Type := "SDL" Load type: SDL(short duration load),

LDL(long duaration load)

a := 9270mm Long side of the glass

b := 400mm Short side of the glass

tg := 30mm Thickness of the glass in

3 Modulus of elasticity of glass

E := 71.7 10 MPa

SIRD-SC-102 revA Page 26 of 173

SIRD-SC-102 revA Page 27 of 173

SIRD-SC-102 revA Page 28 of 173

Checking Stress on Glass

Allowable Stress on Gl ass

(ASTM E1300-12a : Appecdix X.6.2, page 57)

σfAN := 23.3MPa Allowable Stress f or Annealed Glass

σfHS := 46.54MPa Allowable Stress f or Heat Strengthen Glass

σfFT := 93.1MPa Allowable Stress f or Fully Tempered Glass

Check Stress on Glass

Stress Concentration at Bolt Holes

(Roak's Formula s for Stress and Strain: Ta bl e 17.1 Stress

Concentration factors for elastic stress, page 787)

c := 40mm Bolt hole edge distance

r := 23mm Radius of bolt hole

D := 400mm Width of the Glass Fin

2

r r Stress concentration factor parameter

C1 := 3.022 - 0.422 + 3.556 (Roarks Formula for Stress and Strain)

c c

2

r r

C2 := - 0.569 + 2.644 - 4.397

c c

2

r r

C3 := 3.138 - 18.367 + 28.093

c c

2

r r

C4 := - 3.591 + 16.125 - 27.252

c c

r

K t := 3.0 if < 0.05

c

2 3

2c 2c 2c

C1 + C2 + C3 + C4

D D D

K t = 3.9 Stress concentration factor

SIRD-SC-102 revA Page 29 of 173

Maximum Glass Stress

σg := 19.2MPa K t

Maximum Glass Stress

σg = 74.93 MPa < σfFT = 93.1 MPa OK FOR STRESS.

σg

= 0.8 < 1.0 OK!

σfFT

15MM (FT) + 1.52MM PVB + 15MM (FT) GLASS FIN IS ADEQUATE FOR STRESS!

Check of Glass Fin for Lateral Torsional Buckling

Australian Standard 1288-2006

γf := 1.7 Load Factor

b = 400 mm Width of Glass Fin

tg = 30 mm Thickness of Glass in

g2 := 3.3 Slenderness factor

g3 := 1.3 Slenderness factor

Lay := 9068mm Span of beam

E = 71.7 GPa Modulus of Elasticity of glass

3

b tg

Iy := Moment of Inertia about weak axis

12

4

Iy = 900000 mm

b

yh := = 200 mm Extreme iber distance

2

G := 28.7GPa Torsional elastic modulus of glass

3

b tg tg Torsional moment of inertia

J := 1 - 0.63

3 b

4

J = 3429900 mm

1

g2 yh

E Iy

2

M CR :=

Lay

(

E Iy G J ) 1 - g3

Lay G J

M CR = 28.46 kN m Critical elastic buckling moment

M max := 17.959kN m Maximum moment

M max = 17.96 kN m < MCR = 28.46 kN m OK FOR LATERAL TORSIONAL BUCKLING

Mmax

= 0.63 < 1.0 OK!

MCR

15MM (FT) + 1.52MM PVB + 15MM (FT) GLASS FIN IS ADEQUATE FOR LATERAL TORSIONAL

BUCKLING!

SIRD-SC-102 revA Page 30 of 173

Checking De lection of the Glass

Allowable De lection of Glass

a

Δallow := Allowable de lection of glass

200 (as per project speci ications)

Maximum De lection

Δmax := 14.493mm Maximum Glass De lection

Δmax = 14.49 mm < Δallow = 46.35 mm OK FOR DEFLECTION

Δmax

= 0.31 < 1.0 OK!

Δallow

15MM (FT) + 1.52MM PVB + 15MM (FT) GLASS FIN IS ADEQUATE FOR DEFLECTION!

SIRD-SC-102 revA Page 31 of 173

You might also like

- Design of Singly Reinforced Concrete Beam PDFDocument3 pagesDesign of Singly Reinforced Concrete Beam PDFAnton_Young_1962No ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- Deform 3d Hot FormingDocument21 pagesDeform 3d Hot Formingramkumar12175% (4)

- Strength of Material Interview Question and AnswersDocument27 pagesStrength of Material Interview Question and AnswersArjun M Betageri66% (29)

- Anchor Bolt CHKDocument17 pagesAnchor Bolt CHKPriya GNo ratings yet

- Beam DesignDocument14 pagesBeam DesignAbinash MandalNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Load Controlled Cyclic Triaxial Strength of SoilDocument11 pagesLoad Controlled Cyclic Triaxial Strength of SoilJiji Krishnan100% (1)

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- Design Cold Form Section 24may20Document7 pagesDesign Cold Form Section 24may20ramesNo ratings yet

- Enduron Screens CatalogueDocument12 pagesEnduron Screens Catalogueekrem0867No ratings yet

- Design Calculation FOR Rigid Pavement/RoadDocument5 pagesDesign Calculation FOR Rigid Pavement/RoadghansaNo ratings yet

- Design of Steel I-Section (BS5950)Document3 pagesDesign of Steel I-Section (BS5950)gertjaniNo ratings yet

- Calculation of Glass & MullionDocument4 pagesCalculation of Glass & MullionThành KC75% (4)

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- New SlabDocument1 pageNew SlabParthiban ArivazhaganNo ratings yet

- 2062Document17 pages2062hswed91100% (1)

- EA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Document2 pagesEA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Imaduddin KhajaNo ratings yet

- Elastomeric Materials PDFDocument84 pagesElastomeric Materials PDFAnonymous oyUAtpKNo ratings yet

- Analysis and Design of Plate Girder BridgesDocument58 pagesAnalysis and Design of Plate Girder Bridgesadnan-651358No ratings yet

- Non-Associated Plasticity For Soils, Concrete and RockDocument64 pagesNon-Associated Plasticity For Soils, Concrete and RockErnest NsabimanaNo ratings yet

- Natural Bend Radius Cal Rev. C PDFDocument3 pagesNatural Bend Radius Cal Rev. C PDFhamid sobirin100% (2)

- RB8 1200x1200 PDFDocument6 pagesRB8 1200x1200 PDFsallysel90No ratings yet

- Bending Test On Wooden BeamDocument6 pagesBending Test On Wooden BeamAdil Javed Chaudhary85% (13)

- Pipeline Design-InstallationDocument19 pagesPipeline Design-InstallationFaridah ZahraNo ratings yet

- Design of Coping Beam (Portal) : A. Basic DataDocument7 pagesDesign of Coping Beam (Portal) : A. Basic DataUzziel Abib GabiolaNo ratings yet

- Design of Singly Reinforced Concrete BeamDocument4 pagesDesign of Singly Reinforced Concrete BeamAnton_Young_1962No ratings yet

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDocument3 pagesRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNo ratings yet

- Conical Shells (7.6.4) EN 13445-3Document3 pagesConical Shells (7.6.4) EN 13445-3met-calcNo ratings yet

- AD 2000 Head Under Extenal PressureDocument2 pagesAD 2000 Head Under Extenal Pressuremechengg01100% (1)

- WRC 297Document9 pagesWRC 297akisdassasNo ratings yet

- Astm d4767 TX CiuDocument14 pagesAstm d4767 TX CiuMANo ratings yet

- Assignment CSTT 1Document21 pagesAssignment CSTT 1KHÁNH VÕ ĐĂNGNo ratings yet

- Spherical Shells (7.4.3) EN 13445-3Document3 pagesSpherical Shells (7.4.3) EN 13445-3met-calcNo ratings yet

- WRC 297Document9 pagesWRC 297akisdassas100% (1)

- Tension Rod Design PDFDocument1 pageTension Rod Design PDFMarkNo ratings yet

- Bellow As Per EJMA - 1Document2 pagesBellow As Per EJMA - 1966571016208No ratings yet

- Crack Width Check BS5400 4Document4 pagesCrack Width Check BS5400 4fontec.info2023No ratings yet

- Eval T4 SolDocument1 pageEval T4 SolChaitanya BalaniNo ratings yet

- Case N (KN) M V: Position Position PositionDocument10 pagesCase N (KN) M V: Position Position PositionChhengnguonNo ratings yet

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- 09 P Example Shear (Lecturenotes)Document5 pages09 P Example Shear (Lecturenotes)Matteo SoruNo ratings yet

- Rigid Pavement Design PDFDocument2 pagesRigid Pavement Design PDFRaju SainiNo ratings yet

- 36NiCrMo16 10083 06 ENG 01Document1 page36NiCrMo16 10083 06 ENG 01Guru Raj9739No ratings yet

- Design of One-Way SlabDocument4 pagesDesign of One-Way SlabAnton_Young_1962No ratings yet

- Cric Bun AkDocument26 pagesCric Bun AkGabriel AkNo ratings yet

- Bolt SOlved ExampleDocument4 pagesBolt SOlved ExampletarekNo ratings yet

- Isolated - Foundation Design ES en 2015Document10 pagesIsolated - Foundation Design ES en 2015Dino AbdelaNo ratings yet

- Isolated Foundation Design Es en 2015Document10 pagesIsolated Foundation Design Es en 2015Andualem KidusNo ratings yet

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Compensation To Opening Sums NptelDocument9 pagesCompensation To Opening Sums NptelRADHE GRAPHICSNo ratings yet

- Laminated CompressDocument42 pagesLaminated CompressMACHINE-30 ISTENNo ratings yet

- Contact Stress Two CylindersDocument3 pagesContact Stress Two CylindersEng-CalculationsNo ratings yet

- EJ CalculationDocument16 pagesEJ CalculationAmit NayakNo ratings yet

- Design of Machine Elements Assignment 2 Roll 07Document6 pagesDesign of Machine Elements Assignment 2 Roll 07Sharthak GhoshNo ratings yet

- Practical Lesson 4Document11 pagesPractical Lesson 4marjory.dezNo ratings yet

- Base Design (Blocks) - Commented On 26.09.2017Document4 pagesBase Design (Blocks) - Commented On 26.09.2017tsinghal_19No ratings yet

- Mathcad - PART II Ceiling (ICU) 20200602 (Update) - 2Document418 pagesMathcad - PART II Ceiling (ICU) 20200602 (Update) - 2BQ HeNo ratings yet

- Appendix A9Document9 pagesAppendix A9Thomas StephenNo ratings yet

- 01AM - Sample CalcsDocument2 pages01AM - Sample CalcsPrakash SinghNo ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- A Chrome Vanadium Spring A A A Spring Spring Spring SPR NG Spring SpringDocument2 pagesA Chrome Vanadium Spring A A A Spring Spring Spring SPR NG Spring SpringJhon C.C.No ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- Case 0Document53 pagesCase 0Trisha Gaile MoscosoNo ratings yet

- Boquilla N3Document4 pagesBoquilla N3TEAM xILUMINATYxNo ratings yet

- Analisis Balok Tulangan RangkapDocument3 pagesAnalisis Balok Tulangan Rangkapirgan.abdul.tkgd22No ratings yet

- Isolated - Foundation Design ES en 2015Document10 pagesIsolated - Foundation Design ES en 2015Jelal EdrisNo ratings yet

- Engineering Services LTD: CalculationDocument29 pagesEngineering Services LTD: CalculationtomNo ratings yet

- Detale 2Document8 pagesDetale 2MuhamedNo ratings yet

- Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument1 pageTower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- Appendix A11Document3 pagesAppendix A11Thomas StephenNo ratings yet

- Mech 4 Sem Course Info Feb June 07Document66 pagesMech 4 Sem Course Info Feb June 07Saurabh Kalra0% (1)

- Fatigue Fracture of Crankshaft of An Aircraft EngineDocument9 pagesFatigue Fracture of Crankshaft of An Aircraft EngineTchutNo ratings yet

- Kruszewski 2018Document13 pagesKruszewski 2018Firas Rockt100% (1)

- Barnes 1994Document31 pagesBarnes 1994Adarsh VasaNo ratings yet

- Maulana 2020Document11 pagesMaulana 2020Supun RanganaNo ratings yet

- Hilti Anchor DesignDocument7 pagesHilti Anchor DesignJohn Vincent MusngiNo ratings yet

- Design and Analysis of Thick Walled Cylinders With HolesDocument47 pagesDesign and Analysis of Thick Walled Cylinders With HolesKeryn Pelled-FeldmanNo ratings yet

- Mechanical Intro 17.0 M03 Structural Analysis PDFDocument49 pagesMechanical Intro 17.0 M03 Structural Analysis PDFFedericaNo ratings yet

- Chapter-8: Advanced MachiningDocument7 pagesChapter-8: Advanced MachiningAniruddha Bartakke100% (1)

- Mechanics of Deformable BodiesDocument5 pagesMechanics of Deformable BodiesJera Lunar CaliwanaganNo ratings yet

- Simple Stress PDFDocument18 pagesSimple Stress PDFJohn Philip NadalNo ratings yet

- Predicted and Observed Behaviour of Soft Clay Foundations Stabilised With Vertical DrainsDocument8 pagesPredicted and Observed Behaviour of Soft Clay Foundations Stabilised With Vertical DrainsCEG BangladeshNo ratings yet

- Lect#9 - Stresses in Soil PDFDocument27 pagesLect#9 - Stresses in Soil PDFMustafa AytekinNo ratings yet

- Reinforcement Detailing of A CorbelDocument13 pagesReinforcement Detailing of A CorbelAchilles TroyNo ratings yet

- Mechanical Properties of MetalsDocument26 pagesMechanical Properties of MetalsIzzat IkramNo ratings yet

- CV7001 Part 1 NoteDocument267 pagesCV7001 Part 1 NoteasdasNo ratings yet

- Materials: Experimental and Numerical Investigations of High-Speed Projectile Impacts On 7075-T651 Aluminum PlatesDocument15 pagesMaterials: Experimental and Numerical Investigations of High-Speed Projectile Impacts On 7075-T651 Aluminum PlatesYousaf SaidalaviNo ratings yet

- Strength of Materials - PUPDocument60 pagesStrength of Materials - PUPshirelyna100% (1)

- Manual-34 en FemDocument5 pagesManual-34 en FemjessicaNo ratings yet